Ultraviolet curable hydrophilic aluminum foil coating composition

A technology of hydrophilic aluminum foil and composition, which is applied in the direction of polyester coating, epoxy resin coating, polyurea/polyurethane coating, etc., can solve the problems of high energy consumption and environmental protection, and achieve simple production process, fast curing speed, The effect of moderate crosslink density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

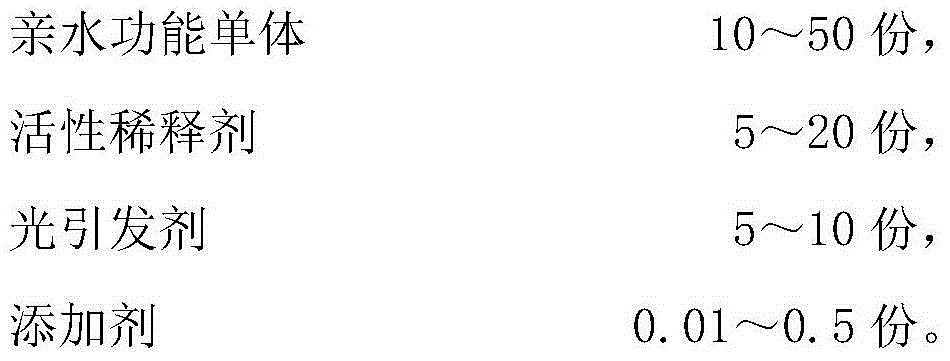

[0037] The UV-curable hydrophilic aluminum foil coating composition of this embodiment includes the components shown in Table 1;

[0038] The coating composition is roll-coated on the pretreated aluminum foil, and the coating dry weight is 0.4-1.0 g / m 2 Between, normal temperature leveling for 1 to 2 minutes, after 800mj / cm 2 The test results of the UV-curable coating are shown in Table 2.

Embodiment 2

[0040] The UV-curable hydrophilic aluminum foil coating composition of this embodiment includes the components shown in Table 1

[0041] The coating composition is roll-coated on the pretreated aluminum foil, and the coating dry weight is 0.4-1.0 g / m 2 Between, normal temperature leveling for 1 to 2 minutes, after 800mj / cm 2 The test results of the UV-curable coating are shown in Table 2.

Embodiment 3

[0043] The UV-curable hydrophilic aluminum foil coating composition of this embodiment includes the components shown in Table 1;

[0044] The coating composition is roll-coated on the pretreated aluminum foil, and the coating dry weight is 0.4-1.0 g / m 2 Between, normal temperature leveling for 1 to 2 minutes, after 800mj / cm 2 The test results of the UV-curable coating are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com