High-tear-resistance and high-heat-conductivity macromolecular interfacial material and preparation method

An interface material and polymer technology, which is applied in the field of high tear resistance and high thermal conductivity polymer interface material and its preparation, to achieve the effects of improving shock resistance and impact resistance, enhancing heat dissipation uniformity and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

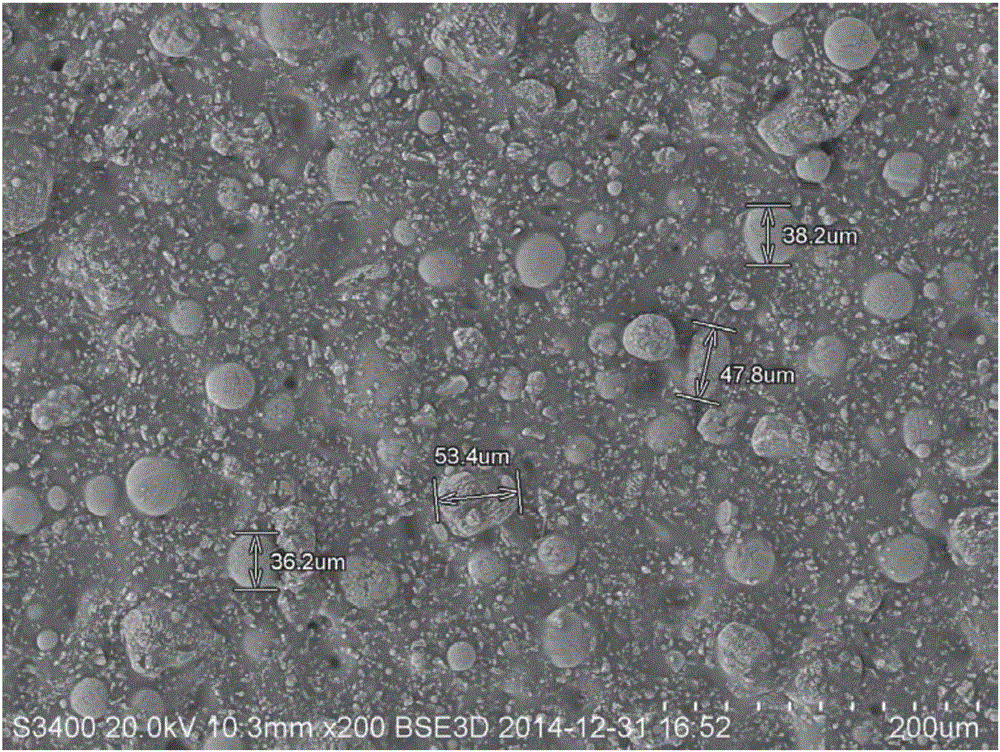

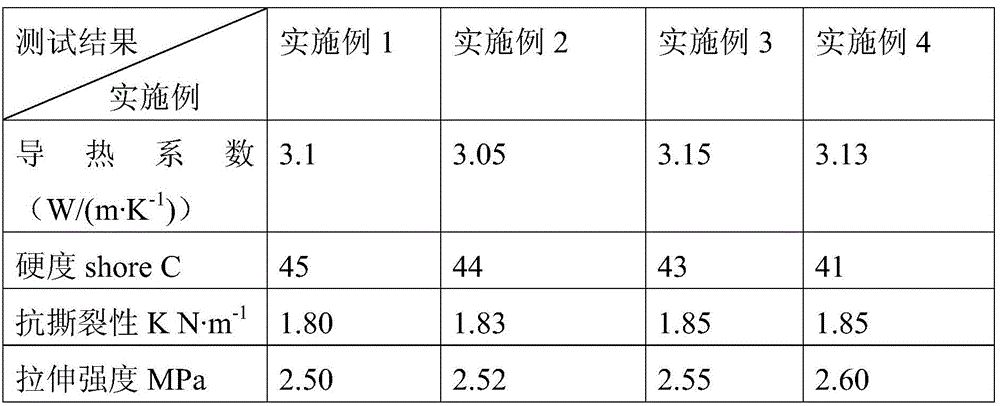

[0033] Example 1, the interface material with high tear resistance and high thermal conductivity provided by this example includes the following components: 10-100 g of silicone oil with a vinyl content of 0.5-2.0%; 800-900 g of spherical alumina; silazane 0.5-1.5g quasi-coupling agent; 1-50g deionized water; 0-100g silicon carbide whiskers.

[0034] The particle size of the spherical alumina is D50=70-90 μm, D50=5-10 μm spherical powder, the particle size of the silicon carbide whiskers is D50=0.5-5 μm, and the spherical alumina and silicon carbide whiskers are mixed , the mixing ratio is: 70-90 μm: 5-10 μm: 0.5-5 μm=50-90%: 10%-40%: 1-10%.

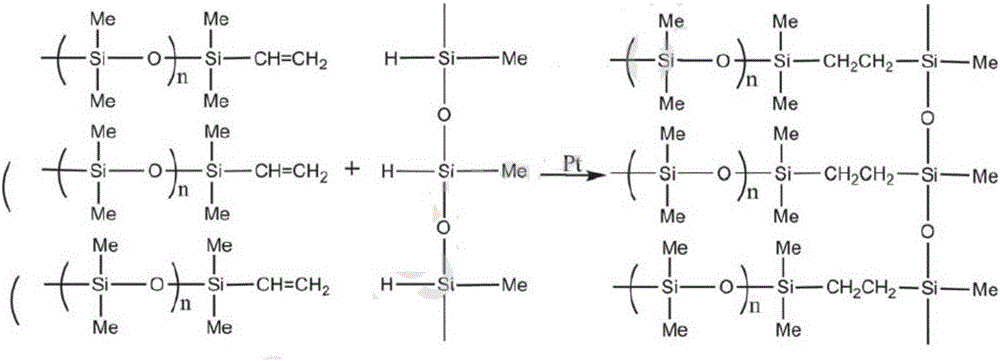

[0035] Special vinyl silicone oil with low viscosity and suitable crosslinking density is used to improve the tear resistance of the material; high thermal conductivity spherical alumina powders with different particle sizes are selected as the main material of the heat conduction channel, and the gap between spherical alumina Adding a ...

Embodiment 2

[0044] Example 2, the preparation method of this example is basically the same as that of Example 1, the difference lies in: the preparation method of high tear resistance and high thermal conductivity polymer interface material, which includes the following steps:

[0045](1) Weigh 10g of silicone oil with 0.5% vinyl content, 1.5g of silazane coupling agent, 1-50g of deionized water, 850g of spherical alumina, and 50g of silicon carbide whiskers, and add them to a kneader heated under vacuum , the heating temperature of the kneader is 130°C, airtight kneading for 1.5 hours, vacuumizing and continuing to keep warm and kneading for 1 hour, cooling to room temperature and discharging to obtain a paste liquid mixture A;

[0046] (2) Add 3‰ of catalyst, 1% of hydrogen-containing silicone oil, and 1‰ of inhibitor to mixture A of paste liquid, stir evenly, vacuumize, and mold the material into a sheet under the conditions of 140°C and 5min to prepare high tear resistance Cracking hi...

Embodiment 3

[0047] Example 3, the preparation method of this example is basically the same as that of Example 1, the difference is: the preparation method of high tear resistance and high thermal conductivity polymer interface material, which includes the following steps:

[0048] (1) Weigh 100g of silicone oil with 1% vinyl content, 0.5g of silazane coupling agent, 1 to 50g of deionized water, and 800g of spherical alumina, and add them to a kneader heated by vacuum. 150°C, airtight kneading for 2.5 hours, evacuating and continuing to keep warm and kneading for 1.2 hours, cooling to room temperature and discharging to obtain a paste liquid mixture A;

[0049] (2) Add catalyst 5‰, hydrogen-containing silicone oil 7%, and inhibitor 5‰ to paste liquid mixture A, stir evenly, vacuumize, and mold the material into a sheet under the conditions of 130°C and 2min to obtain high tear resistance Cracking high thermal conductivity polymer interface material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com