Bismaleimide resin prepolymer and application thereof

A technology of maleimide resin and bismaleimide, applied in the field of thermosetting resin and its preparation, remodelable bismaleimide resin prepolymer and its preparation, can solve the problem of non-remodelable, Poor heat resistance and mechanical properties, low overall performance of remodelable thermosetting resins, etc., to achieve the effect of highlighting heat resistance, high thermal stability, and good shape memory function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of bismaleimide resin prepolymer of the present invention is as follows:

[0042] (1) In the presence of quaternary ammonium salt, react 2-allylphenyl glycidyl ether with terephthalic acid to prepare bis(3-(2-allylphenoxy)-2-hydroxypropyl) terephthalates;

[0043] (2) Mix bis(3-(2-allylphenoxy)-2-hydroxypropyl) terephthalate, bismaleimide and zinc compound to obtain bismaleimide resin prepolymer.

Embodiment 1

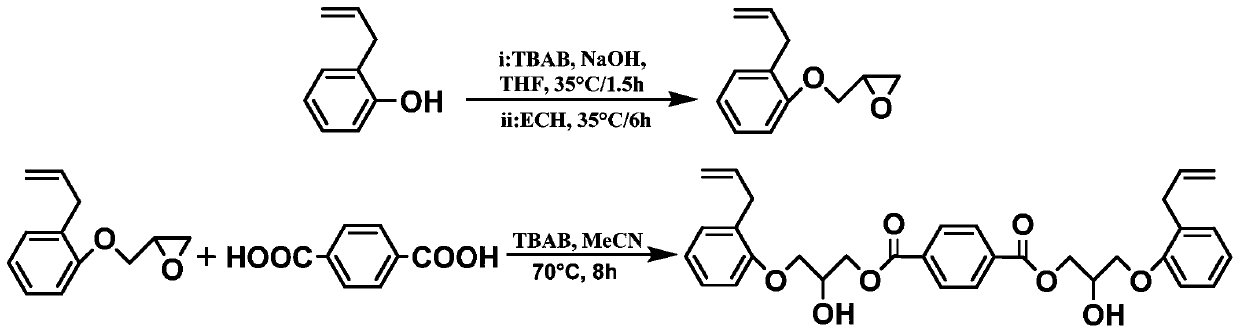

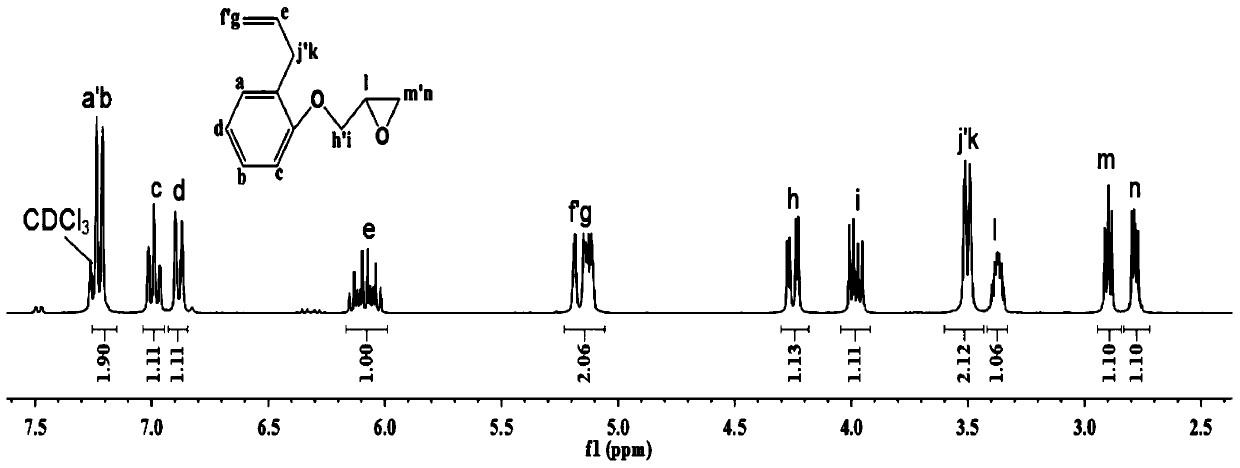

[0045] 1) Preparation of 2-allylphenyl glycidyl ether

[0046] On a mass basis, mix 120g of 2-allylphenol, 140g of sodium hydroxide, 10g of tetrabutylammonium bromide and 230g of tetrahydrofuran, and insulate and react at 35°C for 1.5h under stirring conditions to obtain solution A; Slowly add 270 g of epichlorohydrin dropwise, and keep stirring at 35° C. for 6 hours to react; after the reaction, vacuum rotary evaporation removes tetrahydrofuran and epichlorohydrin to obtain a crude product. The crude product was washed successively with saturated ammonium chloride solution (200 mL×2), deionized water (200 mL×2), and finally separated and purified by chromatography to obtain a yellow transparent liquid, namely 2-allylphenyl Glyceryl ether, the yield is about 93%, its reaction formula and 1 H-NMR see attached figure 1 and 2 .

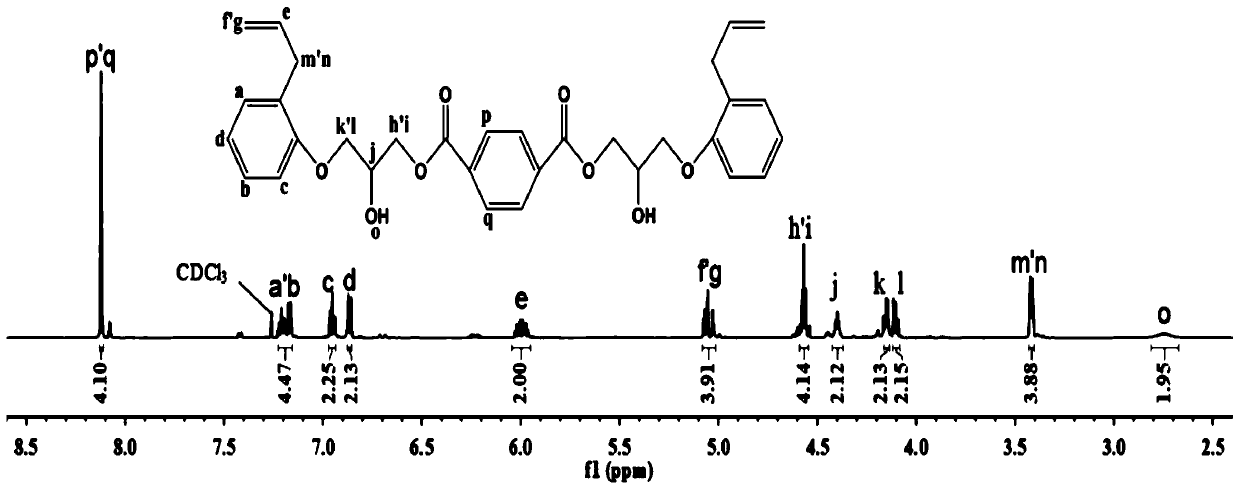

[0047] 2) Preparation of bis(3-(2-allylphenoxy)-2-hydroxypropyl)terephthalate

[0048] On a mass basis, mix 120g 2-allylphenyl glycidyl ether, 45g ...

Embodiment 2

[0090] 1) Preparation of 2-allylphenyl glycidyl ether

[0091] On a mass basis, mix 120g of 2-allylphenol, 100g of sodium hydroxide, 5g of tetramethylammonium bromide and 200g of tetrahydrofuran, and insulate and react for 1 hour at 25°C with stirring to obtain solution A; 250 g of epichlorohydrin was added dropwise, and the mixture was stirred and reacted at 25° C. for 6 hours; after the reaction was completed, tetrahydrofuran and epichlorohydrin were removed by vacuum rotary evaporation to obtain a crude product. The crude product was washed successively with saturated ammonium chloride solution (200 mL×2), deionized water (200 mL×2), and finally separated and purified by chromatography to obtain a yellow transparent liquid, namely 2-allylphenyl Glyceryl ether, the yield is about 90.1%.

[0092] 2) Preparation of bis(3-(2-allylphenoxy)-2-hydroxypropyl)terephthalate

[0093] By mass, mix 120g of 2-allylphenyl glycidyl ether, 40g of terephthalic acid, 5g of tetramethylammoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com