Acrylic polyurethane finish paint as well as preparation method and application thereof

A technology of acrylic polyurethane and low-hydroxy acrylic acid, which is applied in the direction of polyurea/polyurethane coatings and coatings, can solve the problems of less complete requirements, and achieve the effects of easy construction, less addition of matting powder, and moderate crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

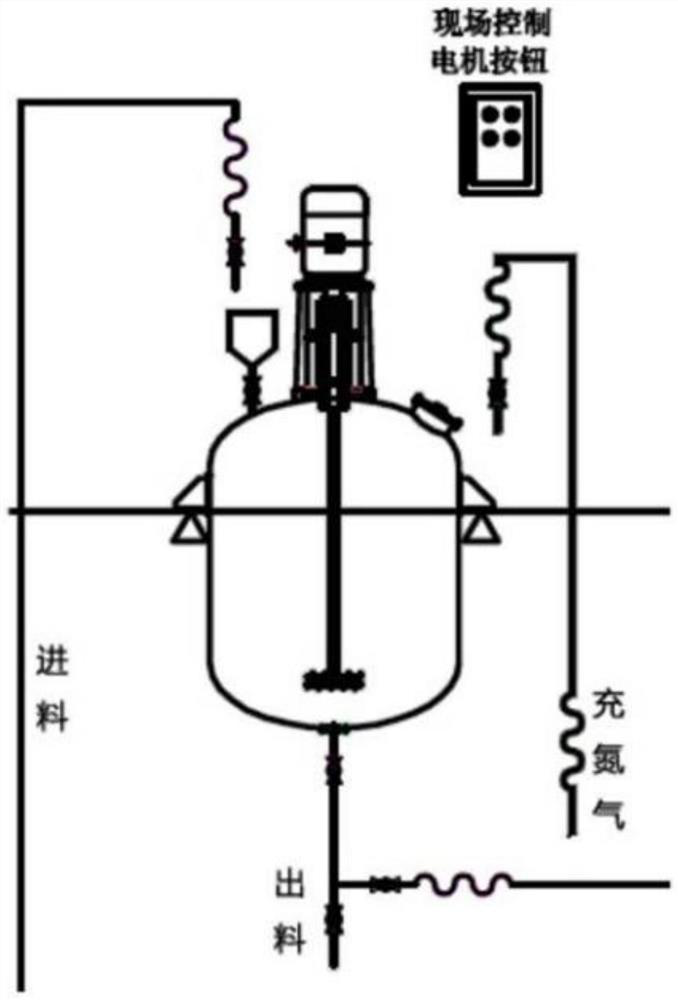

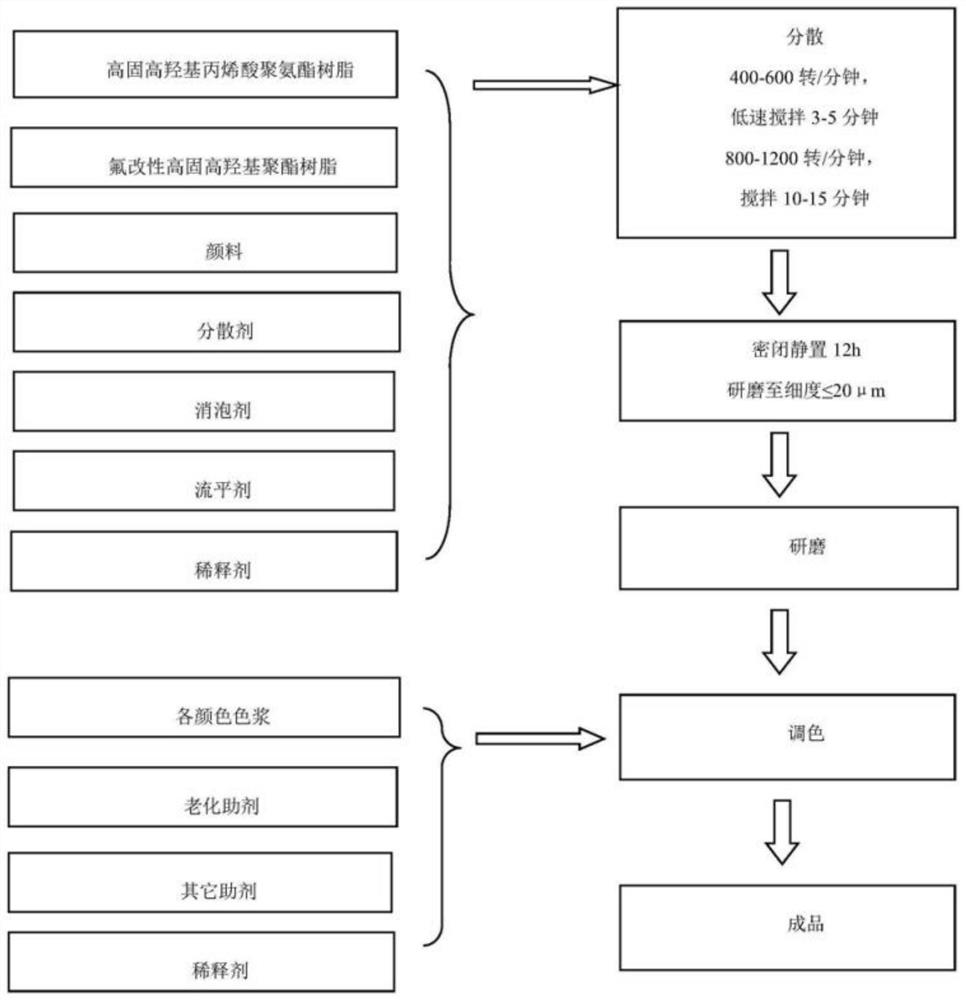

Method used

Image

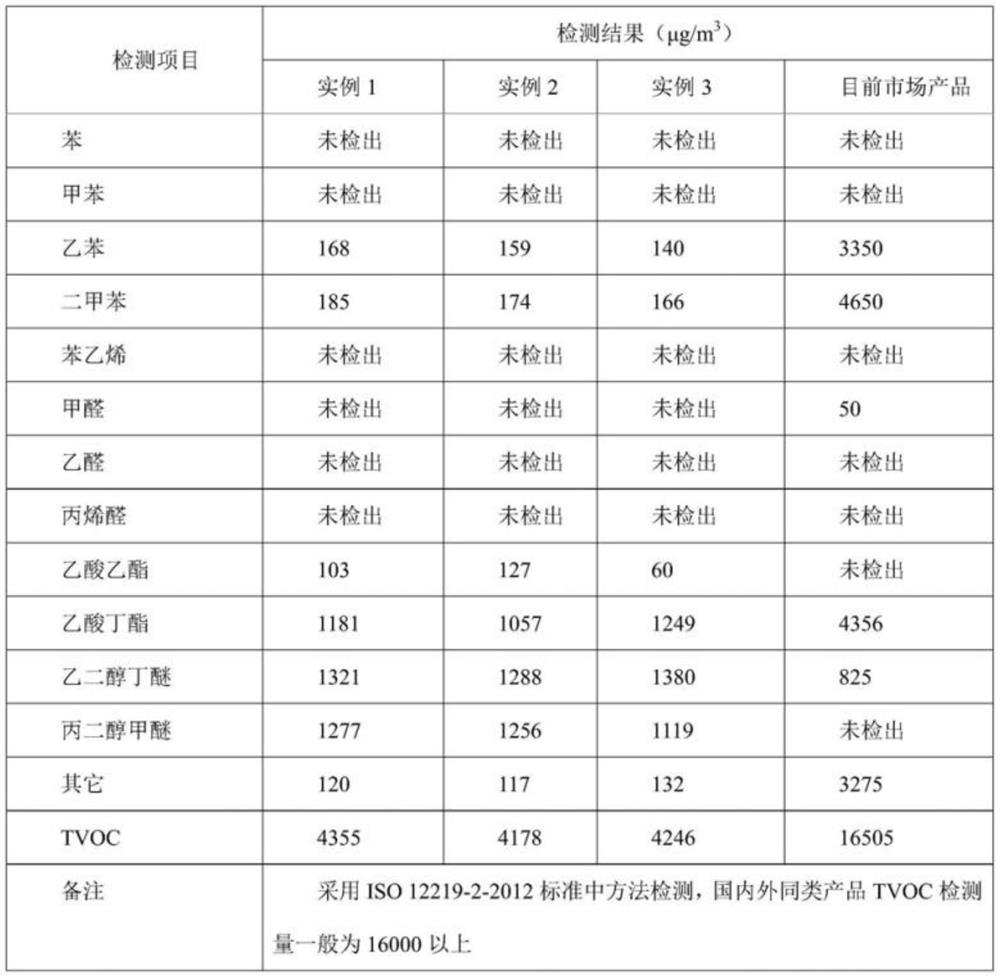

Examples

Embodiment 1

[0057] A kind of acrylic polyurethane topcoat and preparation method thereof, comprise two parts of paint material and curing agent, described this polyurethane paint by weight, comprise following raw material:

[0058] (1) Paint components include: 30 parts of high-solid high-hydroxyl acrylic polyurethane resin, 25 parts of fluorine-modified high-solid high-hydroxyl polyester resin, 1.5 parts of solvent-free anti-graffiti reactive silicone leveling agent, solvent-free 0.8 parts of silicone defoamer, 1.5 parts of solvent-free low molecular weight wetting and dispersing agent, 2 parts of solvent-free anti-aging additive, 0.5 parts of solvent-free leveling agent, 22.7 parts of pigment, 6 parts of matte powder, poly 1 part of amide wax, 9 parts of diluent;

[0059] (2) The curing agent components include:

[0060] 60 parts of solvent-free aliphatic polyisocyanate trimer, 1 part of polyurethane dehydrating agent, 10 parts of ethylene glycol butyl ether, 10 parts of propylene glyc...

Embodiment 2

[0068] A kind of acrylic polyurethane topcoat and preparation method thereof, comprise two parts of paint material and curing agent, described this polyurethane paint by weight, comprise following raw material:

[0069] (1) Paint components include: 35 parts of high-solid high-hydroxyl acrylic polyurethane resin, 17.5 parts of fluorine-modified high-solid high-hydroxyl polyester resin, 1 part of solvent-free anti-graffiti reactive silicone leveling agent, solvent-free 0.5 parts of silicone defoamer, 1 part of solvent-free low molecular weight wetting and dispersing agent, 3 parts of solvent-free anti-aging additive, 0.3 parts of solvent-free leveling agent, 24.7 parts of pigment, 4.5 parts of matte powder, poly 1.5 parts of amide wax, 11 parts of diluent;

[0070] (2) The curing agent components include:

[0071] 60 parts of solvent-free aliphatic polyisocyanate trimer, 1.2 parts of polyurethane dehydrating agent, 10 parts of ethylene glycol butyl ether, 10 parts of propylene...

Embodiment 3

[0076] A kind of acrylic polyurethane topcoat and preparation method thereof, comprise two parts of paint material and curing agent, described this polyurethane paint by weight, comprise following raw material:

[0077] (1) Paint components include: 40 parts of high-solid and high-hydroxyl acrylic polyurethane resin, 13.3 parts of fluorine-modified high-solid and high-hydroxyl polyester resin, 2 parts of solvent-free anti-graffiti reactive silicone leveling agent, solvent-free 1 part of silicone defoamer, 1.3 parts of solvent-free low molecular weight wetting and dispersing agent, 2.5 parts of solvent-free anti-aging additive, 0.4 part of solvent-free leveling agent, 16.5 parts of pigment, 5 parts of matte powder, poly 1 part of amide wax, 17 parts of diluent;

[0078] (2) The curing agent components include:

[0079] 60 parts of solvent-free aliphatic polyisocyanate trimer, 1.5 parts of polyurethane dehydrating agent, 12 parts of ethylene glycol butyl ether, 8 parts of propy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com