Fluorine release film and preparation method thereof

A fluorine release film, fluorine technology, applied in conductive coatings, coatings, etc., can solve the problems of high resistivity of PET, limited application and other problems, achieve good compatibility, long antistatic time, and reduce resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

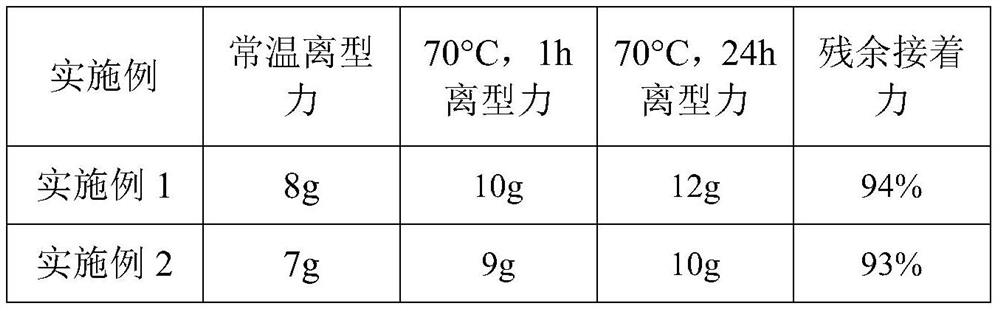

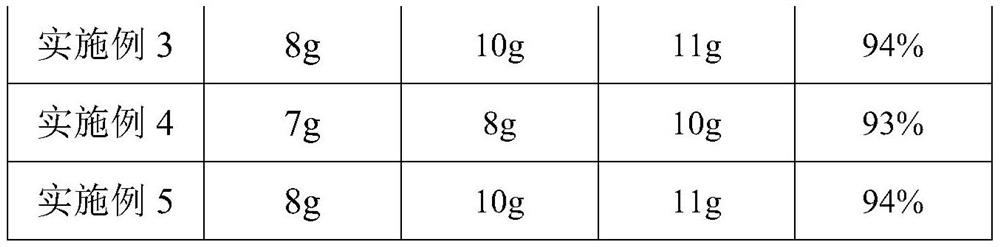

Examples

preparation example Construction

[0032] The second aspect of the present invention provides a method for preparing a fluorine release film. The present invention has no special restrictions on the coating equipment, and a coating production line well known to those skilled in the art can be used, including the following steps:

[0033] S1. Coating the antistatic coating on the base material, solidifying and cooling to obtain the antistatic coating.

[0034] S2. Coating the fluorine release coating on the antistatic coating, curing, cooling and winding to obtain a fluorine release film.

[0035] The preparation method provided by the invention is simple and easy to control, has mild conditions and low raw material cost, and is suitable for large-scale industrial production and application.

[0036] The raw materials used in the present invention are all commercially available.

Embodiment 1

[0040] Embodiment 1 provides a fluorine release film, including a PET substrate layer, an antistatic coating, and a fluorine release coating. The antistatic coating and the fluorine release coating are formed by coating the antistatic coating and the fluorine release coating respectively.

[0041] The preparation method of the antistatic coating is: take 3.5kg of water-soluble acrylic resin (purchased from Foshan Byton New Material Co., Ltd., model BD-8334) and dissolve it in 6.065kg of deionized water, and add 0.4kg of adhesive Antistatic agent (purchased from Shandong Juli Antistatic Technology Co., Ltd.), 15g of nano-TiO 2 (purchased from Ningbo Jiwei Nano New Material Technology Co., Ltd., model MZT-A1, average particle size 3 ~ 5nm), and finally add 20g of dimethylethanolamine (purchased from Jinan Chuangshi Chemical Co., Ltd.) and stir evenly to obtain the anti- Static paint.

[0042] The preparation method of the fluorine-based release coating is as follows: firstly, ...

Embodiment 2

[0047] Similar to Example 1, a fluorine release film and its preparation method are provided, but in the preparation method of the antistatic coating, the water-soluble acrylic resin is 3kg, the deionized water is , the adhesive antistatic agent is 0.3kg, Nano TiO 2 10g, 10g of dimethylethanolamine, and 6.68kg of deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com