Organosilicon joint sealing material with low cost and high performance

A technology of joint filler and silicone, which is applied in the field of joint filler, can solve the problems of high price, unavailable, no products, etc., and achieve the effect of low production cost, excellent bonding performance and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

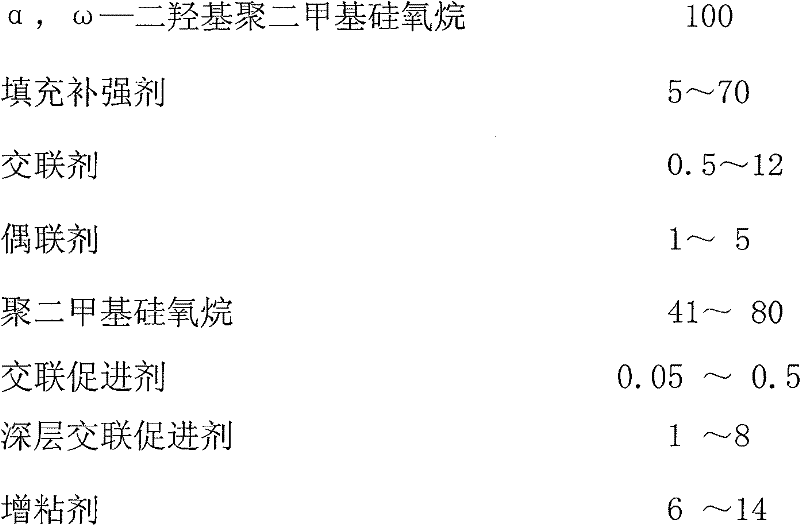

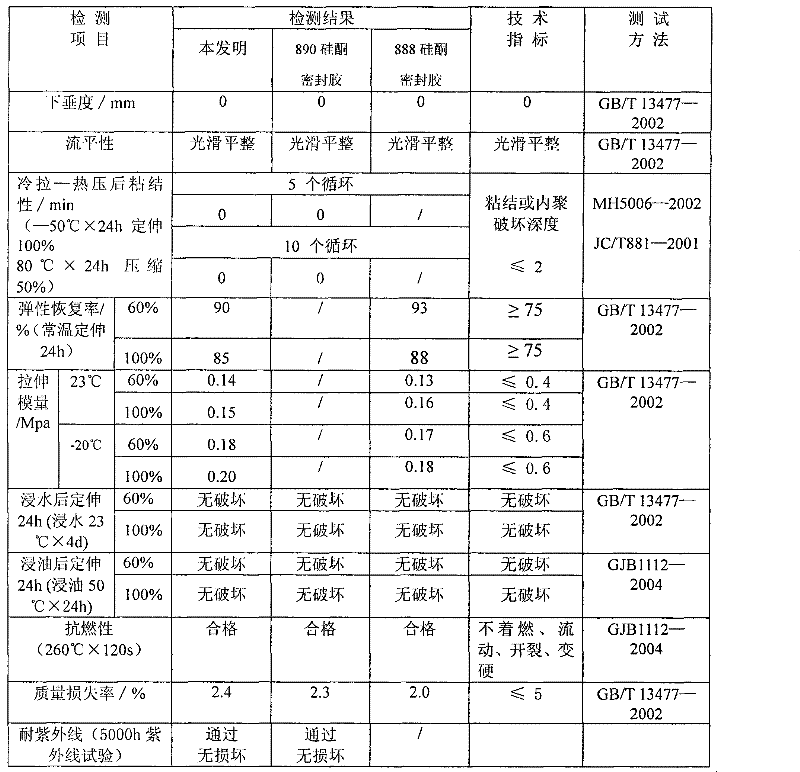

Method used

Image

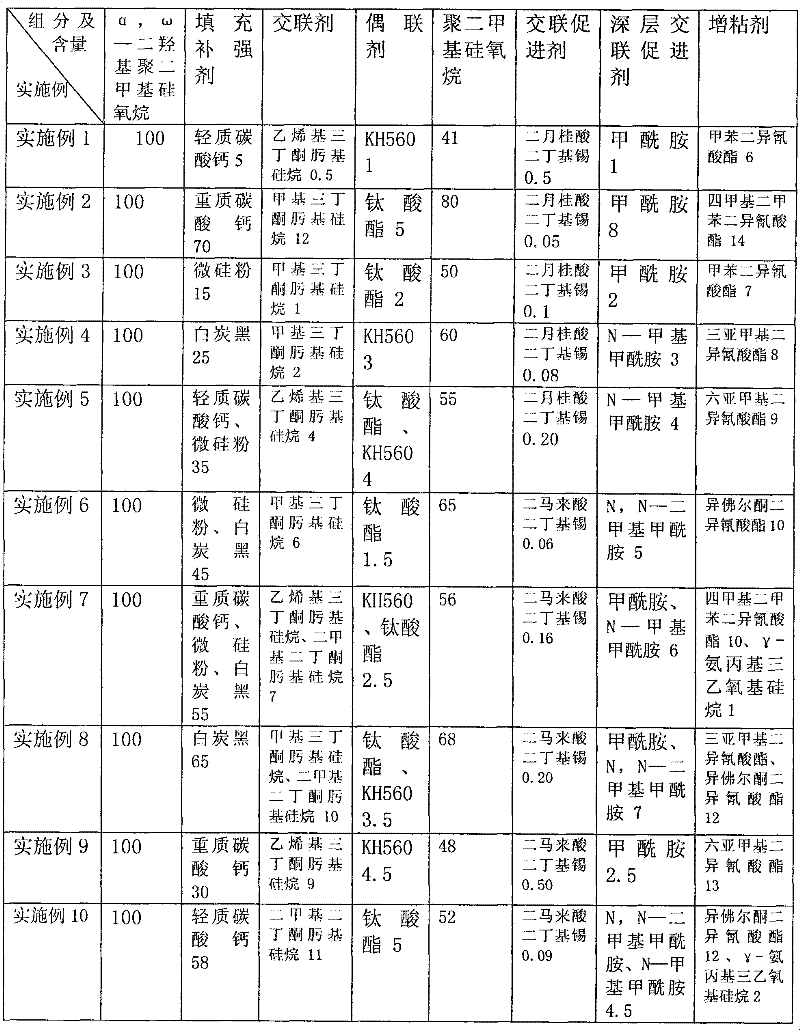

Examples

Embodiment 1

[0045] (1) get raw material by table 2;

[0046] (2) Add α, ω-dihydroxy polydimethylsiloxane and filler reinforcing agent into a vacuum kneader, dehydrate and blend for 60 minutes at 100°C with a vacuum degree of 0.06Mpa, and cool naturally to room temperature to obtain Binder;

[0047] (3) Move the base material into the high-speed dispersion mixer, and at room temperature, add 6 kg of cross-linking agent, coupling agent, polydimethylsiloxane, deep cross-linking accelerator, and tackifier into the high-speed dispersion mixer , mixed with the base material at high speed, and the chemical reaction was carried out for 20 minutes at a vacuum degree of 0.06Mpa and a rotation speed of 300rpm.

[0048](4) Turn on the high-speed dispersing mixer, add a total of 0.5 kilograms of the crosslinking accelerator dibutyltin dilaurate, carry out the chemical reaction for 50 minutes under the same conditions as (3), and obtain the present invention.

Embodiment 2

[0050] (1) get raw material by table 2;

[0051] (2) Add α, ω-dihydroxy polydimethylsiloxane and filling reinforcing agent into a vacuum kneader, dehydrate and blend at 150°C and a vacuum of 0.095Mpa for 180min, and cool naturally to room temperature to obtain Binder;

[0052] (3) Move the base material into the high-speed dispersion mixer, and at room temperature, add the crosslinking agent, coupling agent, polydimethylsiloxane, deep crosslinking accelerator, and tackifier into the high-speed dispersion mixer, and mix with the base The materials were stirred and mixed at a high speed, and the chemical reaction was carried out for 50 minutes at a vacuum degree of 0.095Mpa and a rotation speed of 800rpm.

[0053] (4) Turn on the high-speed dispersing mixer, add a total of 0.05 kilograms of the crosslinking accelerator dibutyltin dilaurate, carry out the chemical reaction for 30 minutes under the same conditions as (3), and obtain the present invention.

Embodiment 3

[0055] (1) get raw material by table 2;

[0056] (2) Add α, ω-dihydroxy polydimethylsiloxane and filler reinforcing agent into a vacuum kneader, dehydrate and blend at 110°C for 80 minutes at a vacuum degree of 0.09Mpa, and cool naturally to room temperature to obtain Binder;

[0057] (3) Move the base material into the high-speed dispersion mixer, and at room temperature, add the crosslinking agent, coupling agent, polydimethylsiloxane, deep crosslinking accelerator, and tackifier into the high-speed dispersion mixer, and mix with the base The materials were stirred and mixed at high speed, and the chemical reaction was carried out for 50 minutes at a vacuum degree of 0.085Mpa and a rotation speed of 700rpm;

[0058] (4) Turn on the high-speed dispersing mixer, add a total of 0.1 kg of the crosslinking accelerator dibutyltin dilaurate, carry out the chemical reaction for 30 minutes under the same conditions as (3), and obtain the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com