Insulation coating method of metal soft magnetic composite material and metal soft magnetic composite material

A technology of insulation coating and composite materials, which is applied in the direction of inorganic material magnetism, inductor/transformer/magnet manufacturing, electrical components, etc., and can solve the problem of low bonding force between coating layer and metal powder, degradation of SMC performance, and uneven coating and other problems, to achieve the effect of good insulation, moderate cross-linking density and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

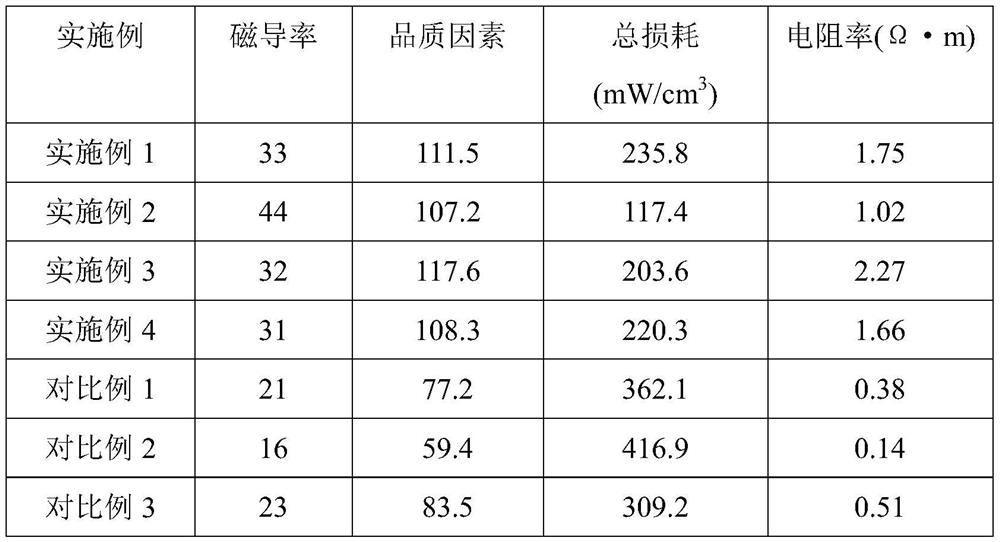

Examples

Embodiment 1

[0029] Mix 0.1mol ethyl orthosilicate and 0.002mol methyltrimethoxysilane and add it to 200g absolute ethanol, add 0.085mol deionized water dropwise for the first time, stir for 25 minutes after the dropwise addition, add 80g acetone to remove oil Iron powder with an average particle size of 200 μm, stirred for 20 minutes, added dropwise 0.13mol deionized water for the second time, stirred for 15 minutes after the dropwise addition, and finally added dropwise 0.6mol deionized water, continued to stir for 40 minutes, filtered, absolute ethanol Wash, dry at 60°C, and then dry at 100°C to obtain insulation-coated powder.

Embodiment 2

[0031] Mix 0.1mol ethyl orthosilicate and 0.004mol methyltrimethoxysilane and add it to 220g absolute ethanol, add 0.09mol deionized water dropwise for the first time, stir for 30 minutes after the dropwise addition, add 180g acetone to remove oil Fe-Si-Al powder with an average particle size of 190 μm, stirred for 25 minutes, added dropwise 0.14mol deionized water for the second time, stirred for 15 minutes after the dropwise addition, and finally added dropwise 0.7mol deionized water, continued to stir for 60 minutes, filtered , washed with absolute ethanol, dried at 50° C., and then dried at 100° C. to obtain an insulation-coated powder.

Embodiment 3

[0033] Add 0.1mol tetraethyl orthosilicate to 200g absolute ethanol, add 0.11mol deionized water dropwise for the first time, stir for 12 minutes after the dropwise addition, add 120g iron powder with an average particle size of 200μm after degreasing with acetone, stir for 17 Minutes, add 0.15mol deionized water dropwise for the second time, stir for 15 minutes after the dropwise addition, finally add 0.85mol deionized water dropwise, continue stirring for 40 minutes, filter, wash with absolute ethanol, dry at 60°C, and then dry at 100°C, Obtain insulating coating powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com