Curved surface compensation conveying belt

A conveyor belt and curved surface technology, applied in the field of curved surface compensation conveyor belt, can solve the problems of high tape cost, waste of high-quality resources, redundant rubber materials, etc., and achieve good synergistic effect, reduced manufacturing cost, and moderate crosslinking density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on the specific embodiments and in conjunction with the accompanying drawings.

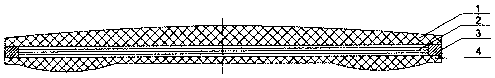

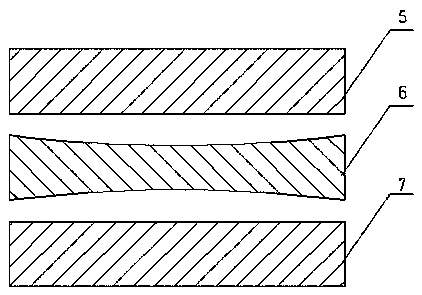

[0038]The conveyor belt is suitable for the transportation of powdery and blocky materials between various processes and sections. It is convenient and fast, and has high production efficiency. It is a necessary means for continuous transportation of modern large-scale production of materials. The skeleton layer is the tape strength layer (either steel wire rope or laminated canvas), which bears the main tension during the operation of the tape, and the upper and lower covering glues play a role in protecting the skeleton layer. During the use of general conveyor belts, the middle part of the upper covering rubber is easy to be worn, and gradually decreases to both sides. The contact part of the lower cover rubber and the roller is easy to be w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com