Patents

Literature

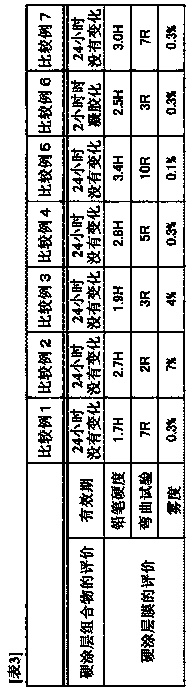

35results about How to "Moderate crosslink density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low modulus silicone sealing gum and its manufacturing method

ActiveCN1618915ALow modulusExcellent displacement abilityOther chemical processesCross-linkChemical reaction

A low-modulus silicone sealant for the expansion joint of express way, airport runway, tunnel, bridge, etc is prepared from alpha, omega-dihydroxy polydimethyl siloxane and filler through proportionally vacuum kneading at 80-150 deg.C while dewatering for 30-300 min, high-speed stirring while cooling to obtain basic material, proportionally mixing chain enlarging agent, cross-linking agent, thixotropic agent, polydimethyl siloxane and toluent diisocyanate, stirring, and vacuum reaction at 20-600 rpm for 30-90 min.

Owner:CHENGDU GUIBAO SCI & TECH

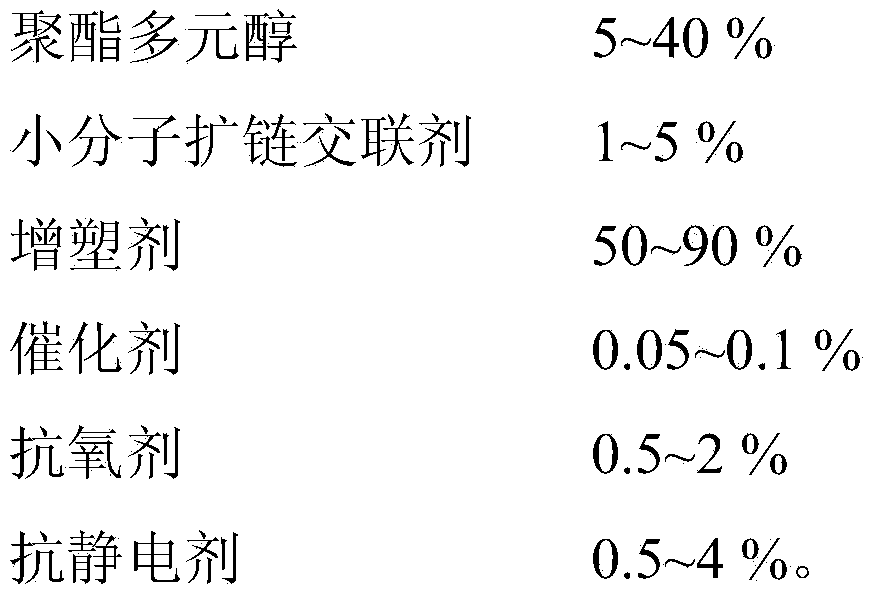

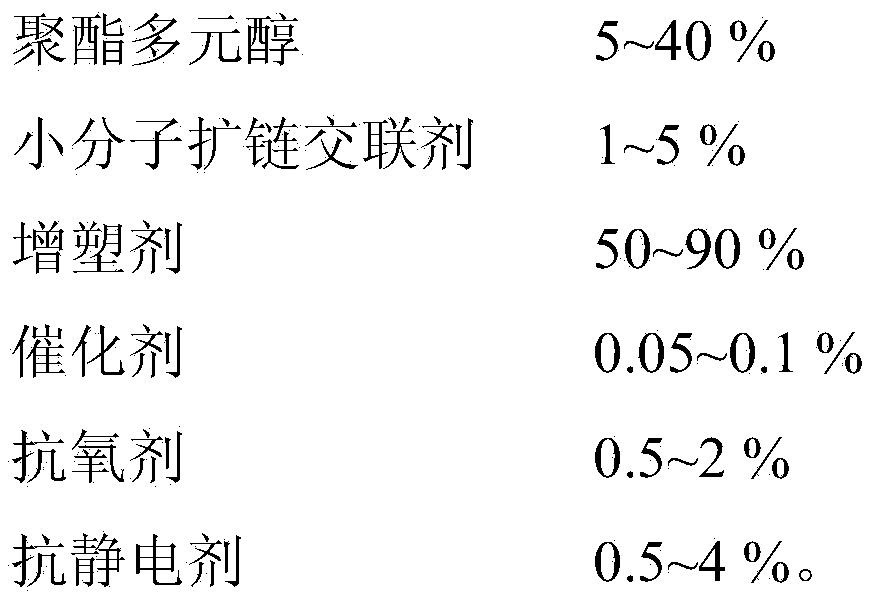

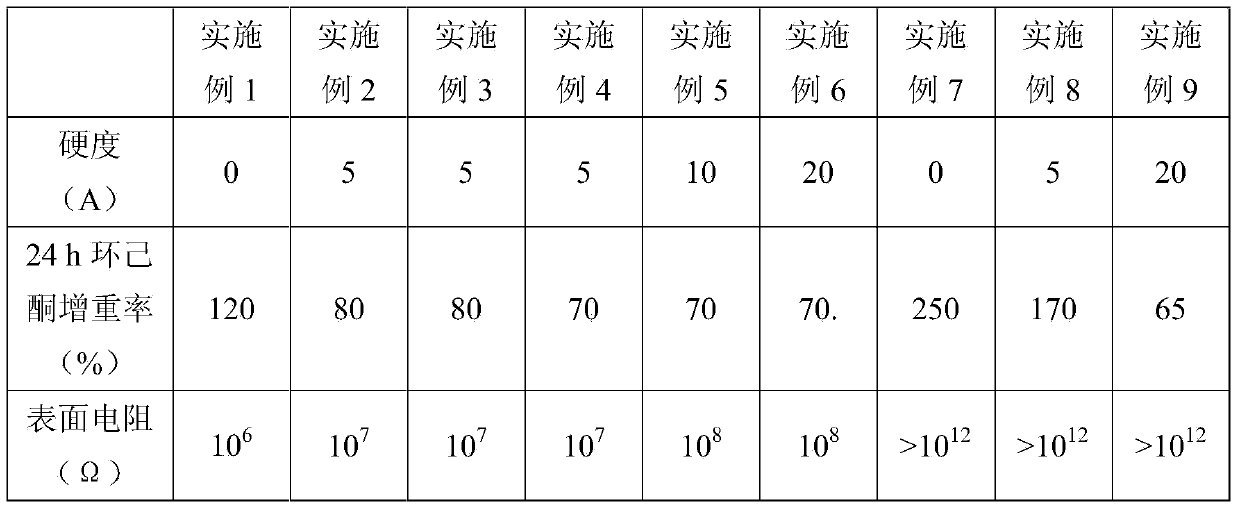

Low-hardness solvent-resistant antistatic polyurethane elastomer and preparation method thereof

The invention belongs to the technical field of polyurethane elastomers, and discloses a low-hardness solvent-resistant antistatic polyurethane elastomer as well as a preparation method and application thereof. The low-hardness solvent-resistant antistatic polyurethane elastomer contains the following components in parts by weight: 100 parts of polyurethane preformed polymer and 50-150 parts of polymer containing active hydrogen. The hardness of the low-hardness solvent-resistant antistatic polyurethane elastomer can be low to Shore 0A, and the low-hardness solvent-resistant antistatic polyurethane elastomer is good in mechanical strength, has extremely good tolerance to a ketone or ester polar solvent, and by adding an antistatic agent, the surface resistance of a product can be controlled to be less than or equal to 108ohm, so that the low-hardness solvent-resistant antistatic polyurethane elastomer can be widely applied to the antistatic field requiring solvent resistance, particularly applied to printing rollers.

Owner:东莞华工佛塑新材料有限公司

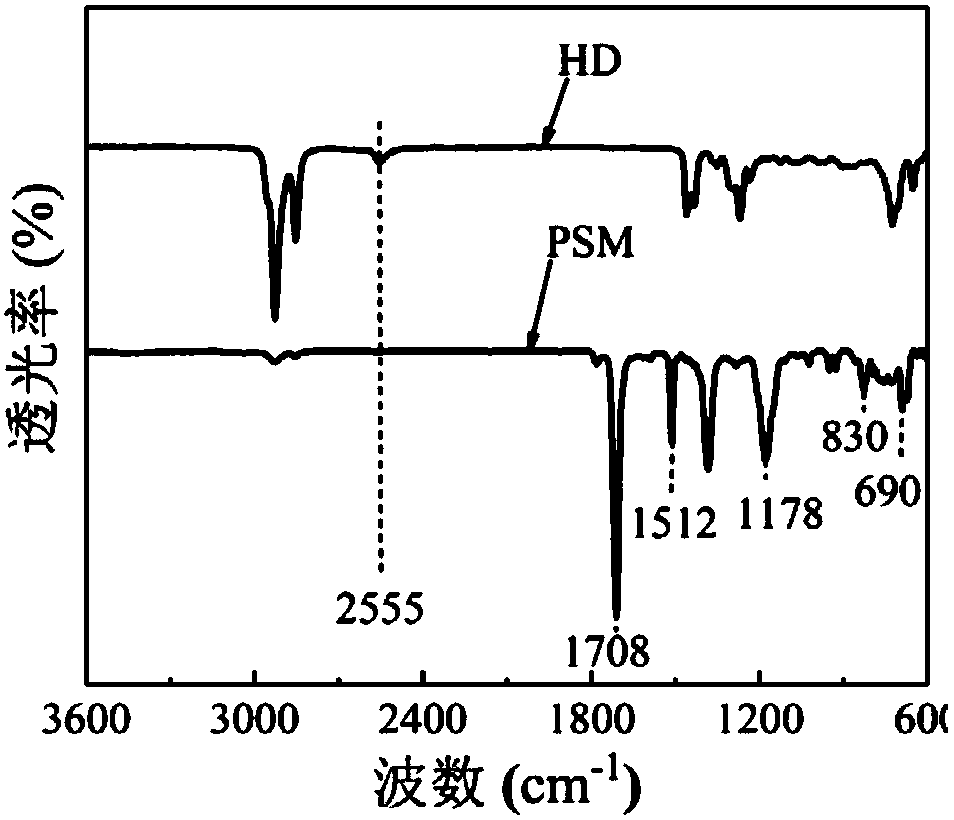

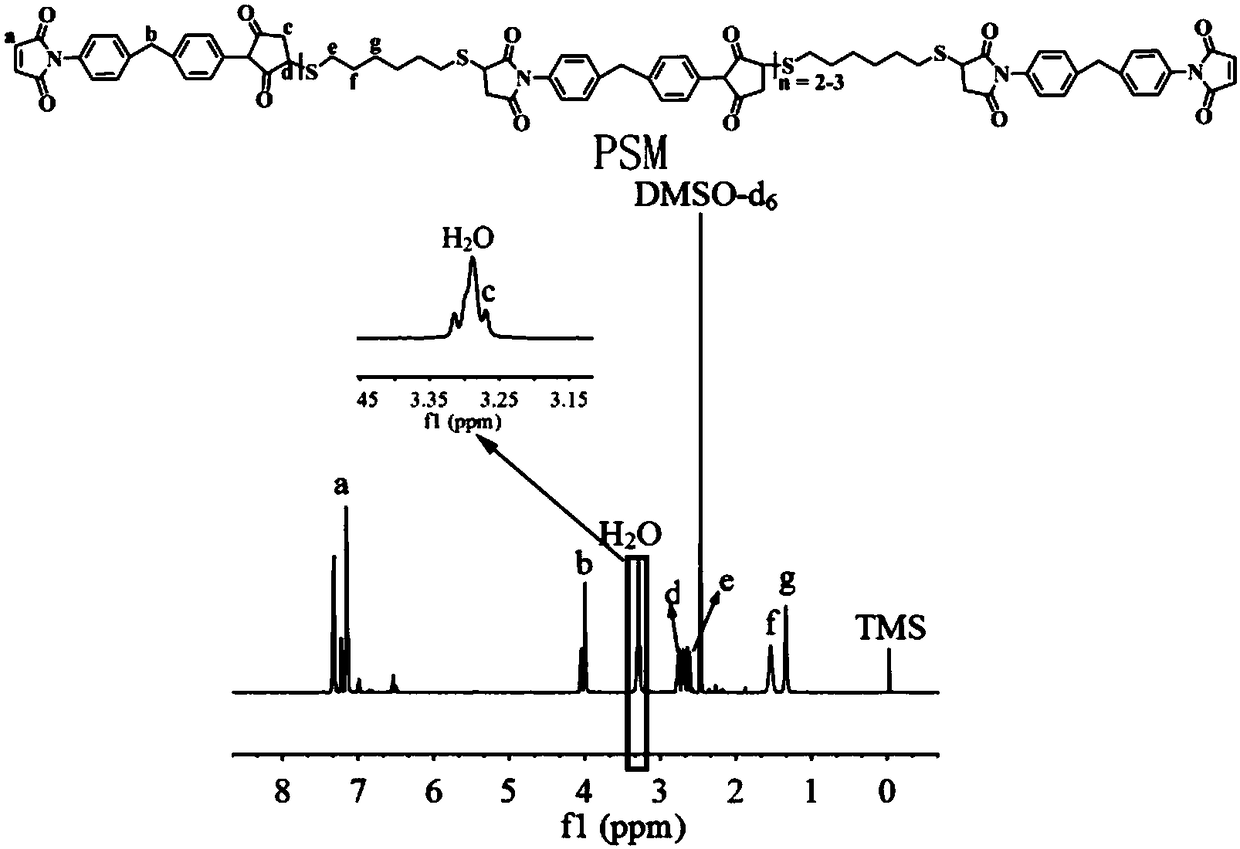

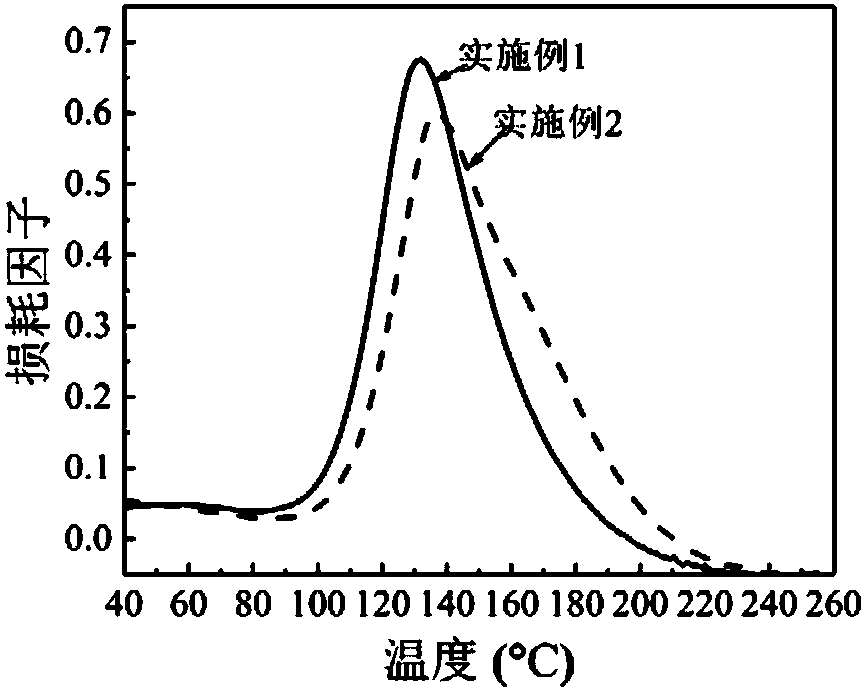

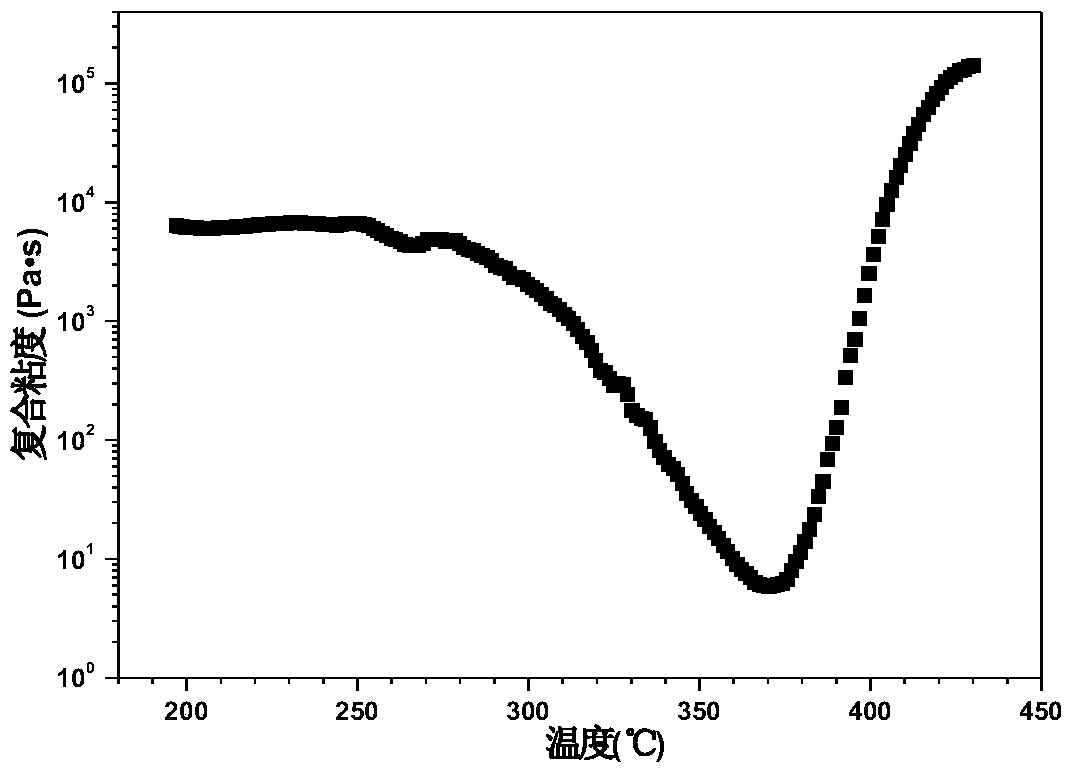

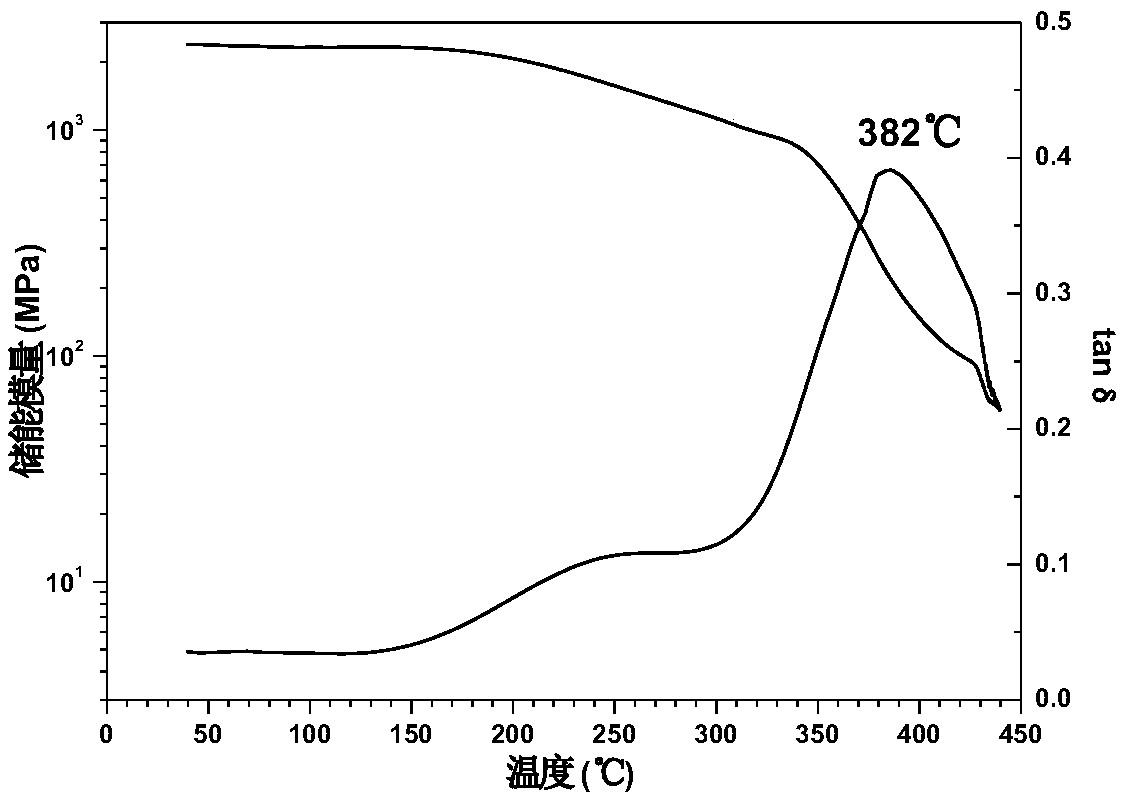

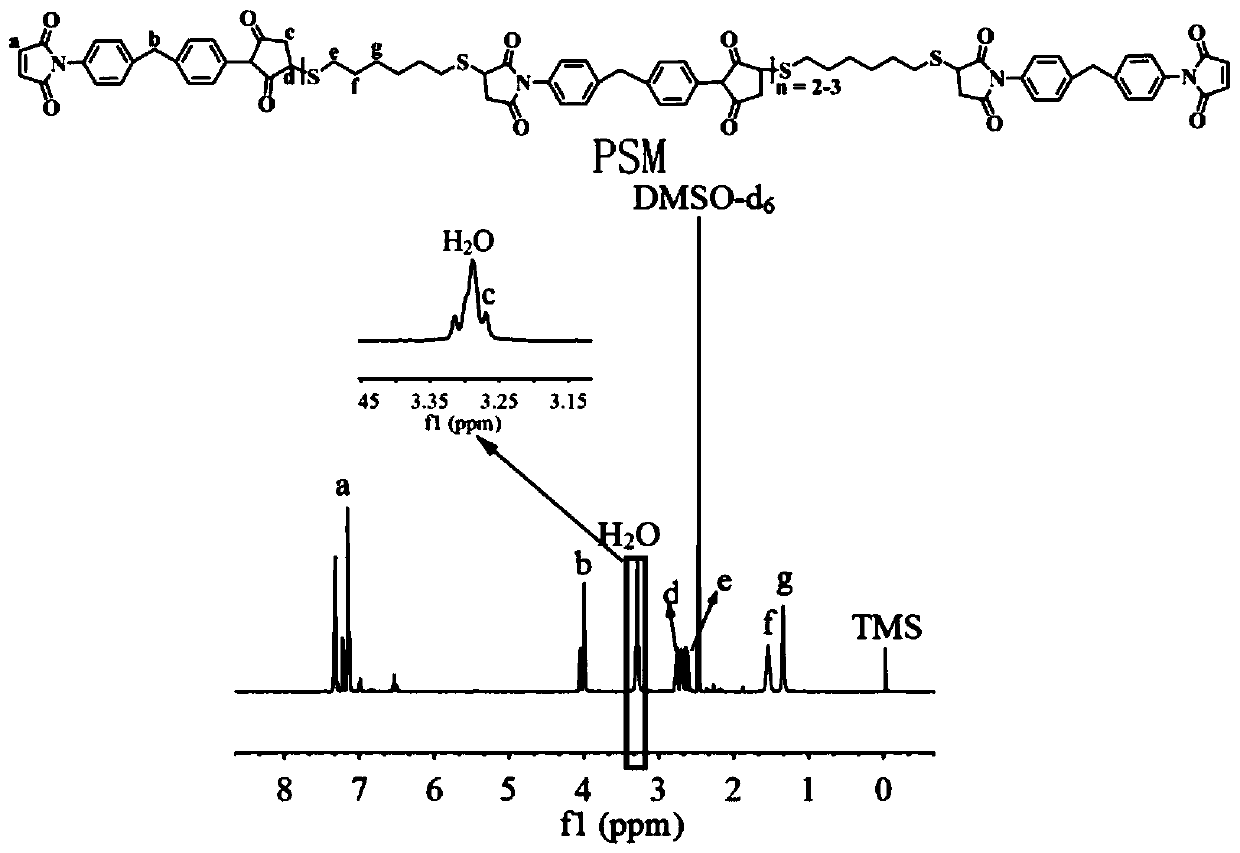

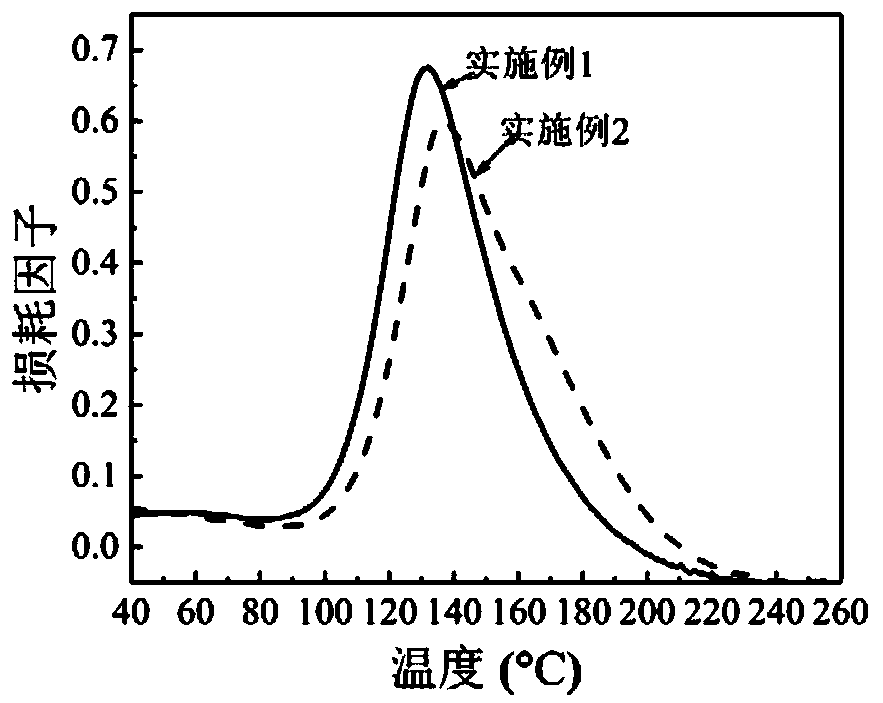

Thermosetting shape memory resin based on bismaleimide and preparation method thereof

The invention relates to high-deformation thermosetting shape memory resin based on bismaleimide and a preparation method thereof. The method includes the following steps that the bismaleimide and 1,6-ethanthiol are added into m-cresol to form a solution; triethylamine is added into the solution dropwisely, and under the protection of N2 and a stirring condition, a reaction is carried out at roomtemperature to obtain a linear oligomer; the bismaleimide, the linear oligomer and O,O'-diallylbisphenol A are mixed by mass, and the reaction is carried out at 130-150 DEG C for 25-45 min to obtain aprepolymer; the prepolymer is subjected to vacuum defoamation at the temperature of 130-150 DEG C, and through solidification and post-treatment, the thermosetting shape memory resin based on the bismaleimide is obtained. Compared with the prior art, the resin has a high deformation capability, and the breaking elongation of the resin at programming temperatures is higher than 30%; moreover, thethermosetting resin has both high glass-transition temperature (larger than 131 DEG C) and initial decomposition temperature (larger than 370 DEG C), high tenacity and outstanding shape memory performance.

Owner:SUZHOU UNIV

Polyimide adhesive and preparation method thereof

The invention relates to a polyimide adhesive and a preparation method thereof and belongs to the technical field of adhesives. The polyimide adhesive solves the problem that the polyimide adhesive ata temperature of greater than 350 DEG C has poor thermal instability and low adhesive properties. The polyimide adhesive is prepared from a polyimide adhesive prepolymer through curing. The preparation raw materials of the polyimide adhesive prepolymer comprise aromatic diamine containing a biphenyl structure, aromatic diamine containing a siloxane structure, aromatic dianhydride and a blocking agent. The preparation method comprises dissolving the polyimide adhesive prepolymer in an organic solvent to obtain a homogeneous solution, coating the surface of the adherend with the homogeneous solution, removing the organic solvent, carrying out curing to obtain the polyimide adhesive and bonding the adherend The polyimide adhesive can be used for the bonding of high temperature resistant parts in the fields of aviation, aerospace, precision machinery and petrochemical industry.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Preparation method of mineral element containing coated sustained-release basic fertilizer for paddy rice

InactiveCN108314539AImprove solubilityReduced particle densityCalcareous fertilisersSuperphosphatesInorganic nutrientUtilization rate

The invention discloses a preparation method of a mineral element containing coated sustained-release basic fertilizer for paddy rice. According to the preparation method, an internal membrane material and an external membrane material are prepared in advance; then the internal membrane material is sprayed on the surface of a fertilizer core to carry out coating so as to obtain a material A; thenthe external membrane material is sprayed on the surface of the material A to carry out coating so as to obtain the basic fertilizer. The provided coated sustained-release basic fertilizer has the advantages that the nutrients of the coated sustained-release basic fertilizer are comprehensive, the fertilizing effect is long-lasting, the utilization rate is high, the water retention performance isgood, the sustained-release effect of inorganic nutrients is good, moreover, the damage of the basic fertilizer to the soil environment is small, the paddy rice yield is high, and the paddy rice quality is good.

Owner:李侠

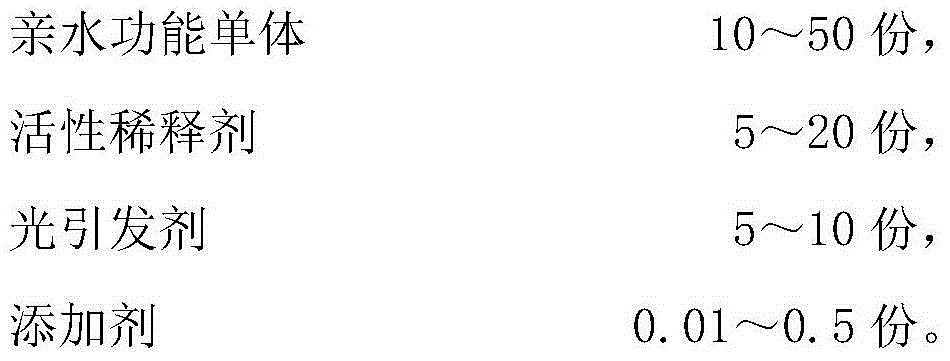

Ultraviolet curable hydrophilic aluminum foil coating composition

InactiveCN105440931ANon-volatileFast curingPolyurea/polyurethane coatingsEpoxy resin coatingsFunctional monomerUltraviolet

The invention discloses an ultraviolet curable hydrophilic aluminum foil coating composition. The composition includes the following components by weight: 30-80 parts of hydrophilic light-cured resin, 10-50 parts of a hydrophilic functional monomer, 5-20 parts of a reactive diluent, 5-10 parts of a photoinitiator, and 0.01-0.5 part of an additive. The coating composition provided by the invention is cured through ultraviolet, and has the characteristics of fast curing speed, no solvent discharge, no need for high-temperature baking, green and environmental protection and energy saving. The cured coating has the advantages of good adhesion, strong continuous hydrophilicity, high salt fog resistance, excellent mechanical properties, good temperature resistance, excellent flexural endurance, environmental protection and energy saving, and is very suitable for application in the hydrophilic aluminum foil field.

Owner:SHANGHAI CHENGYING NEW MATERIALS +2

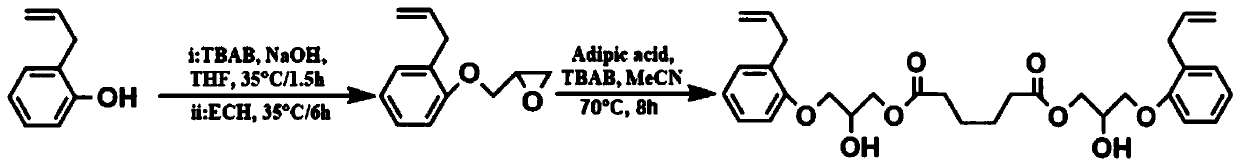

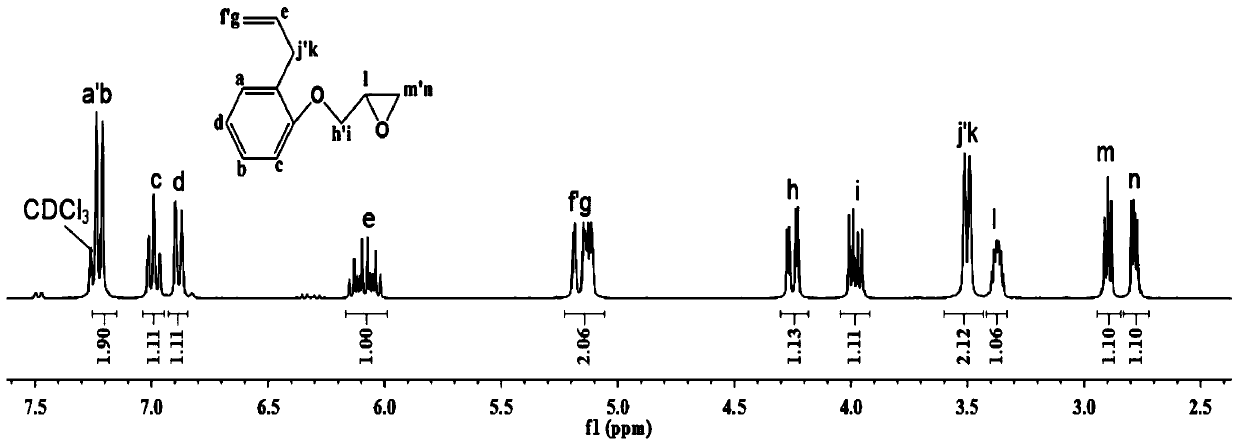

Remoldable bismaleimide resin and application thereof

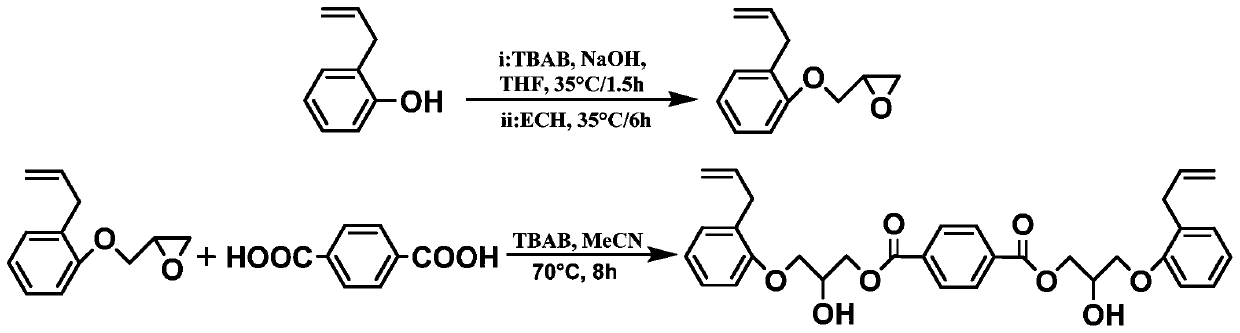

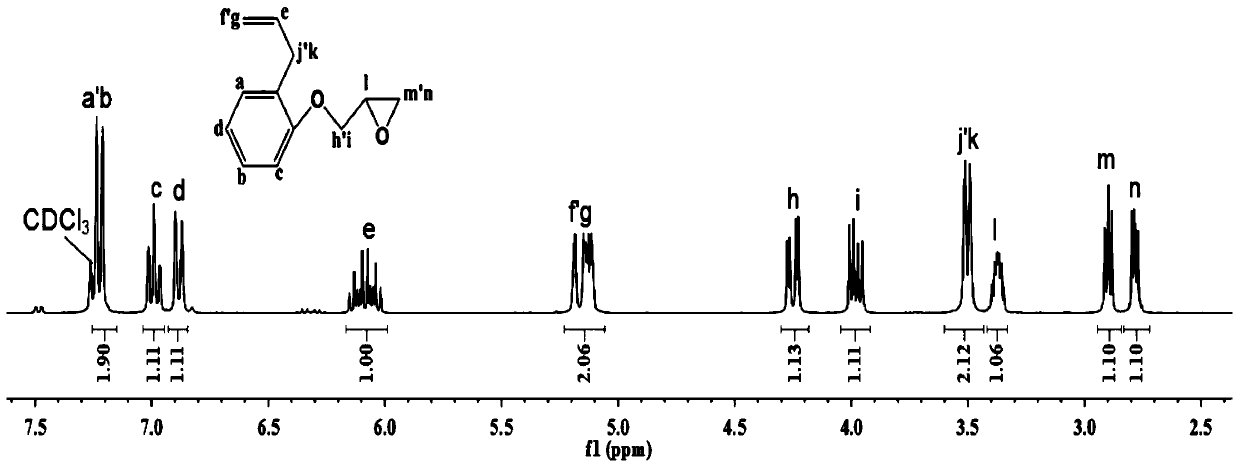

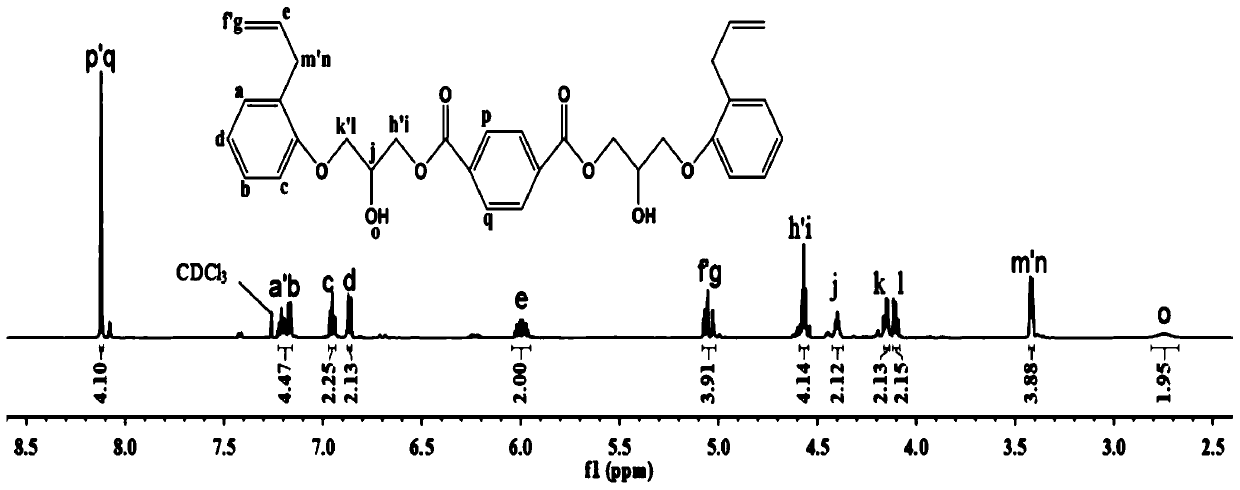

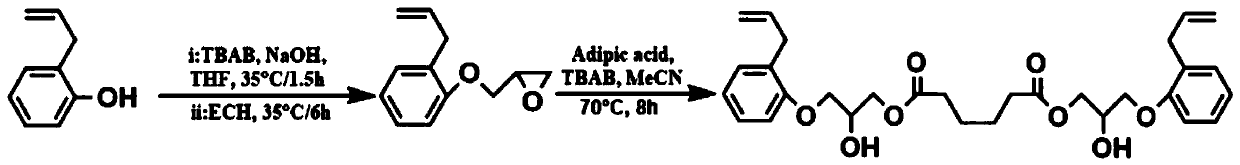

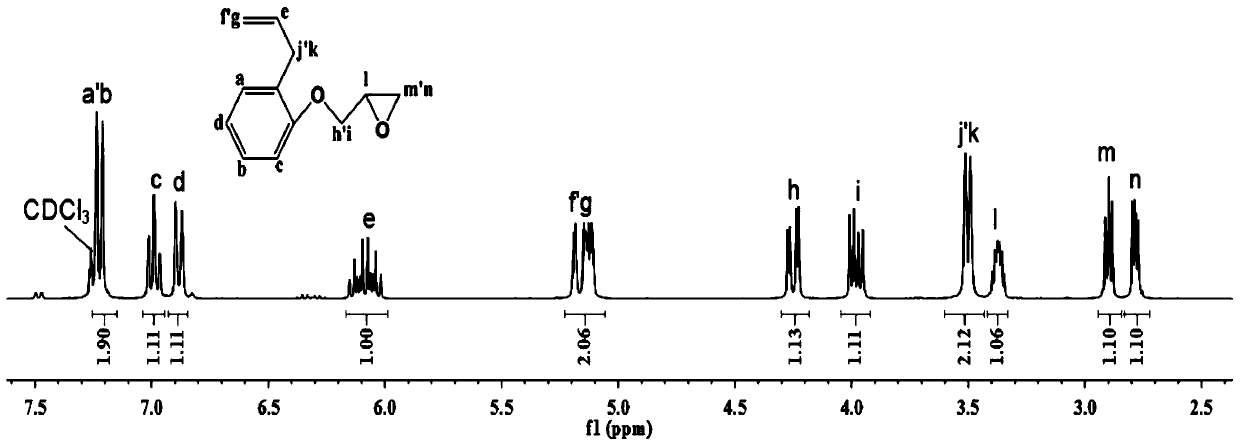

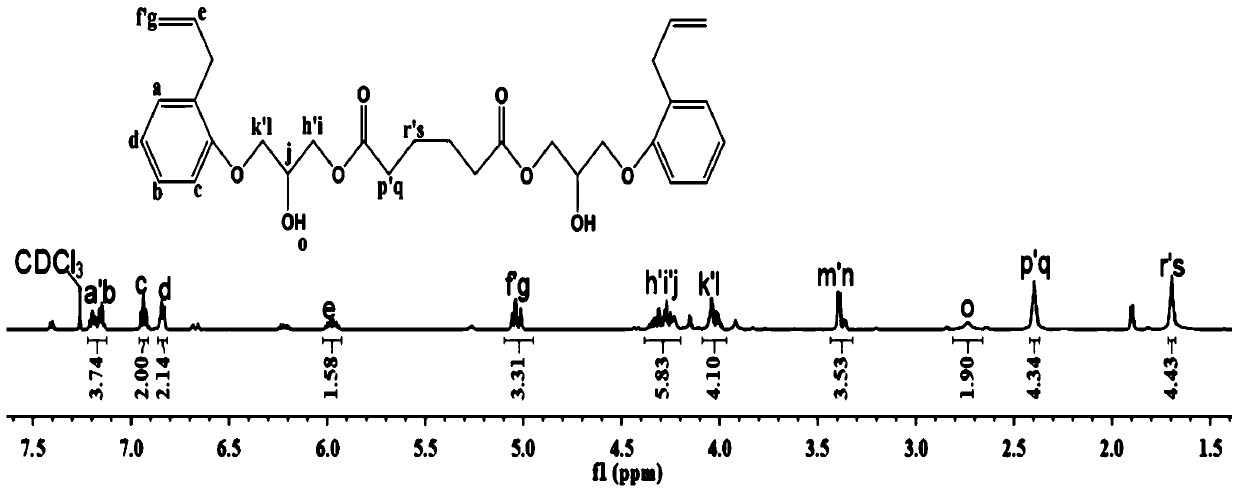

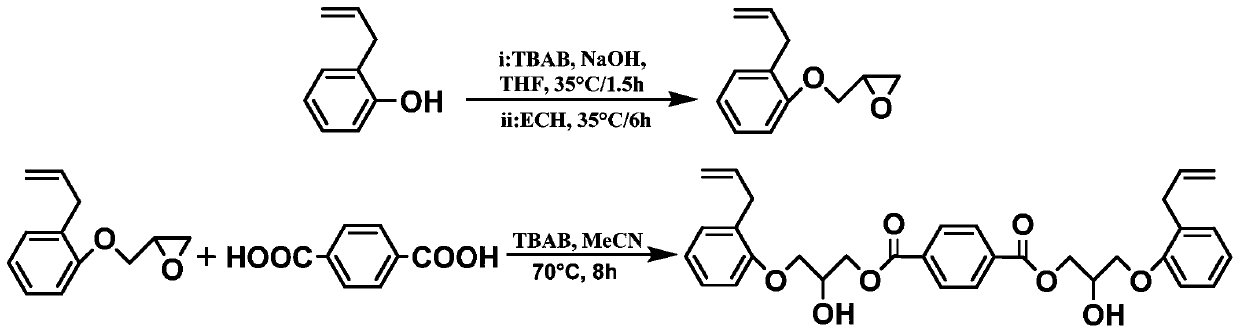

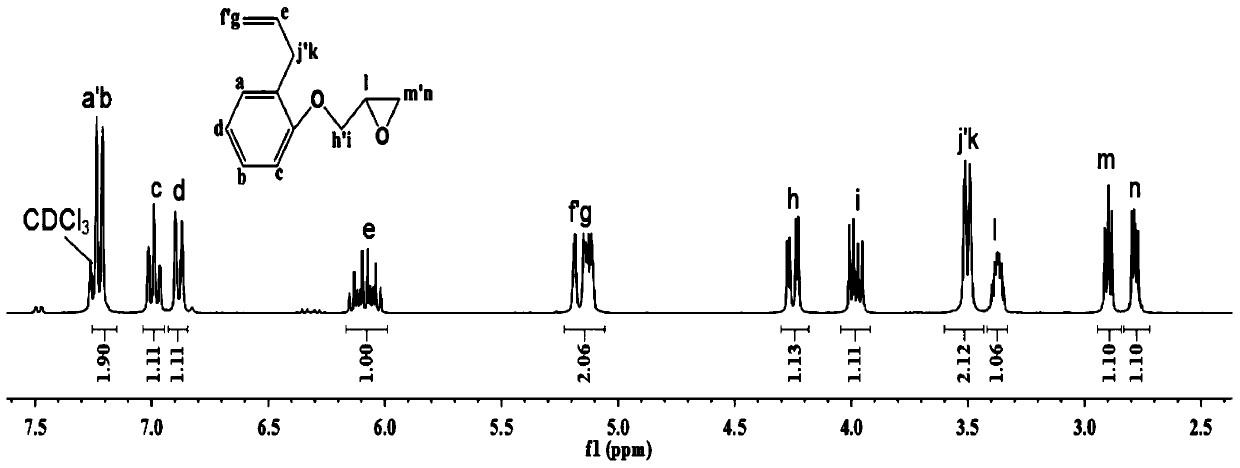

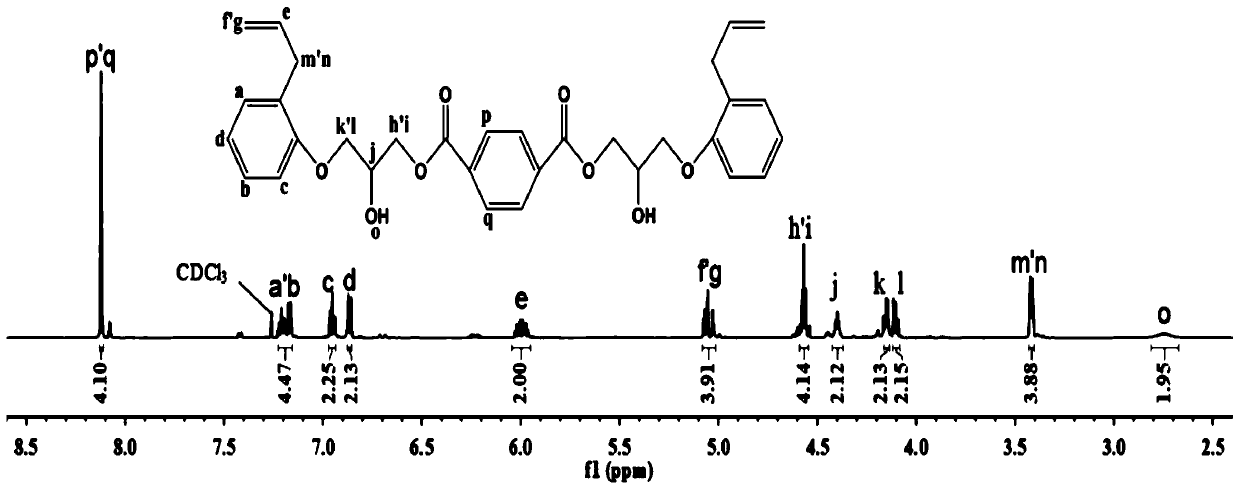

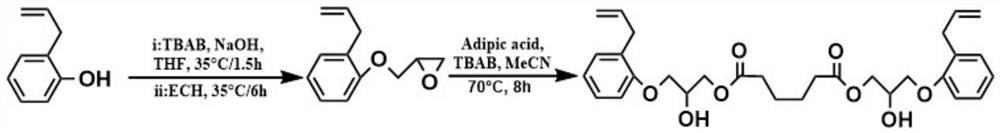

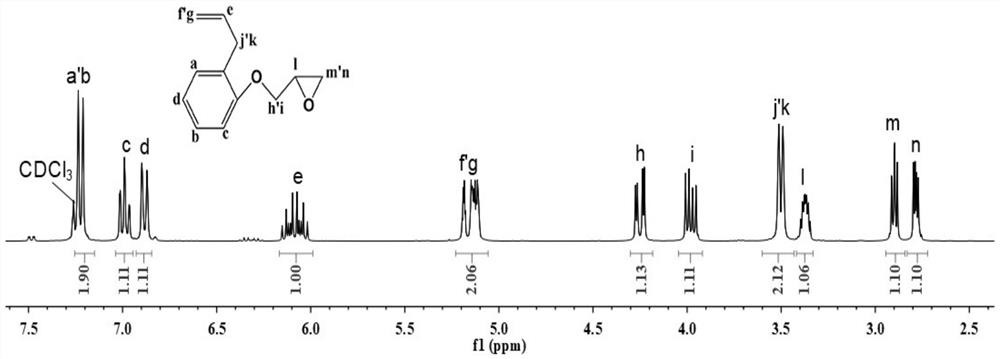

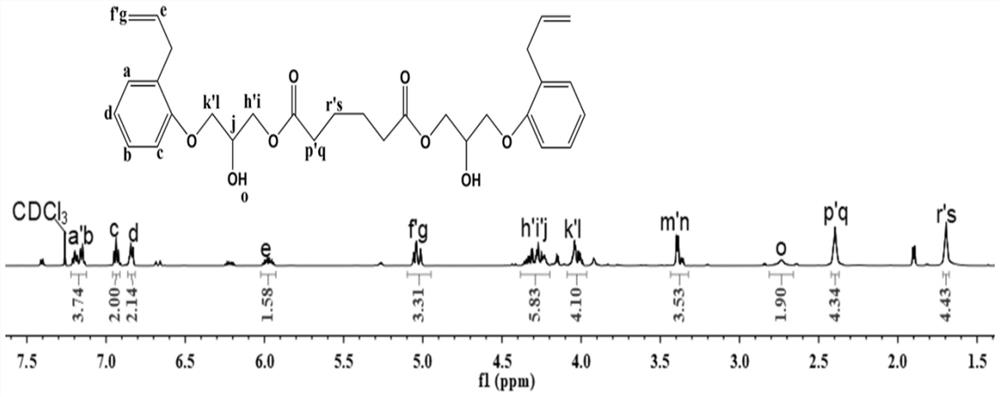

The invention discloses a remoldable bismaleimide resin and an application thereof. The remoldable bismaleimide resin is prepared by the following steps: blending 2-allylphenyl glycidyl ether with terephthalic acid in acetonitrile, carrying out an esterification reaction with a quaternary ammonium salt as a catalyst to obtain a bis(3-(2-allylphenoxy)-2-hydroxypropyl)terephthalate containing a reversible dynamic group; and uniformly mixing the bis(3-(2-allylphenoxy)-2-hydroxypropyl)terephthalate with bismaleimide, and curing the obtained mixture to obtain the remoldable bismaleimide resin. Theremoldable bismaleimide resin prepared in the present invention has excellent heat resistance and excellent mechanical properties, and can be remolded under a hot pressing condition. The preparation method of the remoldable bismaleimide resin has the characteristics of wide sources of raw materials, and simple process, and the has remoldable bismaleimide resin broad application prospects in industrial fields of aerospace, transportation, electronic information, new energy and insulated electrics.

Owner:SUZHOU UNIV

Preparation method of wear-resistant, heat-insulation and corrosion-resistant powder coating

InactiveCN110760234AMeet the needs of efficient operationReduce harmFireproof paintsCarboxyl rubber coatingsNitrile rubberFirming agent

The invention discloses a preparation method of a wear-resistant, heat-insulation and corrosion-resistant powder coating. The powder coating is prepared from the following raw materials: benzoxazine resin, epoxy resin, chlorinated polyether, carboxylated-terminated acrylonitrile-polybutadiene rubber, a curing agent, barite powder and wollastonite powder. The wear-resistant, heat-insulation and corrosion-resistant powder coating can be prepared by processes such as melting, mixing and extruding, cooling for tabletting, crushing and sieving and has excellent wear and corrosion resistance and heat insulation properties, the surface of a processed coating meets the national and industrial standards on the aspects such as adhesive force, flexibility, impact strength, smoothness, hardness and chemical resistance, and the wear-resistant, heat-insulation and corrosion-resistant powder coating is low in curing temperature, convenient to use and capable of reducing the cost.

Owner:孙振龙

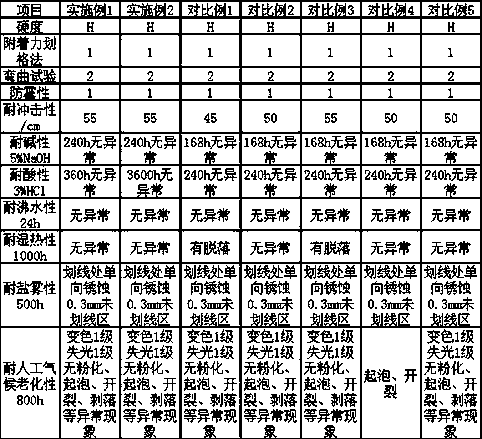

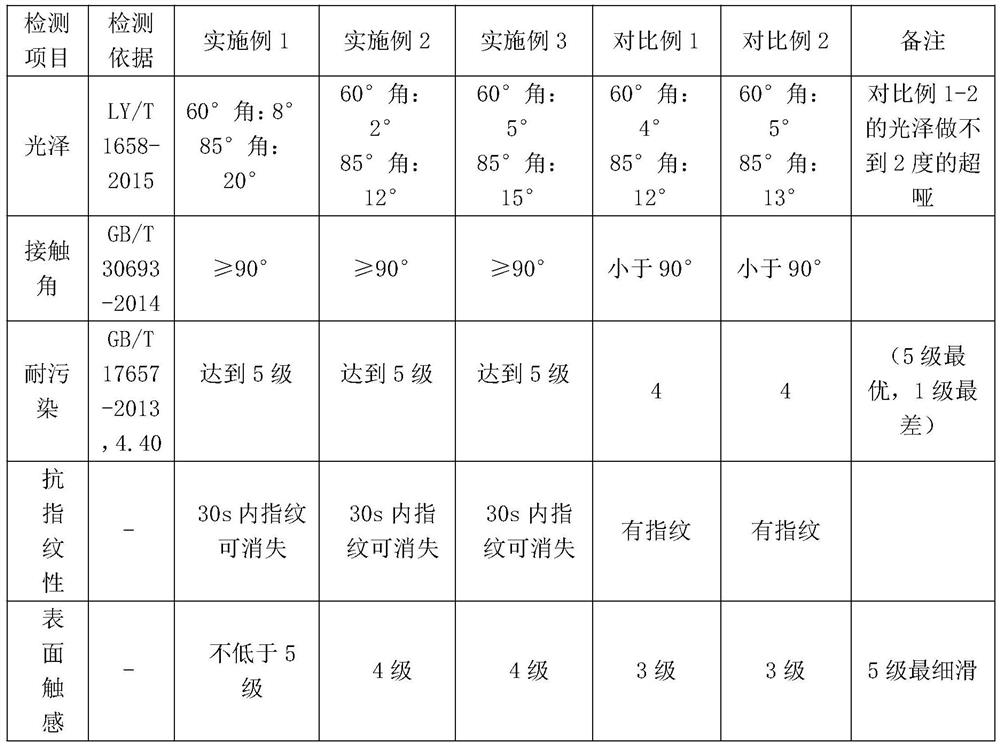

UV-ultra-matte skin-touch surface coating method applied to woodware coating and surface coating paint

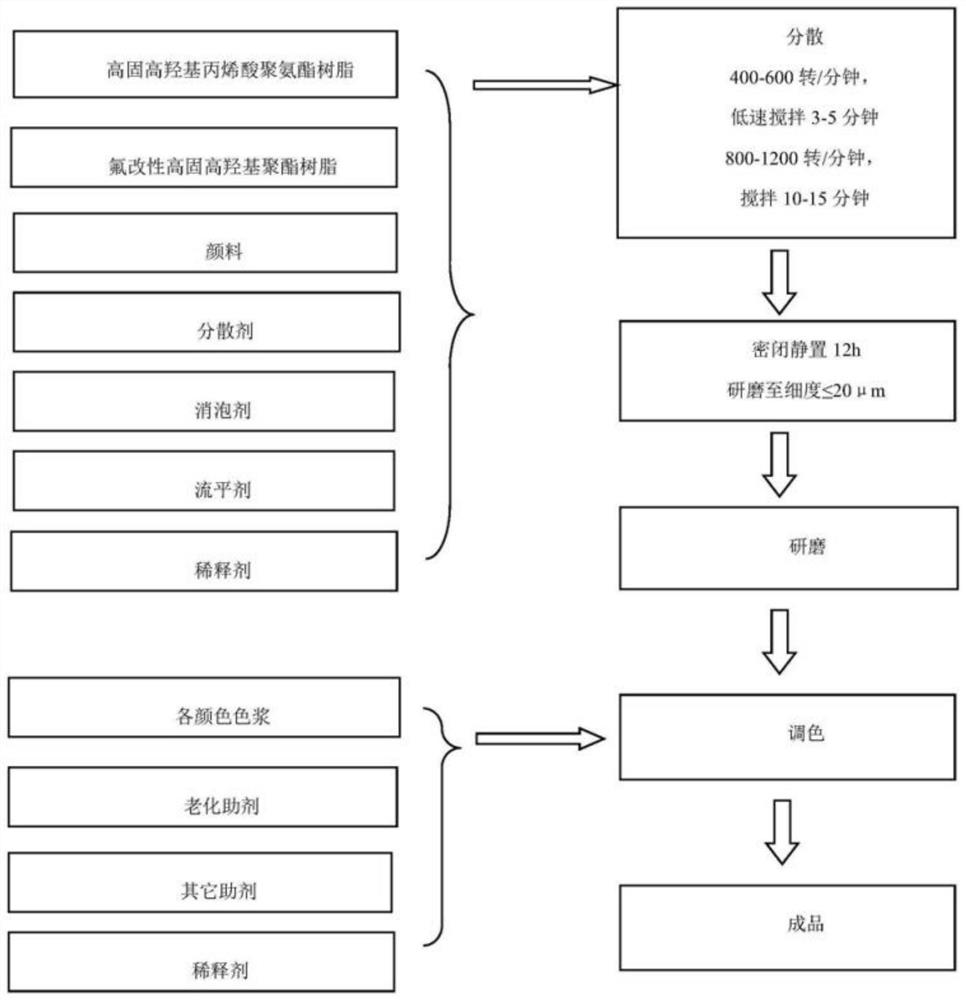

PendingCN114789129AIncrease elasticityModerate crosslink densityPretreated surfacesPolyurea/polyurethane coatingsPolymer scienceExcimer lamp

The invention discloses a UV-ultra-matte skin-feeling surface coating method and a surface coating applied to woodware coating, a conventional UV roller coating process is adopted for bottom coating, a UV-ultra-matte skin-feeling surface coating process is adopted for surface coating, and specifically, special excimer equipment laser roller equipment is adopted for roller coating by adopting the UV-ultra-matte skin-feeling surface coating. The UV-ultra-matte skin-feeling coating is prepared from special raw materials through compatibility of the materials, and then the effects of extinction and skin feeling are achieved in cooperation with special excimer equipment and process. According to the UV-ultra-matte skin-touch coating, in the aspect of selection of UV resin, resin with good elasticity, moderate crosslinking density and good surface curing is selected, the resin can provide a soft framework, meanwhile, the surface curing is good, special excimer curing equipment is matched, after a paint film is cured by an excimer lamp, wrinkled textures are formed on the surface to obtain ultra-matte, the addition amount of matte powder is reduced, and the skin-touch effect is good. The hand feeling of a paint film is greatly improved, and the leveling property of a paint surface is excellent.

Owner:JIANGSU HIMONIA TECH

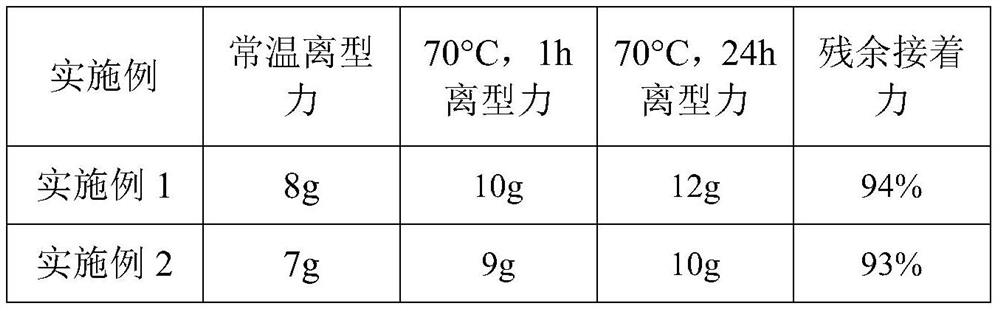

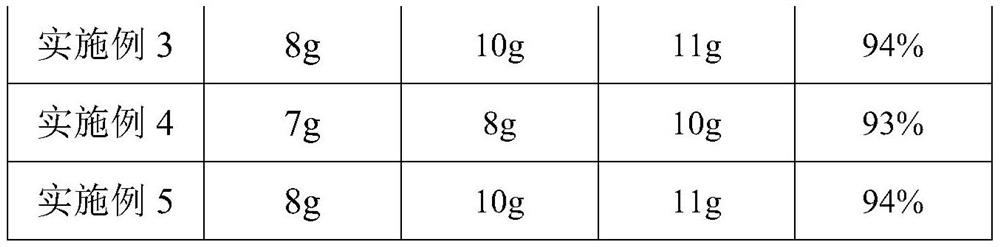

Fluorine release film and preparation method thereof

ActiveCN112143012AImprove antistatic performanceImprove release forcePhotovoltaic energy generationElectrically-conductive paintsBinding forceRelease liner

The invention provides a fluorine release film and a preparation method thereof. The fluorine release film comprises a base material layer, an antistatic coating and a fluorine release coating, wherein the antistatic coating and the fluorine release coating are respectively formed by coating an antistatic coating material and a fluorine release coating material. According to the invention, the binding force among the base material layer, the antistatic coating and the fluorine release coating is high, and the fluorine release film has good release force and high-temperature release force whilemaintaining the excellent properties of PET.

Owner:苏州花蝴蝶新材料科技有限公司

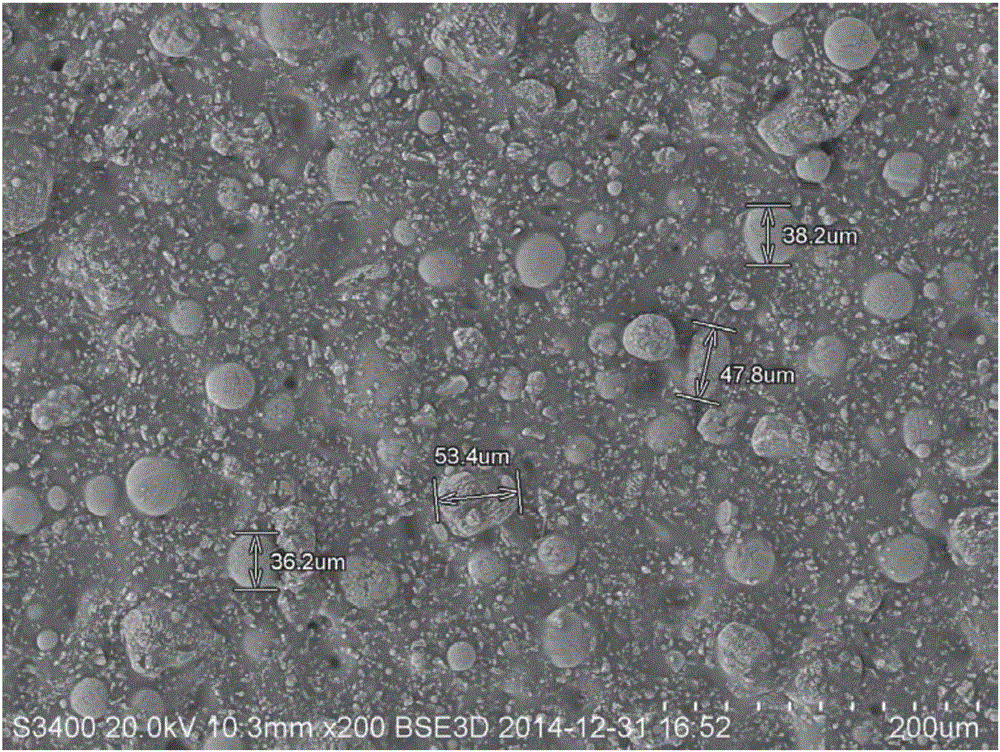

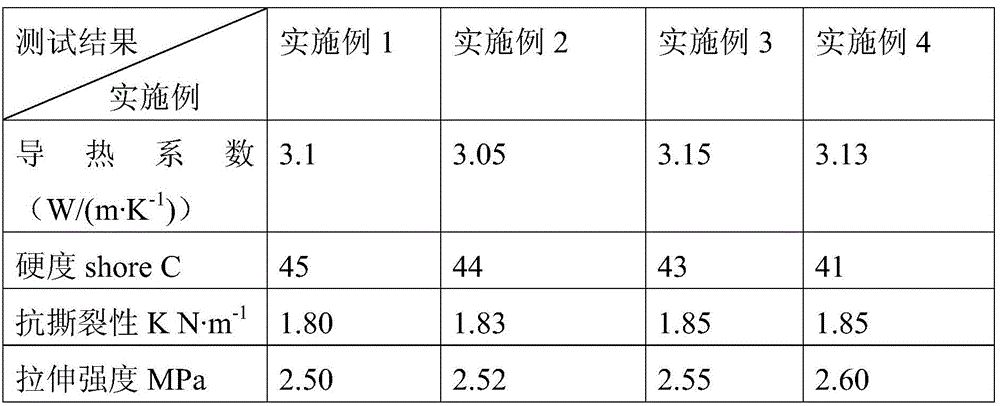

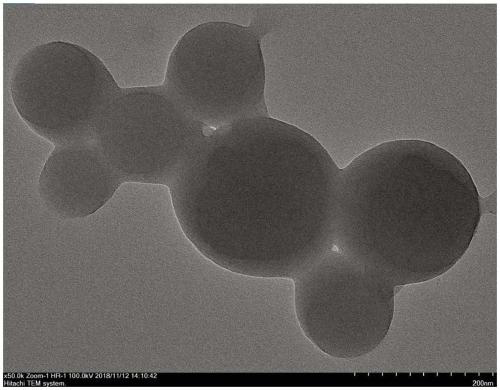

High-tear-resistance and high-heat-conductivity macromolecular interfacial material and preparation method

InactiveCN105733270AImprove tear resistanceImprove mechanical propertiesPolymer scienceHeat conducting

The invention discloses a polymer interface material with high tear resistance and high thermal conductivity, which comprises the following components: 100g of silicone oil with a vinyl content of 0.5-2.0%; 800-900g of spherical alumina; ~1.5g; deionized water 1~50g; silicon carbide whiskers 0~100g. The invention also discloses a preparation method of the interface material with high tear resistance and high thermal conductivity. The polymer interface material with high tear resistance and high thermal conductivity of the present invention uses vinyl silicone oil as the main body, spherical alumina powder as the main material of the heat conduction channel, and uses coupling agent, deionized water, and silicon carbide whiskers as fillers. Various factors such as filler type, content, particle size and preparation process are used to prepare special vinyl silicone oil with low viscosity and suitable crosslinking density, improve the tear resistance of the material, and obtain high tear resistance and high thermal conductivity polymer interface material . Used in automotive power battery modules to improve the shock resistance and impact resistance of the battery pack, enhance the uniformity of heat dissipation between battery cells, and prolong the service life.

Owner:东莞东超新材料科技有限公司

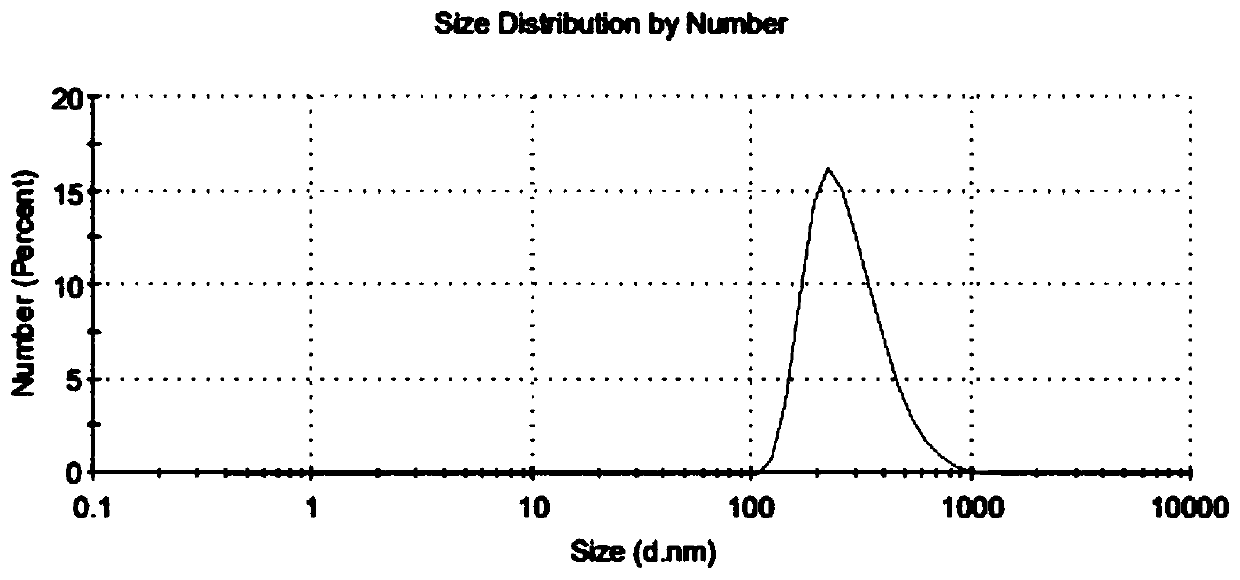

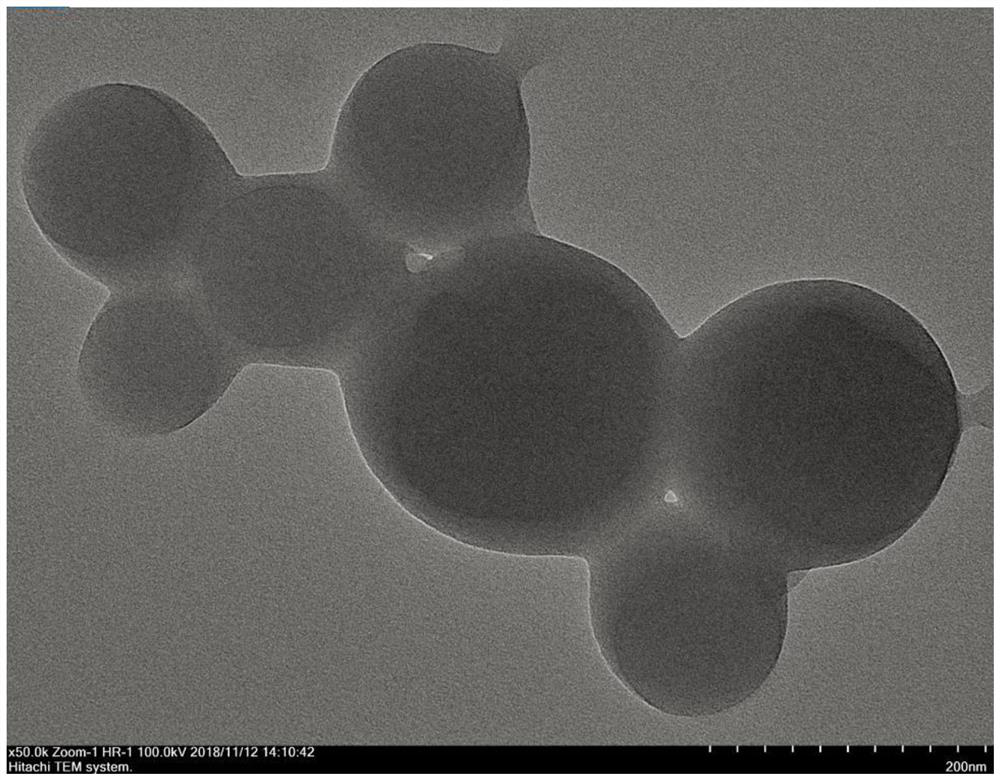

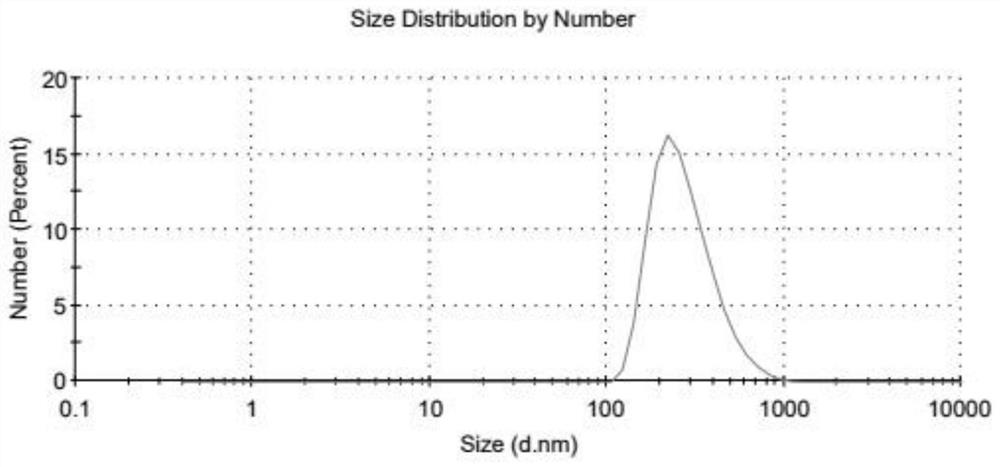

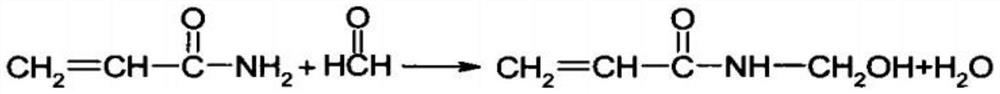

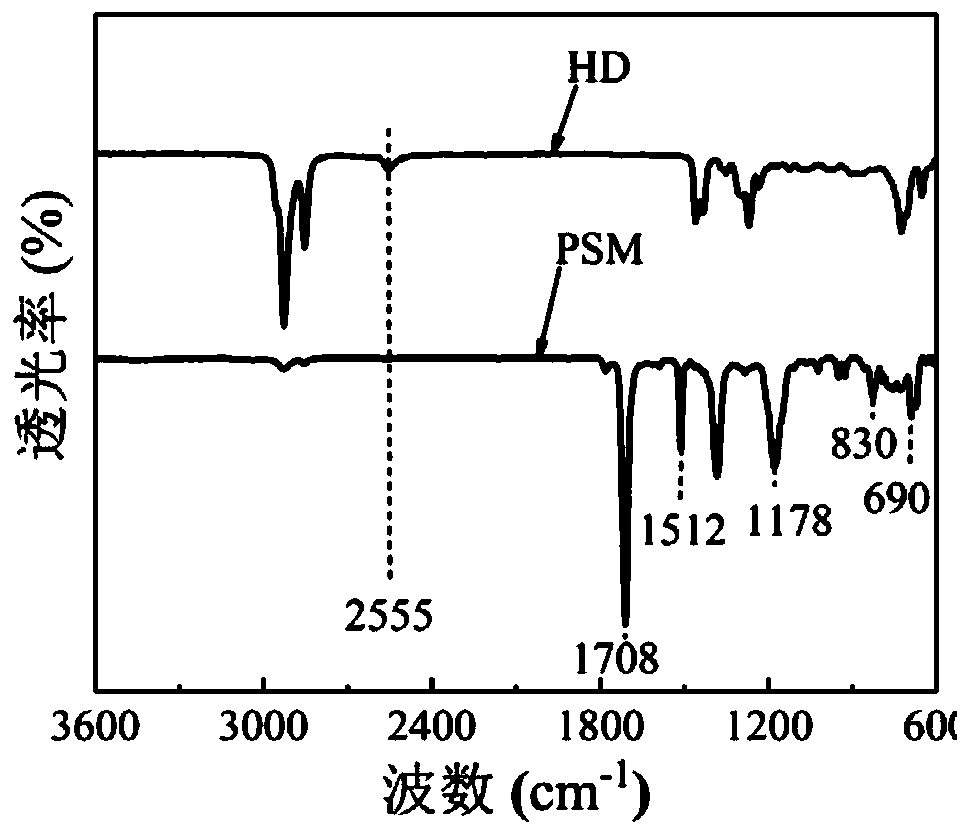

High-performance glass fiber coating and preparation method thereof

The invention discloses a high-performance glass fiber coating and a preparation method thereof and aims to solve the technical problems of poor alkaline resistance and poor storage stability of the conventional urea-formaldehyde resin coating. The glass fiber coating comprises raw materials in parts by mass as follows: 40-70 parts of water, 20-30 parts of acrylic monomers, 1-5 parts of acrylic functional monomers, 10-30 parts of a modified urea-formaldehyde resin adhesive, 0.5-5 parts of a polymerization stabilizer, 0.1-1.5 parts of 2,2'-azobis(2-methylpropionamidine) dihydrochloride, 0.1-0.5parts of azobisisobutyronitrile, 0.1-3 parts of a cationic emulsifier or a cationic reactive emulsifier, 4-7 parts of cationic starch dispersion, 0.05-0.5 parts of an acid-base buffer agent and 0.1-5parts of a chain transfer auxiliary. According to the technical scheme, water resistance, alkaline resistance and storage stability of the coating can be improved effectively, the coating further hasperformance and advantages of urea-formaldehyde resin and acrylate resin, and overall performance of a polymer is improved.

Owner:九江华源新材料有限公司

Low-cost high-performance ethylene-propylene-diene monomer (EPDM) cable sheathing material for mines

InactiveCN105086164AImprove temperature resistanceStrong tear resistanceRubber insulatorsPlastic/resin/waxes insulatorsElastomerParaffin wax

The invention discloses a low-cost high-performance ethylene-propylene-diene monomer (EPDM) cable sheathing material for mines. The low-cost high-performance EPDM cable sheathing material for the mines is prepared through the steps: plastifying 40-50 parts (by weight) of EPDM, 30-40 parts (by weight) of ethylene-butylene elastomer and 10-14wt% (based on EPDM) of chlorinated polyethylene together for 1-2 minutes; then, adding 30-35 parts (by weight) of white carbon black, 30-40 parts (by weight) of ultrafine talcum powder, 35-40 parts (by weight) of modified calcined clay, 10-12 parts (by weight) of nano-silica, 3-4 parts (by weight) of zinc oxide, 1-3 parts (by weight) of stearic acid, 21-23 parts (by weight) of paraffin oil, 4-6 parts (by weight) of paraffin, 1-1.2 parts (by weight) of accelerant MB and 0.8-1 part (by weight) of accelerant RD into the plastified material, carrying out uniform milling, and then, carrying out material discharging; and then, adding 2-2.5wt% (based on EPDM) of 2,5-dimethyl-di (tert-butylperoxy)-3-hexane and 1-1.5wt% (based on EPDM) of crosslinking-activity assistant HVA-2 into the discharged material for vulcanization, discharging the vulcanized material, and cooling the vulcanized material.

Owner:ANHUI TIANCAI CABLE GRP

Preparation method of photocured hydrophilic coating

InactiveCN113786519AShort curing timeLow curing temperatureSurgeryPharmaceutical delivery mechanismPolymer sciencePolymer chemistry

The invention belongs to the technical field of high polymer materials, and particularly relates to a preparation method of a photocured hydrophilic coating. The photocured hydrophilic coating comprises an epoxidized soybean oil acrylate prepolymer or polyurethane acrylate prepolymer, a reactive diluent, a photoinitiator, a hydrophilic polymer and an auxiliary agent. The photocured hydrophilic coating has a semi-interpenetrating network structure, the epoxidized soybean oil acrylate prepolymer or polyurethane acrylate hydrophilic coating is photocured to form a network structure, and the hydrophilic polymer is dispersed in a cross-linked network gap in a molecular entanglement manner, so that the hydrophilic coating not only has a hydrophilic lubricating function, but also has reliable firmness.

Owner:浙江海圣医疗器械股份有限公司

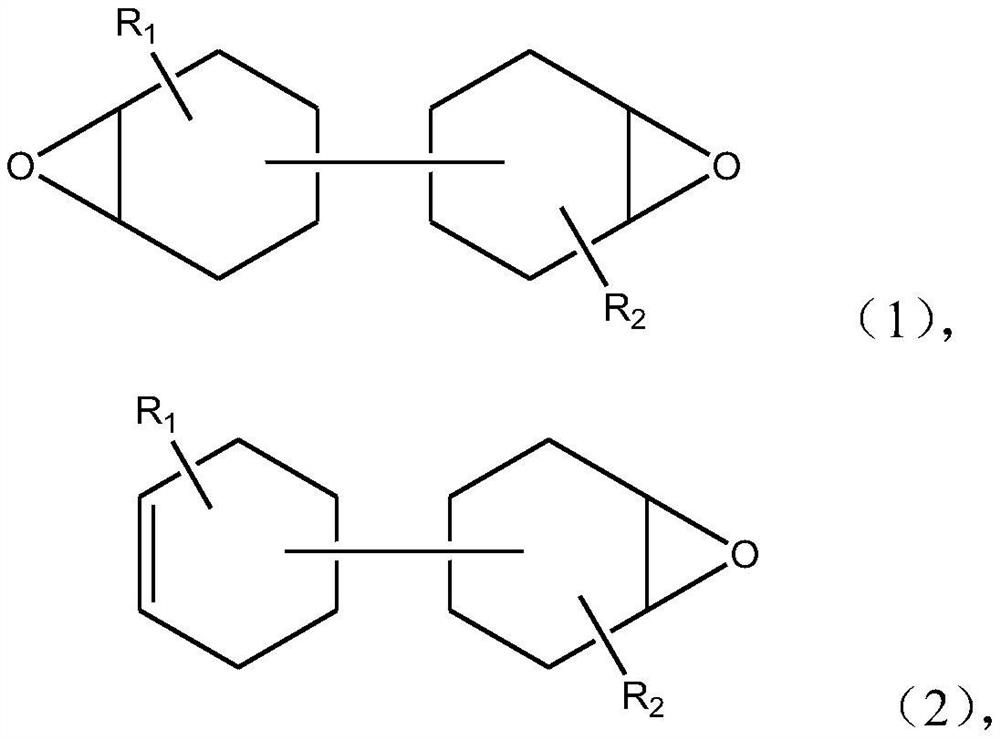

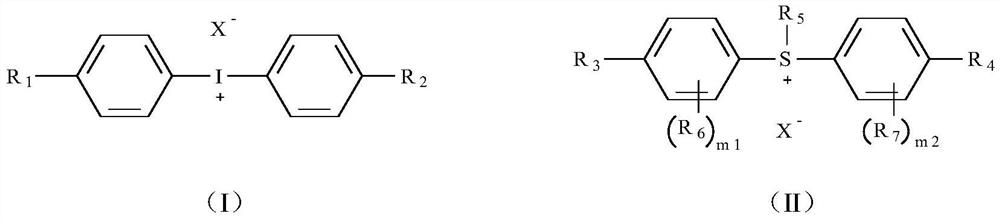

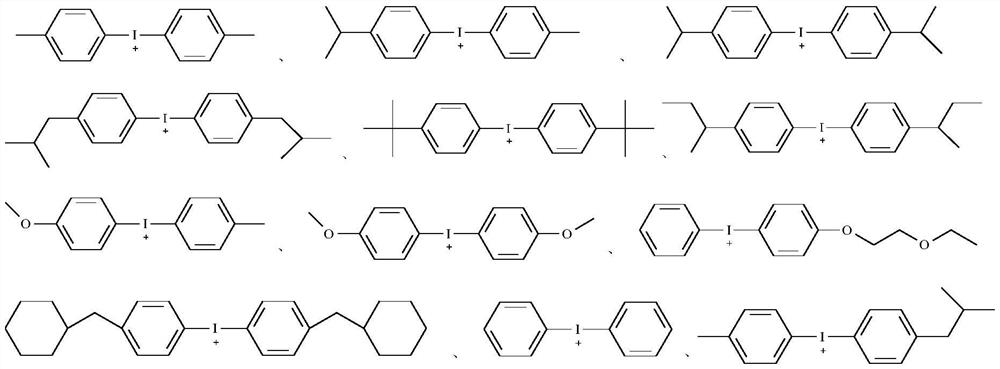

Radiation curable ink and application thereof

The invention provides radiation curable ink and application thereof. The radiation-curable ink comprises a polymerizable compound, a photoinitiator and a pigment, the polymerizable compound comprisesan epoxy compound, the epoxy compound comprises a first alicyclic epoxy compound, and the first alicyclic epoxy compound contains compounds represented by a formula (1) and a formula (2). In the radiation-curable ink, the polymerizable compound comprises the first alicyclic epoxy compounds shown in the formulas (1) and (2), and the first alicyclic epoxy compounds shown in the formulas (1) and (2)have better compatibility with other components in the composition system by adjusting the contents of epoxy and double bond groups. Therefore, the radiation-curable ink has low viscosity, good processability and productivity, the crosslinking density and surface tension of the whole composition are moderate, and the adhesive force is good during recoating, so that the radiation curable ink is more suitable for recoating.

Owner:CHANGZHOU TRONLY NEW ELECTRONICS MATERIALS +1

Environment-friendly UV (Ultraviolet) silk-screen blistering ink

The invention provides environment-friendly UV silk-screen blistering ink, which consists of the following components in percentage by weight: 42-55 percent of aliphatic polyurethane acrylate, 8-12 percent of isoborneol metacrylic acid ester, 8-12 percent of propyloxy glycerol triacrylate, 4-6 percent of 2,4,6-trimethyl benzoyl-diphenyl phosphine oxide, 3-5 percent of 2-methyl-1-4-methylmercapto-2-morpholinyl-1-acetone, 9-11 percent of diphenyl ketone, 5-10 percent of a pigment, 2-4 percent of barium sulfate and 0.5-1 percent of a flatting agent. The environment-friendly UV silk-screen blistering ink is used for direct silk screening of UV color ink; after the ink is cured, a once blistering process is finished; the colorization is uniform, the draftability is good, and no organic solvents are discharged.

Owner:HUIZHOU PERFECT CHEM IND CO LTD

Remoldable shape memory bismaleimide resin and application thereof

Owner:SUZHOU UNIV

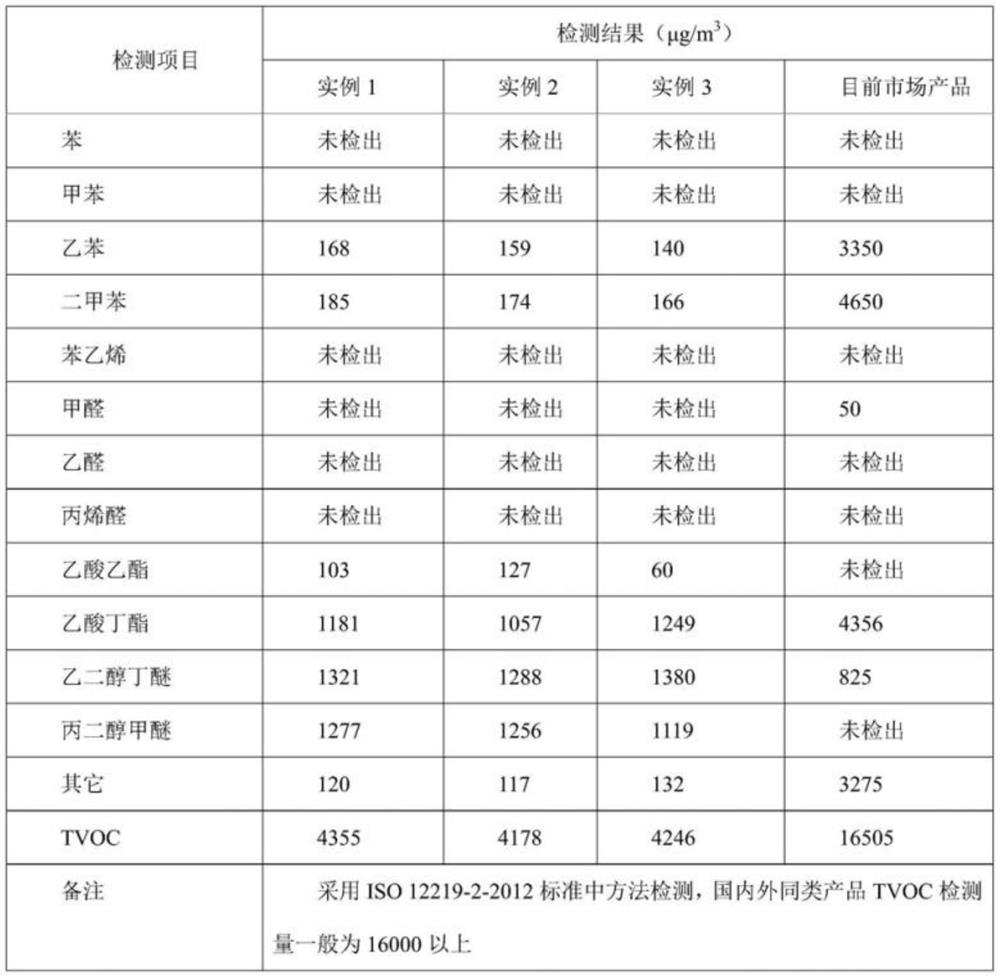

Acrylic polyurethane finish paint as well as preparation method and application thereof

InactiveCN113943527AMaintain gloss and color retentionImprove mechanical propertiesPolyurea/polyurethane coatingsPolymer scienceAcrylic resin

The invention relates to acrylic polyurethane finish paint as well as a preparation method and application thereof. The acrylic polyurethane finish paint comprises a paint vehicle and a curing agent, wherein the paint vehicle comprises the following components in parts by weight: 30-40 parts of high-solid polyether modified low-hydroxyl acrylic resin and 10-25 parts of teflon modified high-solid high-hydroxyl polyester resin; and the curing agent is prepared from 58 to 62 parts of a solvent-free aliphatic polyisocyanate tripolymer and 1 to 3 parts of a polyurethane dehydrating agent. The main purpose of the invention is to obtain the acrylic polyurethane finish paint with low TVOC residual quantity and excellent coating performance. The paint can meet the performance requirements and the environmental protection requirements of related product coating of customers, solves the problem that the existing solvent type product for the interior decoration of a railway vehicle has relatively strong pungent smell, and creates a comfortable and environment-friendly in-vehicle environment for passengers who go out by taking rail transit vehicles.

Owner:株洲市九华新材料涂装实业有限公司

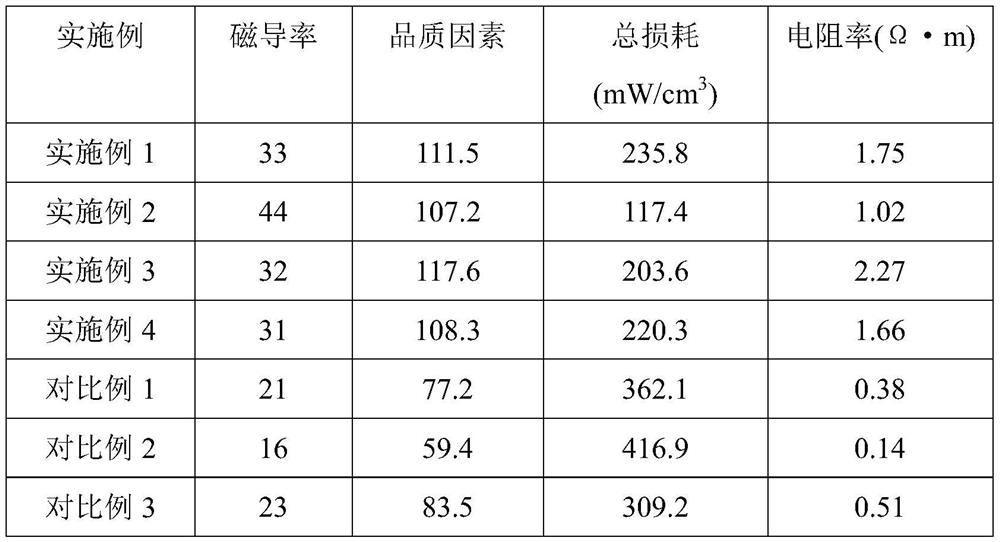

Insulation coating method of metal soft magnetic composite material and metal soft magnetic composite material

PendingCN113066629AImprove rigidityImprove insulation performanceInorganic material magnetismInductances/transformers/magnets manufactureCompression moldingSilicic acid

The invention provides an insulation coating method of a metal soft magnetic composite material and the metal soft magnetic composite material. The insulation coating method of the metal soft magnetic composite material comprises the following steps: mixing tetraethoxysilane and trialkoxysilane, then adding the mixture into absolute ethyl alcohol, dropwise adding insufficient water for the first time, stirring for 2-30 minutes after dropwise adding, adding soft magnetic metal powder, stirring for 5-30 minutes, dropwise adding insufficient water for the second time, stirring for 2-20 minutes after dropwise adding, finally dropwise adding sufficient water, and continuously stirring for 5-60 minutes, filtering and drying to obtain the insulating coating powder. According to the preparation method, water is gradually added to promote gradual hydrolytic condensation of tetraethoxysilane and trialkoxysilane, the surface of the soft magnetic metal powder is coated with an insulating layer with the cross-linking density changing in a gradient mode, and after compression molding and annealing, the obtained metal soft magnetic composite material has the performance of insulation, low eddy current loss and the like.

Owner:福建尚辉润德新材料科技有限公司

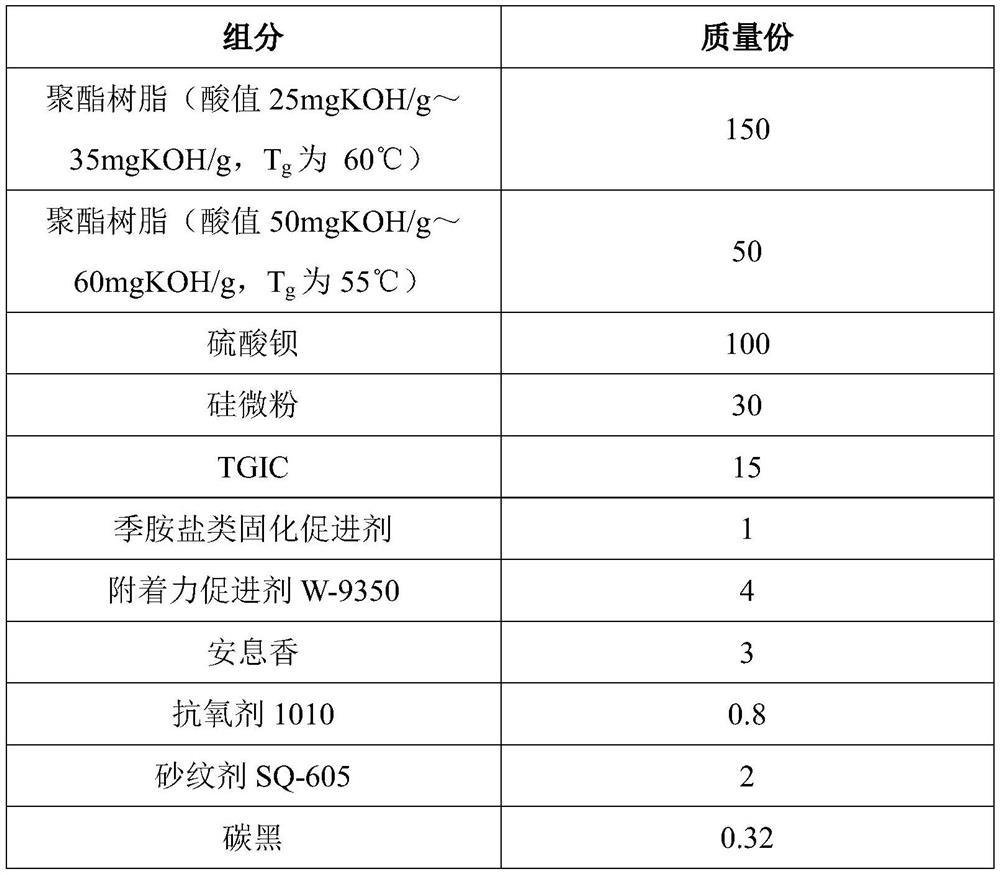

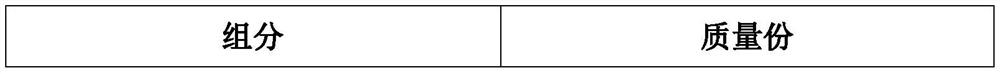

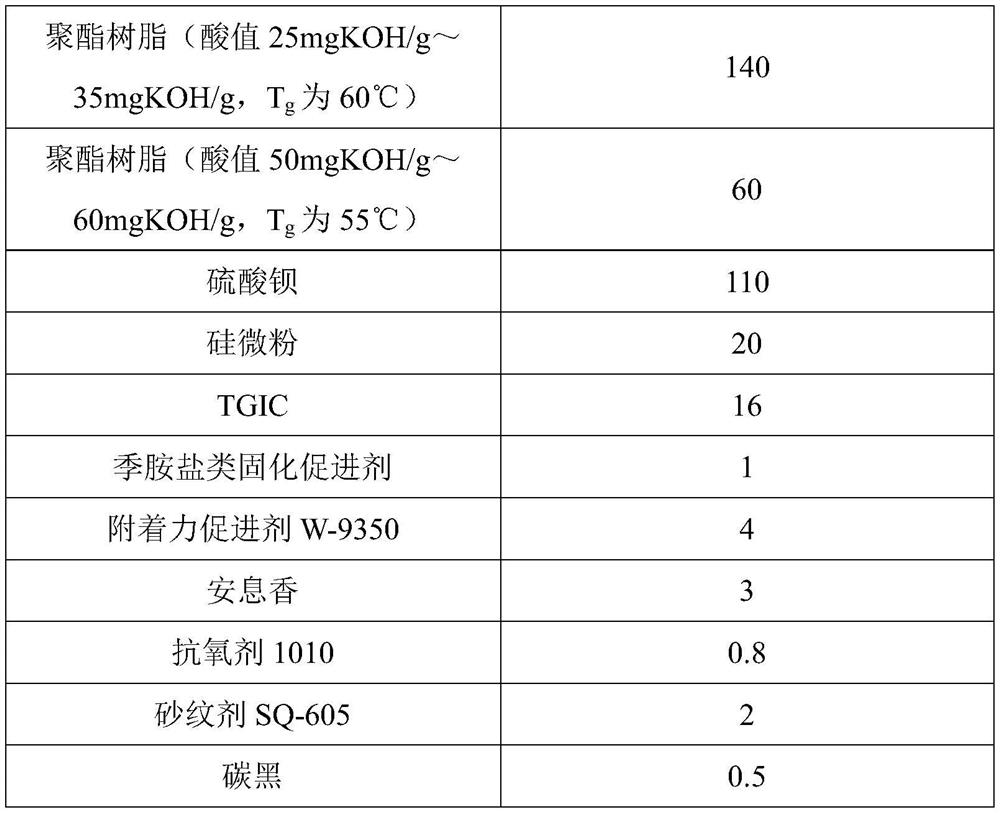

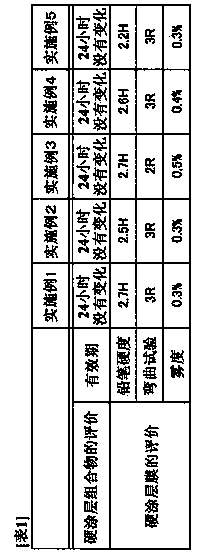

Food-grade powder coating and preparation method thereof

InactiveCN112266711AGood high and low temperature resistanceExcellent baking resistancePowdery paintsPolyester coatingsPolymer scienceWeather resistance

The invention discloses a food-grade powder coating and a preparation method thereof. The food-grade powder coating provided by the invention comprises the following components in parts by mass: 160 to 240 parts of polyester resin; 80 to 140 parts of a filling material; 12 to 22 parts of a curing agent; 0.5 to 1.6 parts of a curing accelerator; 2 to 6 parts of an adhesion promoter; and 1 to 15 parts of other auxiliary agents. The polyester resin is formed by compounding polyester resin with a low acid value and polyester resin with a high acid value. The preparation method of the food-grade powder coating comprises the following steps: mixing the components, conducting stirring, conducting extruding by using a double-screw extruder, and conducting crushing and sieving to obtain the food-grade powder coating. A paint film formed by the powder coating has excellent high and low temperature resistance, baking resistance, acid and alkali resistance and weather resistance, is high in adhesive force, meets the national standard of food-grade coating products, and meets the standard of household appliance coating enterprises.

Owner:GUANGZHOU KINTE IND

Hard coating composition

Provided is a hard coating composition that exhibits excellent extensibility, and that is capable of forming a hard coating layer that has high hardness and is transparent. The hard coating composition contains: (a) a bisphenol A-type epoxy resin having a secondary hydroxyl group and / or a bisphenol F-type epoxy resin having a secondary hydroxyl group, each having a number-average molecular weight of 900-7,000; (b) a melamine resin; (c) a photopolymerization initiator; and (d) a multifunctional (meth)acrylate monomer having at least one hydroxyl group, and / or an oligomeric compound having at least one hydroxyl group.

Owner:NIPPON PAINT CO LTD

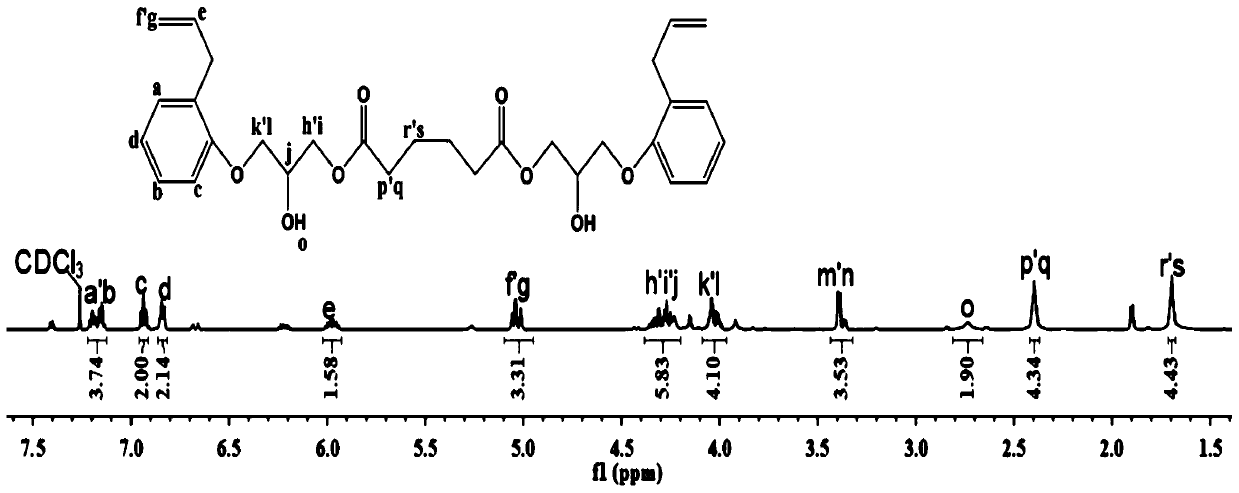

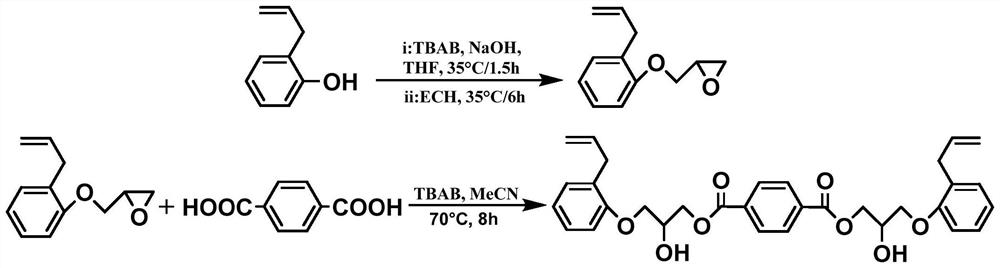

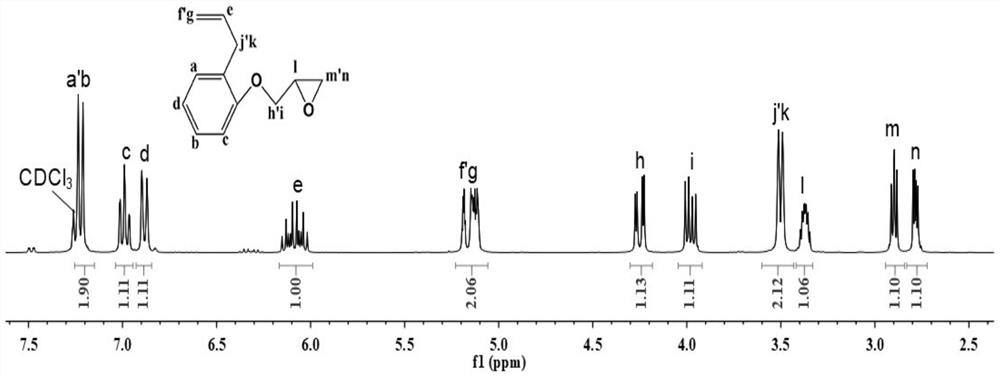

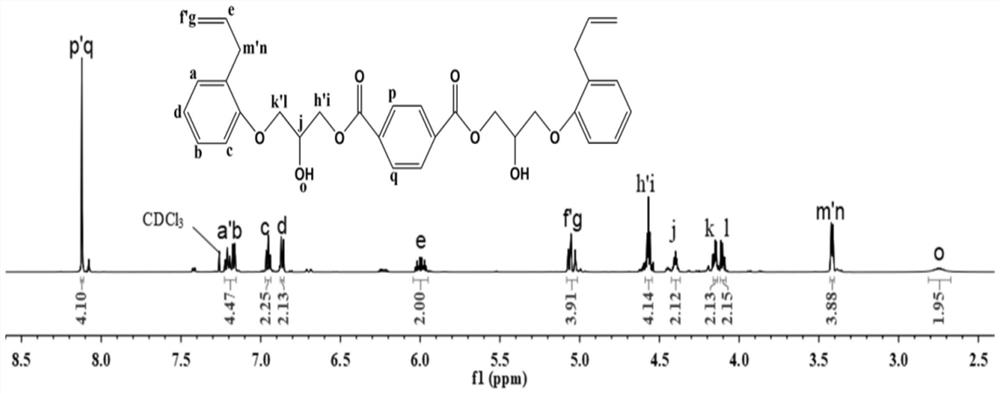

Bismaleimide resin prepolymer and application thereof

The invention discloses a bismaleimide resin prepolymer and an application thereof. 2-allylphenyl glycidyl ether is blended with terephthalic acid in acetonitrile, and an esterification reaction is carried out with a quaternary ammonium salt as a catalyst to obtain a bis(3-(2-allylphenoxy)-2-hydroxypropyl)terephthalate containing a reversible dynamic group; and the bis(3-(2-allylphenoxy)-2-hydroxypropyl)terephthalate is uniformly mixed with bismaleimide to obtain the bismaleimide resin prepolymer, and the bismaleimide resin prepolymer is cured to obtain a remoldable bismaleimide resin. The remoldable bismaleimide resin prepared by using the bismaleimide resin prepolymer has good heat resistance and good mechanical properties, also can be remolded under a hot pressing condition, and has broad application prospects in the fields of aerospace, transportation, electronic information, new energy and insulated electrics.

Owner:SUZHOU UNIV

A kind of glass fiber coating and preparation method thereof

The invention discloses a high-performance glass fiber coating and a preparation method thereof. The glass fiber coating and the preparation method aim to solve the technical problems of poor alkali resistance and poor storage stability of the existing urea-formaldehyde resin coating; the glass fiber coating The coating is counted in parts by mass, and the raw material components include: 40-70 parts of water, 20-30 parts of acrylate monomer, 1-5 parts of acrylate functional monomer, 10-30 parts of modified urea-formaldehyde resin glue, 0.5-5 parts of polymerization stabilizer, 0.1-1.5 parts of azobisisobutylamidine hydrochloride, 0.1-0.5 parts of azobisisobutyronitrile, 0.1-3 parts of cationic emulsifier or cationic reactive emulsifier, cationic starch dispersion Solution 4-7 parts, acid-base buffer 0.05-0.5, chain transfer aid 0.1-5. The technical solution can effectively improve the water resistance, alkali resistance and storage stability of the coating, and make it have the performance advantages of urea-formaldehyde resin and acrylate resin, and improve the overall performance of the polymer.

Owner:九江华源新材料有限公司

Thermosetting shape memory resin based on bismaleimide and preparation method thereof

The invention relates to a bismaleimide-based thermosetting shape memory resin with high deformation and a preparation method thereof. Comprise the following steps, bismaleimide and 1,6-hexanedithiol are added in m-cresol to form a solution; triethylamine is added dropwise in the solution, and N 2 Under protection and stirring conditions, react at room temperature to obtain linear oligomers; by mass, mix bismaleimide, linear oligomers and O, O´‑diallyl bisphenol A at a temperature of 130 ~ React at 150°C for 25-45 minutes to obtain a prepolymer; vacuum defoam the prepolymer at a temperature of 130-150°C, and then undergo curing and post-treatment to obtain a thermosetting shape memory resin based on bismaleimide. Compared with the prior art, the resin of the present invention has a large deformability, and its elongation at break at the programmed temperature is greater than 30%. In addition, the cured resin combines high glass transition temperature (>131°C) and initial decomposition temperature (>370°C), high toughness and outstanding shape memory properties.

Owner:SUZHOU UNIV

Prepolymer for remoldable bismaleimide resin, and application thereof

The invention discloses a prepolymer for remoldable bismaleimide resin, and an application thereof. 2-allylphenyl glycidyl ether is blended with terephthalic acid in acetonitrile, and an esterification reaction is carried out with a quaternary ammonium salt as a catalyst to obtain a bis(3-(2-allylphenoxy)-2-hydroxypropyl)terephthalate containing a reversible dynamic group; the bis(3-(2-allylphenoxy)-2-hydroxypropyl)terephthalate is uniformly mixed with bismaleimide to obtain the prepolymer for remoldable bismaleimide resin; and the prepolymer for remoldable bismaleimide resin is cured to prepare the remoldable shape memory bismaleimide resin. The remoldable shape memory bismaleimide resin prepared by using the prepolymer for the remoldable bismaleimide resin has good shape memory property,heat resistance and mechanical properties, also can be remolded under a hot pressing condition, and has broad application prospects in the fields of aerospace, space self-expanding structures, sensors and actuators.

Owner:SUZHOU UNIV

Bismaleimide resin prepolymer and its application

The invention discloses a bismaleimide resin prepolymer and its application. The specific preparation is as follows: 2-allylphenyl glycidyl ether and terephthalic acid are blended in acetonitrile, and an esterification reaction occurs under the condition of a quaternary ammonium salt as a catalyst to obtain bis(3- (2‑allylphenoxy)‑2‑hydroxypropyl)terephthalate; bis(3‑(2‑allylphenoxy)‑2‑hydroxypropyl)terephthalate The formate ester and the bismaleimide are uniformly mixed to obtain a bismaleimide resin prepolymer, which is cured to obtain a remodelable bismaleimide resin. The remodelable bismaleimide resin prepared by the bismaleimide resin prepolymer of the present invention not only has excellent heat resistance and mechanical properties, but also can realize remodeling under hot pressing conditions, and is used in aerospace, It has broad application prospects in industrial fields such as transportation, electronic information, new energy, and electrical insulation.

Owner:SUZHOU UNIV

Organosilicon joint sealing material with low cost and high performance

InactiveCN101760174BQuality improvementReduce manufacturing costOther chemical processesChemical reactionWeather resistance

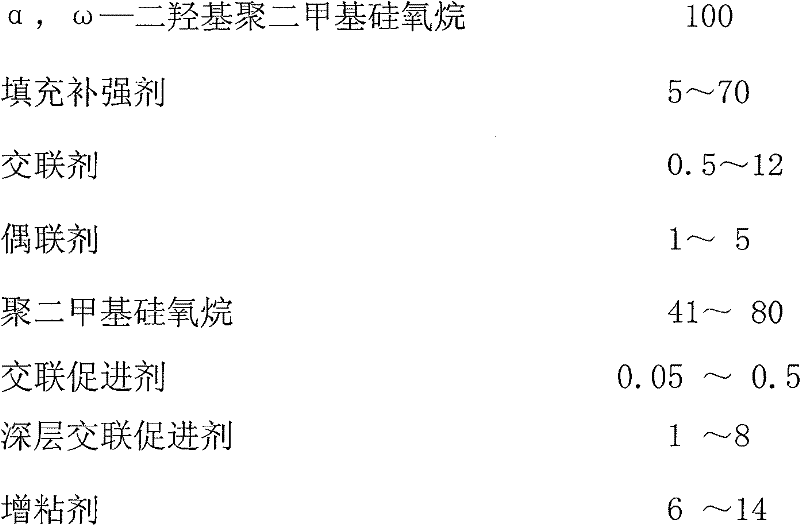

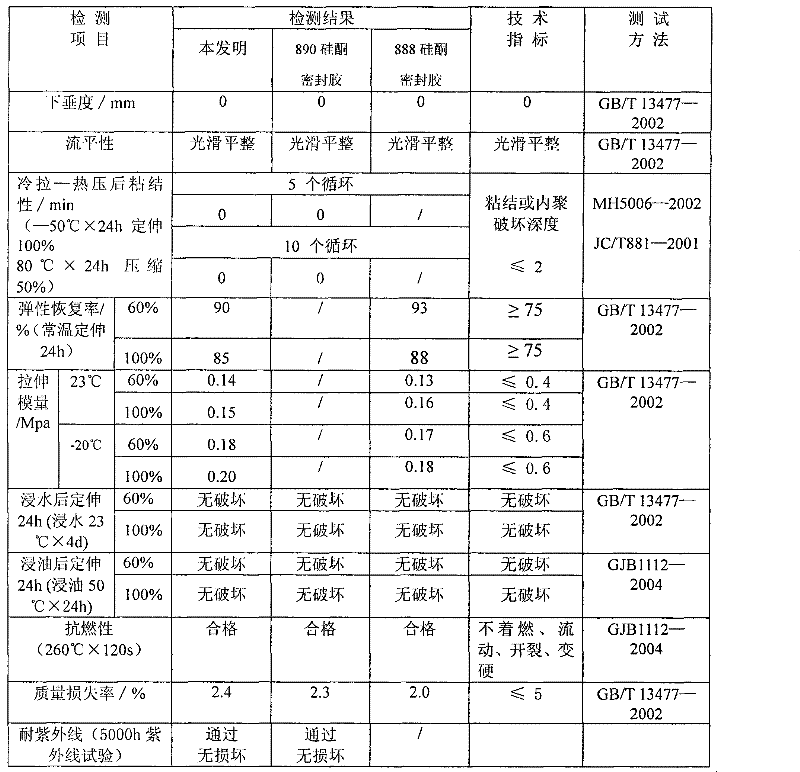

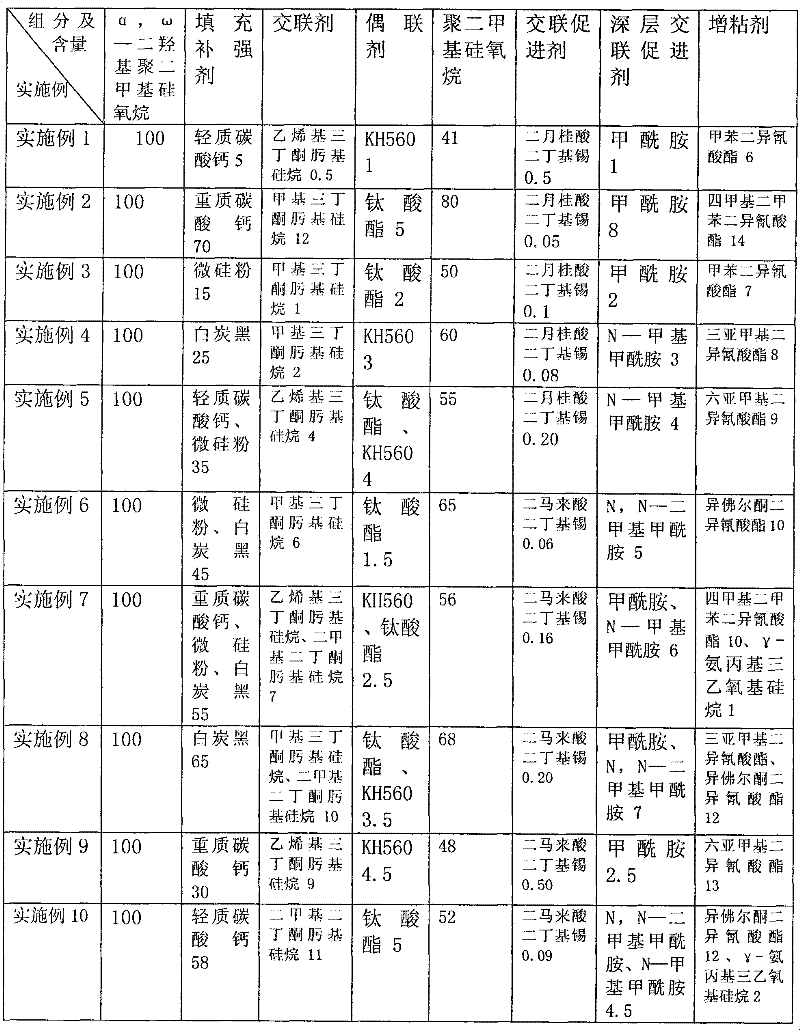

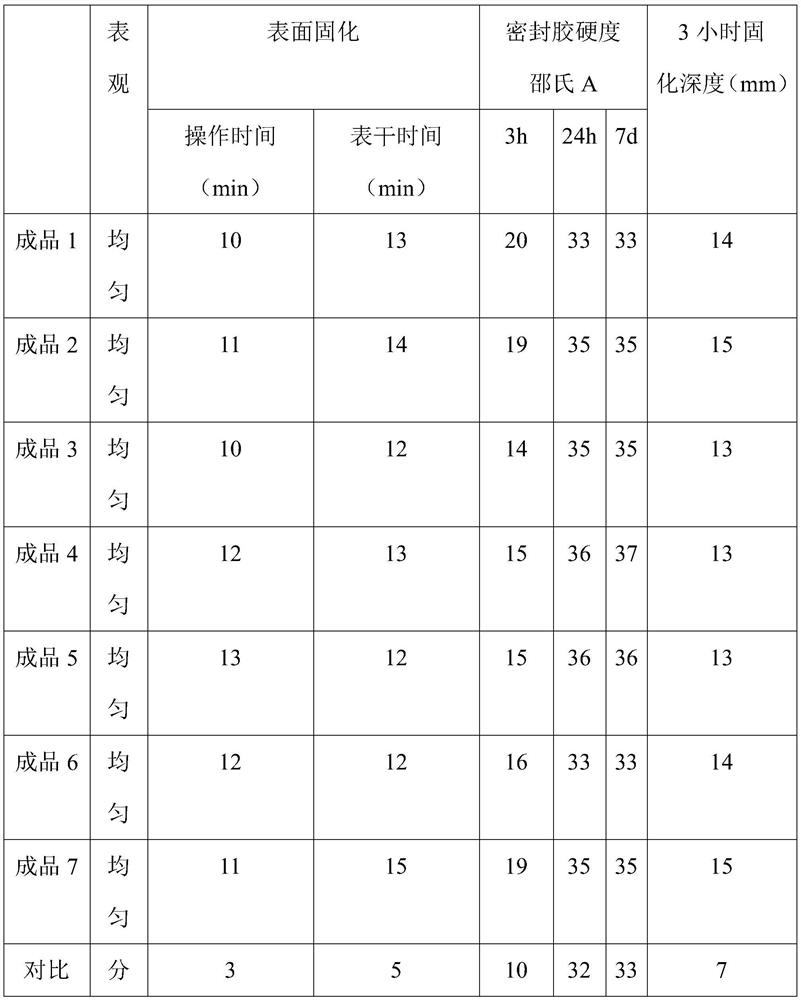

The invention provides organosilicon joint sealing materials with low cost and high performance. A product prepared from the organosilicon joint sealing materials comprises the following components in proportion by weight: 100 alpha, omega-dicarboxylic dimethyl polysiloxane, 5 to 70 filler reinforcement agents, 0.5 to 12 crosslinking agents, 1 to 5 o coupling agents, 41 to 80 dimethyl polysiloxane, 1 to 8 deep-layer crosslinking accelerant and 6 to 14 tackifier, wherein the alpha, omega-dicarboxylic dimethyl polysiloxane and the filler reinforcement agents are added into a vacuum kneader, dehydrated and mixed to obtain base materials, the base materials are moved in a high-speed dispersator, and stirred and mixed with other components in a high-speed mode, and finally the crosslinking accelerants are added to carry out chemical reaction to obtain the joint sealing materials. Various raw materials used by the invention can be bought in the market; thereby the invention has low manufacturing cost, high performance in various aspects, low modulus, high extension percentage, normal temperature crosslinking, good bonding effect and sealing effect on cement and earth, good elastic restitution capability, embedding resistance, weather resistance and long service life.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

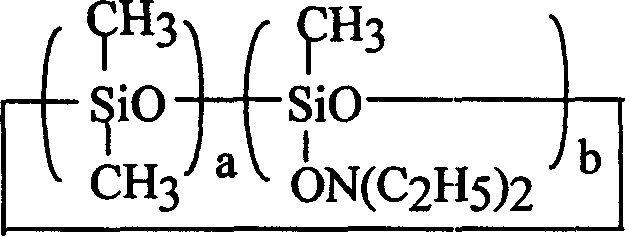

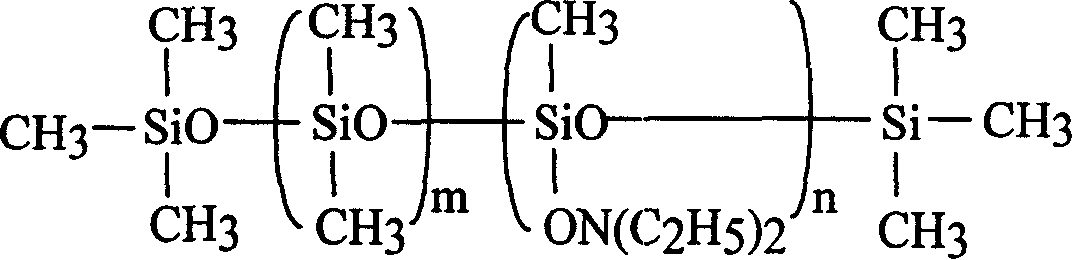

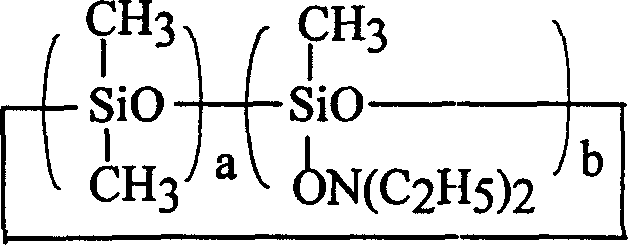

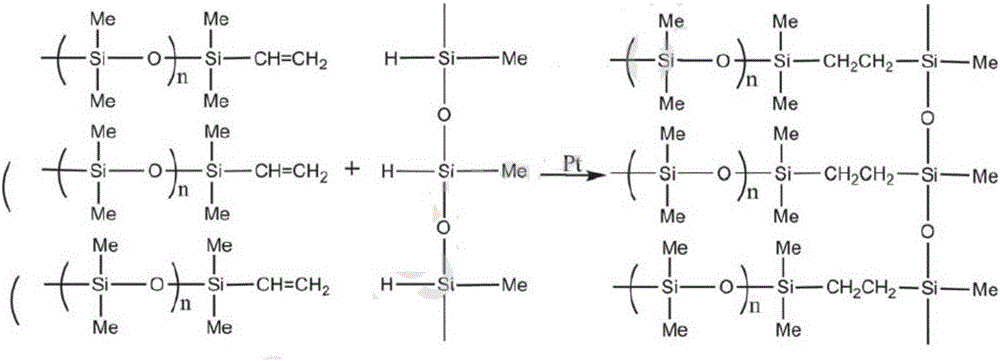

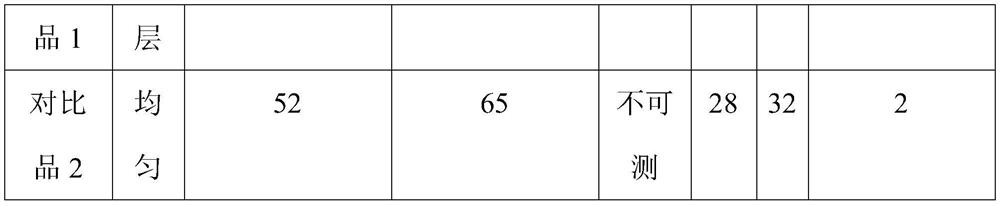

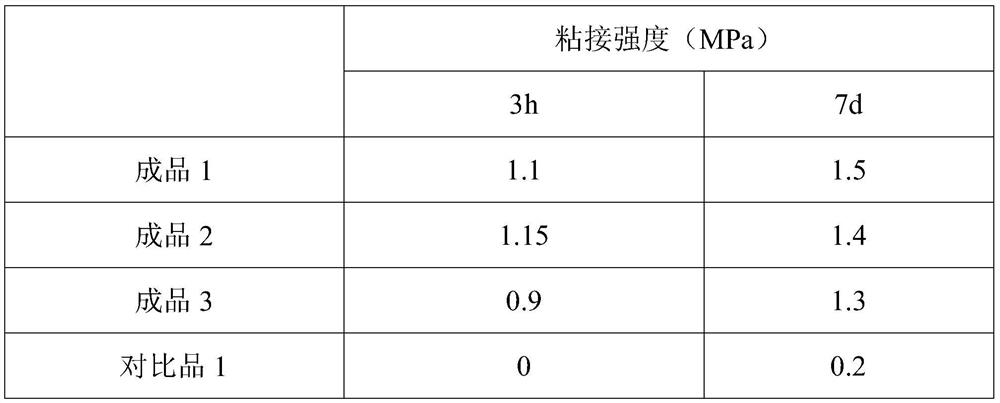

A two-component silicone sealant for floodlights

ActiveCN110257002BSufficient Reactive CrosslinksModerate crosslink densityNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePtru catalyst

The invention discloses a two-component silicone sealant for floodlights, which comprises independently packaged component A and component B, and the weight ratio of component A to component B is (5-10):1 and, in parts by weight, component A includes: 100 parts of hydroxyl-terminated polydimethylsiloxane, 2-10 parts of trimethyl-terminated polydimethylsiloxane, 80-150 parts of reinforcing filler, 10-40 parts of composite flame retardant; in parts by weight, component B includes: 30-50 parts of trimethyl-terminated polydimethylsiloxane, 3-10 parts of carbon black or titanium dioxide, and 10 parts of reinforcing filler -50 parts, 5-20 parts of silane crosslinking agent, 5-20 parts of silane coupling agent, 0.01-3 parts of composite synergistic condensation catalyst. The invention has the advantages of relatively uniform deep-layer curing speed and better bonding quality.

Owner:宁波聚力新材料科技有限公司

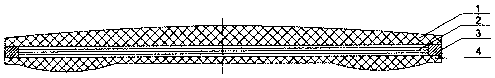

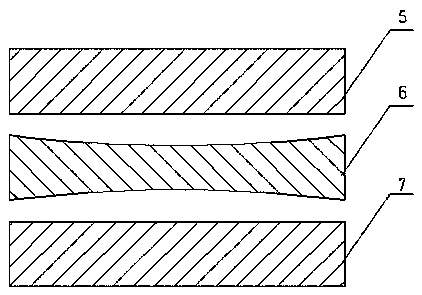

Curved surface compensation conveying belt

PendingCN110712925AReduce manufacturing costExtended service lifeConveyorsAdhesiveStructural engineering

The invention discloses a curved surface compensation conveying belt, and relates to the technical field of conveying belts. The curved surface compensation conveying belt comprises a skeleton layer,an upper covering layer and a lower covering layer, wherein the upper covering layer is positioned on the outward side of the skeleton layer, and comprises a middle upper adhesive section and an edgeupper adhesive section in the width direction; the middle upper adhesive section is thicker than the edge upper adhesive section; the lower covering layer is positioned on the inward side of the skeleton layer, and comprises a middle lower adhesive section and an edge lower adhesive section in the width direction; and the middle lower adhesive section is thinner than the edge lower adhesive section. The service life of easily worn parts of the covering layers is prolonged through a curved surface compensation method, so that the service life of the conveying belt is prolonged.

Owner:江苏凯嘉橡胶科技股份有限公司

Prepolymer for Remodelable Bismaleimide Resin and Its Application

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com