Patents

Literature

41results about How to "Reduce energy and water consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

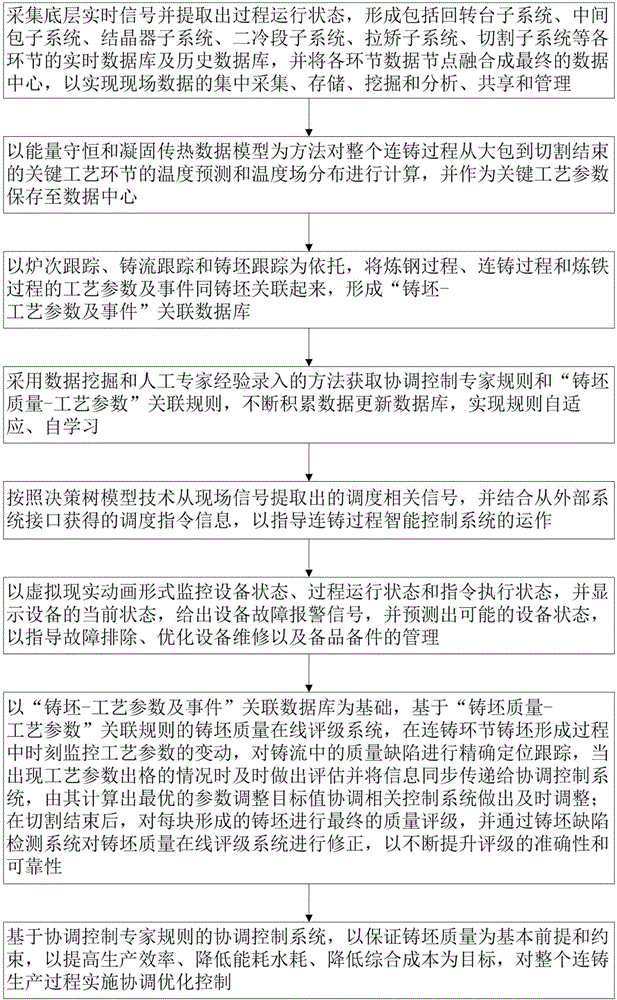

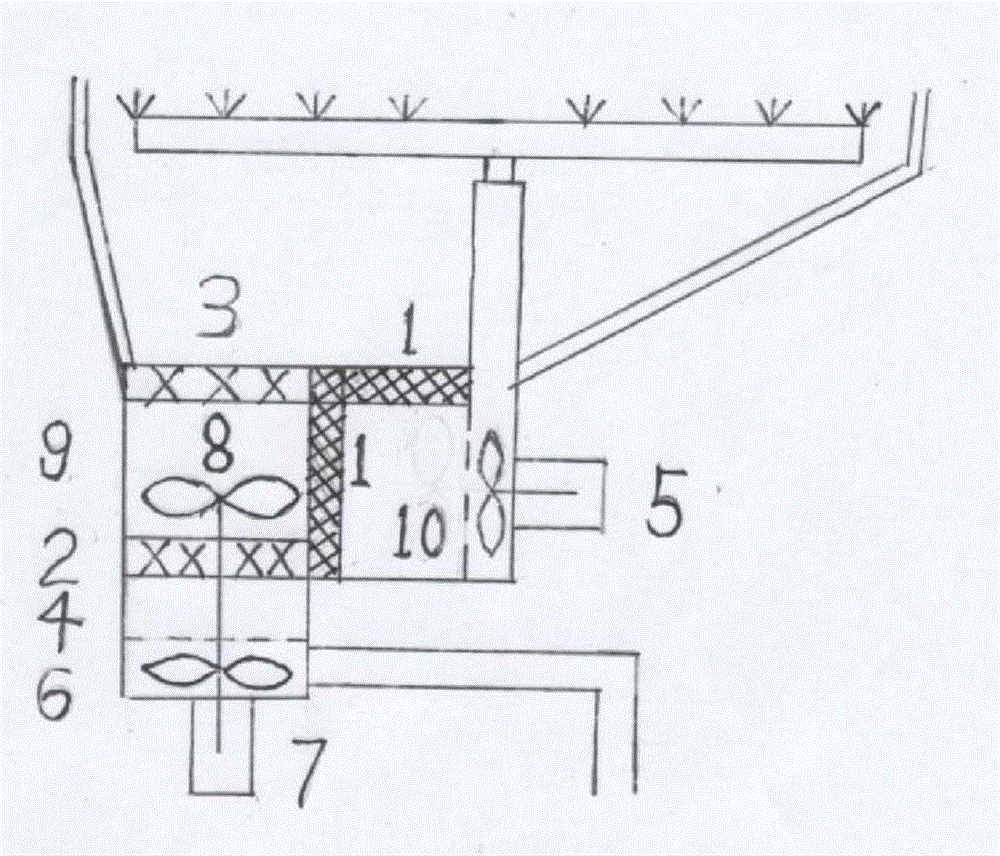

System method for intelligent control over continuous-casting process

The invention discloses a system method for intelligent control over the continuous-casting process. Firstly, signals are collected to form a data center; then a temperature field model is designed to calculate the temperatures of continuous-casting key process nodes, and the temperatures of the continuous-casting key process nodes are stored into the data center; then logistics tracking of the continuous-casting process is achieved, and a 'casting blank-technological parameter and event' related database is formed; then rules and dispatching command information are obtained through data mining and artificial expertise, and virtual reality animation displaying of the equipment state, process operation state and command execution state is conducted; then a casting blank quality online grading system is built and casting blank grading is achieved; and finally, a coordination control system is built, energy consumption and water consumption are optimized, and large-closed-loop quality control and underlying loop control are achieved. Energy conservation and consumption reduction are achieved by optimizing the related parameters of energy consumption and water consumption while the effects that the continuous casting blank quality is stable and the quality is improved continuously are ensured, so that the yield is improved, the cost of per ton of steel is reduced, the comprehensive production cost is reduced continuously, and normal and efficient operation of continuous casting is ensured.

Owner:HUNAN CHAIRMAN IOT INFORMATION TECH CO LTD

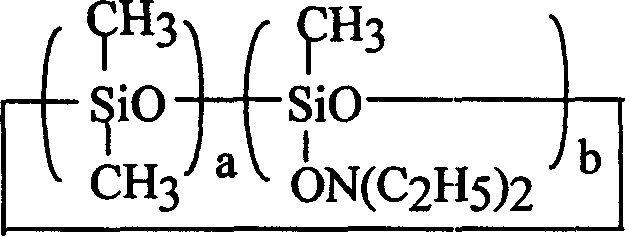

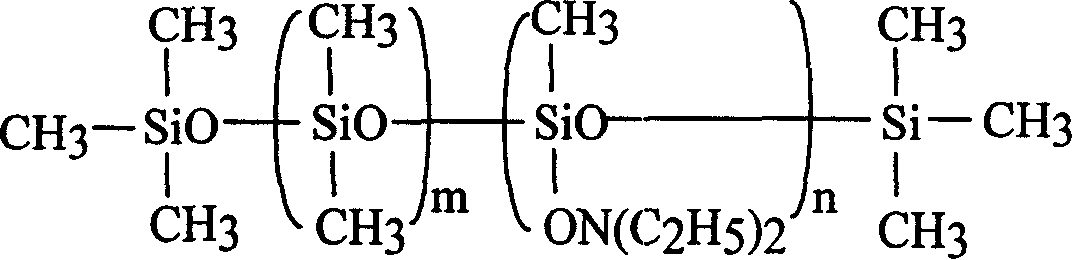

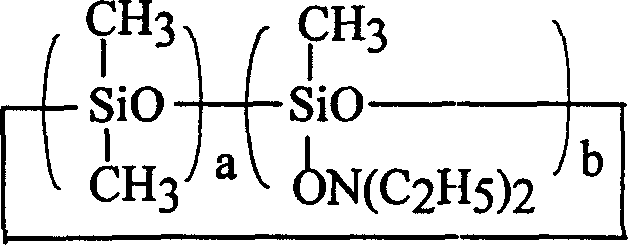

Low modulus silicone sealing gum and its manufacturing method

ActiveCN1618915ALow modulusExcellent displacement abilityOther chemical processesCross-linkChemical reaction

A low-modulus silicone sealant for the expansion joint of express way, airport runway, tunnel, bridge, etc is prepared from alpha, omega-dihydroxy polydimethyl siloxane and filler through proportionally vacuum kneading at 80-150 deg.C while dewatering for 30-300 min, high-speed stirring while cooling to obtain basic material, proportionally mixing chain enlarging agent, cross-linking agent, thixotropic agent, polydimethyl siloxane and toluent diisocyanate, stirring, and vacuum reaction at 20-600 rpm for 30-90 min.

Owner:CHENGDU GUIBAO SCI & TECH

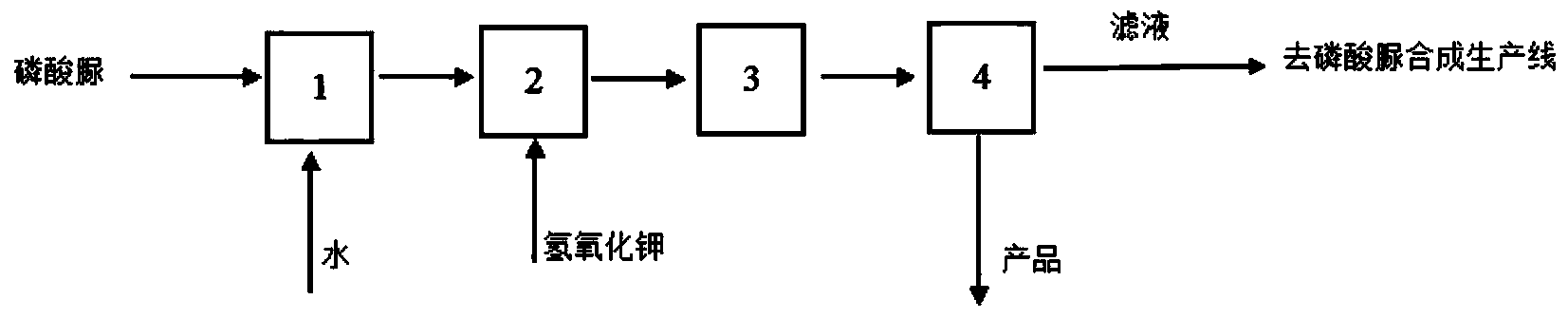

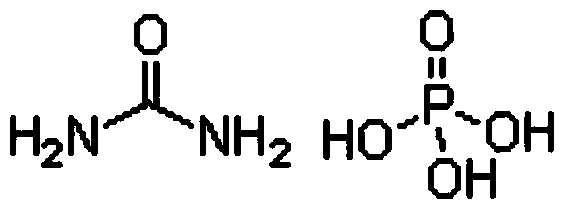

Production method of dipotassium phosphate

InactiveCN104003362ASimplify the production processReduce energy and water consumptionPhosphorus compoundsPotassium hydroxideHeavy metals

The invention relates to the technical field of chemical engineering and particularly relates to a production method of dipotassium phosphate. The method comprises the following step: carrying out a reaction on urea phosphate and potassium hydroxide in a stirring manner for 20 to 70 minutes by controlling a reaction temperature within 50 DEG C to 90 DEG C and controlling a pH (Potential Of Hydrogen) value at a final point of the reaction within 8 to 9.5 so as to prepare the dipotassium phosphate product. The produced dipotassium phosphate product completely conforms to the standard of food-grade dipotassium phosphate by controlling the whole process conditions, i.e., the content of the dipotassium phosphate is between 98.15% and 98.31%, the pH (10g / L of solution) is between 8.9 and 9.2, the content of water insoluble matters is between 0.11% and 0.17%, the content of fluorides is between 8.04mg / kg and 9.13mg / kg, the content of arsenic is between 2.03mg / kg and 2.71mg / kg, the content of heavy metal is between 8.9mg / kg and 9.4mg / kg as well as the loss on drying is between 1.64% and 1.82% according to physical and chemical indexes in a manner of sampling analysis.

Owner:GUIYANG KAILIN FERTILIZER CO LTD +1

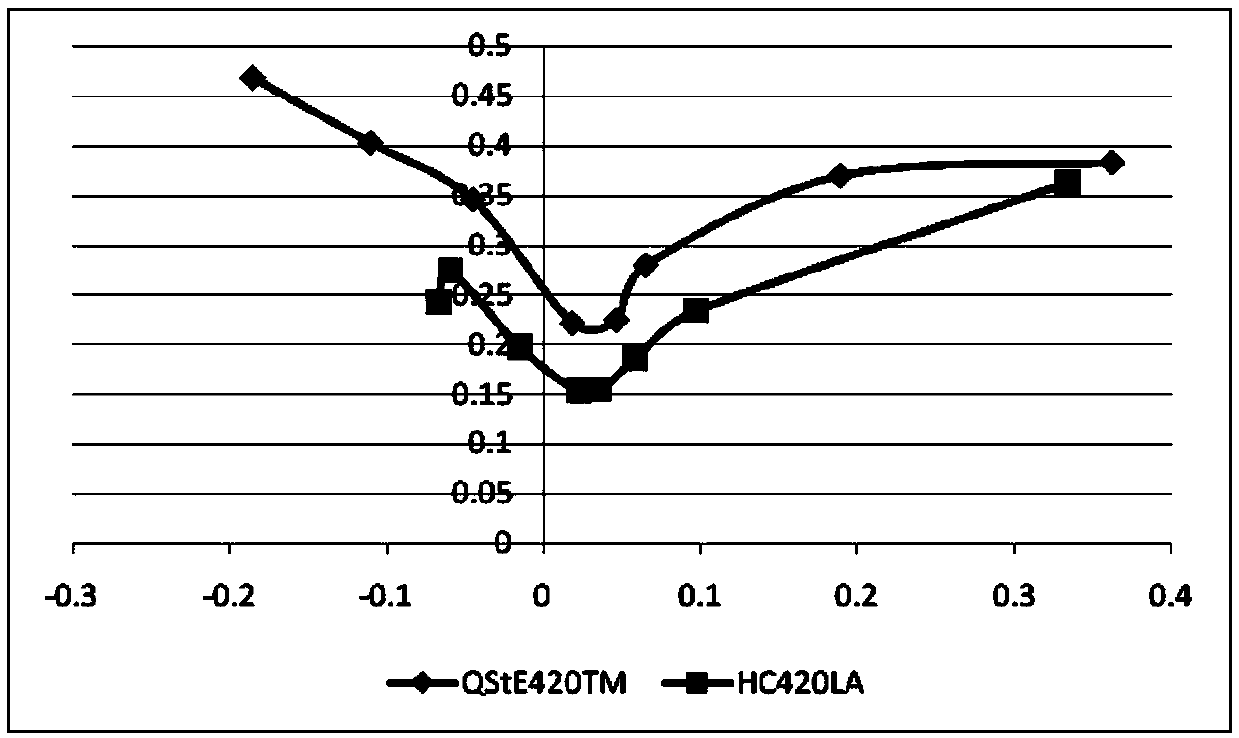

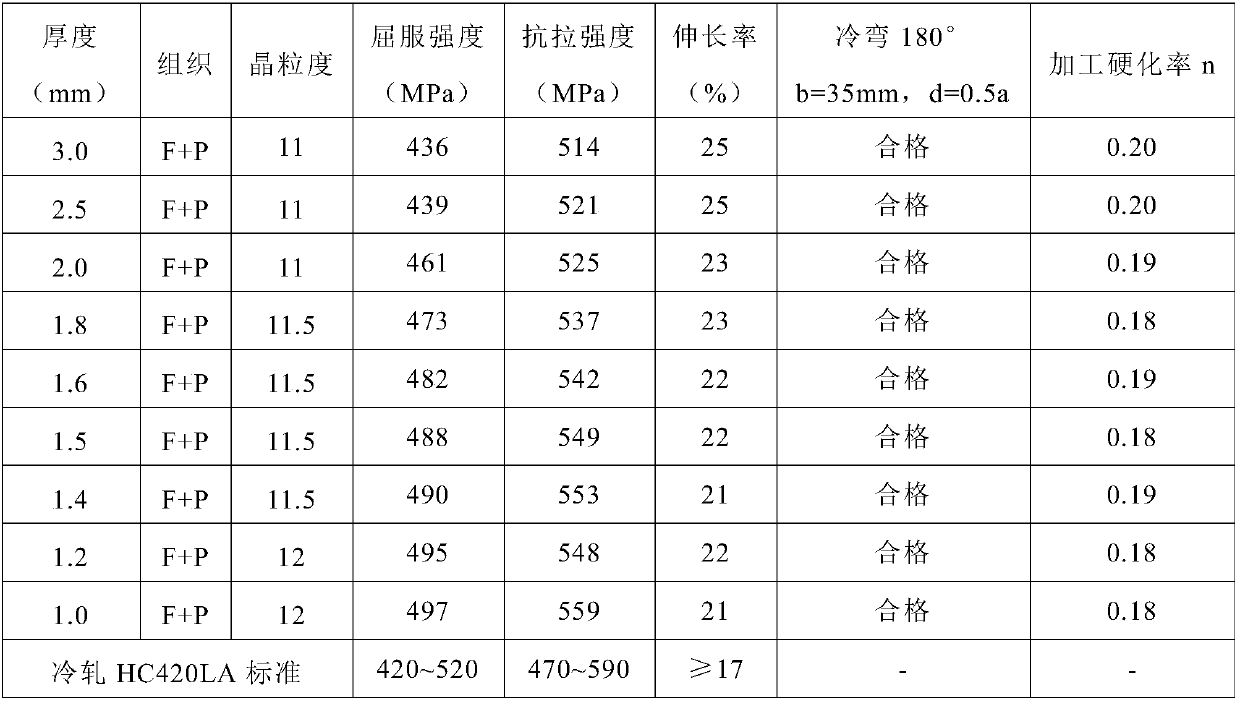

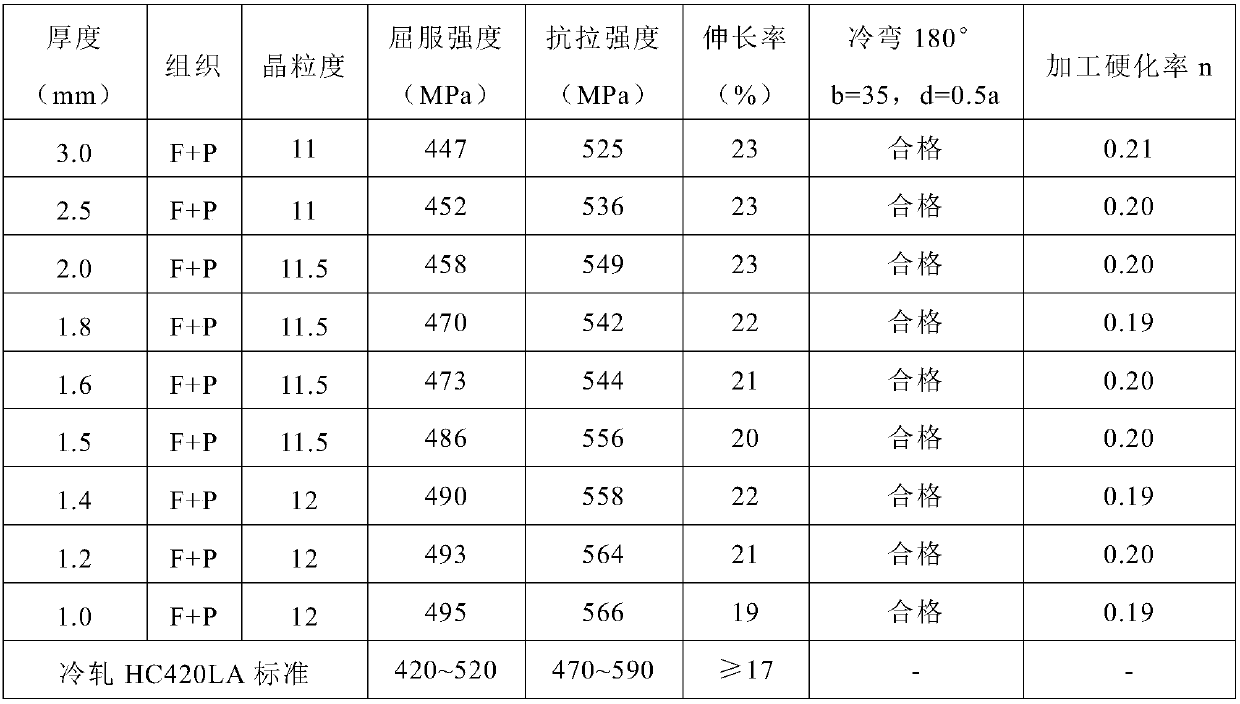

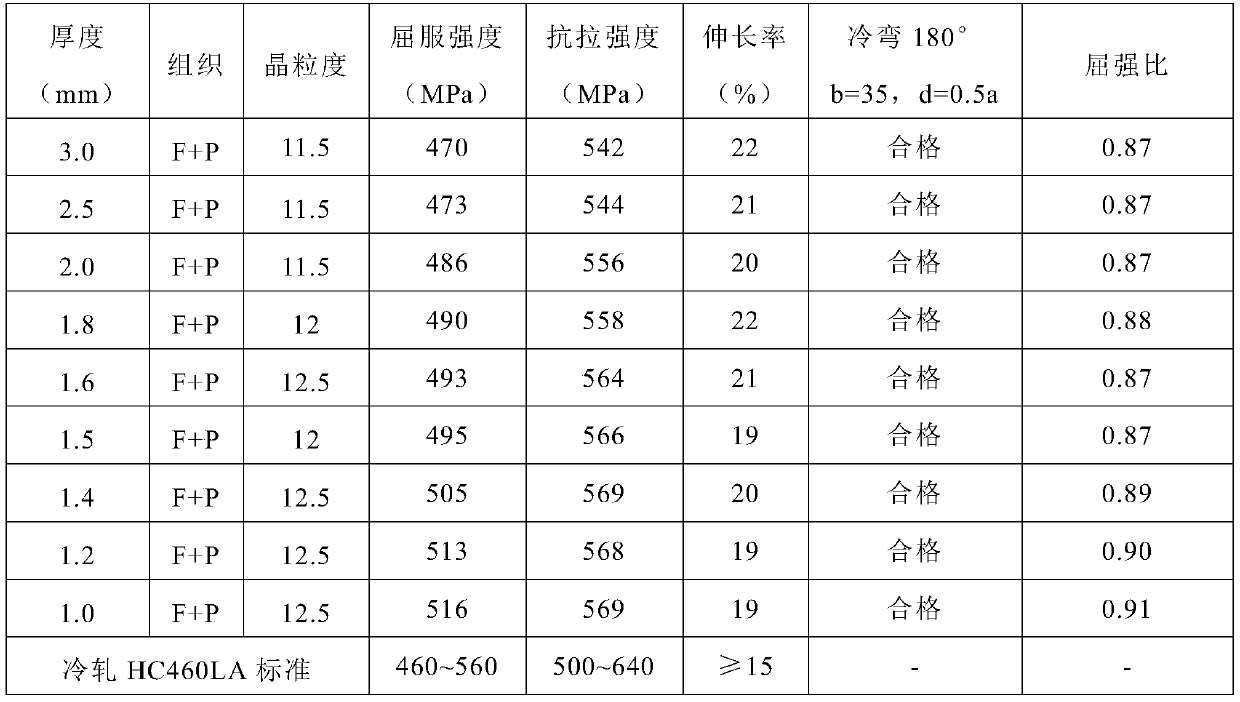

Hot-rolled automobile structural steel plate with yield strength of 420MPa and excellent cold-forming performance and manufacturing method

The invention discloses a hot-rolled automobile structural steel plate with the yield strength of 420MPa and excellent cold-forming performance and a manufacturing method. The hot-rolled automobile structural steel plate with the yield strength of 420MPa and the excellent cold-forming performance comprises, by weight, 0.03-0.06% of carbon, 0.7-0.9% of manganese, 0.020-0.030% of niobium, 0.020-0.030% of titanium, less than 0.10% of silicon, no more than 0.005% of sulfur, no more than 0.015% of phosphorus, no more than 40 ppm of nitrogen, 0.025-0.050% of acid soluble aluminum, and the balance iron and inevitable impurities. According to the hot-rolled automobile structural steel plate with the yield strength of 420MPa and the excellent cold-forming performance and the manufacturing method, the Nb-Ti microalloying technique is adopted for a short process, S and N (S<=0.005%, and N<=40 ppa) in steel are fixed through a trace of Ti, the grain refining effect of Nb is brought into full playto obtain a fine F+P structure, and thus the cold-forming performance of the steel is improved while high strength is obtained.

Owner:武汉钢铁有限公司

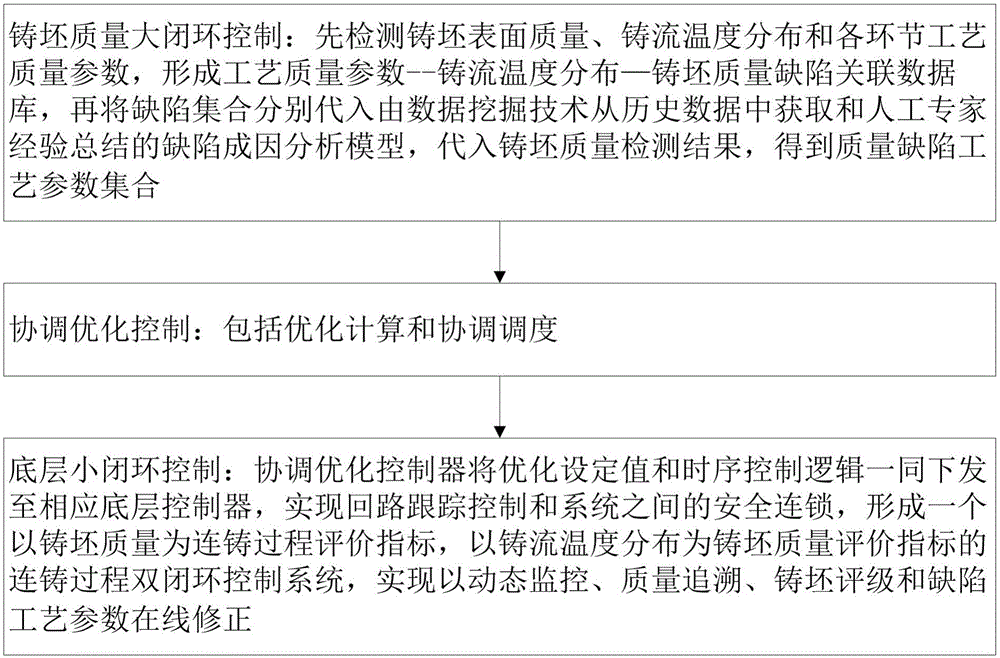

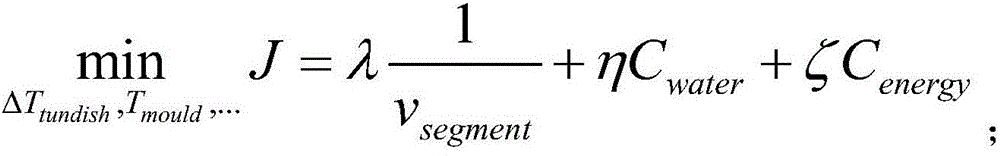

Continuous casting coordinated optimization control method

InactiveCN106077555AClear logical structureIn line with the actual production of continuous castingClosed loopEnergy consumption

The invention discloses a continuous casting coordinated optimization control method. The continuous casting coordinated optimization control method comprises the steps of casting blank quality large closed-loop control, coordinated optimization control and bottom layer small closed-loop control, the design concept of optimizing control is adopted, zero defect in quality of a continuous casting billet is taken as restriction, technological parameters in a continuous casting process are optimized, sequential control logic is coordinated, and an optimization calculation result is issued to each bottom layer controller to be executed, so that optimal coordinated control of a continuous casting production process is realized, productivity is steadily improved while product quality is guaranteed, and energy consumption and water consumption are reduced at the same time.

Owner:HUNAN CHAIRMAN IOT INFORMATION TECH CO LTD

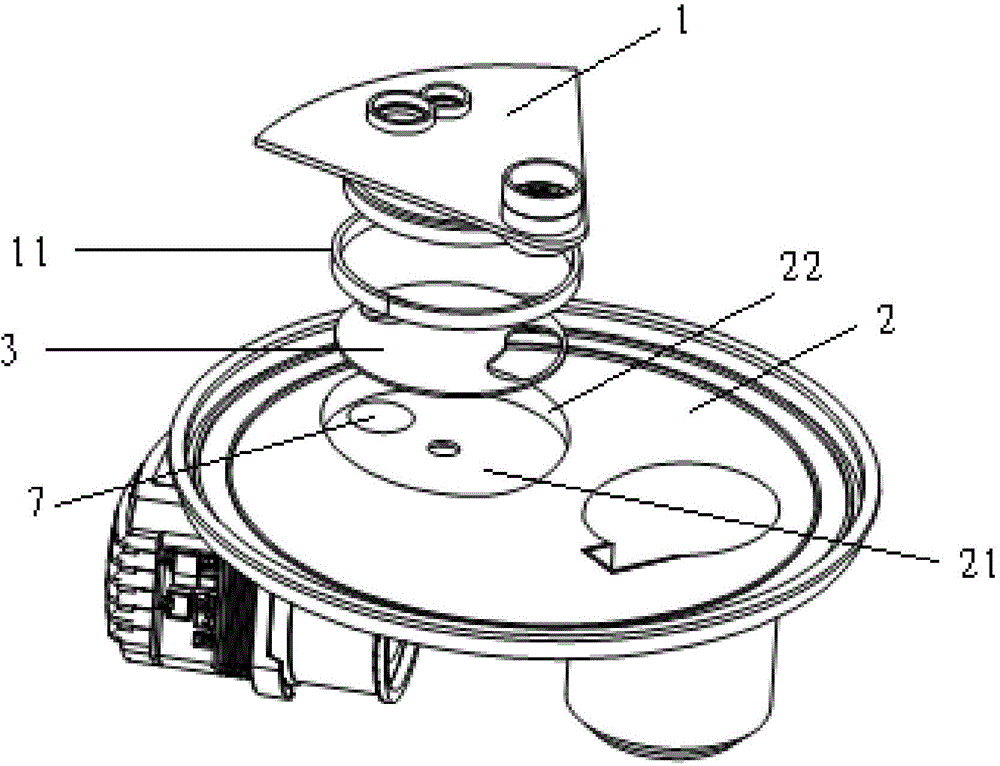

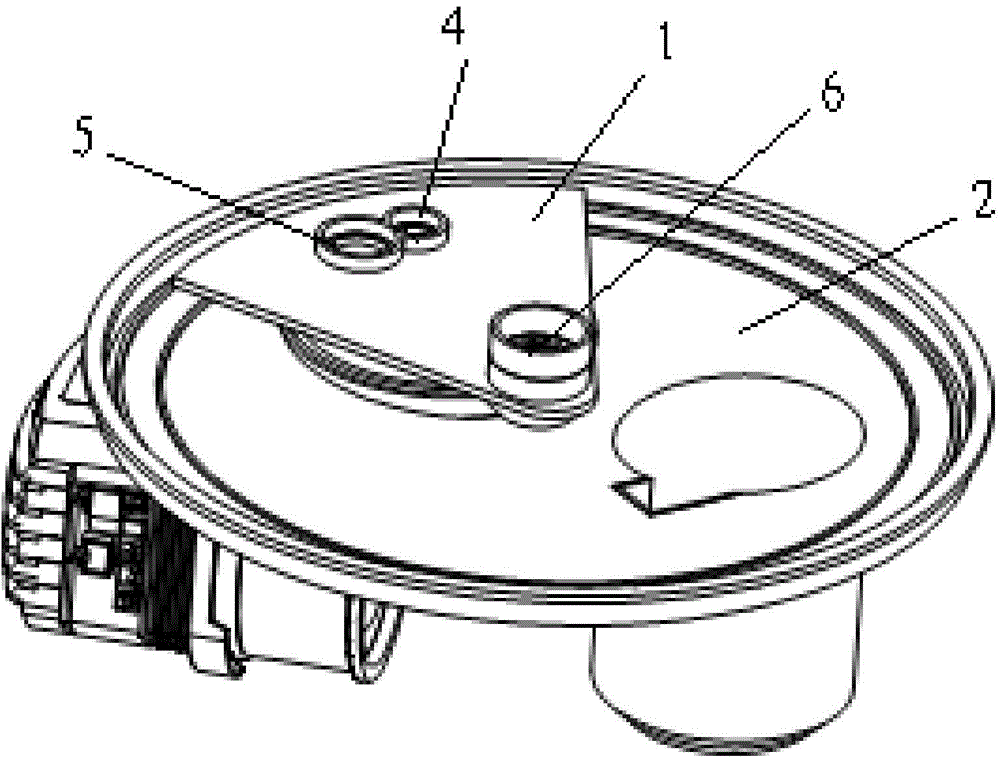

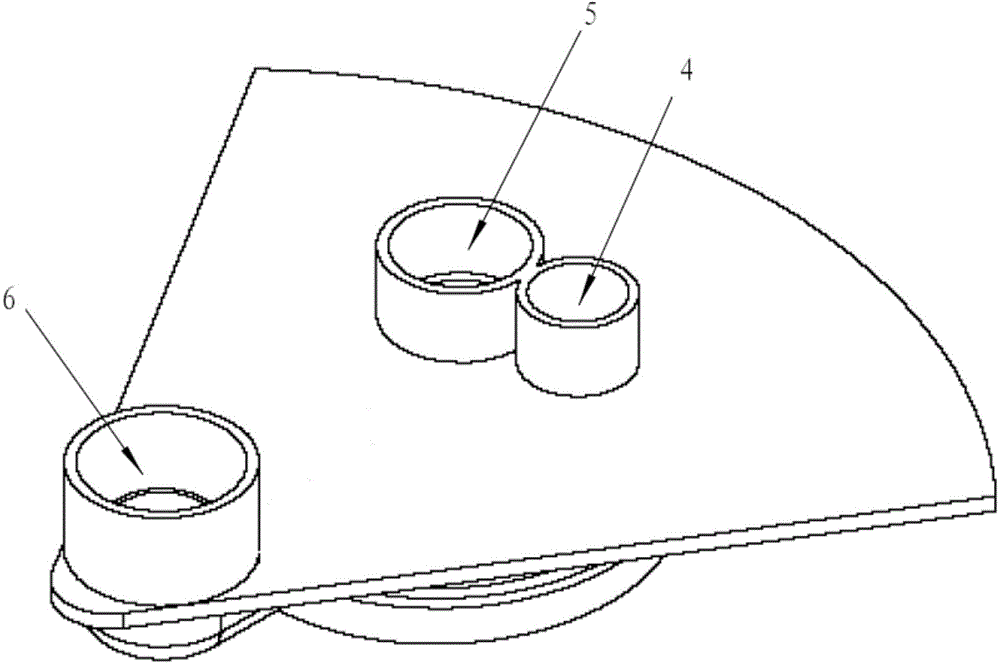

Shunt valve component and dish-washing machine

ActiveCN106151592AReduce thicknessAchieve conductionTableware washing/rinsing machine detailsMultiple way valvesEngineeringValve seat

The invention discloses a shunt valve component and a dish-washing machine and relates to the technical field of cleaning appliances. The shunt valve component comprises a valve seat and a valve deck buckled on the valve seat; a water inlet is formed in the valve deck; at least three water outlets are formed in the valve seat; a shunt catch of a disk-shaped structure is arranged between the valve seat and the valve deck; at least one through hole is formed in the shunt catch; and the shunt catch can be rotated to enable the through holes to be aligned with the different water outlets in the valve seat so as to realize communication between any one or more of the at least three water outlets and the water inlet. The invention also provides the dish-washing machine with the shunt valve component. According to the shunt valve component, communication and disconnection between any one or at least two of the water outlets and the water inlet are realized through rotation of the shunt catch, so that the functions of single-water-outlet water discharge and multi-water-outlet combined water discharge are achieved. The shunt valve component is simple in structure, and as the shunt catch adopts the disk-shaped structure, the thickness of the shunt valve component is reduced, and more space is saved.

Owner:QINGDAO HAIER DISHWASHER

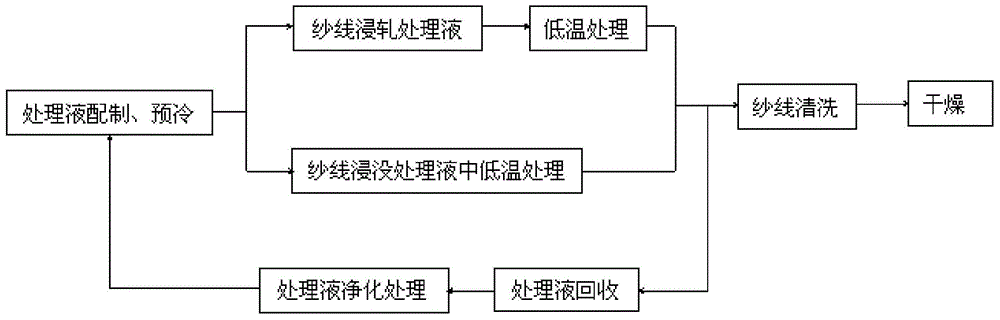

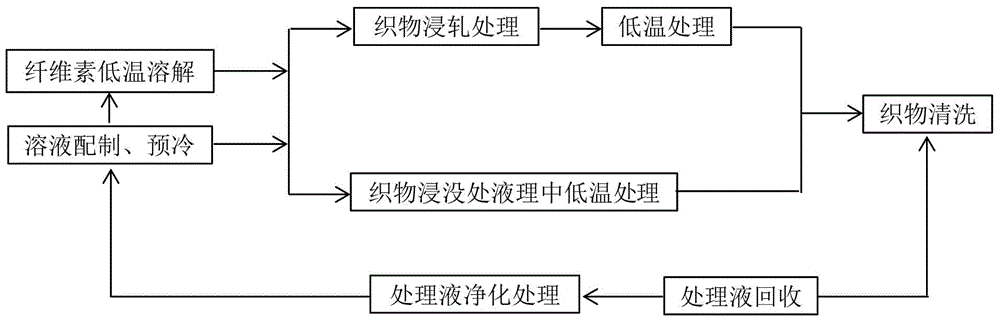

Non-slurry self-sizing method for cellulosic fiber containing yarns

ActiveCN104480722AAchieve repeated useRealize environmentally friendly processingVegetal fibresYarnHydrogen

The invention relates to a non-slurry self-sizing method for cellulosic fiber containing yarns. The non-slurry self-sizing method for the cellulosic fiber containing yarns comprises the following steps: mixing alkali, components effectively breaking hydrogen bonds among polysaccharide molecules and water to obtain a dissolved solution, and pre-cooling the solution to be 5 DEG C to 15 DEG C below zero; at 5 DEG C to 80 DEG C below zero, processing cellulosic fiber containing yarns in the dissolving solution or a padding solution for 10 seconds to 15 minutes, washing, and processing the yarns for once to ten times, drying and obtaining self-sized yarns. According to the non-slurry self-sizing method for the cellulosic fiber containing yarns, no slurry is consumed, the utilized various solutions and washing liquids can be recycled, the production cost is low, the energy and water consumption is reduced, the dependency of the textile industry on non-degradable or high-cost traditional slurry is reduced, and the transformation of the textile industry is beneficial of transforming to the low-carbon environment protection industry.

Owner:DONGHUA UNIV

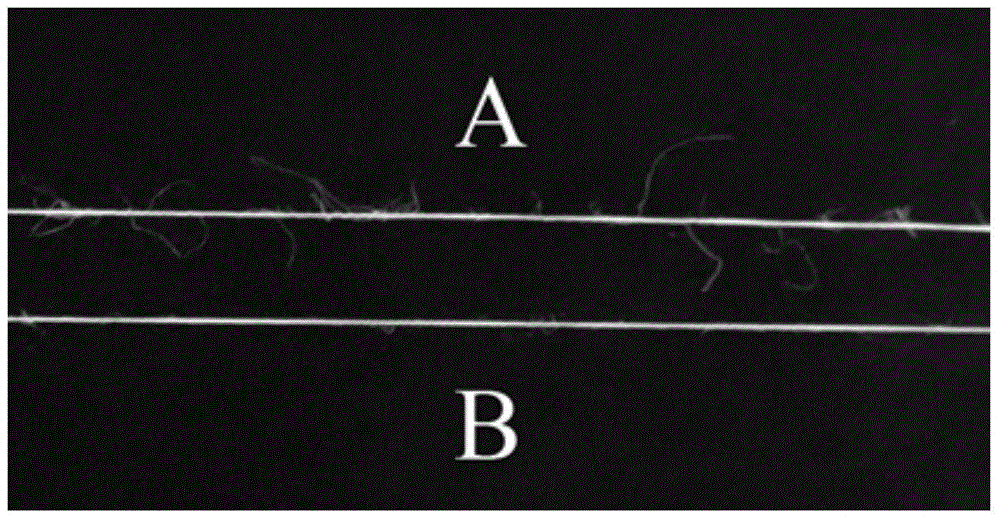

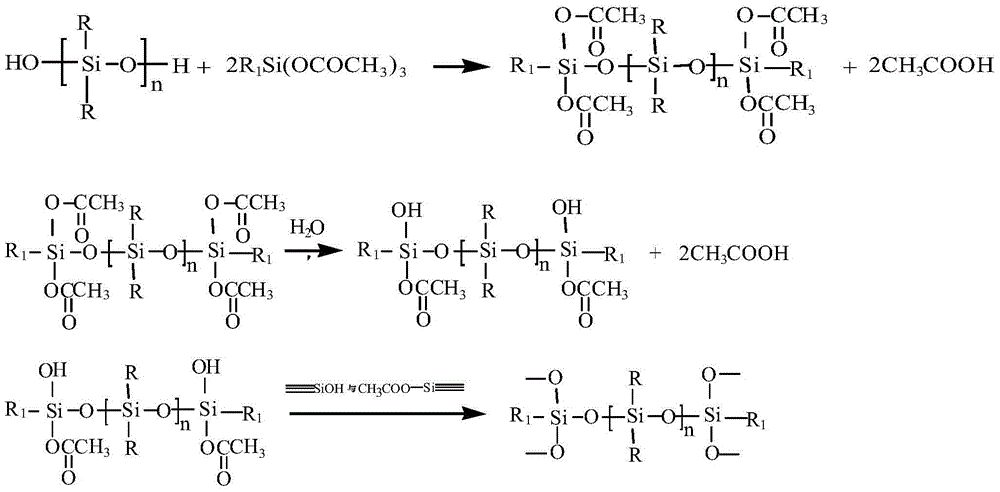

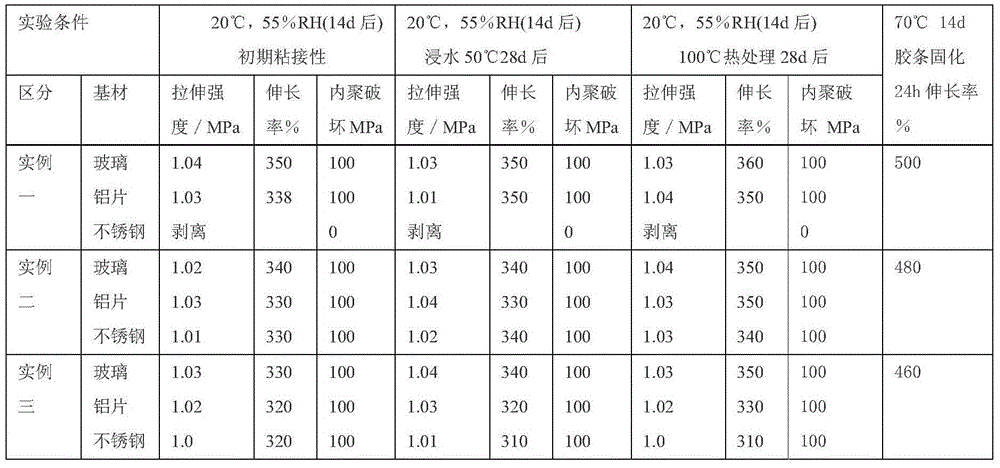

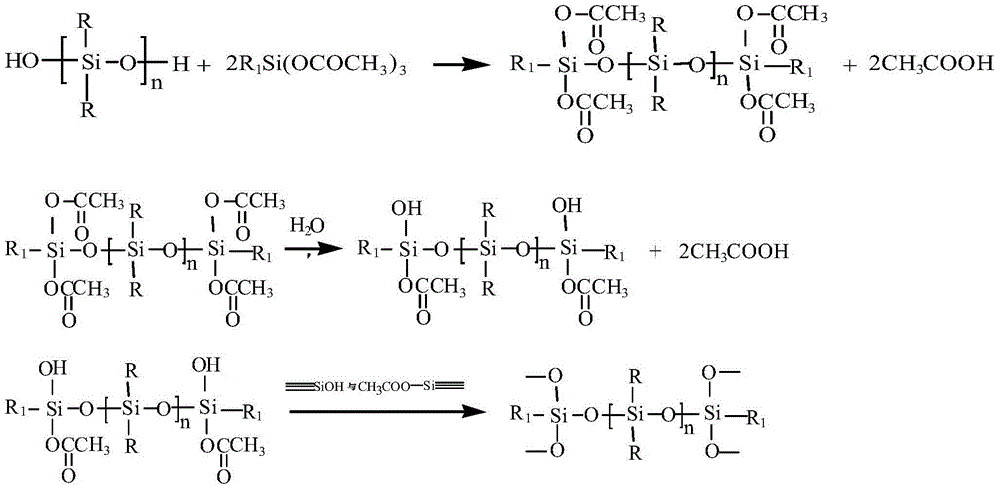

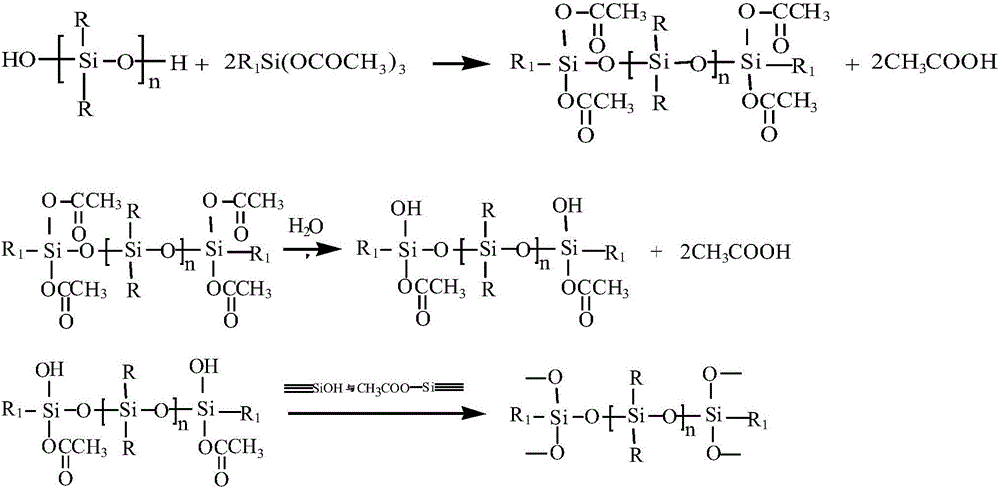

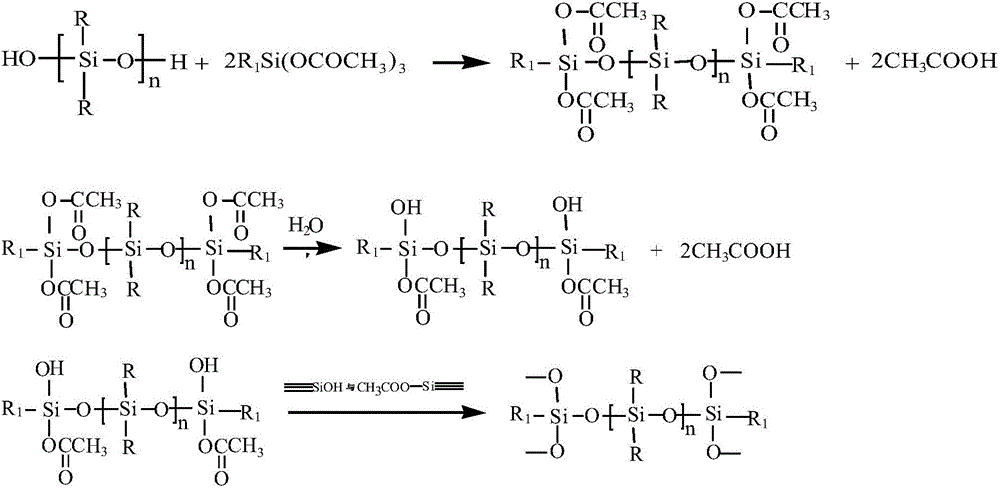

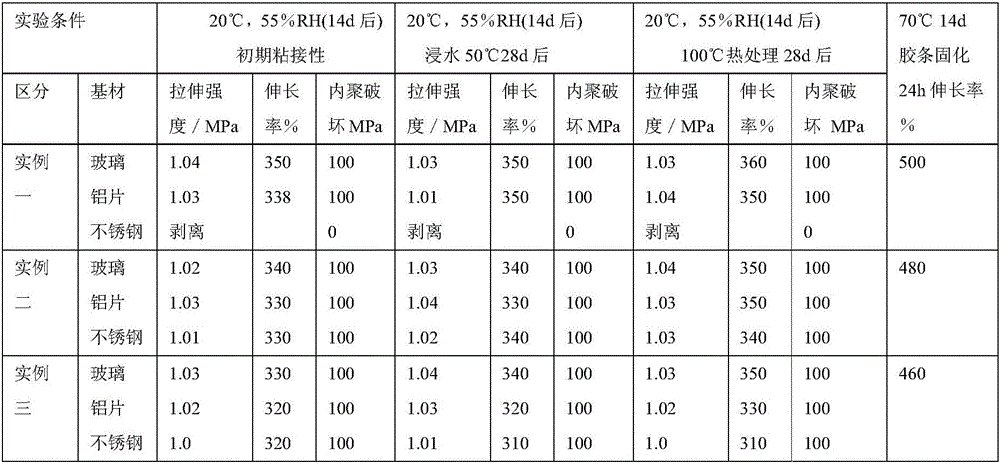

Acidic silicone sealant with good bonding performance on stainless steel, and preparation method thereof

ActiveCN104130738AGood adhesionInhibit sheddingNon-macromolecular adhesive additivesOther chemical processesCross-linkSocial benefits

The invention discloses an acidic silicone sealant with good bonding performance on stainless steel, and a preparation method thereof. The sealant comprises the components of, by weight: 20-90 parts of a,w-dihydroxy polysiloxane, 2-10 parts of a plasticizer, 10-50 parts of a filling material, 3-10 parts of a thixotropic agent, 2-10 parts of a cross-linking agent, 1-5 parts of a tackifying agent, and 0.1-5 parts of a catalytic curing agent. Compared with prior arts, according to the invention, the novel tackifying agent is added, such that the sealant has good bonding performance on stainless steel. A silver-grey colorant is added into an acidic transparent system, such that the sealant has a shiny color that is substantially similar to that of stainless steel. Because the sealant is an acidic silicone sealant, curing speed is high. With the sealant, production efficiency can be substantially improved, bonding performance can be improved, and glass and stainless steel falling can be prevented. During the production process, energy consumption and water consumption are low, no three-waste (waste gas, waste water, and solid waste) is produced, and no environment pollution is caused. The sealant and the method has significant economic and social benefits.

Owner:圣戈班汇杰(杭州)新材料有限公司

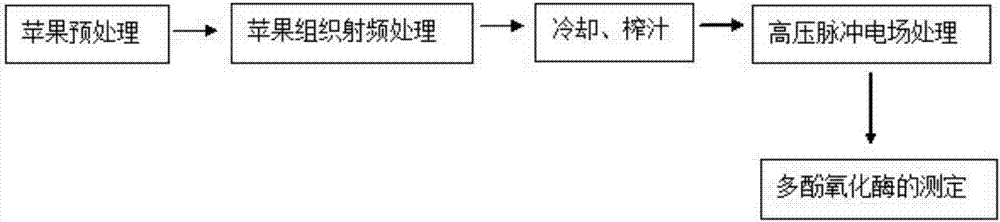

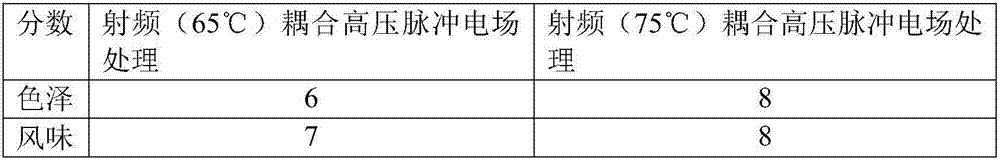

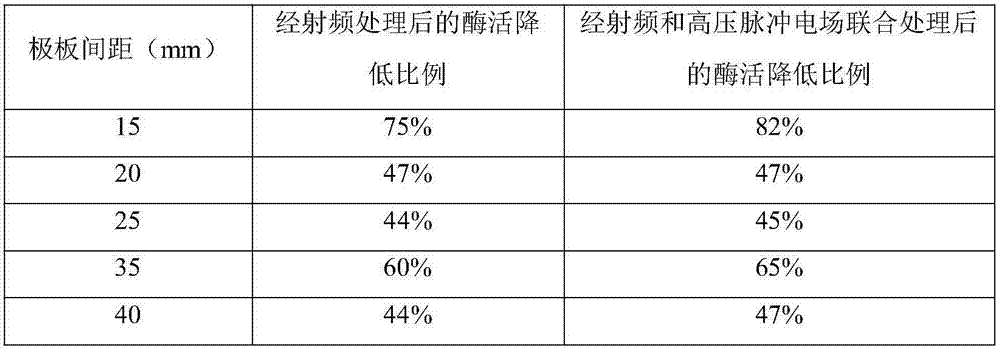

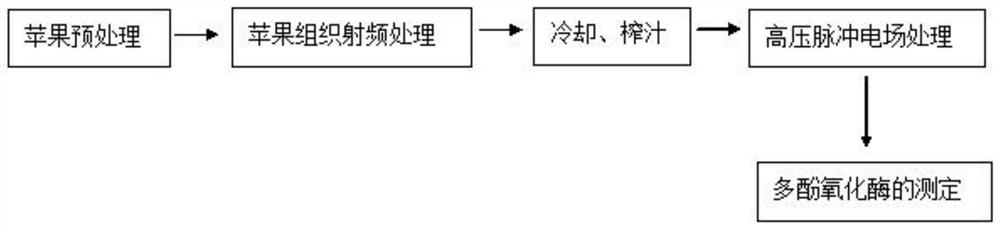

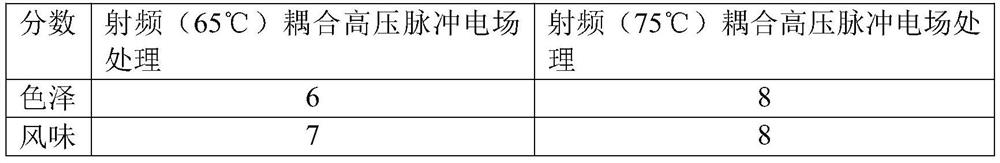

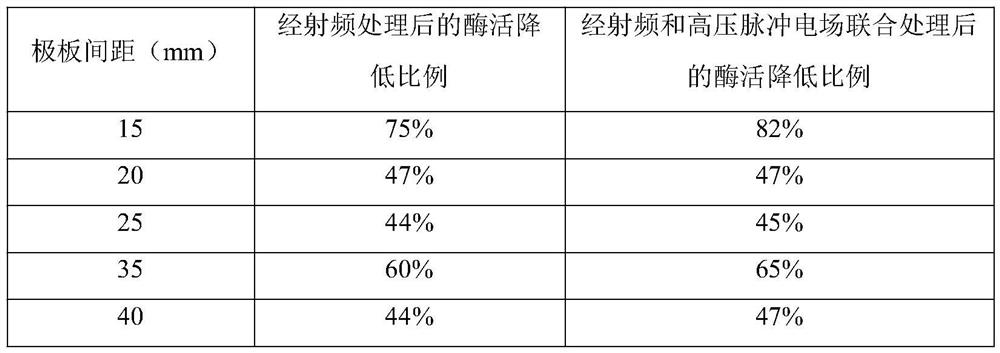

Fruit and vegetable juice processing method by radio frequency coupling high-voltage pulse electric field processing

ActiveCN107183445AStrengthen the effect of blunt enzymeReduces flavor loss and quality degradationFood thermal treatmentFood electrical treatmentRadio frequencyProduct processing

The invention discloses a fruit and vegetable juice processing method by radio frequency coupling high-voltage pulse electric field processing, and belongs to the field of farm product processing. According to the method, in an apple juice production process, apple tissues are subjected to radio frequency enzyme inactivation processing; for the radio frequency processing, a radio frequency continuous processing device disclosed in the patent application of CN104782758A and OSU-4L type high-voltage pulse electric field continuous processing equipment in a laboratory scale are used for radio frequency processing; apple slices are fast cooled after being processed in a radio frequency processing cavity, and are extruded into juice; then, the apple juice is processed by a high-voltage pulse electric field. The processing method has the advantages that 70 to 80 percent of activity of polyphenol oxidase can be passivated; the enzyme inactivation effect is good; the apple juice browning can be better prevented; meanwhile, the flavor loss of the apple juice can be reduced; the nutrition and the quality of apples is ensured.

Owner:JIANGNAN UNIV

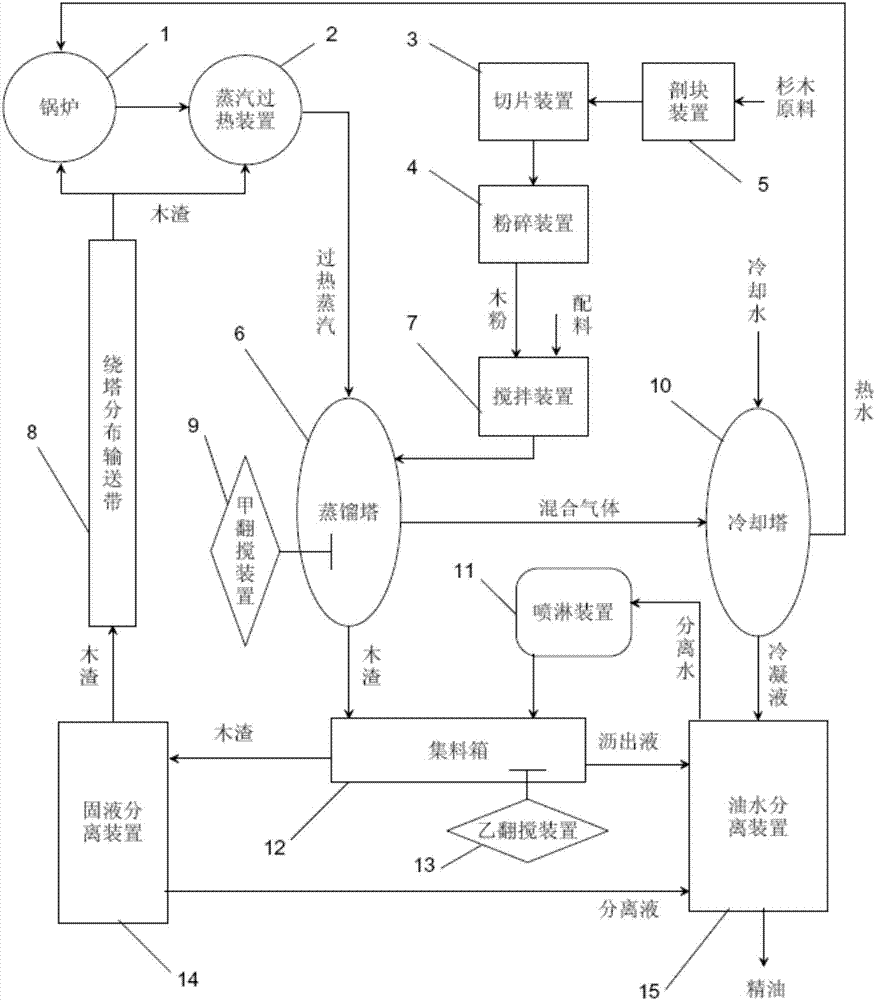

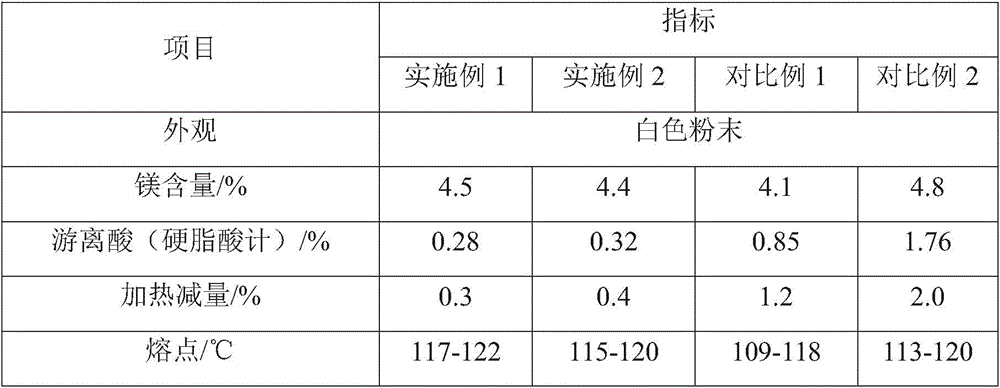

Production method and production line for obtaining Chinese fir essential oil at low energy and high yield

ActiveCN106883932AReduced total distillation timeHigh yieldEssential-oils/perfumesSuperheaterProcess engineering

The invention discloses a production method and a production line for obtaining Chinese fir essential oil at low energy and high yield. The production line comprises a boiler, a steam superheater, a block-cutting device, a slicing device, a crushing device, a stirring device, a distilling tower, a cooling tower and an oil and water separating device, and further comprises a solid and liquid separating device, a material collecting box with an overturning device 2 and a sprinkling device, and an overturning device 1 arranged inside the distilling tower, wherein a water outlet pipe of the cooling tower is communicated with the boiler; the sprinkling device is communicated with the oil and water separating device; a leachate outlet of the material collecting box is communicated with the oil and water separating device; a residue outlet of the material collecting box is connected with a feed inlet of the solid and liquid separating device; a liquid outlet of the solid and liquid separating device is communicated with an inlet of the oil and water separating device; a residue outlet of the solid and liquid separating device is connected with a fuel inlet of the boiler and a fuel inlet of the steam superheater through a conveyor belt distributed around the tower. After adoption of the production line, the Chinese fir essential oil is obtained by preparing powder, mixing, primarily distilling, secondarily distilling, cooling, sprinkling, overturning, performing solid and liquid separation, performing solid material drying and performing oil and water separation. The yield is high and the energy consumption is low.

Owner:FUJIAN XINLYULIN PROD DEV

Dish washing machine

InactiveCN105615799AImprove washing effectImprove self-cleaning abilityTableware washing/rinsing machine detailsHome appliance efficiency improvementFilter systemEnergy consumption

The invention discloses a dish washing machine. The dish washing machine comprises a filtering system, a washing system, a residue shredding system and a drainage system and is characterized in that a residue shredding cavity, a washing pump cavity and a drainage pump cavity are formed in the dish washing machine, a residue shredding filtering net is arranged at a water inlet of the residue shredding cavity, residue shredding blades are arranged in the residue shredding cavity, a water inlet of the washing pump cavity is communicated with the residue shredding cavity, a washing filtering net is arranged at the water inlet of the washing pump cavity, a washing pump is arranged in the washing pump cavity, a water outlet of the washing pump cavity is connected with a spray device of the washing system, a drainage filtering net is arranged at a water outlet of the residue shredding cavity, a water outlet of the residue shredding cavity is connected with a water inlet of the drainage pump cavity, and a drainage pump is arranged in the drainage pump cavity. The dish washing machine comprises the drainage pump provided with cutting blades and filters out, collects, shreds and discharges food residues, so that water consumption and energy consumption of the dish washing machine are reduced, the cleaning rate of the dish washing machine is increased, the dish washing machine has the self-cleaning function, and manual washing of the filtering nets is avoided.

Owner:林贤华

Preparation method of cellulosic ethanol

PendingCN112608950AEasy to manufactureReduce energy and water consumptionBiofuelsMicroorganism based processesXylanPulp and paper industry

The invention discloses a preparation method of cellulosic ethanol, which comprises the following steps of pulverizing lignocellulosic biomass, carrying out hydrothermal reaction, cooling to obtain a mixed solution, regulating the pH value, adding cellulase and xylanase, carrying out enzymolysis, inoculating yeast, and fermenting to prepare cellulosic ethanol. According to the method, hydrothermal short-time depolymerization pretreatment is utilized to obtain the low-toxicity pretreatment liquid, and the cellulosic ethanol is prepared by a one-pot method, so that the operation steps are simplified, xylan in the pretreatment liquid is retained, pentose and hexose co-fermentation is realized, the yield of the cellulosic ethanol is remarkably increased, and the method is low in cost, low in energy consumption, free of wastewater discharge and effective sugar components in lignocellulose can be comprehensively utilized.

Owner:GUANGDONG UNIV OF TECH

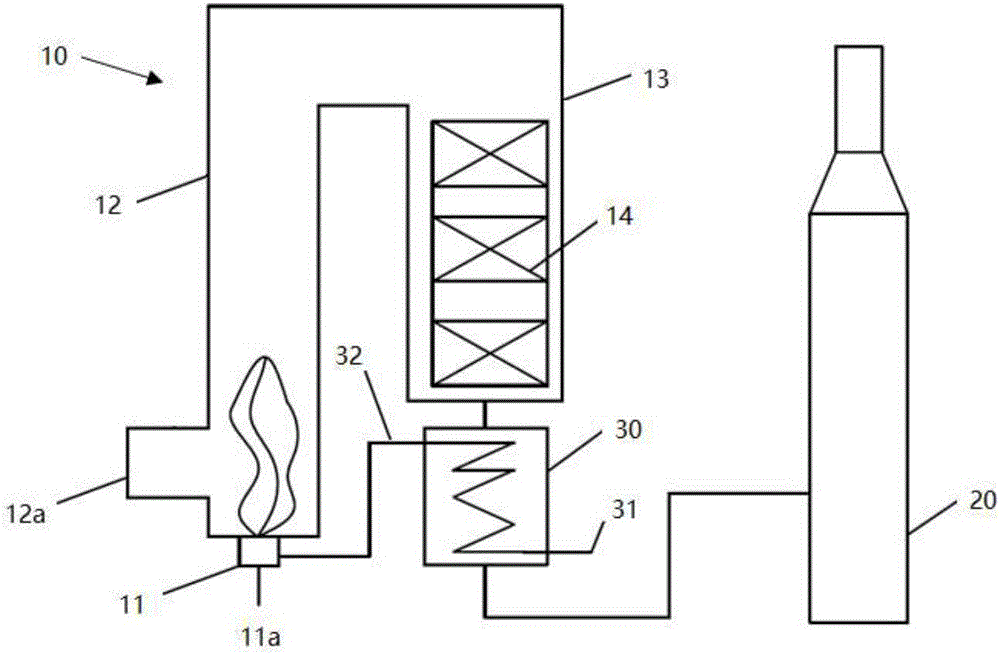

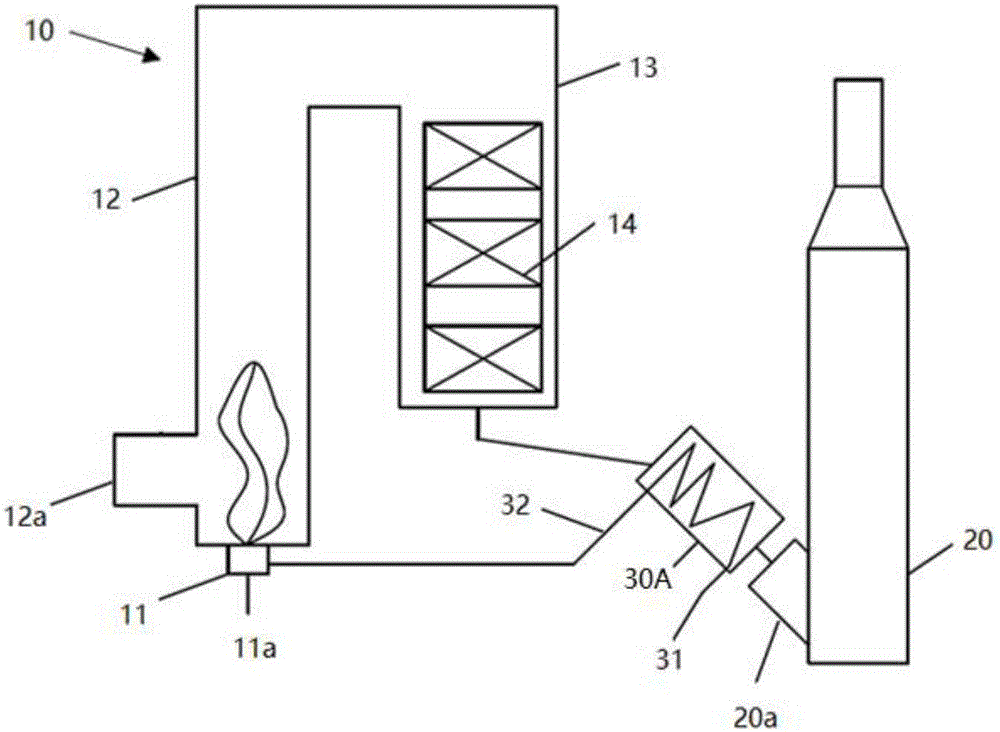

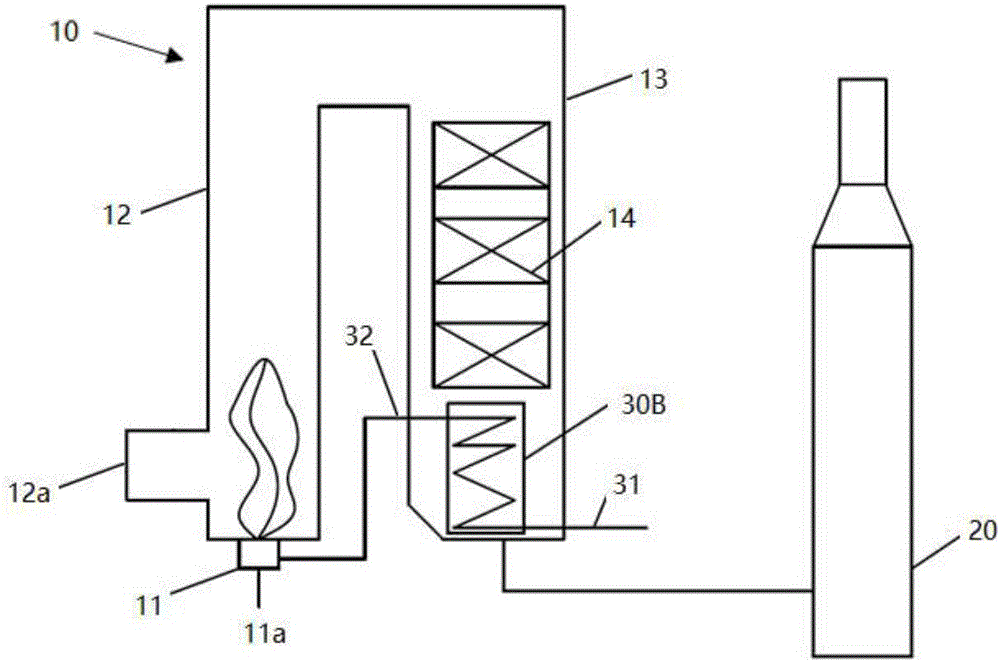

Catalytic cracking flue gas treatment device

PendingCN106765211AReduce dosageMitigation of cooling workEmission preventionIndirect carbon-dioxide mitigationAir preheaterCombustion

The invention discloses a flue gas treatment device. The device includes a CO boiler, a flue gas desulfurization device and an air preheater, wherein the air preheater is arranged between a steam generating unit of the CO boiler and a flue gas desulfurization device of the CO boiler; the air preheater is used for recycling incineration flue gas waste heat generated by incineration in the CO boiler to preheat combustion-aiding air. According to the flue gas treatment device, by recycling flue gas waste heat generated by incineration in the CO boiler, combustion air in the CO boiler is preheated, the consumption of fuels is significantly reduced, and the efficiency of the boiler is improved. Moreover, cooling work in the desulfurization device can be alleviated, especially for a wet desulphurization device, the water and energy consumption of the desulfurization device can be largely reduced, and energy conservation and emission reduction are achieved.

Owner:LUOYANG MINGYUAN PETROCHEM IND TECH +1

Undertint open width pad dyeing technology for dacron jacquard

InactiveCN103541244AEmission reductionGood color consistency before and afterDyeing processDisperse dyeEngineering

The invention discloses an undertint open width pad dyeing technology for dacron jacquard. The technology comprises the following steps of alkali washing, stoving, bottoming, stoving, shaping and fixing color, and tentering; wherein the alkali washing step comprises steps of adding 2-3g / l of sodium carbonate, adding 1-2g / l of detergent, and washing in a rinsing machine; after stoving, the step moves on to bottoming, the bottoming step comprises steps of adding disperse dyes, padding, dyeing and stoving in a padding machine, wherein the stoving temperature is 78-82 DEG C; shaping and color fixing are carried out on the cloth processed in the former step, the shaping temperature is 195-200 DEG C, the shaping time is 38-42 seconds, and the width of the fabric is taken as the finished product width; the cloth processed in the former step enters a stenter for tentering so as to obtain the finished product. The undertint open width pad dyeing technology has the characteristics of short steps, low energy consumption, light contamination, good consistency of colored light, and high efficiency; the step of shaping is for fixing color of the dye, so that steps of baking and washing are saved, the processes are shortened, and water consumption and energy consumption are lowered.

Owner:淮北维科印染有限公司

Moisture-absorbing, dry and comfortable textile fabric for casual pants

InactiveCN103835049AReduce energy and water consumptionReduce dosageWoven fabricsProtective garmentPolymer chemistryTextile

The invention relates to moisture-absorbing, dry and comfortable textile fabric for casual pants. The fabric is prepared from, by weight, 51 to 62 parts of cotton, 22 to 31 parts of real silk, 20 to 27 parts of mulberry silk, 21 to 30 parts of tencel, 13 to 19 parts of spandex, 10 to 11 parts of acrylic fiber, 3 to 8 parts of polyvinyl chloride fiber and 1 to 3 parts of polypropylene fiber. The moisture-absorbing, dry and comfortable textile fabric for casual pants can fast take away moisture in the body, fast scatter the moisture and accelerates evaporation of the moisture, and the surface of the skin is kept dry. Fresh and cool feeling can be kept for a long time, dryness of the skin is kept, a user can feel fresh and cool, and clothes can be as smooth and clean as a new one. Besides, due to the continuity of the innovation effect of the environment, the fabric can be fast dried, and stain on the fabric can be easily removed, in other words, the fabric can be fast aired, and therefore water using amount and energy consumption can be reduced, and the using amount of detergent can be reduced.

Owner:JIANGSU SANFONDO TEXTILE BIOLOGICAL SCI & TECH

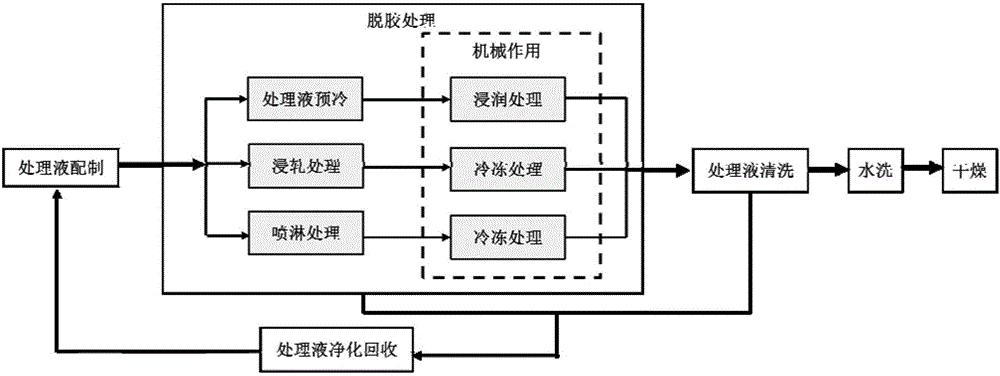

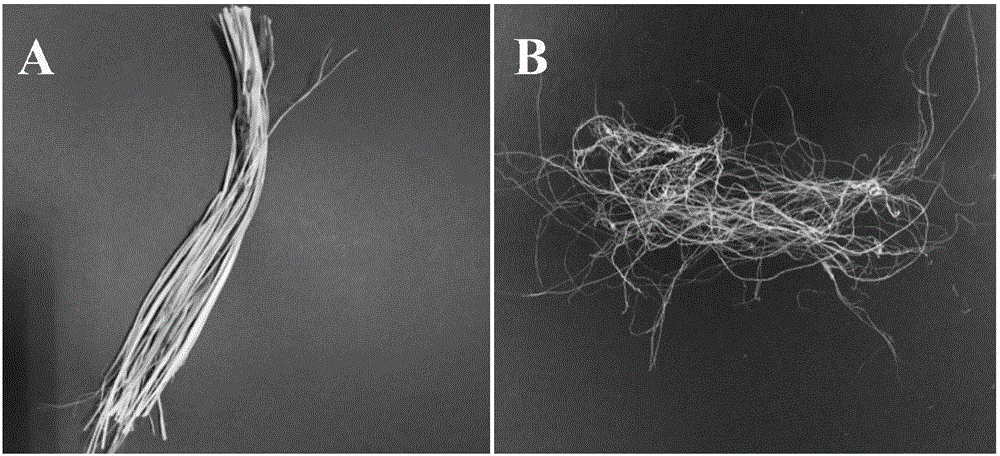

Method for efficiently degumming hemp by means of peroxidating at low temperatures under low-emission conditions

ActiveCN106400129AImprove efficiencySimple processFibre treatment to obtain bast fibreLow emissionEnergy consumption

The invention relates to a method for efficiently degumming hemp by means of peroxidating at the low temperatures under low-emission conditions. The method includes mixing alkali metal peroxide, amide substances and water with one another to obtain degumming treating fluid; carrying out degumming treatment on to-be-degummed hemp materials by the aid of the degumming treating fluid in wetting, padding or spraying modes under certain treatment conditions; carrying out first-pass cleaning on materials obtained by means of degumming treatment by the aid of the treating fluid in environments at the temperatures ranging from 5 DEG C to -20 DEG C, then cleaning the materials until the materials are neutral and drying the materials. The treatment conditions include that the to-be-degummed hemp materials are treated by 1-10 passes under the conditions of the temperatures ranging from 5 DEG C to -80 DEG C and are treated for 10s-30s in each pass. The method has the advantages that the method is high in efficiency and includes simple processes; the treating fluid can be reused, accordingly, the method is low in energy consumption, water consumption, production cost and sewage discharge, degumming byproducts can be timely collected, and transformation of the hemp spinning industry to the low-carbon environment-friendly industry can be promoted.

Owner:DONGHUA UNIV

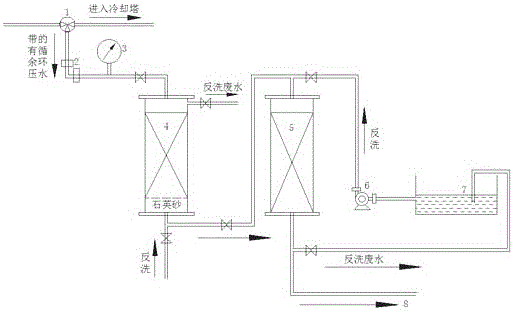

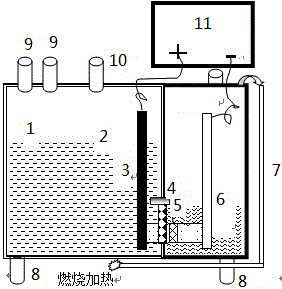

Residual pressure type circulating water system discharge water recycling device

InactiveCN105776674AFull of energyExtended replacement cycleSpecific water treatment objectivesTreatment involving filtrationWater qualityIon exchange

The invention discloses a residual pressure type circulating water system discharging water recycling device. The device comprises a shallow filter and an ion exchanger. The water outlet of the shallow filter is connected with the water inlet of the ion exchanger, the water inlet of the shallow filter is connected with a water outlet pipe of a circulating water system, and the water outlet of the ion exchanger is connected into a water collecting tank of the circulating water system. The shallow filter adopts garnet as a filtering medium. The ion exchanger adopts macroporous cation exchange resin. A backwashing loop is connected between the water inlet and the water outlet of the ion exchanger in parallel. The device disclosed by the invention reasonably utilizes system residual pressure, energy consumption is effectively reduced; a shallow filtration and ion exchange combined treatment technology is adopted; effluent quality meets standards of reclaimed water used for circulating cooling water, and effluent can be directly recycled to a circulating cooling water system; and an ion regenerated liquid recycling unit realizes regeneration of ion exchange resin, recycling of regenerated liquid and profit from selling precipitate byproducts at the same time.

Owner:NANJING NORMAL UNIVERSITY

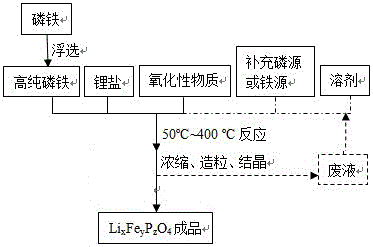

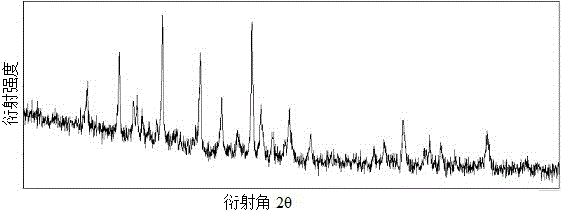

Method for preparing LixFeyPzO4 from ferrophosphorous

ActiveCN106082156AReduce energy and water consumptionHigh product purityMaterial nanotechnologyPhosphorus compoundsCorrosionPhosphate

The invention relates to a method for preparing LixFeyPzO4 from ferrophosphorous at a low temperature in a closed system. A raw material is purified through physical and chemical reaction processes, oxygen in an oxidation raw material provides an oxygen source for the above product, and the self material balance reaction and the self-produced pressure driving reaction of reactants are realized through raw material selection and technology regulation to solve the disadvantages of traditional ferrophosphorous high temperature reactions, the reaction temperature is low, the energy consumption and the water consumption are low, device corrosion is light, byproducts can only be water, and energy saving , emission reduction and clean production are realized. The method utilizes a convenient operating technology, and promotes the reaction by using the pressure generated in the reaction process, so the product has the advantages of high purity, small granularity, easy morphology control and easy reaction control, and the preparation method has the advantages of simplicity, high resource utilization rate, low cost, less investment, good benefit, cleanness and environmental protection, easy industrialization, and suitableness for high-value comprehensive utilization of chemical engineering byproducts and large-scale industrial low-cost clean production of high-end phosphates.

Owner:SICHUAN UNIV

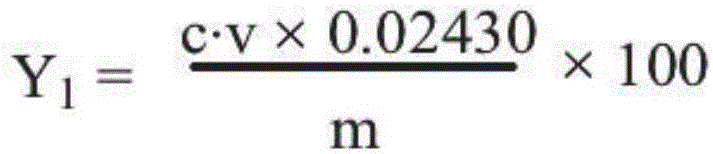

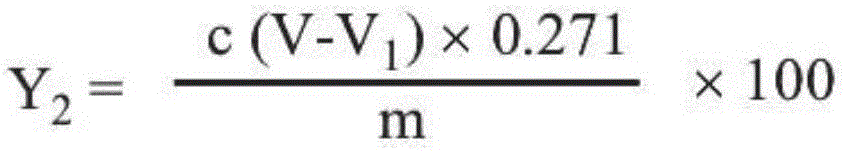

Magnesium stearate and preparation process thereof

ActiveCN105949049ALow raw material costReduce energy and water consumptionOrganic compound preparationPreparation from carboxylic acid esters/lactonesChemistryMagnesium

The invention belongs to the technical field of chemical engineering, and particularly relates to magnesium stearate and a preparation process thereof. The preparation process includes the following steps: (1) subjecting tristearin and water to hydrolysis under the action of catalyst and antioxidant; (2) adding magnesium oxide and catalyst step by step, and performing condensation, dehydration and salifying to synthesize magnesium stearate. The magnesium stearate provided is industrial-grade magnesium stearate, and is low in raw material cost, high in production yield, good in color, low in free acid content and stable in quality. In the preparation process of magnesium stearate, discharge of wastewater containing chlorine and sulfate ions is avoided, the production process is safe and environment friendly, and overall production cost is low. The provided magnesium stearate is high in quality, and is more practical and comparable than similar products on the market in practical application.

Owner:HUIZHOU AIMSEA NEWWAY TECH CO LTD

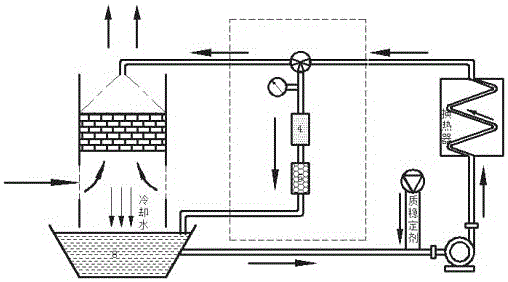

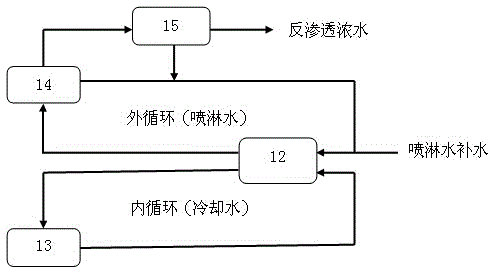

Closed cooling tower and closed circulating water system

InactiveCN105716442AGuaranteed uptimeImprove cooling effectTrickle coolersCooling towerReverse osmosis

The invention discloses a closed cooling tower and a closed circulating water system. The closed cooling tower comprises air inlet, a spray thrower, a heat exchange coil, a PVC heat exchange layer, a water collecting tank and an axial flow fan. The top and one side of a tower body are provided with the air inlets. The other side of the tower body is provided with an air outlet. The axial flow fan is installed at the air outlet. The heat exchange coil is arranged on the upper portion of the tower body. The spray thrower is arranged over the heat exchange coil. The PVC heat exchange layer is arranged under the heat exchange coil. The water collecting tank is arranged below the heat exchange layer and at the bottom of the tower body. The closed circulating water system adopting the closed cooling tower comprises an inner circulating part and an outer circulating part. The inner circulating part comprises the closed cooling tower and a heat exchanger. The outer circulating part comprises the closed cooling tower, the filter and a reverse osmosis device. According to the closed cooling tower and the closed circulating water system, the specific closed cooling tower and closed circulating water system are adopted, so that efficient operation of the circulating water system is ensured, the cooling ability is improved significantly, and water consumption and energy consumption are reduced more obviously.

Owner:CHINA PETROLEUM & CHEM CORP +1

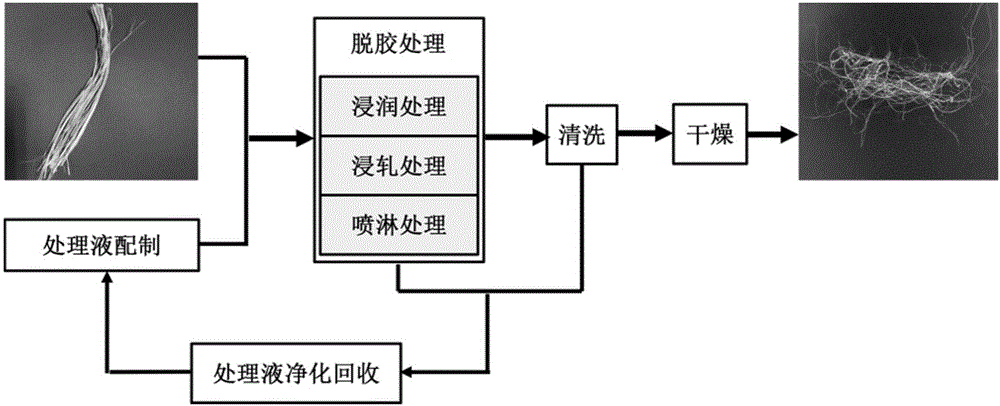

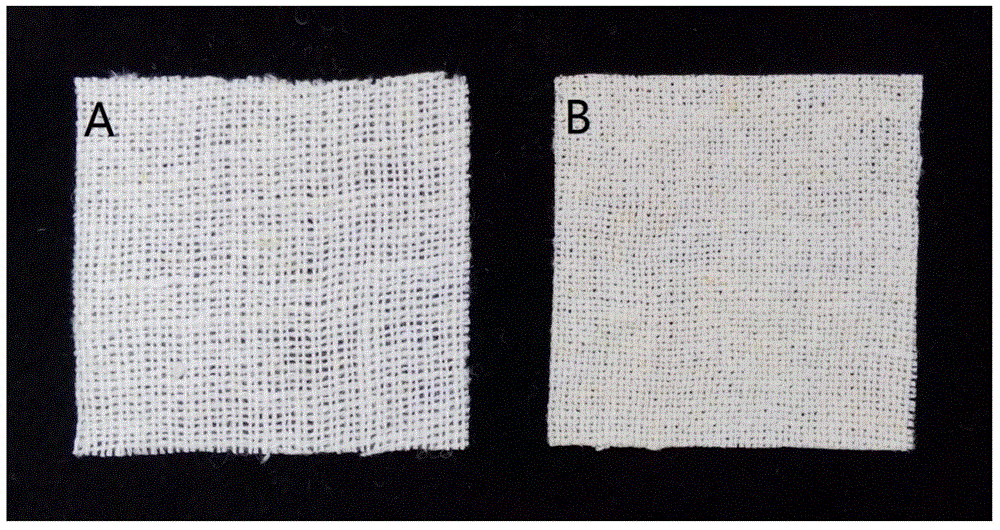

Method for manufacturing environment-friendly cellulosic-fiber-containing fabric lining cloth

The invention relates to a method for manufacturing environment-friendly cellulosic-fiber-containing fabric lining cloth. The method includes the steps that a multi-ratio aqueous solution prepared from alkali metal hydroxide and amide substances capable of being effectively combined with hydrogen bonds of hydroxide radicals between cellulose molecules serves as treating fluid; cellulosic-fiber-containing fabric is immersed or padded into the treating fluid; hairlines parts of cellulose in the fabric are dissolved to be cured at the low temperature to improve the compactness and the stiffness of the structure of the fabric; in addition, cellulose base materials can be dissolved into the treatment fluid according to the rigidity requirement to further improve the rigidity of the fabric after the curing process. According to the method, the treatment process does not involve any slurry consumption, and only the small quantity of cellulose base materials wide in source are consumed; in addition, the use treatment fluid and washing liquor can be recycled, and the production cost is low accordingly; in the production process, energy consumption and water consumption are reduced, toxic ingredients including adhesives are avoided, and production of healthy and environment-friendly safe clothes can be promoted.

Owner:DONGHUA UNIV

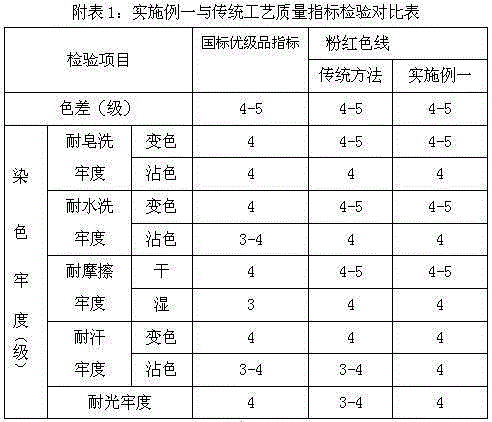

Method for washing pure cotton cone yarn dyed with light-medium-color active macromolecular dye

InactiveCN105064089AShort processReduce energy and water consumptionDyeing processOrganic acidEnzyme

The invention provides a method for washing pure cotton cone yarn dyed with light-medium-color active macromolecular dye. The pure cotton cone dyed yarn processed with the method has stable colors, and each fastness index meets or exceeds the national standard requirement. The method has the effects of energy saving, consumption reduction and productivity increase. The method comprises following steps: (1) a desalination process, (2) a soaping process, (3) a neutralization process (4), a dye fixing and softening process and (5) a water extruding and drying process, wherein the soaping process comprises process conditions as follows: a dye vat is filled with soft water, 1.0 g / L of engineered soaping enzyme 5NPF is added, the temperature is increased to 60 DEG C, and a residual liquid is drained after the heat preservation is performed for 10 min; the neutralization process comprises process conditions as follows: the dye vat is filled with tap water, 1.0 g / L of organic acid ACR is added, and a liquid is drained after neutralizing and washing are performed for 10 min at the temperature of 45 DEG C; the addition of 1.0 g / L of organic acid ACR means that the organic acid ACR is added in a ratio of 1.0 g / L with the volume of the dye vat serving as a standard.

Owner:ANHUI HUAMAO TEXTILE

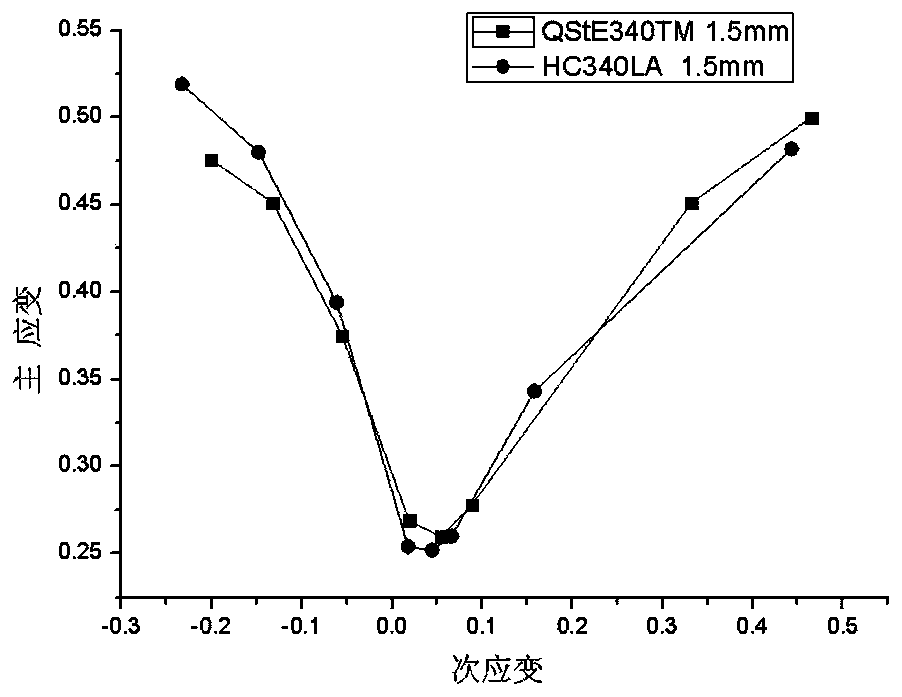

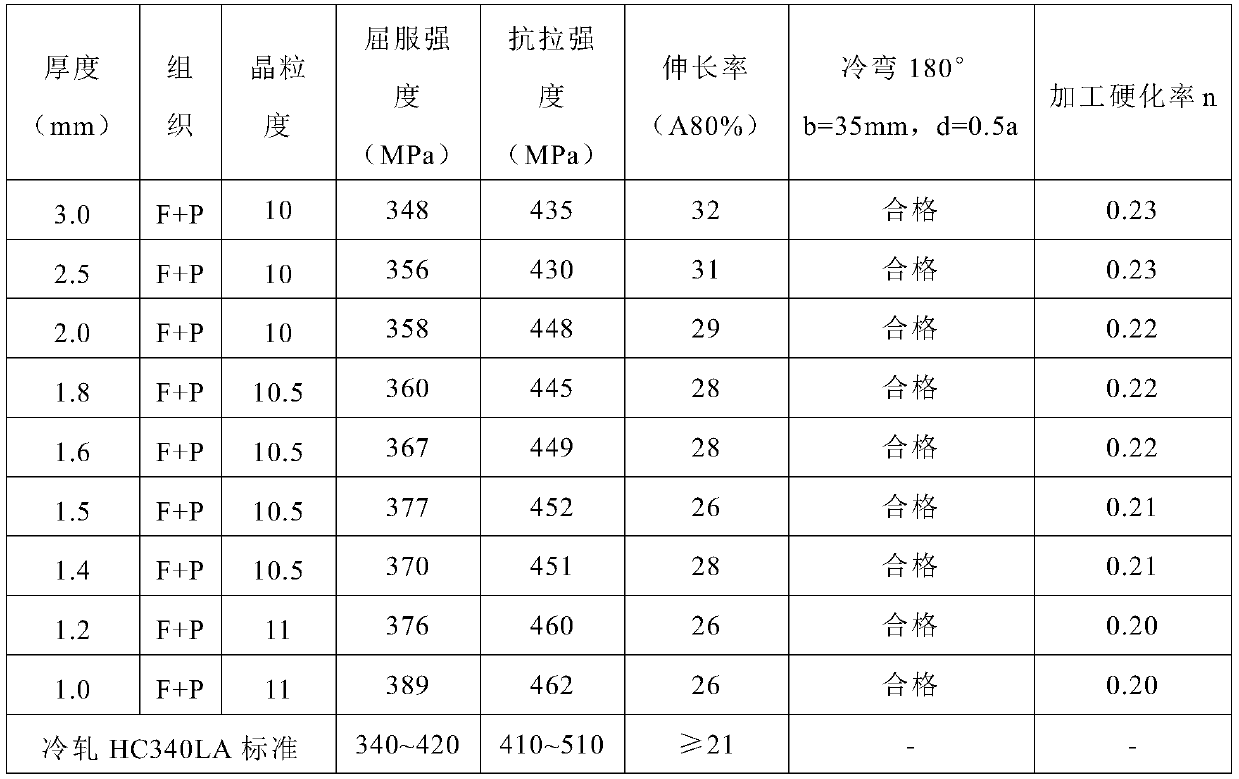

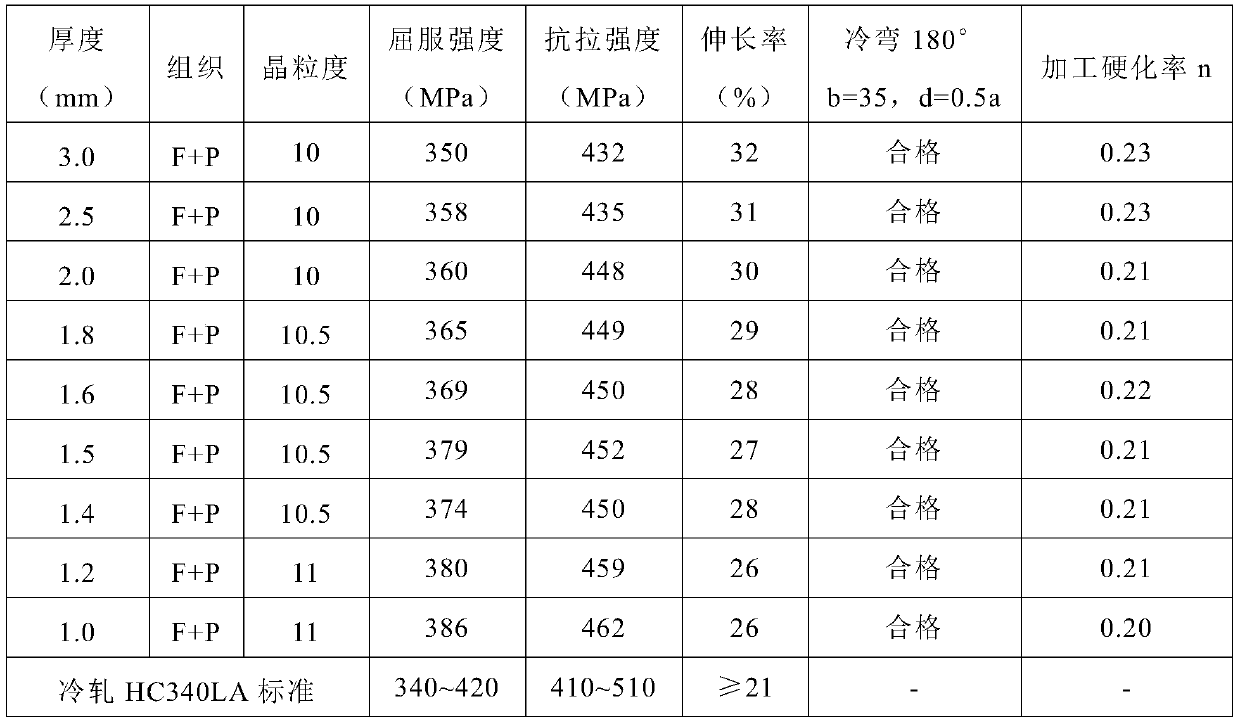

340mpa grade hot-rolled automotive structural steel plate with excellent cold formability and manufacturing method

Owner:武汉钢铁有限公司

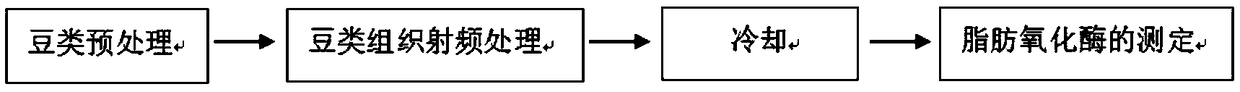

Method for passivating lipoxygenase in beans

The invention discloses a method for passivating lipoxygenase in beans, and belongs to the technical field of food processing. The method for passivating the lipoxygenase in beans provided by the invention has the advantages that the radio frequency is used for treating nutrition inhibition factors; 85 to 99 percent of activity of the lipoxygenase can be passivated; the activity of the lipoxygenase can be well reduced; the generation of beany flavor can be well prevented; meanwhile, the bean flavor loss can be reduced; the nutrition and the quality of the beans can be ensured.

Owner:JIANGNAN UNIV

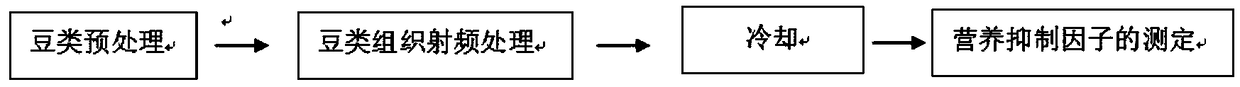

Method for passivating anti-nutritional factors in beans

InactiveCN109287938AImprove thermal stabilityImprove passivation effectFood scienceFlavorTrypsin inhibitor

The invention discloses a method for passivating anti-nutritional factors in beans, and belongs to the technical field of food processing. According to a new method for passivating anti-nutritional factors provided by the invention, the anti-nutritional factors are treated with radio frequency, so that 87-99% of activity of trypsin inhibitors and urease can be passivated, the vitality of the anti-nutritional factors can be well reduced, the flavor loss of the beans can be reduced, and nutrition and quality of the beans can be guaranteed.

Owner:JIANGNAN UNIV

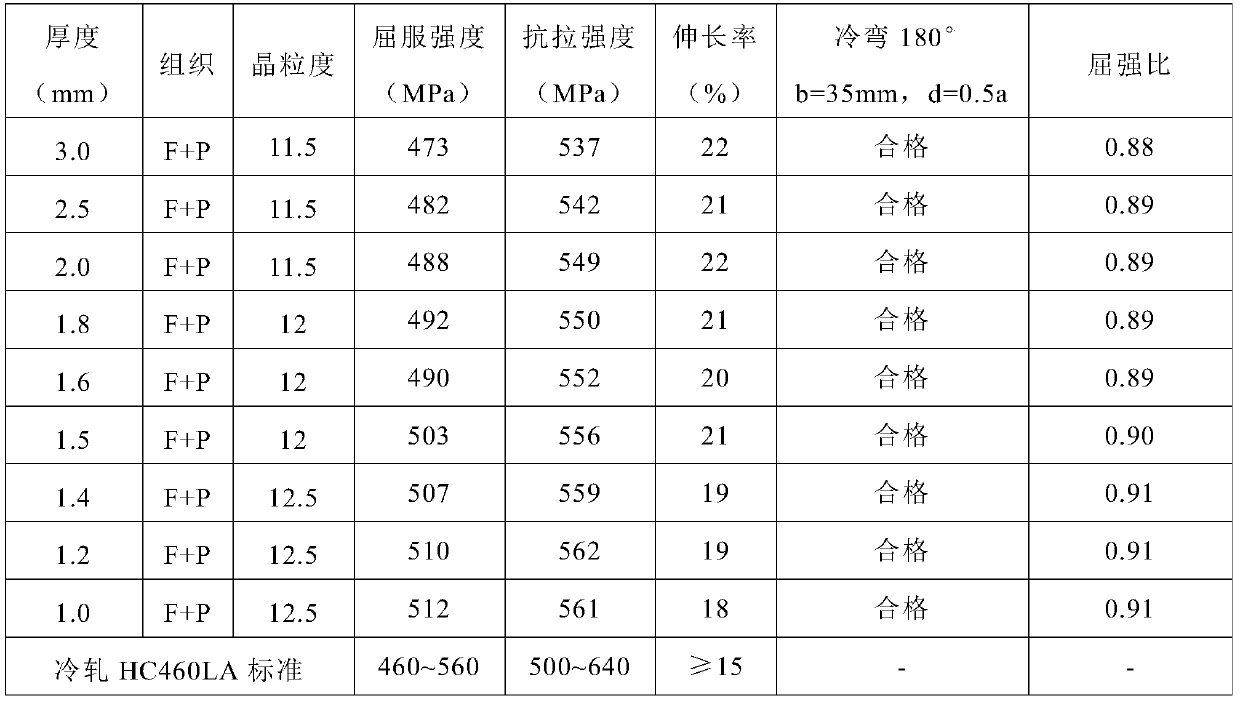

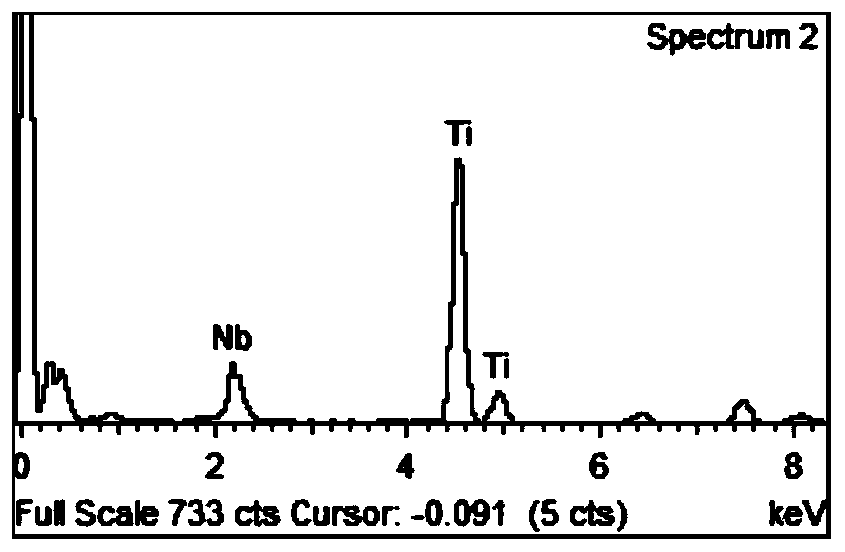

460mpa grade hot-rolled automotive structural steel plate with good fatigue performance and manufacturing method

The invention discloses a 460MPa-grade hot-rolled automotive structural steel plate with a good fatigue property and a manufacturing method. The 460MPa-grade hot-rolled automotive structural steel plate comprises the following chemical elements in percent by weight: 0.03-0.06% of C, 1.0-1.2% of Mn, 0.025-0.035% of Nb, 0.025-0.035% of Ti, smaller than 0.10% of Si, smaller than or equal to 0.005% ofS, smaller than or equal to 0.015% of P, smaller than or equal to 40ppm of N, 0.025-0.050% of acid-soluble aluminum and the balance of Fe and unavoidable impurities. An Nb-Ti microalloying technologyis adopted in a short process; trace Ti is used for fixing S and N in steel (S is smaller than or equal to 0.005% and N is smaller than or equal to 40ppm); MnS inclusions in steel are reduced; the fine grain effects of Nb and Ti are fully played, and a fine F+P texture is obtained; the fatigue property of a steel grade is improved while relatively high strength is achieved.

Owner:武汉钢铁有限公司

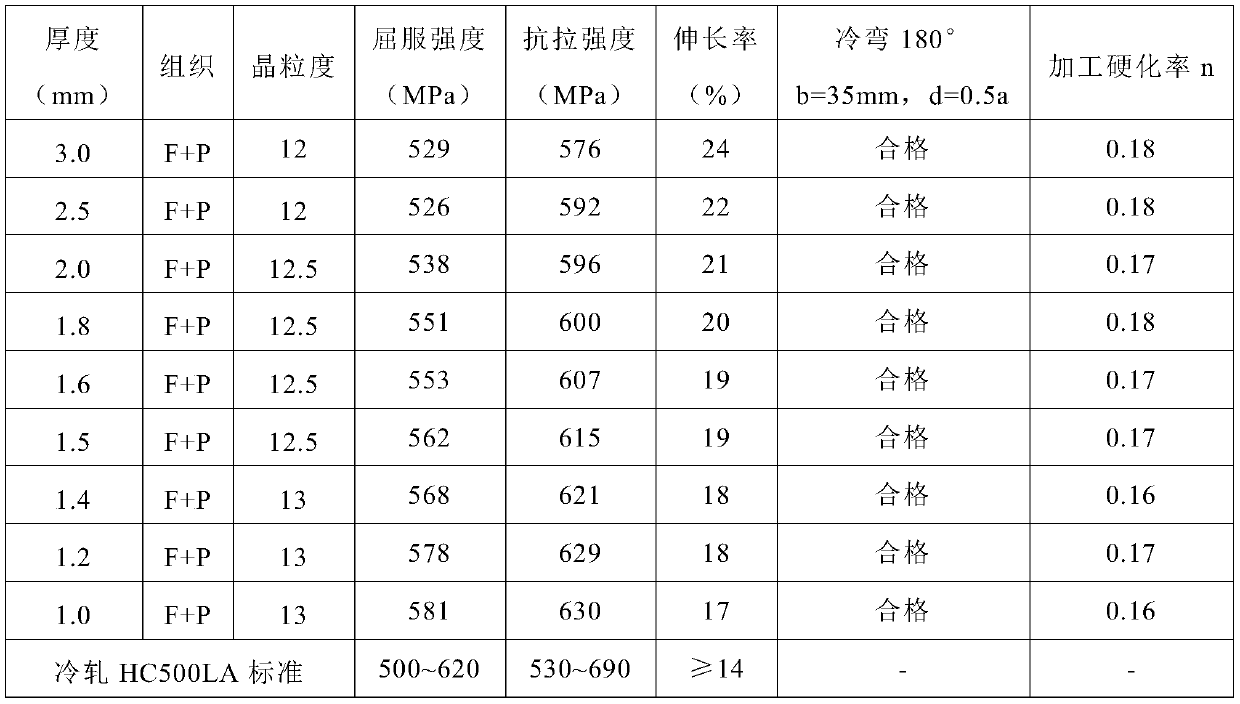

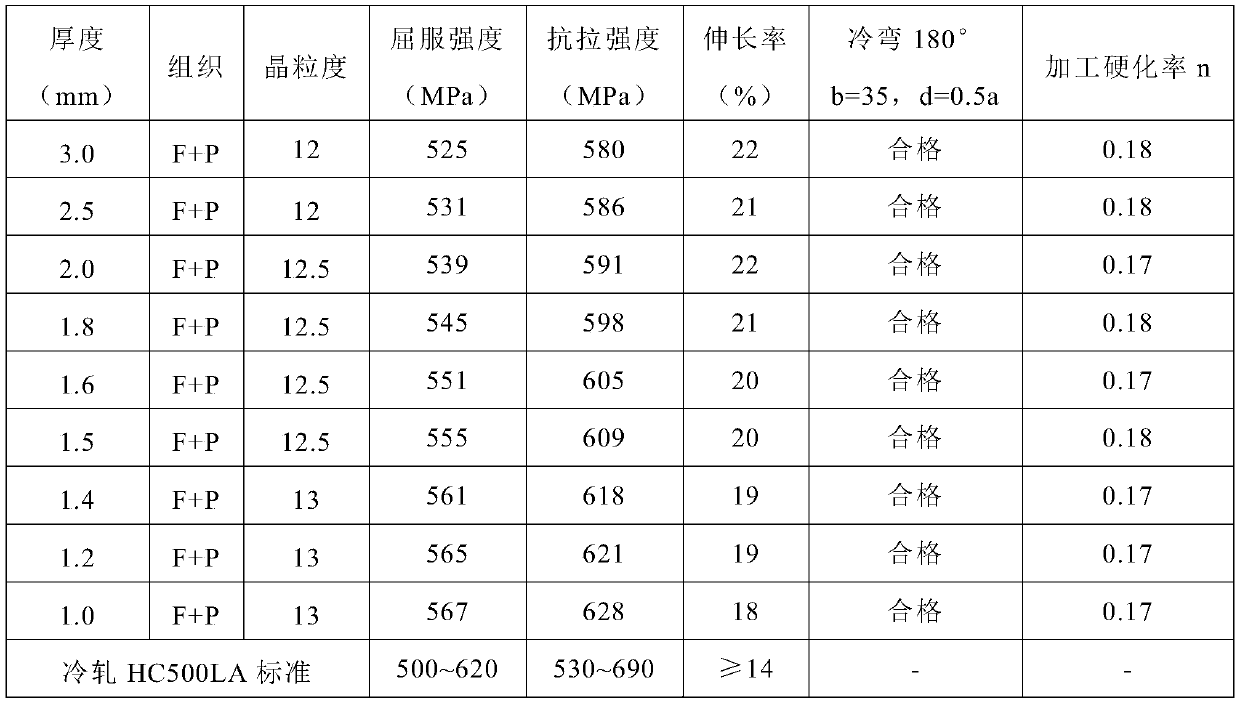

500mpa grade hot-rolled automotive structural steel plate with good weldability and manufacturing method

The invention discloses a 500MPa-grade hot-rolled automotive structural steel plate with a good welding property and a manufacturing method. The 500MPa-grade hot-rolled automotive structural steel plate comprises the following chemical elements in percent by weight: 0.03-0.06% of C, 1.0-1.3% of Mn, 0.035-0.045% of Nb, 0.035-0.045% of Ti, smaller than 0.10% of Si, smaller than or equal to 0.005% ofS, smaller than or equal to 0.015% of P, smaller than or equal to 40ppm of N, 0.025-0.050% of acid-soluble aluminum and the balance of Fe and unavoidable impurities. An Nb-Ti microalloying technologyis adopted in a short process; through adoption of a low-carbon component design, the carbon equivalent in steel is reduced; meanwhile, trace Ti is used for fixing S and N in steel (S is smaller thanor equal to 0.005% and N is smaller than or equal to 40ppm); the fine grain effects and the precipitation strengthening effects of Nb and Ti are fully played, and a fine F+P texture and fine precipitates of Nb and Ti are obtained; the welding property of a steel grade is improved while relatively high strength is achieved.

Owner:武汉钢铁有限公司

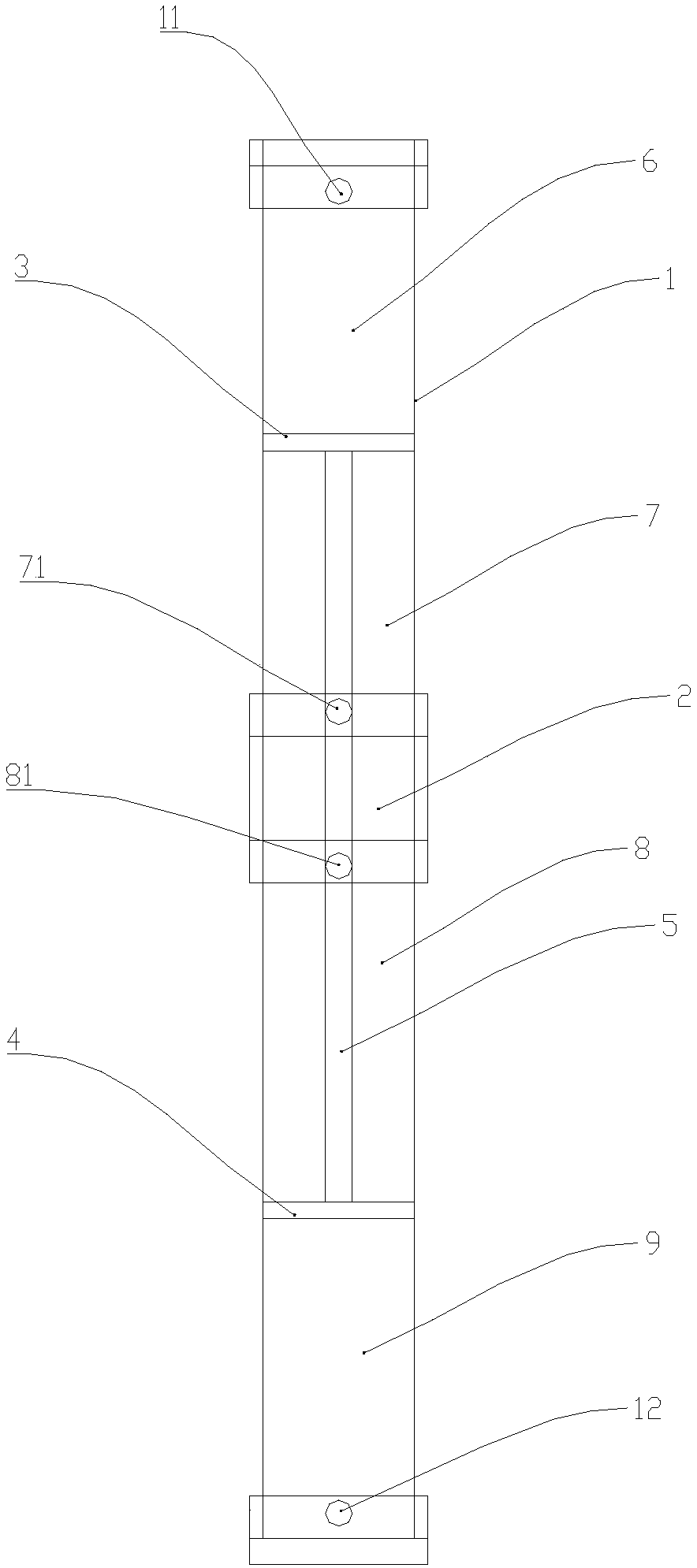

Dynamic pressure tester for water purifier

PendingCN107831008AQuick Stress TestReal-time monitoring of deformationMachine part testingEngineeringDynamic pressure

The invention discloses a dynamic pressure tester for a water purifier. The dynamic pressure tester for the water purifier comprises a tube, wherein two ends of the tube are sealed; a partition is arranged in the middle of the tube; a first piston and a second piston are separately arranged in the tube and positioned on two sides of the partition; the first piston and the second piston are connected through a transmission rod which penetrates in the partition; an oil injection opening is formed in the upper end of the tube; and a water injection opening is formed in the lower end of the tube.Compared with the prior art, the dynamic pressure tester for the water purifier has the advantages that a pressurizing oil cylinder, a pressure return oil cylinder, a metering oil cylinder and a pressurizing water cylinder which are sealed are formed among the pistons and the tube to rapidly detect pressure of accessories of the water purifier, deformation and water leakage of a tested piece can be monitored in real time, and when pressure is relieved, the dynamic pressure tester stops automatically to reduce energy consumption and water consumption.

Owner:SHENZHEN HUAMAI ENVIRONMENTAL PROTECTION CO LTD

A kind of acidic silicone sealant with good adhesion to stainless steel and preparation method thereof

ActiveCN104130738BGood adhesionInhibit sheddingNon-macromolecular adhesive additivesOther chemical processesSocial benefitsCross-link

The invention discloses an acidic silicone sealant with good bonding performance on stainless steel, and a preparation method thereof. The sealant comprises the components of, by weight: 20-90 parts of a,w-dihydroxy polysiloxane, 2-10 parts of a plasticizer, 10-50 parts of a filling material, 3-10 parts of a thixotropic agent, 2-10 parts of a cross-linking agent, 1-5 parts of a tackifying agent, and 0.1-5 parts of a catalytic curing agent. Compared with prior arts, according to the invention, the novel tackifying agent is added, such that the sealant has good bonding performance on stainless steel. A silver-grey colorant is added into an acidic transparent system, such that the sealant has a shiny color that is substantially similar to that of stainless steel. Because the sealant is an acidic silicone sealant, curing speed is high. With the sealant, production efficiency can be substantially improved, bonding performance can be improved, and glass and stainless steel falling can be prevented. During the production process, energy consumption and water consumption are low, no three-waste (waste gas, waste water, and solid waste) is produced, and no environment pollution is caused. The sealant and the method has significant economic and social benefits.

Owner:圣戈班汇杰(杭州)新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com