Food-grade powder coating and preparation method thereof

A powder coating, food-grade technology, applied in powder coatings, polyester coatings, coatings, etc., can solve problems such as difficulty in meeting the growing demand, and achieve good weather resistance, strong adhesion, and appropriate crosslinking density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

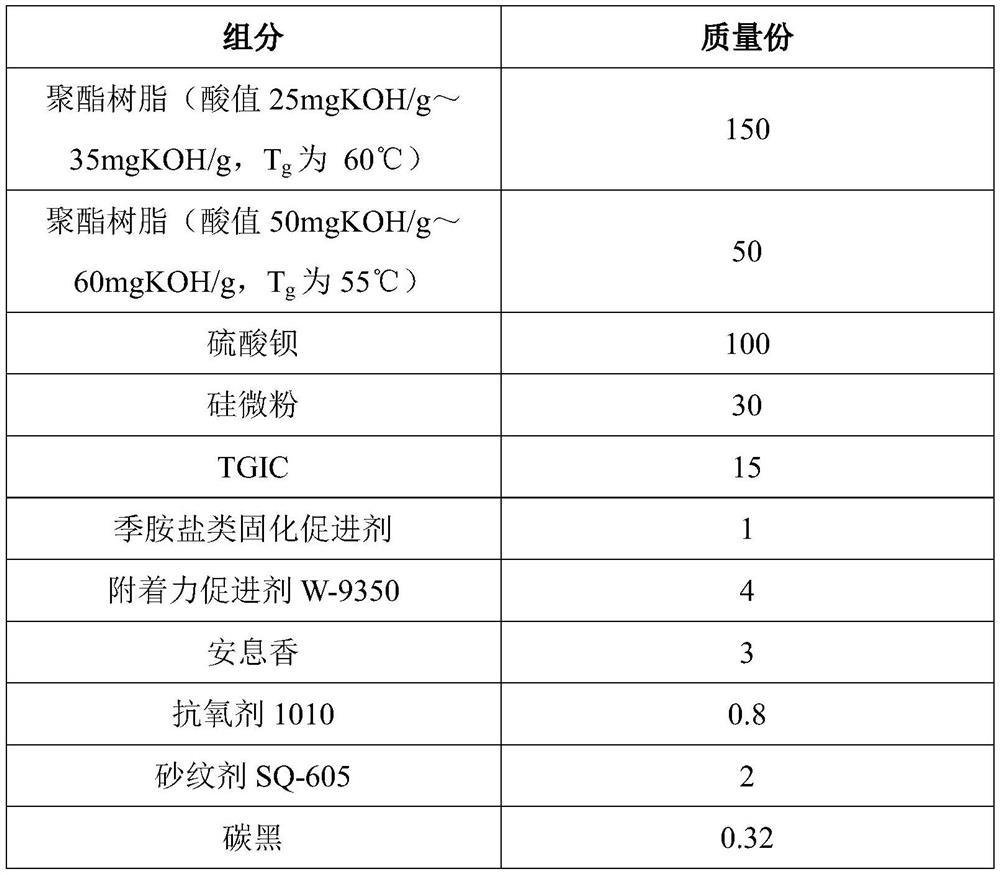

[0052] A food-grade powder coating, its composition is shown in the following table:

[0053] Table 1 Composition Table of a Food Grade Powder Coating

[0054]

[0055] The preparation method of the above-mentioned food-grade powder coating comprises the following steps: adding each component into a mixer, adjusting the rotation speed of the mixer to 100rpm, stirring for 10min, and then transferring the material into a twin-screw extruder, extruding, and extruding into two temperature sections , the temperature of the first stage is 100°C-105°C, the temperature of the second stage is 105°C-110°C, pulverize and sieve to obtain the median particle size (D 50 ) 25μm ~ 35μm powder, that is, food-grade powder coating.

Embodiment 2

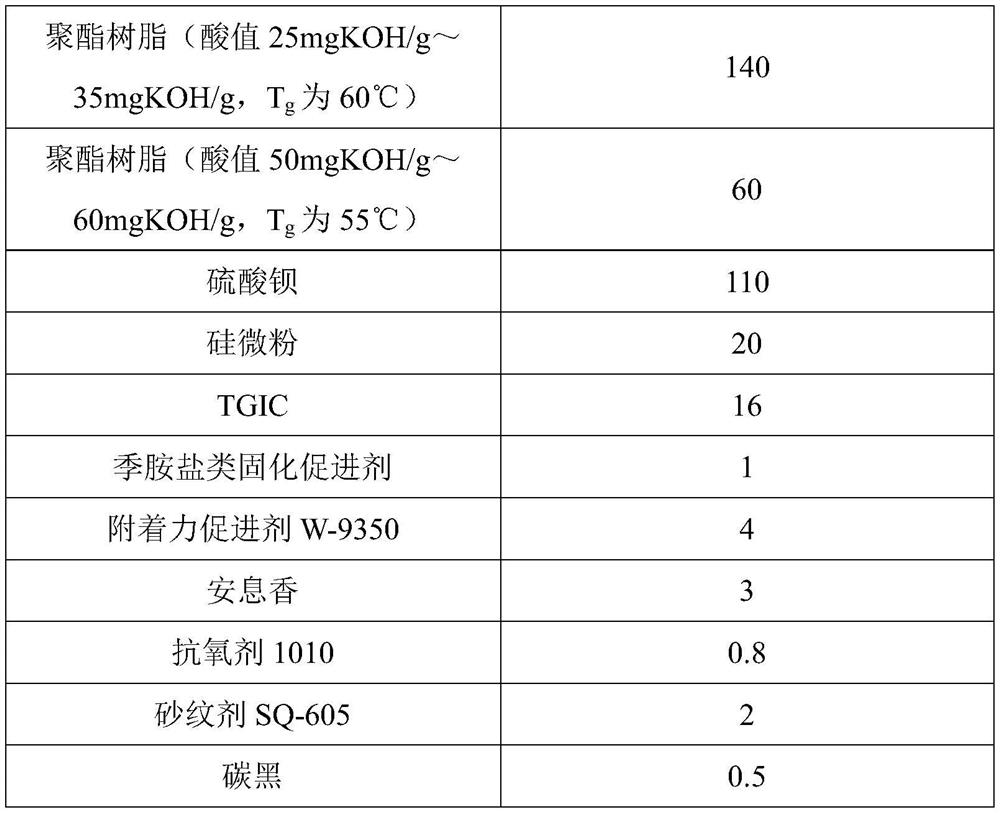

[0057] A food-grade powder coating, its composition is shown in the following table:

[0058] Table 2 Composition Table of a Food Grade Powder Coating

[0059]

[0060]

[0061]The preparation method of the above-mentioned food-grade powder coating comprises the following steps: adding each component into a mixer, adjusting the rotation speed of the mixer to 100rpm, stirring for 10min, and then transferring the material into a twin-screw extruder, extruding, and extruding into two temperature sections , the temperature of the first stage is 100°C-105°C, the temperature of the second stage is 105°C-110°C, pulverize and sieve to obtain the median particle size (D 50 ) 25μm ~ 35μm powder, that is, food-grade powder coating.

Embodiment 3

[0063] A food-grade powder coating, its composition is shown in the following table:

[0064] Table 3 Composition Table of a Food Grade Powder Coating

[0065]

[0066]

[0067] The preparation method of the above-mentioned food-grade powder coating comprises the following steps: adding each component into a mixer, adjusting the rotation speed of the mixer to 100rpm, stirring for 10min, and then transferring the material into a twin-screw extruder, extruding, and extruding into two temperature sections , the temperature of the first stage is 100°C-105°C, the temperature of the second stage is 105°C-110°C, pulverize and sieve to obtain the median particle size (D 50 ) 25μm ~ 35μm powder, that is, food-grade powder coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com