Radiation curable ink and application thereof

A technology of radiation curing and ink, applied in the field of light curing, which can solve the problems of low market value, high cost, poor binding force, etc., and achieve the effects of moderate crosslinking density and surface tension, low viscosity, good processability and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0090]

[0091] After the required pigment dispersion is prepared, the above-mentioned ink of the present invention can be prepared by conventional methods in the field of radiation-curable compositions.

[0092] Representatively, the preparation method of above-mentioned ink comprises the following steps:

[0093] (1) prepare pigment dispersion;

[0094] (2) Put the polymerizable compound, photoinitiator, pigment and other optional components in a dark or inactive light source (that is, a light source that does not cause photocuring reaction, such as a yellow or red safe light), constant voltage Under the condition of constant temperature, mixing, stirring, dispersing, and filtering (filtering through a filter screen of a specified size to obtain a product with a desired particle size) are sufficient.

[0095] The above-mentioned pigment dispersion is prepared by mixing pigment D, dispersing aid, and dispersing monomer.

[0096] The above-mentioned dispersing aids may be ...

Embodiment 1

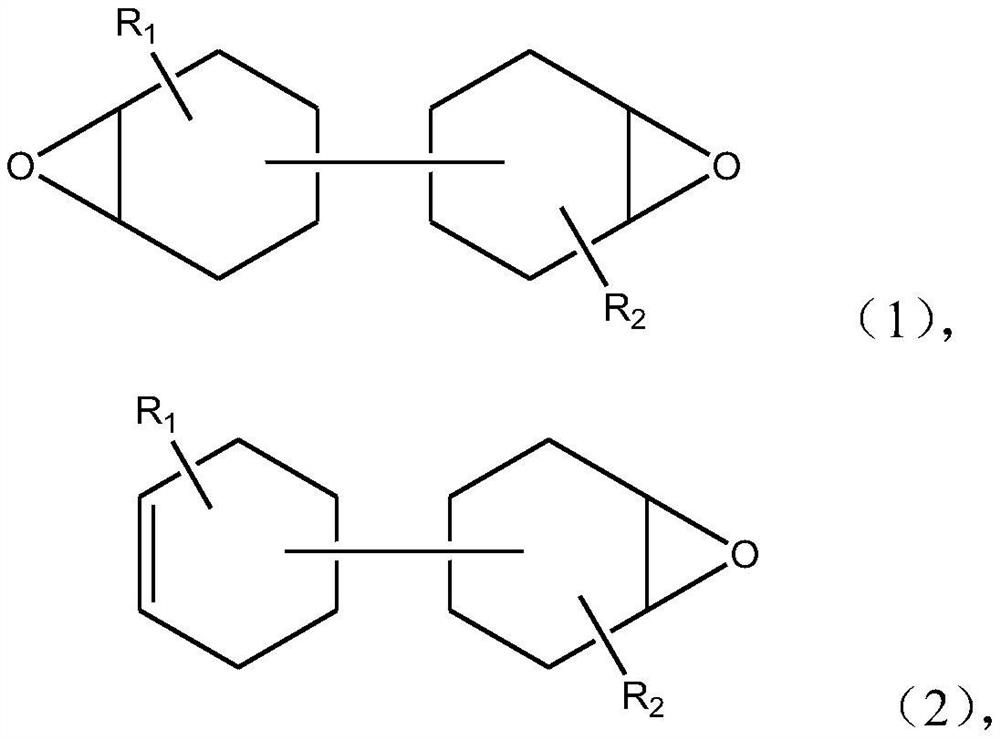

[0109] Add 200g of 2,2'-dihydroxyhydrogenated biphenyl, 20g of sodium bisulfate, 0.1g of p-hydroxyphenol, and 200g of xylene into the reaction flask, reflux for dehydration, react for 6 hours, and separate 17g of water. After the reaction is complete, wash with 150g of water twice. Remove xylene by distillation under reduced pressure, then add 200g of dichloromethane, 5g of phosphotungstic acid, 5g of cetylpyridine, dropwise add 150g of 30% hydrogen peroxide at 30-40°C, keep warm for 3 hours, wash twice with 200g of water, remove under reduced pressure Solvent, then decompression distillation goes out product, obtains material A1, and the epoxy equivalent of material A1 is 124g / mol, double bond content 2.05mol / Kg, and its main component (referring to two kinds of compounds of following structure, the same below) content is 96%;

[0110] Among them, substance A1 includes compounds of the following structure:

[0111]

Embodiment 2

[0113] The difference with Example 1 is that the consumption of cetylpyridine is 8g, the consumption of hydrogen peroxide is 180g, and the substance A2 is prepared, the epoxy equivalent of substance A2 is 110g / mol, the double bond content is 1.12mol / Kg, and its main component content 96.5%;

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com