Low-hardness solvent-resistant antistatic polyurethane elastomer and preparation method thereof

A polyurethane elastomer, polyurethane prepolymer technology, applied in rotary printing presses, printing, printing presses, etc., can solve the problems of static charge not easily disappearing, easy to absorb dust, poor tolerance, etc., to achieve excellent balance of mechanical strength, resistance to Excellent balance of solvent properties, good tolerance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

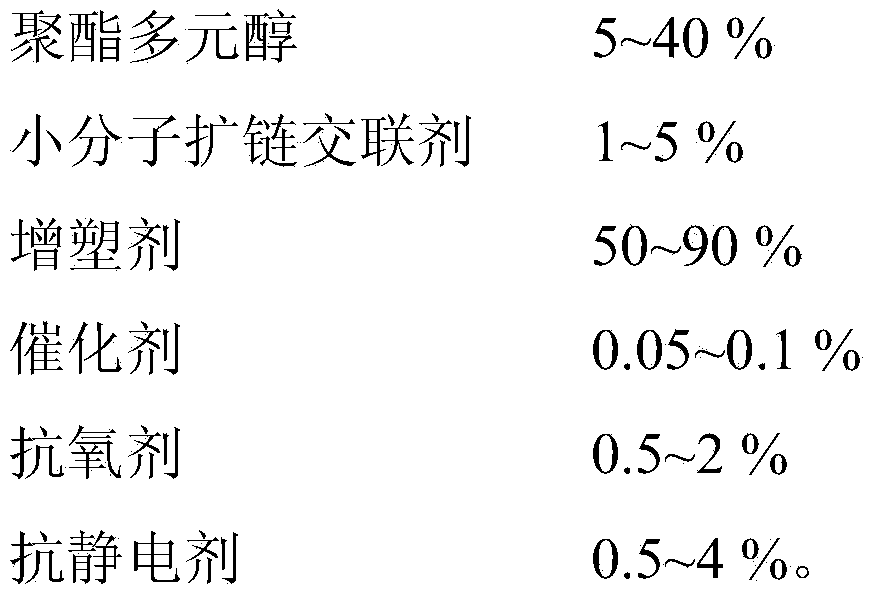

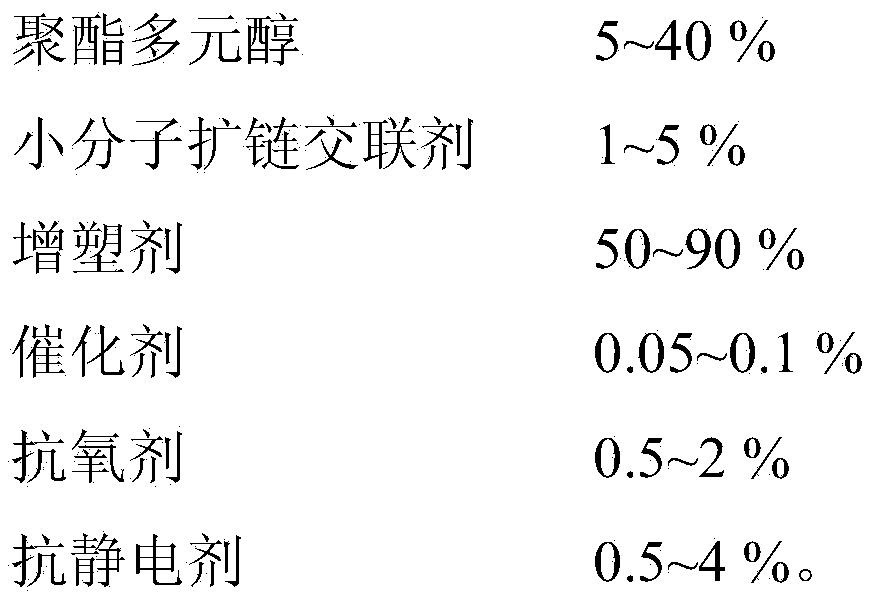

Method used

Image

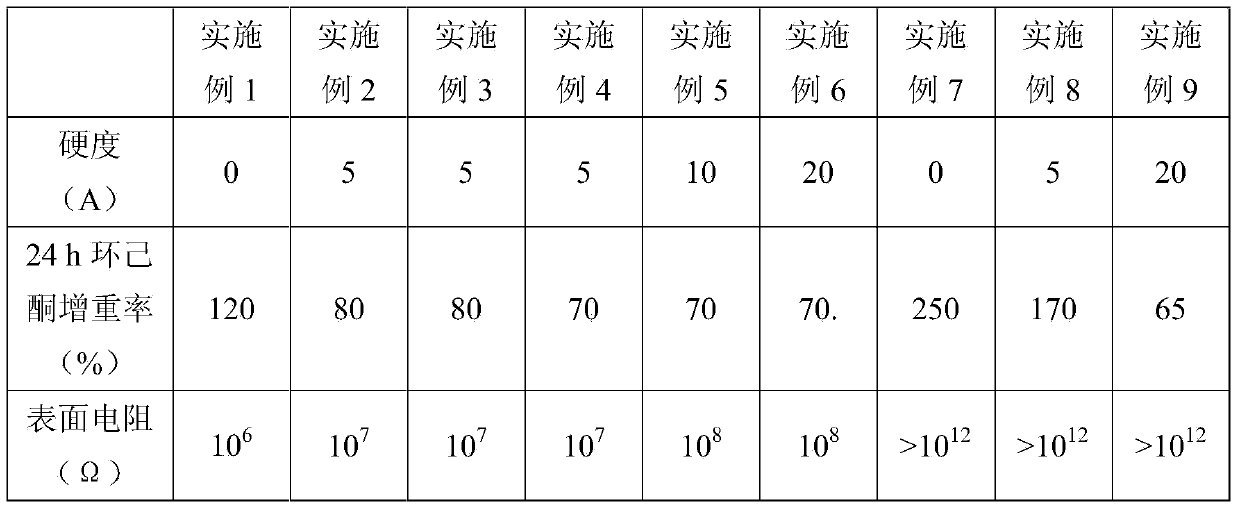

Examples

Embodiment 1

[0072] Example 1: Preparation of antistatic polyurethane elastomer with low hardness and solvent resistance

[0073] Preparation of polyurethane prepolymer: mix 500 parts by weight of PEA1000 and 314.5 parts by weight of DEP, heat to 110°C and dehydrate in vacuum at -0.1MPa for 2h. When the water content is lower than 0.05wt%, cool to 60°C, and under the protection of dry nitrogen After adding 129 parts by weight of T-80 and reacting at 70°C for 2 hours, the reaction can be stopped when the test residual NCO content reaches 2wt%, and the temperature is discharged.

[0074] Preparation of active hydrogen-containing polymer: 100 parts by weight of MX2325, 17.9 parts by weight of TMP, 745 parts by weight of DEP, 400 parts by weight of DMEP, 2.5 parts by weight of organic bismuth, 11 parts by weight of antioxidant 264, 22 parts by weight of antistatic agent Cyastat LS and an appropriate amount of defoamer, heated to 110°C and vacuum dehydrated at -0.1MPa for 2h, cooling and discharging...

Embodiment 2

[0076] Example 2: Preparation of low-hardness and solvent-resistant antistatic polyurethane elastomer

[0077] Preparation of polyurethane prepolymer: mix 500 parts by weight of PEA1000 and 314.5 parts by weight of DEP, heat to 110°C and dehydrate in vacuum at -0.1MPa for 2h. When the water content is lower than 0.05wt%, cool to 60°C, and under the protection of dry nitrogen After adding 129 parts by weight of T-100 and reacting at 70°C for 2 hours, the reaction can be stopped when the test residual NCO content reaches 2wt%, and the temperature is discharged.

[0078] Preparation of active hydrogen-containing polymer: 100 parts by weight of MX2325, 26 parts by weight of TIPA, 417 parts by weight of DEP, 300 parts by weight of DMEP, 0.54 parts by weight of organic bismuth, 9 parts by weight of antioxidant 264, 18 parts by weight of antistatic agent Cyastat LS and an appropriate amount of defoamer, heated to 110°C and vacuum dehydrated at -0.1MPa for 2h, cooling and discharging when ...

Embodiment 3

[0080] Example 3: Preparation of low-hardness and solvent-resistant antistatic polyurethane elastomer

[0081] Preparation of polyurethane prepolymer: mix 200 parts by weight of PEA1000, 100 parts by weight of PEPA2000 and 370 parts by weight of DEP, heat to 110°C and vacuum dehydration at -0.1MPa for 2h, and cool to 60°C when the water content is less than 0.05wt%, Add 162 parts by weight of MDI-50 under the protection of dry nitrogen, and after reacting at 70°C for 2 hours, the reaction can be stopped after the test residual NCO content reaches 4wt%, and the temperature is discharged.

[0082] Preparation of active hydrogen-containing polymer: 180 parts by weight of MX2325, 16.1 parts by weight of TMP, 2.7 parts by weight of BDO, 230 parts by weight of DMEP, 230 parts by weight of DBP, 0.50 parts by weight of dibutyltin dilaurate, 7 parts by weight of antioxidant 264 , 14 parts by weight of antistatic agent Cyastat SP and an appropriate amount of defoaming agent, heated to 110 ℃,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com