A two-component silicone sealant for floodlights

A silicone sealant, two-component technology, used in adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problem of increasing production and operation costs, high bonding reaction temperature, poor storage stability, etc. problems, to achieve the effect of improving density, enhancing air tightness, and uniformity of curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

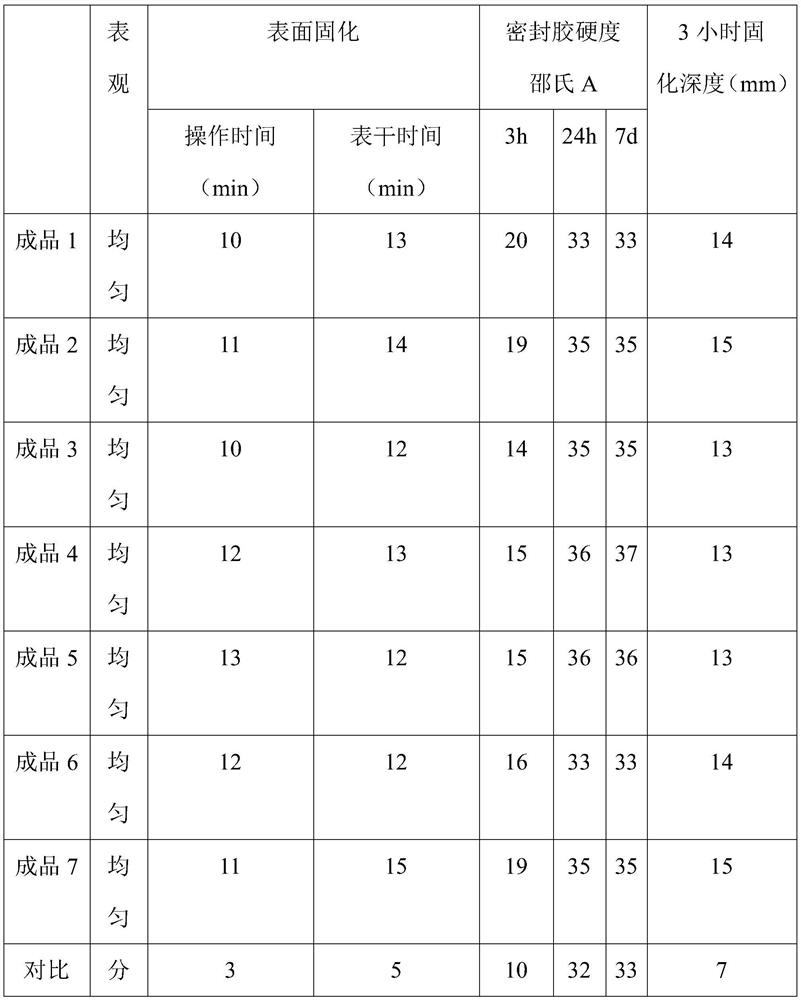

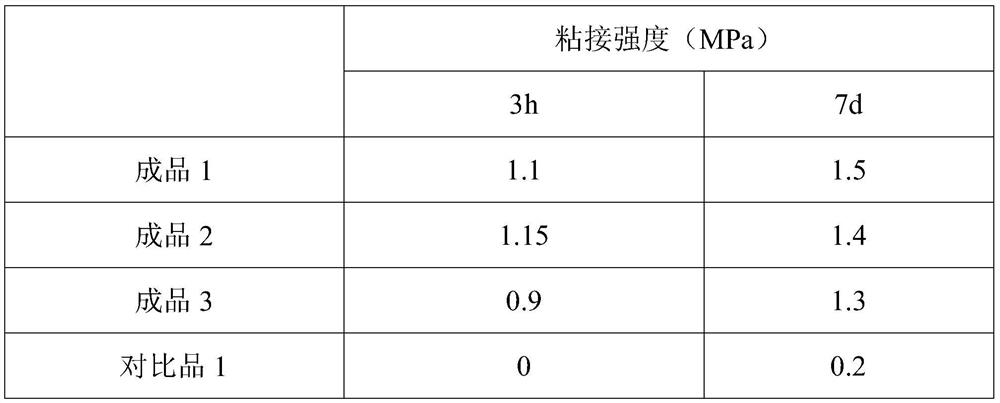

Examples

Embodiment 1

[0026] A flushing light is two-component silicone sealing gum, including a separate package of A component and B component, and the weight ratio of the A component and the B component is 5: 1. In the preparation, the preparation of the A component and the B component is included.

[0027] The preparation of the A component is: 100 parts of the heterodoxy polyimethylsiloxane, 2 parts of the tetramethylene sealing end polyimethylsiloxane, 80 parts of the filler, composite flame retardant 10 copies. Thereafter, the aforementioned components are in an environment of inert gas, the maximum temperature does not exceed 0 °, and the mixing is uniform, and the last inert gas protection, and the independent sealing package is loaded in the room temperature state. At the time of concrete preparation, the alarmability of the product time when the product is used is found.

[0028] The preparation of the B component is: 30 parts of the trimethyl group, 3 parts of the trimethyl group, 3 parts o...

Embodiment 2

[0039] And the difference between Example 1 is only:

[0040] The weight ratio of the A component and the B component is 8: 1.

[0041] In the preparation of the A component, 100 parts of the tetramethylene siloxane, 5 parts of the tetramethylene seal end polyimethylsiloxane, 10 parts of the tetramethylene chromatoxane, 10 parts of the trimethyl, and 120 composite flame retardants. 30 copies.

[0042] In the preparation of the B component, 40 parts of the trimethyl group, 5 parts of the trimethyl, 5 parts of titanium powder, 40 parts of the filler, 10 parts of the silane interchange agent, silane coupling agent 10 copies of composite coordinated condensation catalysts.

[0043]The terminal hydroxy polyimethylsiloxane is mutually collided by two endoxy polyimethylsiloxane I and end hydroxyl polymethylsiloxane II having different viscosity. The viscosity range of the terminal hydroxyl polymethylsiloxane I is 5000 mPas, and the viscosity range of terminal hydroxyl polymethylsiloxane ...

Embodiment 3

[0052] And the difference between Example 1 is only:

[0053] The weight ratio of the A component and the B component is 10: 1.

[0054] In the preparation of the A component, 100 parts of the heterodoxy polymethylsiloxane, 10 parts of the tetramethylene seal end polyimethylsiloxane, 10 parts of the tetramethylene seal end polyimethylsiloxane, 150 parts of the filler, composite flame retardant 40 copies.

[0055] In the preparation of the B component, 50 parts of the trimethyl group, 10 parts by weight, 10 parts of carbon black, 20 parts of the silane interchange agent, and silane diploma. 20 copies of composite coordinated condensation catalysts.

[0056] The terminal hydroxy polyimethylsiloxane is mutually collided by two endoxy polyimethylsiloxane I and end hydroxyl polymethylsiloxane II having different viscosity. The viscosity range of the terminal hydroxy polyimethylsiloxane I is 10,000 mPas, the viscosity range of the terminal hydroxyl polymethylsiloxane II ranges from 5000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com