Patents

Literature

41results about How to "Less Flavor Loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-salt liquid state fermented soy sauce production process

The invention discloses a low-salt liquid state fermented soy sauce production process, comprising the following main processes: preparing koji in a koji-maker machine; mixing the wheat which is fried and smashed with koji, inoculating the mixture in soybean meal and bran which are cooked; preparing finished koji in a koji making disc machine; mixing the finished koji with brine, sending the mixture in a fermenting vat for fermentation; preparing the finished soy sauce through soaking, pouring oil, filtrating, mixing, sterilizing and filling to obtain the finished soy sauce. The soy sauce is characterized in that materials containing zygosaccharomyces Rouxii 2.180 accounting for 1.5-2.5% of the total weight of materials and torulopsis candida 2.202 accounting for 1.5-2.5% of the total weight of materials are added during the medium term of the fermentation process and the raw materials--soybean meal and bran are cooked by high temperature short-time continuous cooking process. Compared with the prior art, the raw material digestion rate can reach 88-90%, the protein utilization rate can reach 83%, the activity of neutral protease of the finished koji can reach 2000mu / g, the enzymesystem is complete, the defects such as long period of high-salt liquid state fermentation (180 days), burnt flavour and heavy bitter taste of low-salt solid state fermentation and the like are overcame and the produced soy sauce is characterized by strong soysauce-like aroma, alcohol-like aroma and ester-like aroma and the like.

Owner:QIANHE CONDIMENT & FOOD CO LTD

Heated food product with coating of encapsulated flavors

InactiveUS20070269553A1Improve performanceLess Flavor LossYeast food ingredientsChewing gumFlavouring agentEvaporation

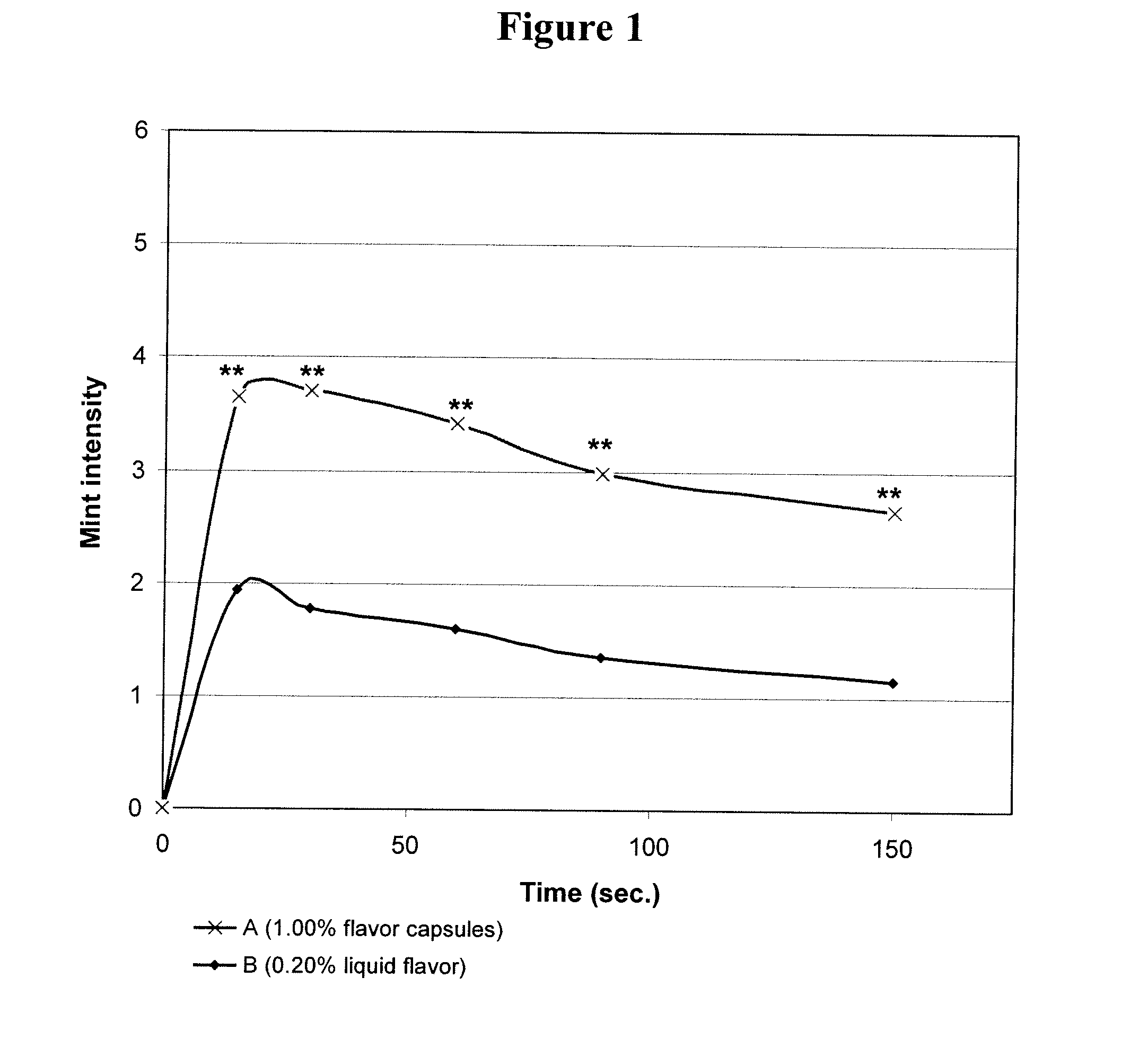

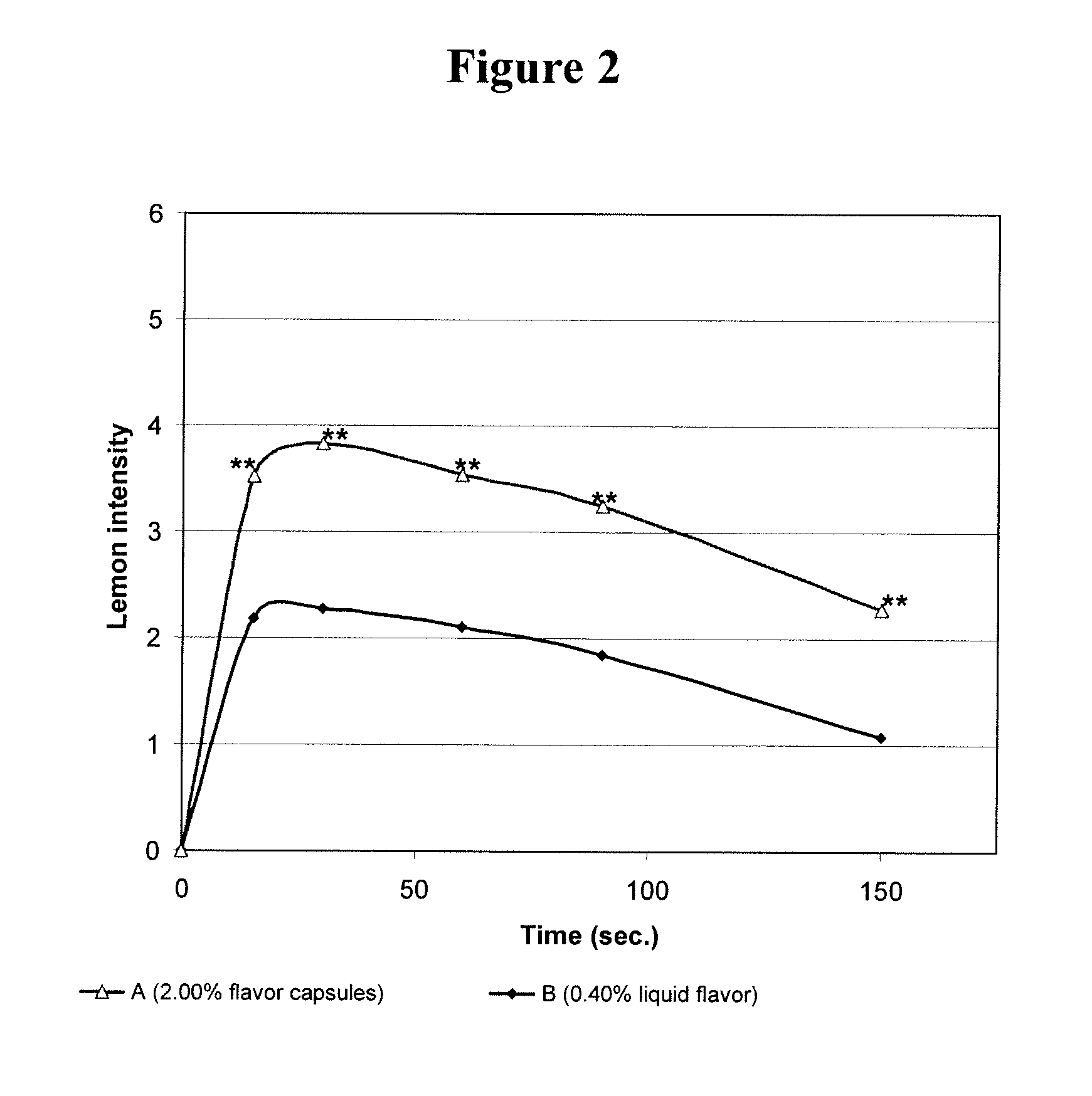

The present invention relates to a method for preparing a flavored food product, and to a method for reducing loss of flavors in a flavored product due to heat treatments. Loss of flavors by evaporation at high temperatures could be prevented by applying coating solutions in which water and encapsulated flavors have been mixed at 0.5% to 30 wt. % of capsules based on micro-organisms, a matrix component and encapsulated flavors. The coating solution was applied in high temperature coating processes or processes including heat treatment following the coating step and resulted in surprising retention of flavors in the coated food product.

Owner:FIRMENICH SA

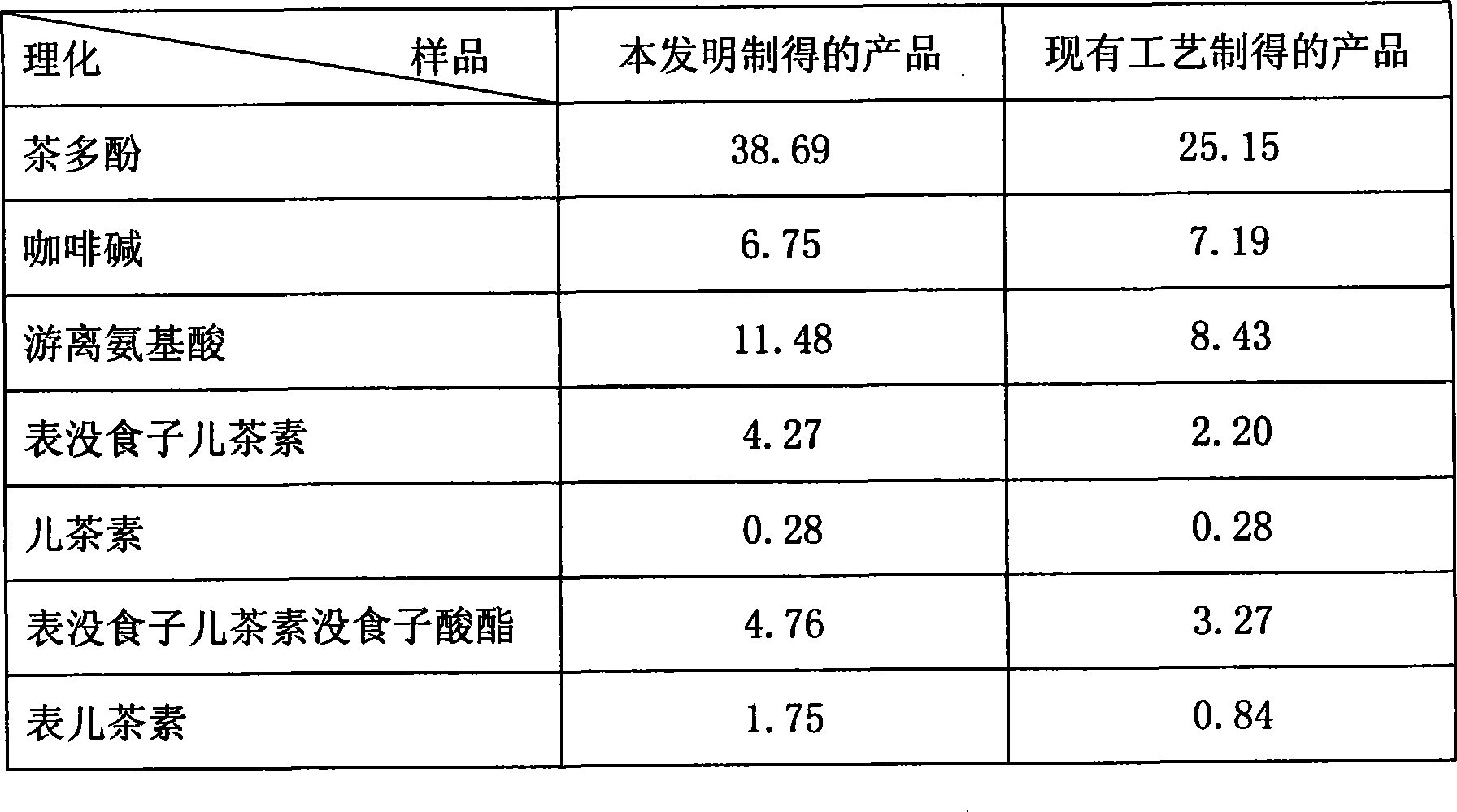

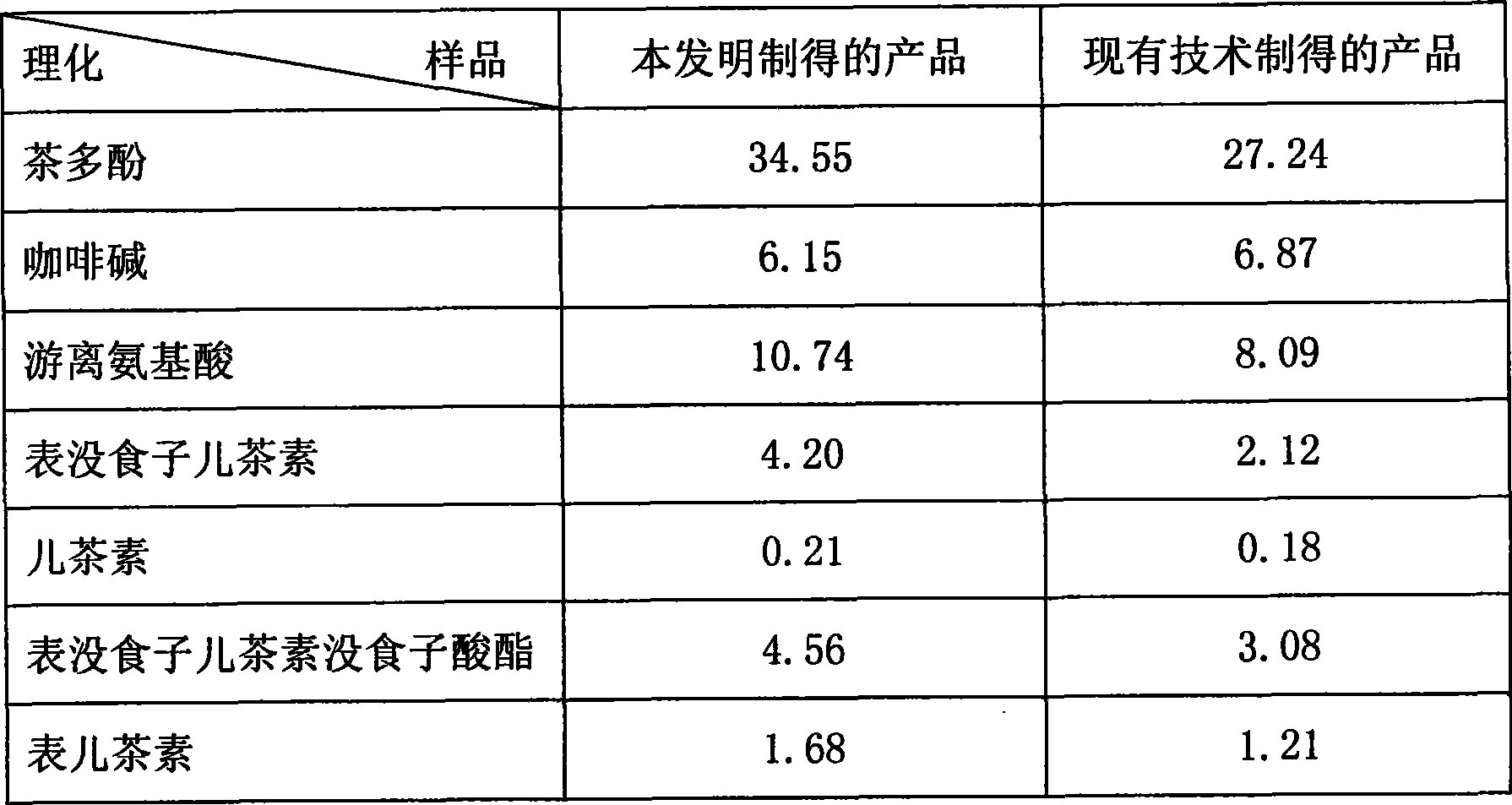

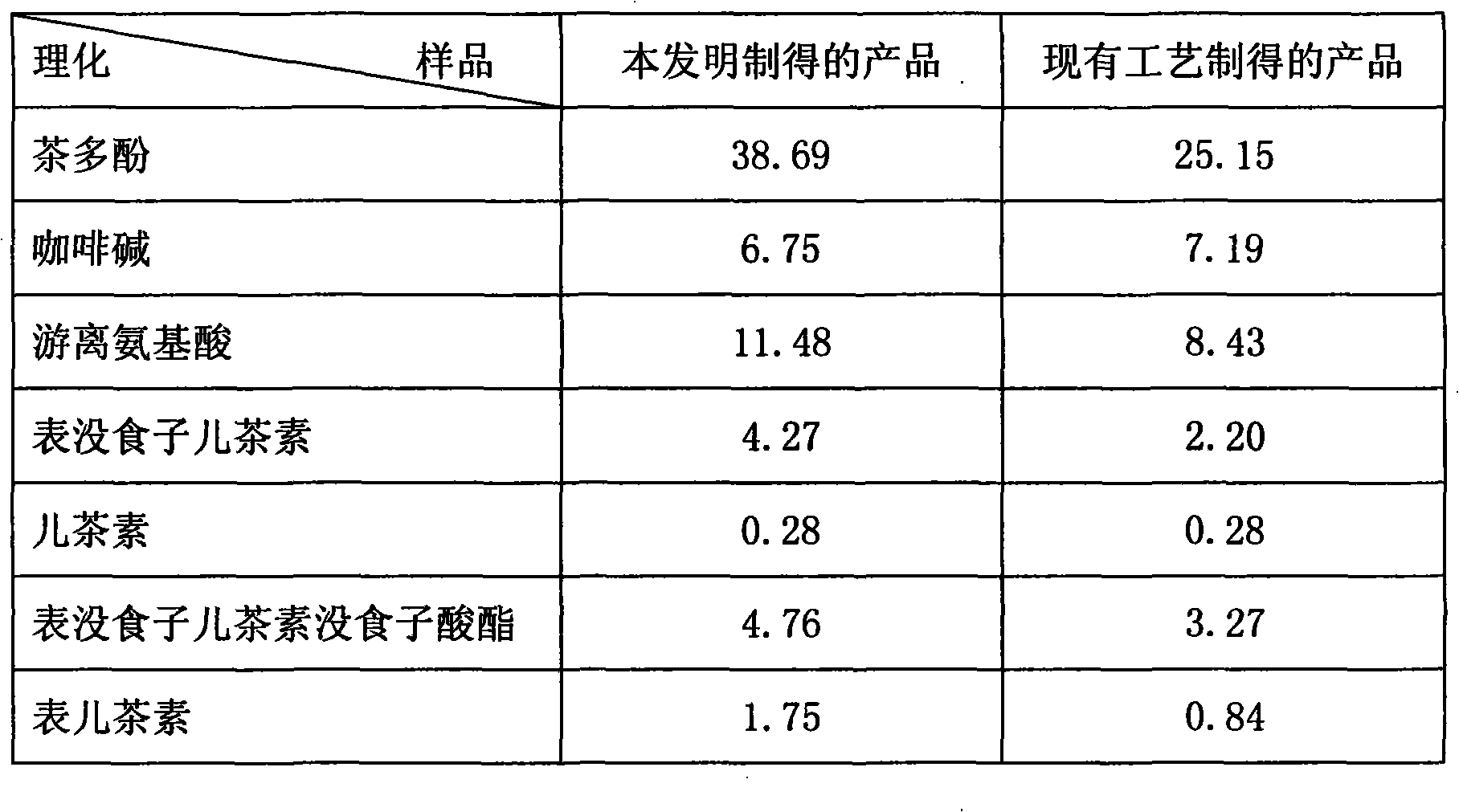

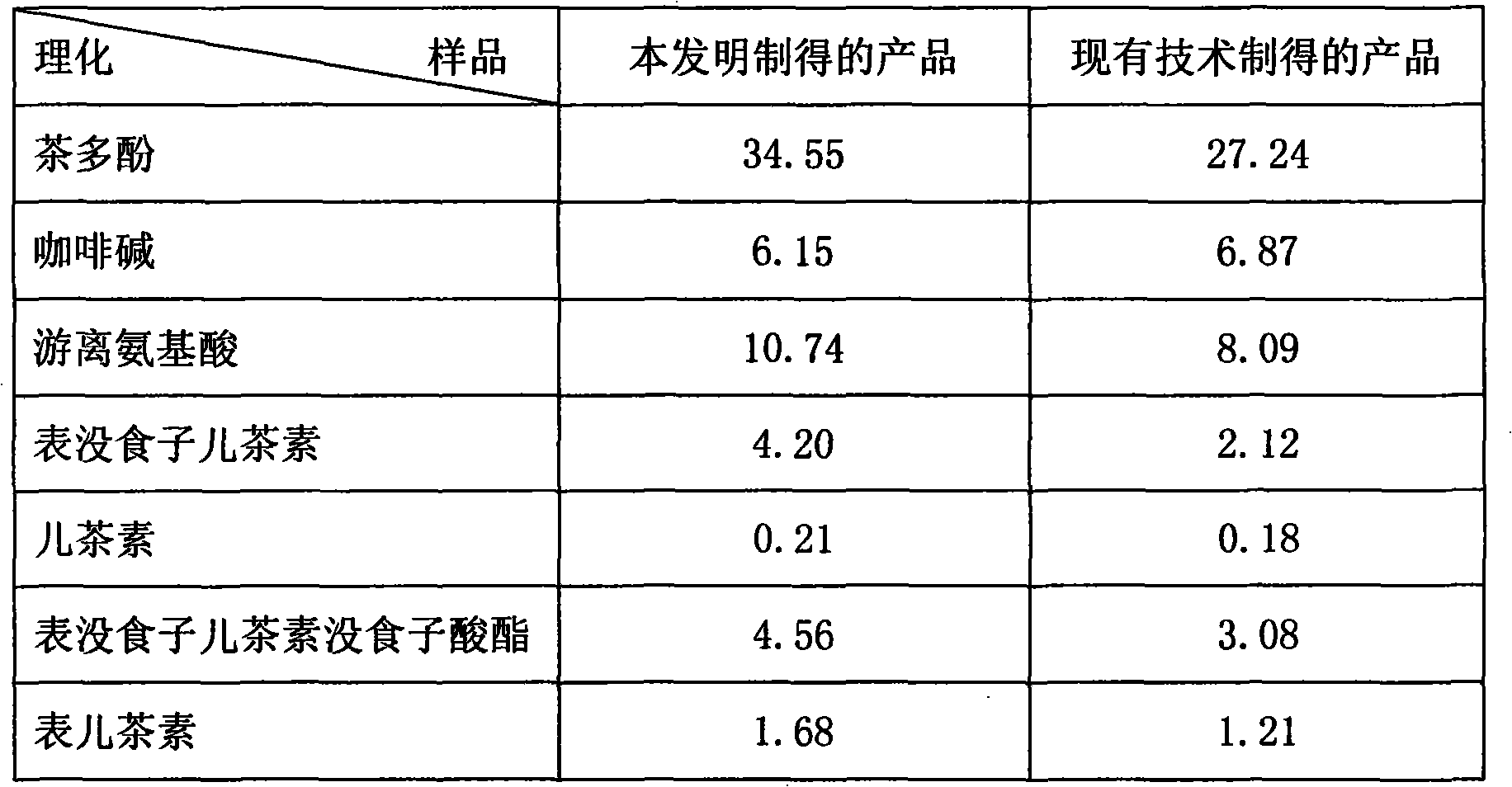

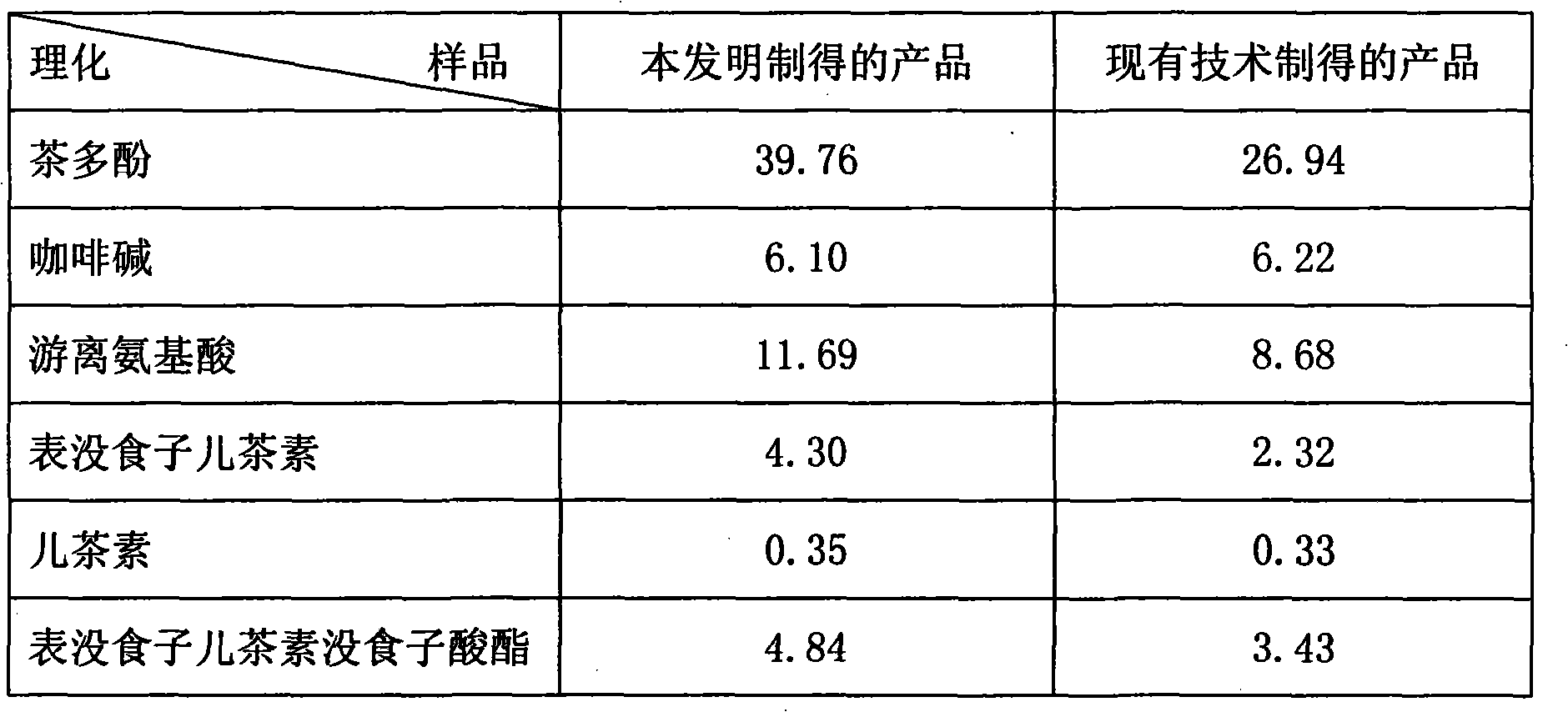

Instant tea powder and processing method thereof

ActiveCN101385492ALess Flavor LossReduce subsequent enrichment linksTea extractionFlavorHigh concentration

The invention provides a processing method of instant tea powder, which comprises the following steps: an extracted medium is mixed with tea leaves and the third grade countercurrent leaching technology is adopted to obtain the first tea juice; the extracted first tea juice is filtered to obtain the second tea juice; a proper amount of auxiliary materials are added in the second tea juice to obtain the third tea juice; the third tea juice is pasteurized to obtain the fourth tea juice; and the fourth tea juice is then dehydrated and dried under the pressure condition to finally obtain fine and even instant powder. The extraction working procedures of the invention adopts multi-grade countercurrent leaching technologies, thereby being capable of obtaining the extraction solution with high concentration, reducing the subsequent concentration links, saving the energy consumption and reducing the loss of tea flavor; the addition of the auxiliary materials can play an embedding role, therefore, the loss of the tea flavor and the flavor matter contents in the spraying process can be reduced, the better tea flavor and the mellow mouthfeel can be brought after the instant tea powder is mixed with powdered milk and simultaneously the liquidity of the instant powder can be improved; and the granularity of the instant powder can be controlled better by the steps of spraying and drying.

Owner:婺源县聚芳永茶业有限公司

Processing method for cold instant white tea powder

The invention relates to a method for processing coldly-dissolved white tea powder. White tea is used as a raw material and is added with water in proper amount for extraction; extracting solution is obtained by the procedures of filtration, enzymolysis, condensation, drying and the like; during extraction, iso-ascorbyl sodium accounting for 0.03 percent of water content is added into water, thereby playing a role in color protection to the tea extracting solution and oxidation resistance, effectively reserving tea polyphenol and other effective components in tea leaves and reserving the original flavor of the tea leaves as much as possible; the tea extracting solution is filtered and added with 0.1 percent tannase for enzymolysis (the tannase is added according to the content of a solid-containing substance), thereby reducing the bitter and harsh taste, improving the mouthfeel and increasing the quality of a product; the product is refrigerated and kept stand to improve the solubility of the product in order that the product can be dissolved into ice water at a temperature of between 5 and 8 DEG C and is convenient to drink.

Owner:DAMIN FOODSTUFF ZHANGZHOU CO LTD

Preparation method of instant dissolution spice particles

The invention relates to a preparation method of instant dissolution spice particles. Supercritical CO2 fluid is used for extracting spice powder; after the separation, spice resin crude oil and spice slag materials can be obtained; then, the spice resin crude oil is sequentially subjected to water separation and emulsification; next, obtained materials are stirred and mixed with spice slag materials subjected to ultrafine crushing; the mixed materials are subjected to pulp making, granulation and drying; the finally prepared instant dissolution spice particles can maintain the original flavor of the spice to the maximum degree; the concentration of the active ingredients in the instant dissolution spice particles is much higher than that of the spice raw materials; in addition, in the use process, the instant dissolution spice particles provided by the invention can be directly dissolved in water; the effective ingredients can be completely released; no solid residue remains; the product utilization rate is as high as 90 percent or more; the shelf life of the instant dissolution spice particles is long; the flavor loss is small after the long time placement; the agglomeration cannot easily occur.

Owner:QINGDAO H EXTRACT CO LTD

Red chili oil needle mushrooms with pickled peppers flavor and production method of mushrooms

ActiveCN103535700AAvoid damageMake up for the shortcomings of single tasteFood preparationBiotechnologyEdible oil

The invention discloses red chili oil needle mushrooms with pickled peppers flavor and a production method of the mushrooms. The red chili oil needle mushrooms are prepared from the following raw materials in parts by weight: 100 parts of needle mushrooms, 20-50 parts of pickled peppers, 2-8 parts of dry chilies, 4-30 parts of edible oil, 1-6 parts of table salt, 0-3 parts of white sugar, 0.1-4 parts of spices, 0.5-2 parts of gourmet powder and 0.5-5 parts of ginger. The needle mushrooms with the pickled peppers are prepared by process steps provided by the invention and have the advantages of strong appetite feeling, appetite promotion and the like.

Owner:CHENGDU GOLDENZONE IND DEV

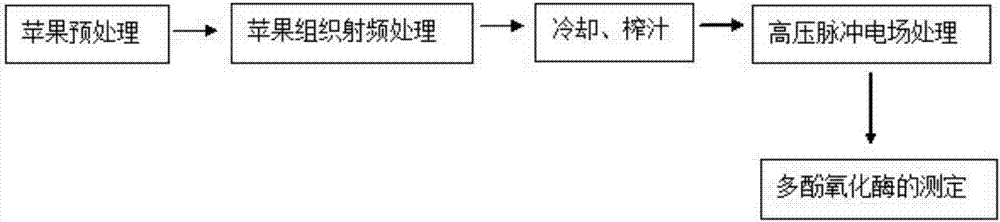

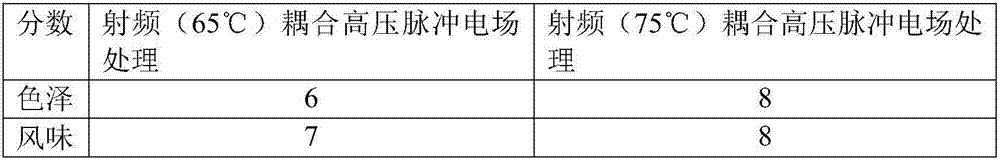

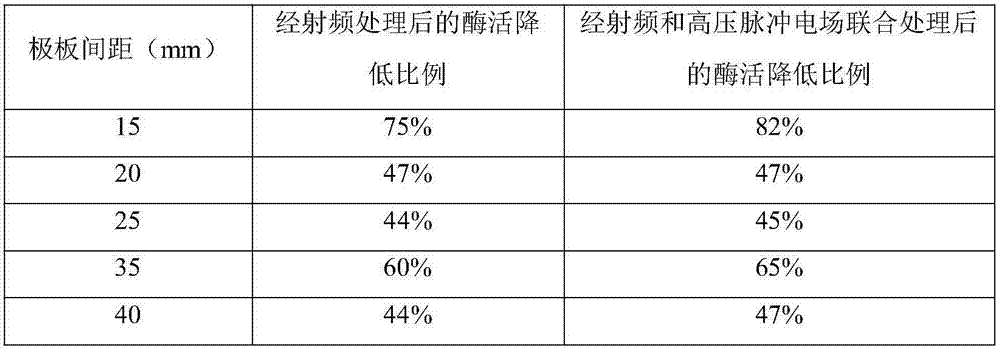

Fruit and vegetable juice processing method by radio frequency coupling high-voltage pulse electric field processing

ActiveCN107183445AStrengthen the effect of blunt enzymeReduces flavor loss and quality degradationFood thermal treatmentFood electrical treatmentRadio frequencyProduct processing

The invention discloses a fruit and vegetable juice processing method by radio frequency coupling high-voltage pulse electric field processing, and belongs to the field of farm product processing. According to the method, in an apple juice production process, apple tissues are subjected to radio frequency enzyme inactivation processing; for the radio frequency processing, a radio frequency continuous processing device disclosed in the patent application of CN104782758A and OSU-4L type high-voltage pulse electric field continuous processing equipment in a laboratory scale are used for radio frequency processing; apple slices are fast cooled after being processed in a radio frequency processing cavity, and are extruded into juice; then, the apple juice is processed by a high-voltage pulse electric field. The processing method has the advantages that 70 to 80 percent of activity of polyphenol oxidase can be passivated; the enzyme inactivation effect is good; the apple juice browning can be better prevented; meanwhile, the flavor loss of the apple juice can be reduced; the nutrition and the quality of apples is ensured.

Owner:JIANGNAN UNIV

Coffee concentrated solution and preparation method thereof

The invention discloses a coffee concentrated solution and a preparation method thereof, wherein the coffee concentrated solution is prepared by taking green coffee bean powder, adding water for extraction, performing filtration, collecting a filtrate and a filter residue, separating fragrance of the filtrate, stacking an enzyme solution on the filter residue, baking to prepare baked coffee grounds, adding water in the baked coffee grounds for extraction, performing filtration, collecting a filtrate, separating fragrance of the filtrate, using ceramic membrane to filter a trapped fluid, concentrating until Brix is 30-60%, obtaining coffee pulp, and mixing the fragrance parts of the two stages with the coffee pulp to prepare the coffee concentrated solution with the Brix up to 20-50%. The loss of the flavor of the coffee concentrated solution is low, the coffee concentrated solution is mellow and has no warmed-over flavor, scorched flavor or astringent flavor, the fragrance is real, and the quality is high.

Owner:陈爱梅

Low-salt liquid state fermented soy sauce production process

The invention discloses a low-salt liquid state fermented soy sauce production process, comprising the following main processes: preparing koji in a koji-maker machine; mixing the wheat which is fried and smashed with koji, inoculating the mixture in soybean meal and bran which are cooked; preparing finished koji in a koji making disc machine; mixing the finished koji with brine, sending the mixture in a fermenting vat for fermentation; preparing the finished soy sauce through soaking, pouring oil, filtrating, mixing, sterilizing and filling to obtain the finished soy sauce. The soy sauce is characterized in that materials containing zygosaccharomyces Rouxii 2.180 accounting for 1.5-2.5% of the total weight of materials and torulopsis candida 2.202 accounting for 1.5-2.5% of the total weight of materials are added during the medium term of the fermentation process and the raw materials--soybean meal and bran are cooked by high temperature short-time continuous cooking process. Compared with the prior art, the raw material digestion rate can reach 88-90%, the protein utilization rate can reach 83%, the activity of neutral protease of the finished koji can reach 2000mu / g, the enzymesystem is complete, the defects such as long period of high-salt liquid state fermentation (180 days), burnt flavour and heavy bitter taste of low-salt solid state fermentation and the like are overcame and the produced soy sauce is characterized by strong soysauce-like aroma, alcohol-like aroma and ester-like aroma and the like.

Owner:QIANHE CONDIMENT & FOOD CO LTD

Orange flower honey purifying equipment and process

The invention provides an orange flower honey purifying equipment and process. An orange flower honey is melted at a low temperature, filtered to remove impurities, sterilized, further melted to be crystallized into cores and concentrated, so that the quality of the orange flower honey can be improved, flavor and nutrition loss are reduced and an orange flower honey product with no pollution, uniform taste, original flavor and rich nutrition is produced; and the process provided by the invention has the advantages of reasonable step design, convenience in operation and easiness in promotion.

Owner:YICHANG ZIYUAN FOOD

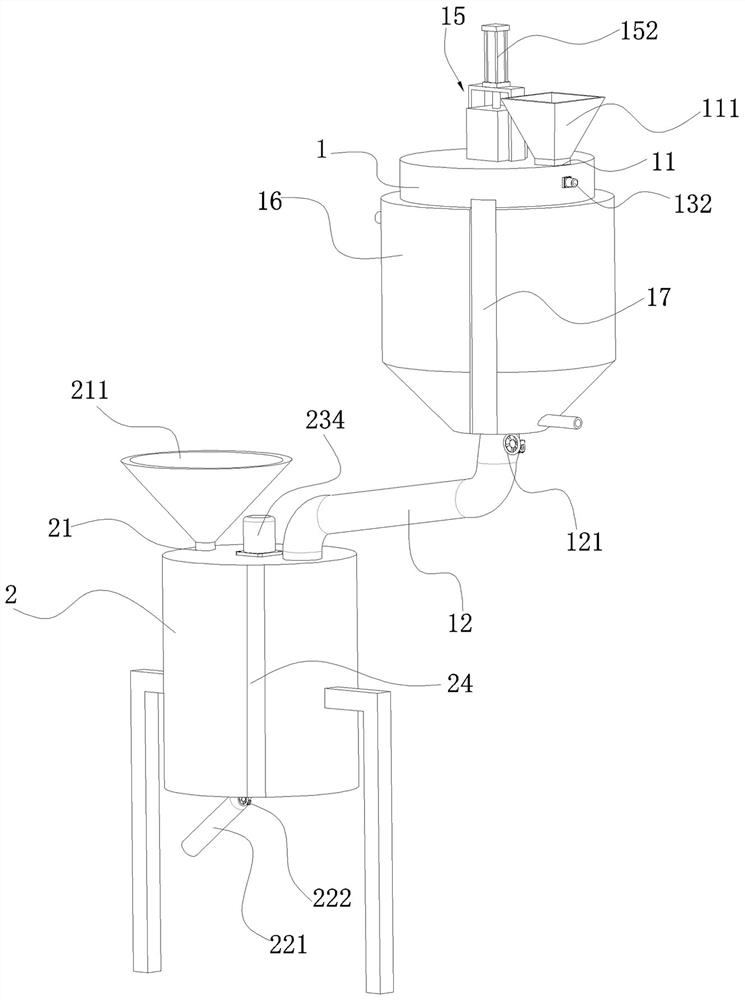

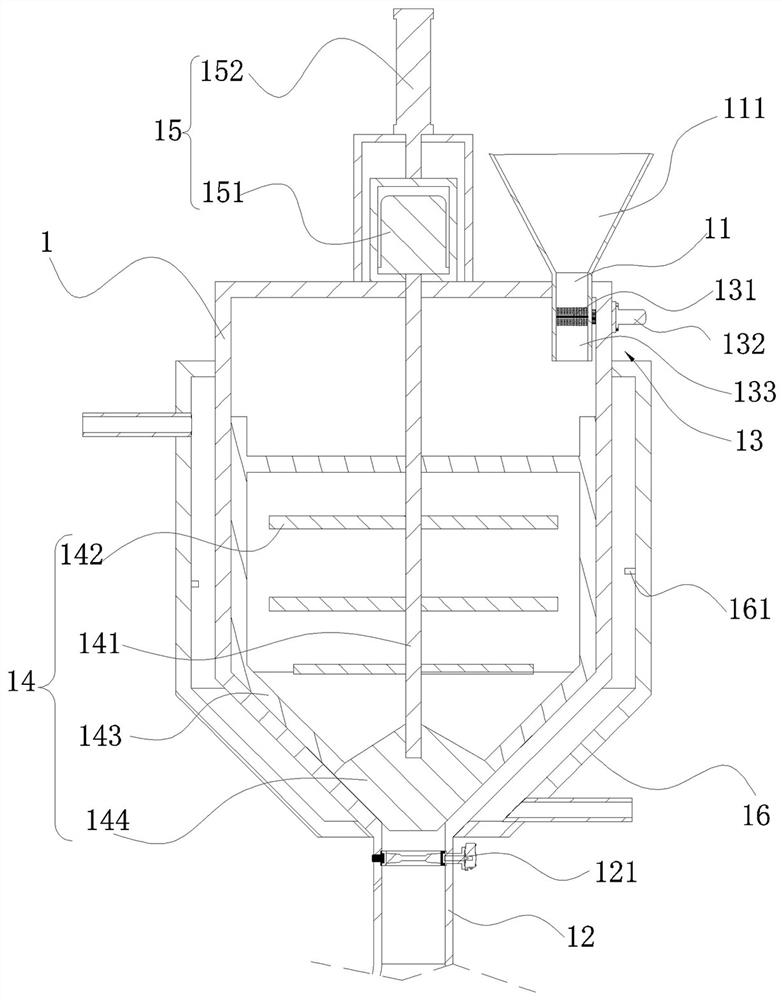

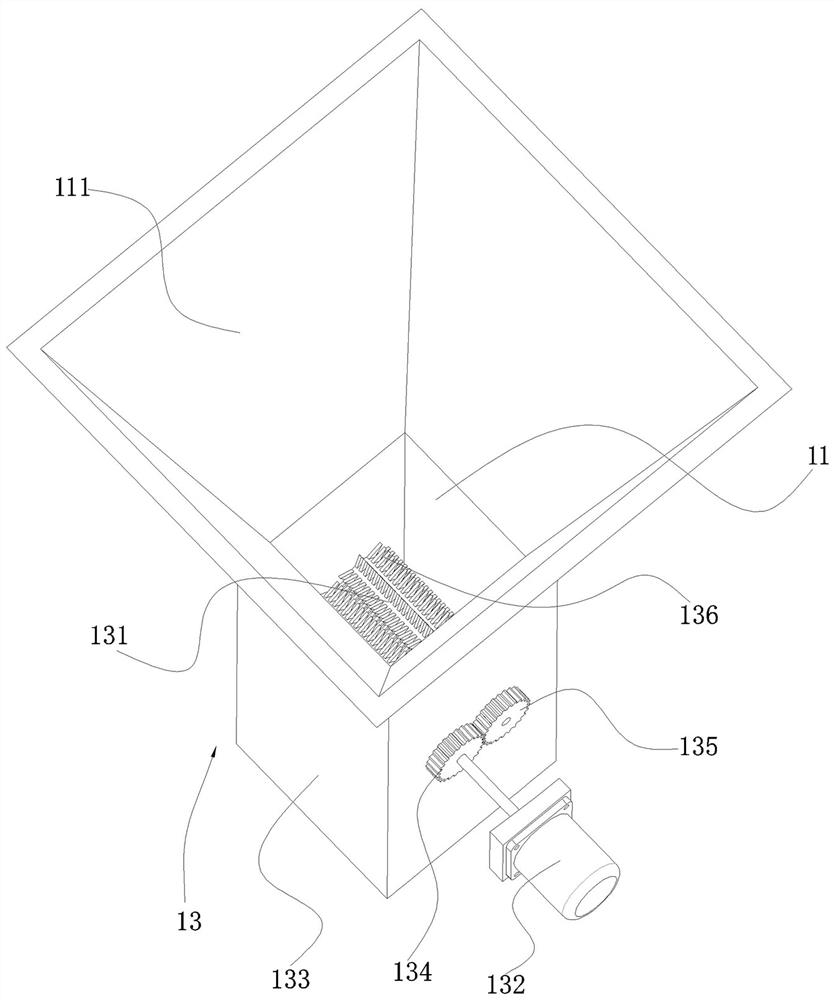

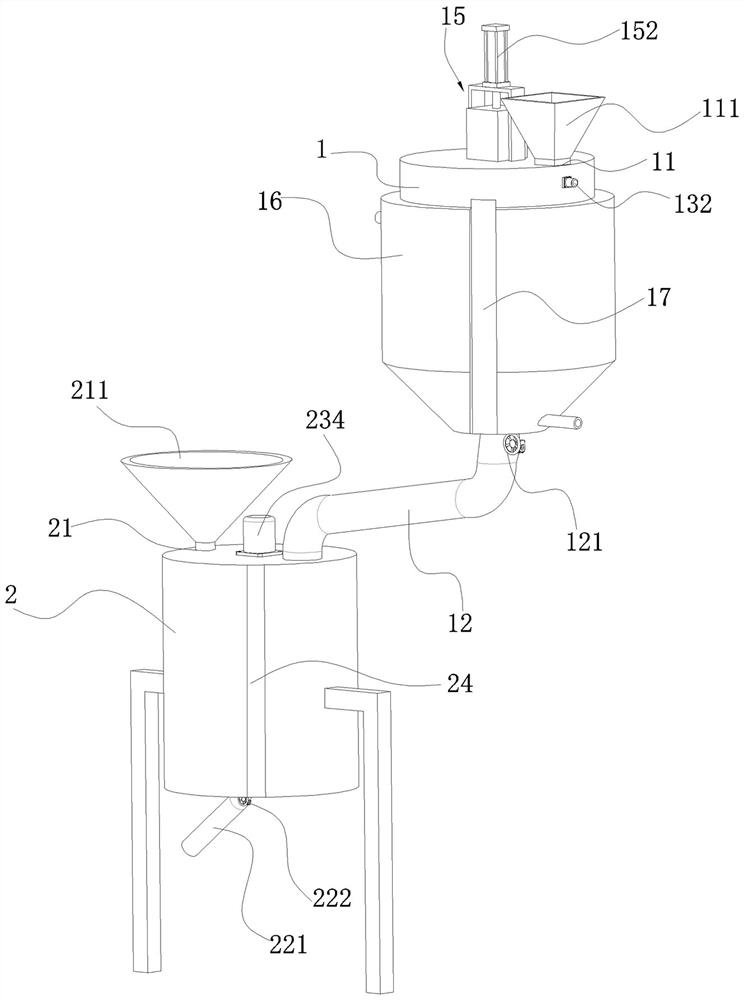

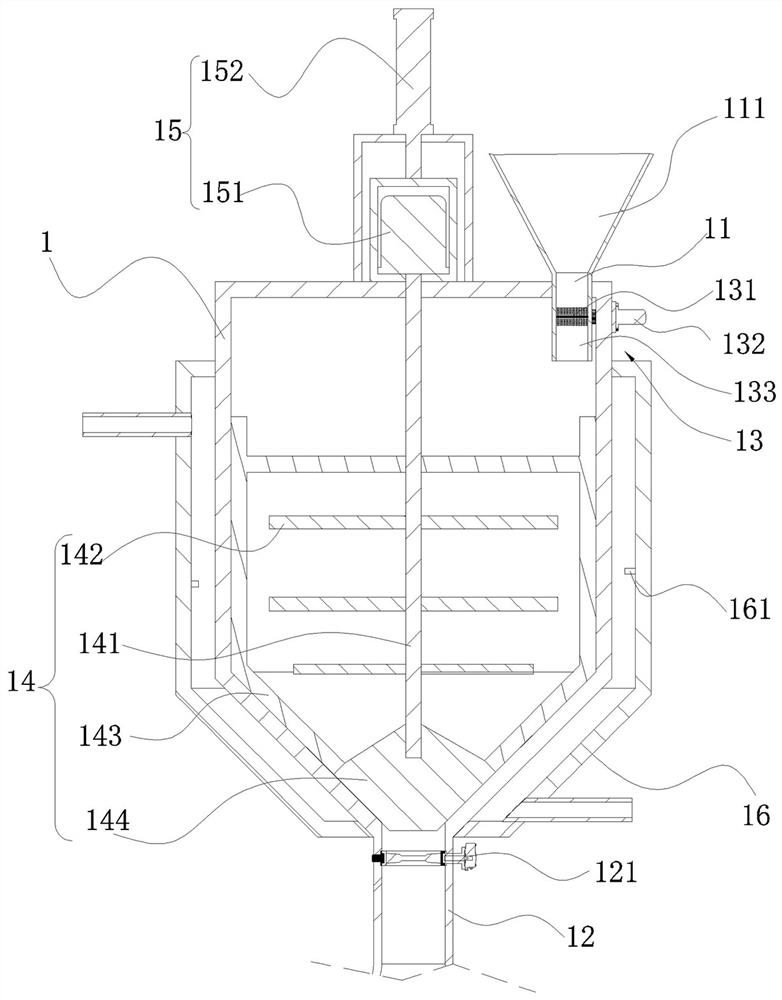

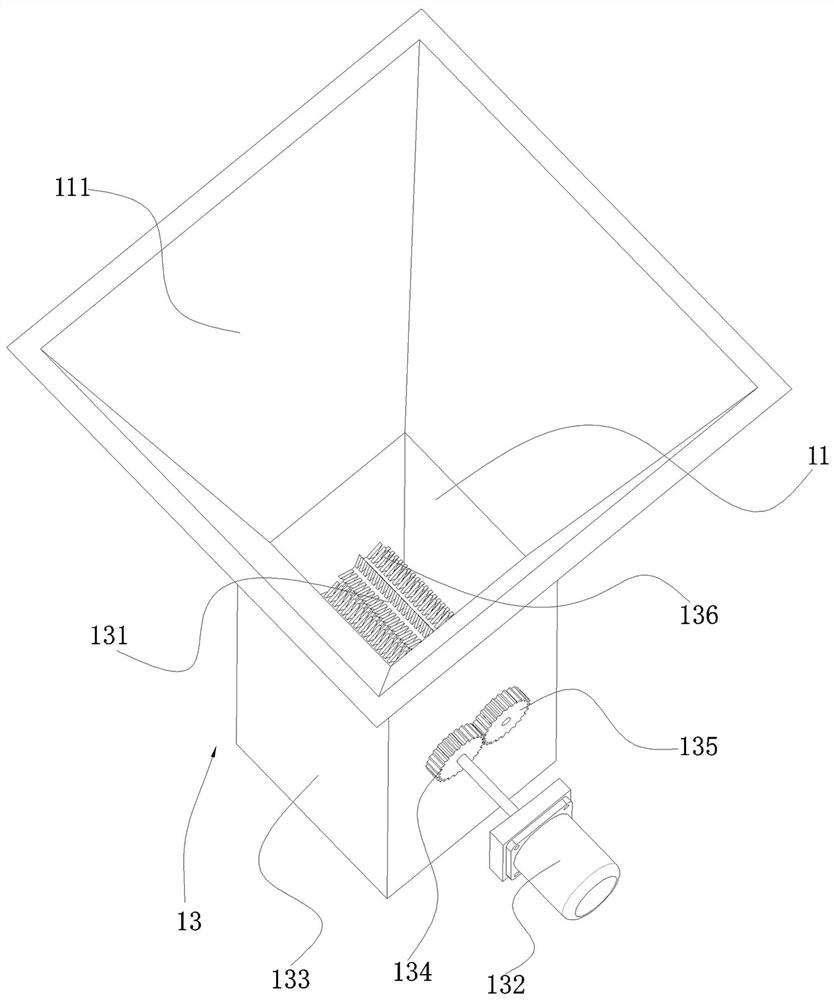

Mixing device for producing fruit mousse and using method

ActiveCN112657413AImprove solubilityImprove finenessMixer accessoriesMixing materials pretreatmentGelatinBiology

The invention relates to a mixing device for producing fruit mousse and a using method, and belongs to the field of mixing equipment, the mixing device comprises a dissolving barrel, a feeding port is formed in the top end of the dissolving barrel, a crushing device is arranged at the position, close to the feeding port, of the dissolving barrel, a stirring and hammering device is arranged in the dissolving barrel, and a temperature control jacket is arranged outside the dissolving barrel; a first discharging pipe is arranged at the bottom end of the dissolving barrel in a penetrating mode, a first discharging valve is arranged on the first discharging pipe, the end, away from the dissolving barrel, of the first discharging pipe is fixedly connected and communicated with a mixing tank, a feeding port is formed in the top end of the mixing tank, and a discharging port is formed in the bottom end of the mixing tank. Fruit and gelatin are crushed through the crushing device and stirred and beaten through the stirring and hammering device, on one hand, the fineness of puree is improved, the taste of a finished product is improved, on the other hand, the gelatin is crushed into small pieces and can be quickly dissolved into fruit pulp, and effective mixing of the gelatin and the fruit pulp is achieved at a low temperature; and the mouth feel and the flavor of the mousse are improved.

Owner:莱阳永安食品有限公司

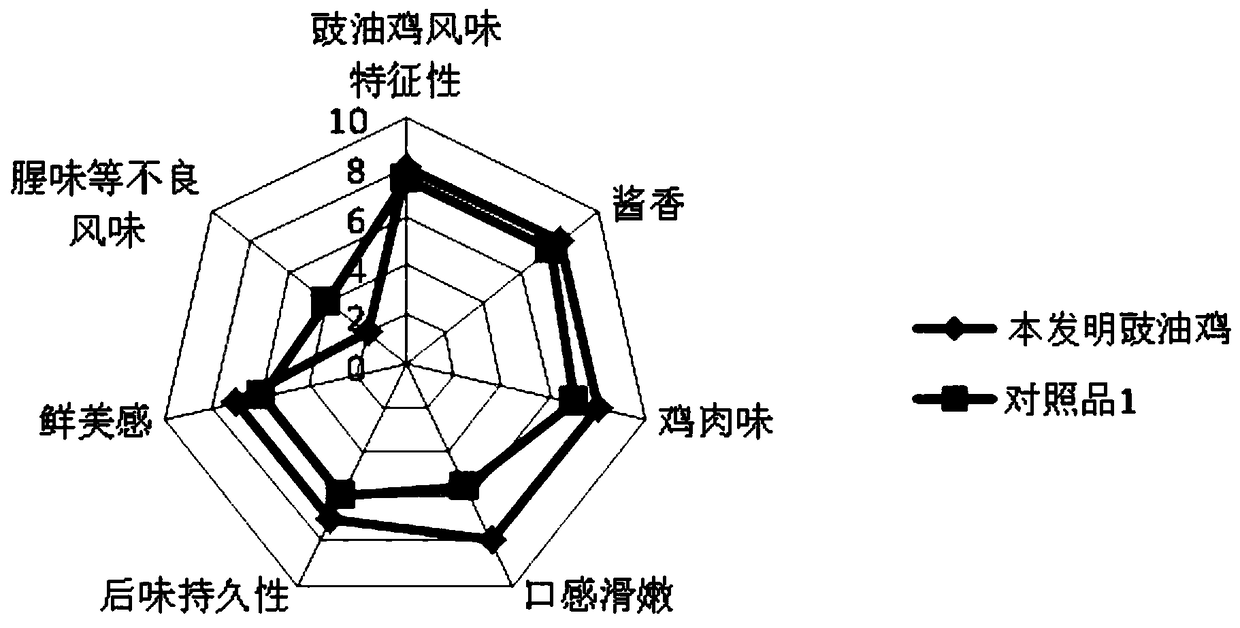

Preserving seasoning for soy-poached chicken, making method of preserving seasoning, preserved products using preserving seasoning, and preparation method of preserved products

The invention relates to a preserving seasoning for a soy-poached chicken. The preserving seasoning comprises the following components in parts by weight of 5-10 parts of table salt, 5-10 parts of monosodium glutamate, 20-30 parts of white granulated sugar, 5-10 parts of crystal sugar, 20-50 parts of spice, 2-5 parts of soy sauce powder, 1-3 parts of sesame oil and 5-10 parts of acetylated distarch phosphate. The preserving seasoning for a soy-poached chicken is prepared from various spices and other ingredients, has rich composite spice flavor, is rich in sauce fragrance, and has good effectsof removing fishy smell and increasing aroma. Products using the preserving seasoning can be richer in taste, fresher and tender in meat quality, full of juice and smooth and tender in mouth feel, and fishy smell of meat products can be effectively removed. Besides, the preserving seasoning for a soy-poached chicken also fills in the blank of markets, the making time for the soy-poached chicken is greatly shortened, the operation steps are simplified, driving force is provided for promotion of conventional dainty, and new kinds are provided for trade of quick-frozen conditioning products.

Owner:SHANDONG TIANBO FOOD INGREDIENTS

American Buffalo spicy chicken wing seasoning and preparation method and using method thereof

The invention discloses an American Buffalo spicy chicken wing seasoning. The seasoning comprises the following components in parts by weight: 1 to 2 parts of Buffalo chili sauce essence, 5 to 10 parts of Mexican chili powder, 3 to 5 parts of cheese powder, 1 to 3 parts of butter powder, 5 to 10 parts of garlic powder, 1 to 5 parts of onion powder, 2 to 5 parts of minced black pepper, 1 to 2 partsof minced parsley, 20 to 30 parts of edible salt, 1 to 10 parts of white granulated sugar, 10 to 20 parts of monosodium glutamate, 5 to 10 parts of starch, 0.5 to 1 part of capsicum oleoresin, 0.5 to1 part of capsanthin, 1 to 5 parts of a composite acidulant, 1 to 5 parts of yeast extract and 1 to 2 parts of silicon dioxide. The seasoning integrates the pungent taste of the Mexican chili powderand the sour taste of the composite acidulant, is added with auxiliary materials such as the Buffalo chili sauce essence and the cheese powder so as to perfectly present the unique flavor of AmericanBuffalo spicy chicken wings, is natural and harmonious, meets the requirements of consumers, fills the blank of the market, and enriches the variety of compound seasonings.

Owner:SHANDONG TIANBO FOOD INGREDIENTS

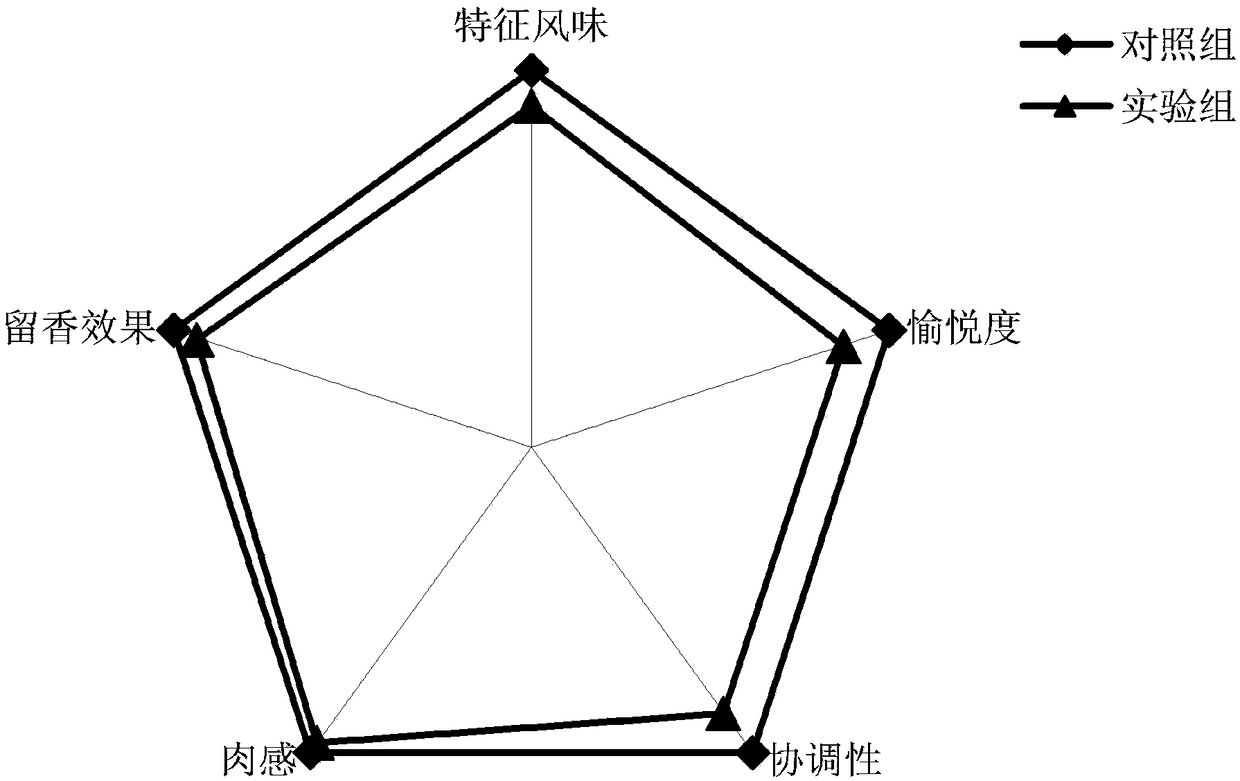

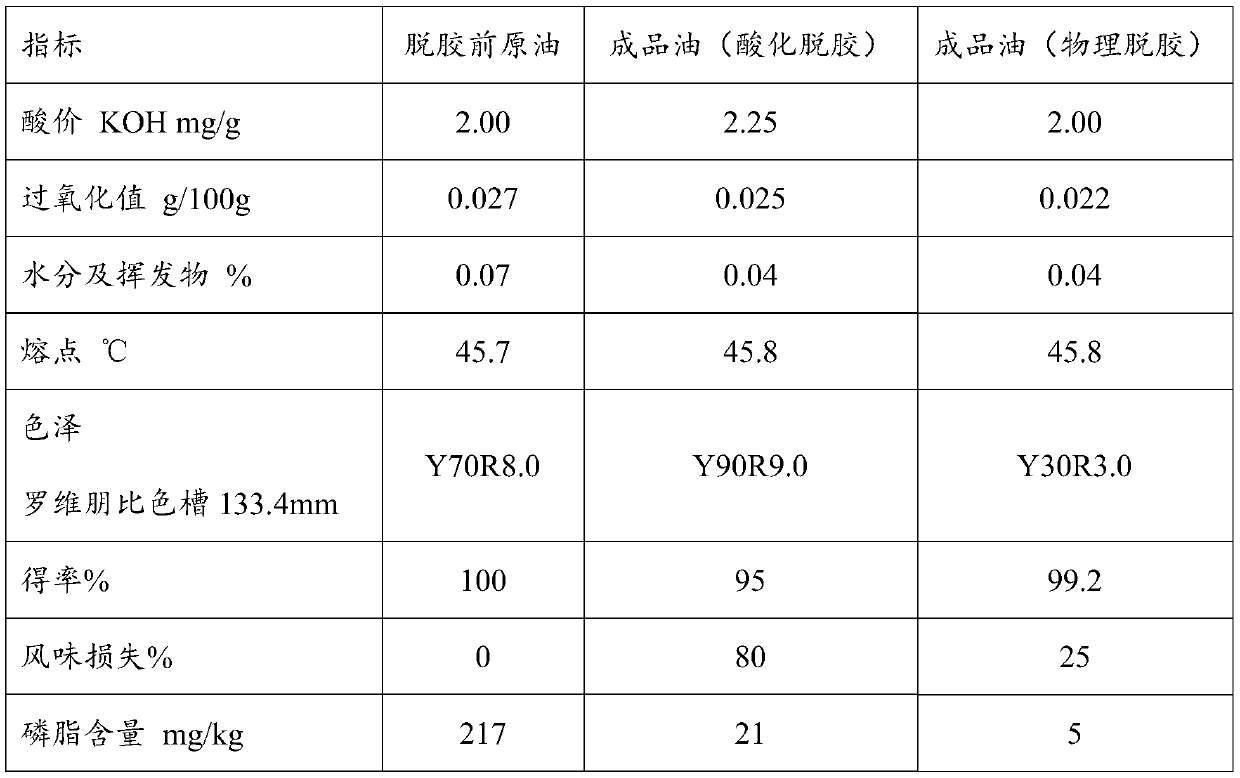

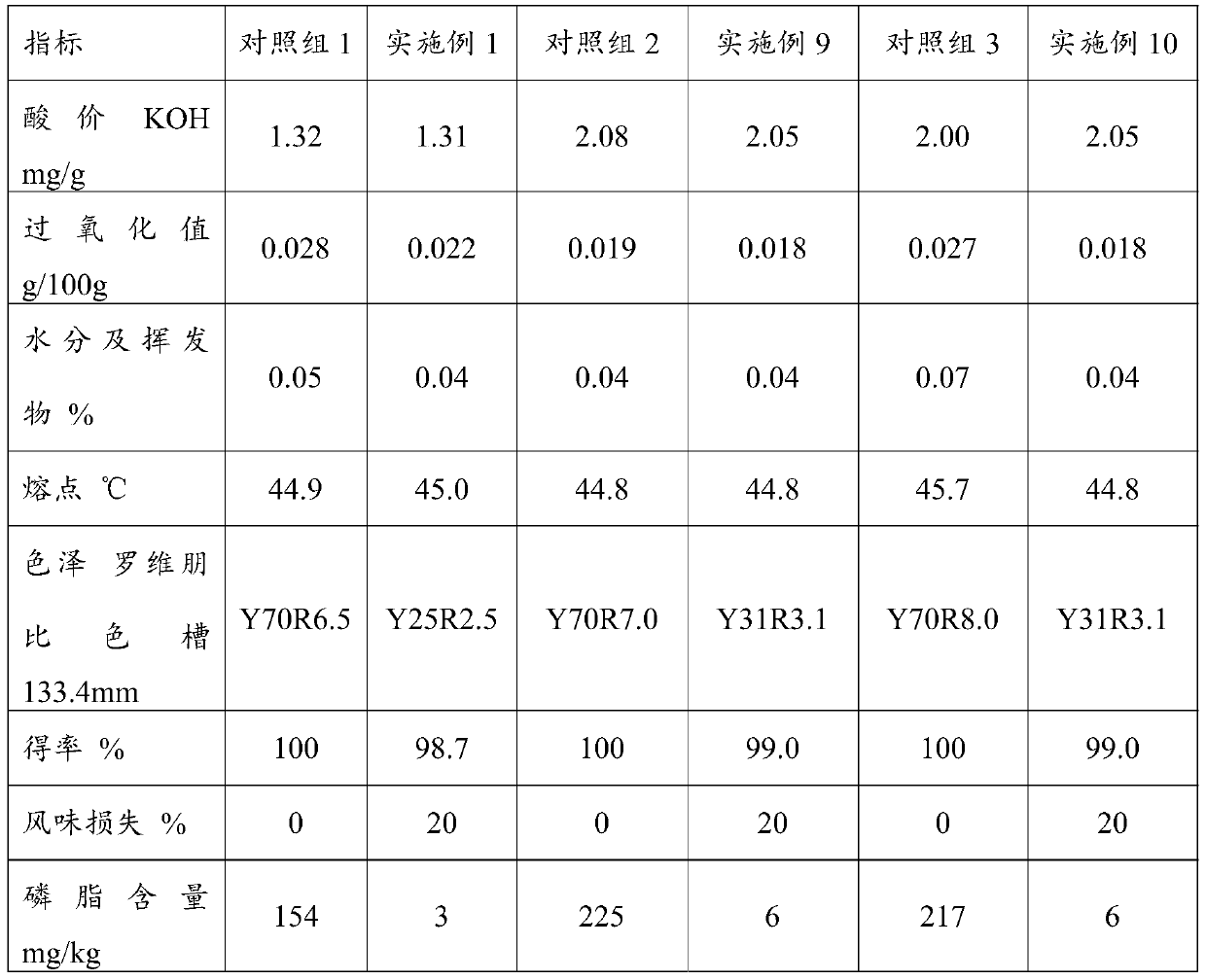

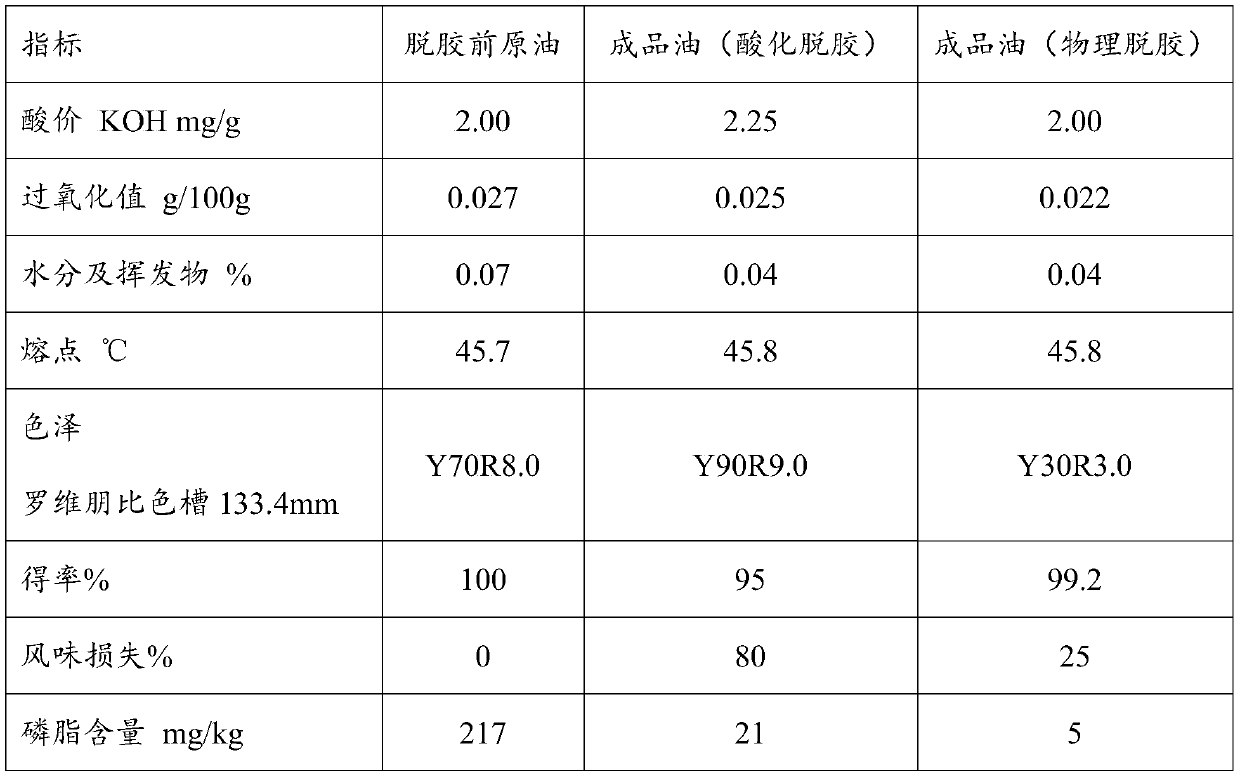

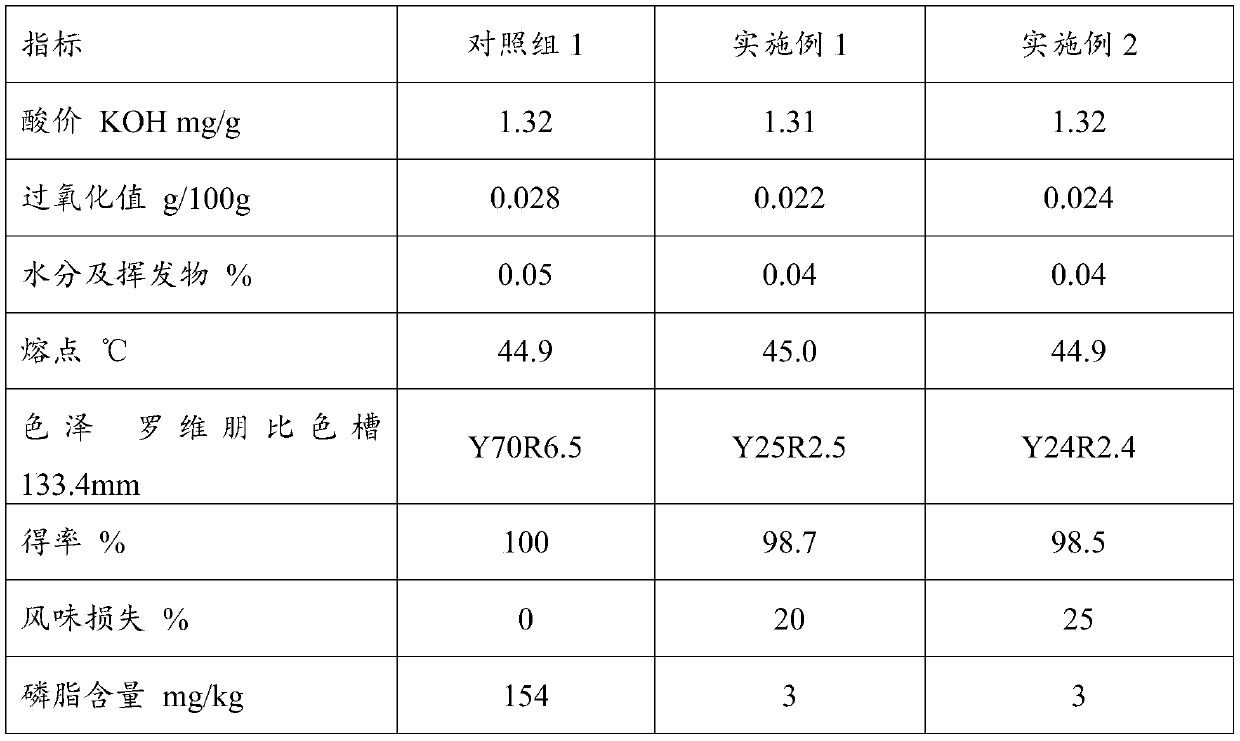

Degumming adsorbent for hotpot beef tallow and application of degumming adsorbent

InactiveCN110548480AImprove degumming effectLow costOther chemical processesFatty-oils/fats refiningFood flavorSilicon dioxide

The invention provides a degumming adsorbent for hotpot beef tallow. The degumming adsorbent comprises silicon dioxide and a filter aid, and the filter aid comprises perlite and / or diatomite. The degumming adsorbent can be applied to the degumming technology of the hotpot beef tallow, animal oil and fat and vegetable oil and fat. By adopting the degumming adsorbent, the advantage of low cost is achieved, and the degumming effect is significant; the beef tallow obtained from degumming is light in chrominance, high in yield and low in flavor loss, and the original flavor of the beef tallow is maintained.

Owner:GUANGHAN MAIDELE FOOD CO LTD

Processing method of hypsizygus marmoreus quick-frozen product

PendingCN113662038AShort storage timeLess Flavor LossFood freezingFood thermal treatmentEconomic benefitsEngineering

The invention provides a processing method of a hypsizygus marmoreus quick-frozen product, and belongs to the technical field of food processing. The processing method of the hypsizygus marmoreus quick-frozen product comprises the steps of pre-freezing, soaking, blanching, draining, quick-freezing, ice glaze plating and the like. According to the method, the storage time of the hypsizygus marmoreus can be remarkably prolonged, and the inhibition effect on the activity of polyphenol oxidase in the hypsizygus marmoreus reaches 95%. The quick-frozen hypsizygus marmoreus product prepared by adopting the technical scheme not only keeps good appearance, but also keeps the special flavor and nutritional ingredients of hypsizygus marmoreus, and the method has the characteristics of simple process and low cost, can realize large-scale industrial production, and has good economic benefits.

Owner:福建省顺昌县饶氏佰钰食品有限公司

Chili sauce pickled-pepper-flavor auricularia cornea ehrenb and making method thereof

The invention discloses chili sauce pickled-pepper-flavor auricularia cornea ehrenb and a making method of the chili sauce pickled-pepper-flavor auricularia cornea ehrenb. The chili sauce pickled-pepper-flavor auricularia cornea ehrenb comprises the following components by weight: 150-200 parts of auricularia cornea ehrenb, 4-100 parts of rod chili, 4-16 parts of dried chili, 6-150 parts of edibleoil, 0.2-0.4 part of citric acid, 0.15-0.2 part of glacial acetic acid, 0.7-1.0 part of white spirit, 0.4-0.6 part of sodium hexametaphosphate, 0.2-0.4 part of sodium diacetate, 2-12 parts of refinedsalt, 3-6 parts of white granulated sugar, 0.2-8 parts of spice, and 1-4 parts of aginomoto. The chili sauce pickled-pepper-flavor auricularia cornea ehrenb is sour, spicy and tasty and arouses the high appetite, the special matching mode of the chili sauce pickled pepper and the auricularia cornea ehrenb makes up the defect of single flavor of the auricularia cornea ehrenb, so that a novel auricularia cornea ehrenb product is further popularized and applied, meanwhile, a brand new instant auricularia cornea ehrenb product is also created, and has a broad market prospect.

Owner:JILIN AGRICULTURAL UNIV

Processing method for cold instant white tea powder

The invention relates to a method for processing coldly-dissolved white tea powder. White tea is used as a raw material and is added with water in proper amount for extraction; extracting solution is obtained by the procedures of filtration, enzymolysis, condensation, drying and the like; during extraction, iso-ascorbyl sodium accounting for 0.03 percent of water content is added into water, thereby playing a role in color protection to the tea extracting solution and oxidation resistance, effectively reserving tea polyphenol and other effective components in tea leaves and reserving the original flavor of the tea leaves as much as possible; the tea extracting solution is filtered and added with 0.1 percent tannase for enzymolysis (the tannase is added according to the content of a solid-containing substance), thereby reducing the bitter and harsh taste, improving the mouthfeel and increasing the quality of a product; the product is refrigerated and kept stand to improve the solubility of the product in order that the product can be dissolved into ice water at a temperature of between 5 and 8 DEG C and is convenient to drink.

Owner:DAMIN FOODSTUFF ZHANGZHOU CO LTD

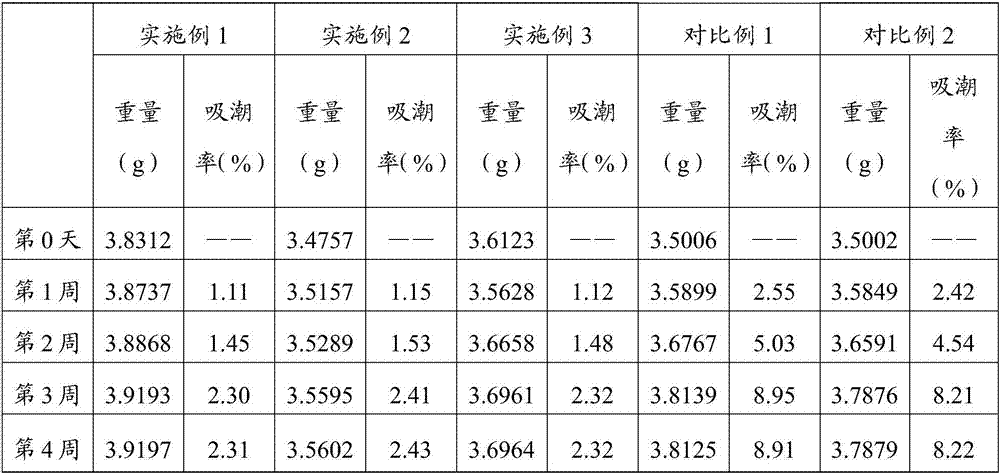

Kelp gourmet powder and preparation method thereof

InactiveCN107095251ARetain nutrientsLong-lasting umami tasteFood preservationFood coatingMonosodium glutamateFlavor

The invention provides kelp gourmet powder and a preparation method thereof. The preparation method includes following steps: step 1, drying and crushing cleaned kelp, and enabling the kelp to pass a sieve with 200-300 meshes to obtain kelp powder; step 2, mixing edible salt, spice, freshener, pregelatinized starch and the kelp powder obtained in the step 1, granulating, and drying to obtain kelp gourmet powder granules; step 3, using a moistureproof coating material to prepare coating liquid of 3-10wt% in solid content, spraying the coating liquid onto the kelp gourmet powder granules obtained in the step 2, and drying to obtain the kelp gourmet powder. The preparation method is simple in process, convenient to control and capable of effectively maintaining original nutritional ingredients of kelp; the prepared kelp gourmet powder has strong flavor of natural kelp, is safer and healthier, more lasting in flavor and good in moistureproof performance.

Owner:FUJIAN YIDA FOOD CO LTD

A mixing device for producing fruit mousse and its use method

ActiveCN112657413BImprove finenessGreat tasteMixer accessoriesMixing materials pretreatmentTemperature controlEngineering

Owner:莱阳永安食品有限公司

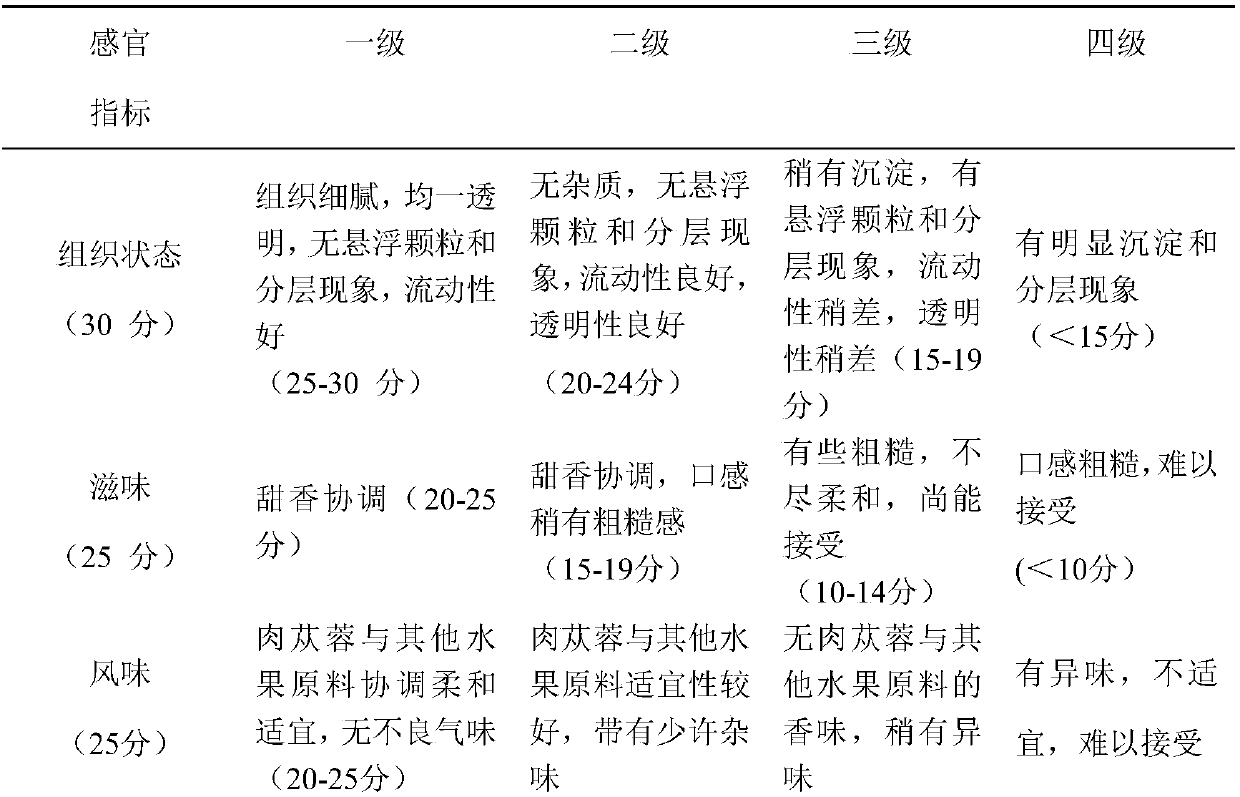

Fruit beverage with herba cistanche and preparation method thereof

InactiveCN107772177AEffectively preserve the tasteMask bitternessFood ingredient functionsTraditional medicineSugar

The invention belongs to the technical field of beverages and particularly relates to a fruit beverage with herba cistanche and a preparation method thereof. Per 100 parts of the fruit beverages are prepared from the following raw materials in parts by weight: 1-4 parts of herba cistanche juice, 3-8 parts of grape juice, 1-4 parts of melon juice, 1-4 parts of dried red jujube, 5-15 parts of whitegranulated sugar and the balance of water. According to the fruit beverage with herba cistanche, the herba cistanche is capable of replenishing kidney, tonifying essence and blood and relaxing bowel;the grape juice is capable of tonifying qi, nourishing blood and strengthening heart; the melon juice is capable of clearing summer heat, relieving polydipsia and inducing urination; the red jujube iscapable of tonifying deficiency, tonifying qi, nourishing blood, calming nerves, tonifying spleen and harmonizing stomach; the fruit beverage with herba cistanche is capable of tonifying qi, nourishing blood and relaxing bowel, and is good in taste.

Owner:JIANGSU KANION PHARMA CO LTD

Galangal essence as well as preparation method and application thereof

PendingCN113575906ARich flavorQuality improvementFood ingredient as flavour affecting agentBiotechnologyFood products

The invention discloses galangal essence as well as a preparation method and application thereof. The essence composition contains food spices, a flavor enhancer and plant spice oil. The seasoning powder can be applied to seasoning powder or directly used in food, and is convenient to use. Moreover, the food can be really endowed with fresh galangal flavor only under the addition amount of 0.2%-2%, the unique special pungent cool feeling and faint scent of galangal are created, the flavor of the product is enriched, the quality of the product is improved, the use amount is small, the heat resistance is high, the flavor loss in the heating process is less, the flavor is durable and stable, and the fidelity is high; and the method has extremely high application value and economic value.

Owner:GUANGZHOU HUABAO FOOD CO LTD

Degumming process of non-foaming beef tallow for hot pot

InactiveCN110616113ADegummingAlso has decolorization effectFatty-oils/fats refiningFlavorSilicon dioxide

The invention provides a degumming process for non-foaming beef tallow for a hot pot. The process comprises the following steps: S1, heating beef tallow, keeping the temperature at 60-100 DEG C, and carrying out subsequent steps; S2, adding a degumming adsorbent into the beef tallow obtained in the step S1, and fully stirring the adsorbent with the beef tallow to form a mixed solution; and S3, filtering the mixed solution obtained in the step S2 to obtain a non-foaming beef tallow finished product. In the step S2, the degumming adsorbent comprises silicon dioxide and a filter aid, and the filter aid comprises perlite and / or kieselguhr. The process has the advantages of low cost and high yield, the degumming process is simple, and the degumming effect is remarkable; the beef tallow obtainedthrough degumming is high in yield and low in flavor loss, and the original flavor of the beef tallow is kept.

Owner:GUANGHAN MAIDELE FOOD CO LTD

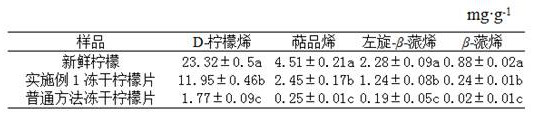

Method for improving flavor substances of dried fruit and vegetable products through combination of nanometer embedding and integrated freeze-drying

PendingCN113598333ASolving Flavor Loss ProblemsReduce energy consumptionFruit and vegetables preservationFood coatingBiotechnologyFreeze-drying

The invention relates to a method for improving the flavor of dried fruit and vegetable products, in particular to a method for improving flavor substances of the dried fruit and vegetable products through combination of nanometer embedding and integrated freeze-drying, and belongs to the technical field of fruit and vegetable drying processing. Recycled flavor substances are subjected to nano-embedding to obtain flavor nano-embedding substances, the flavor nano-embedding substances enter the porous structures of the freeze-dried fruits and vegetables through a vacuum impregnation technology, and then the flavor nano-embedding substances are exogenously added to perform vacuum freezing and freeze-drying integrated freeze-drying. The surfaces of fruits and vegetables are covered with a layer of the flavor nano-embedding substances to form internal and external fusion, the freeze-dried fruit and vegetable products are obtained, and the preparation method of the flavor nano-embedding substances are further provided, so that the freeze-dried fruit and vegetable products can emit rich fragrance and achieve a slow-release effect in the storage and eating process, flavor loss in the freeze-drying process of the fruits and the vegetables is effectively reduced, and resource waste is avoided.

Owner:NANJING XIAOZHUANG UNIV

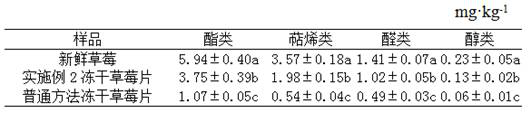

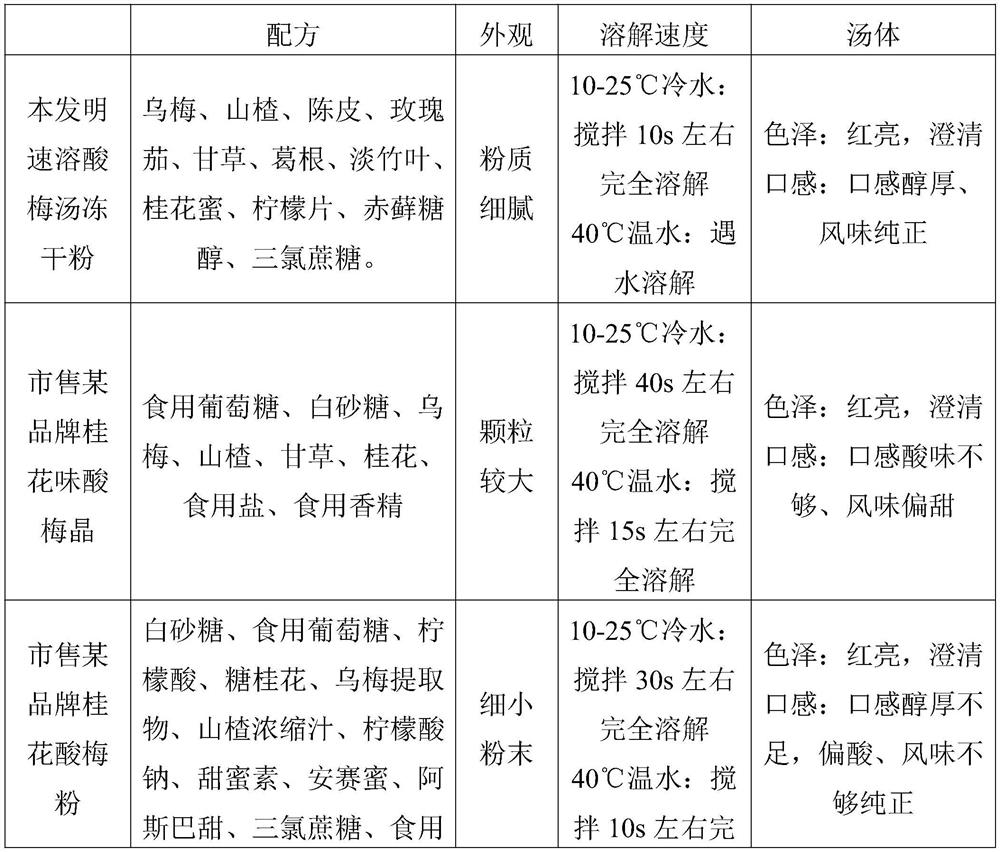

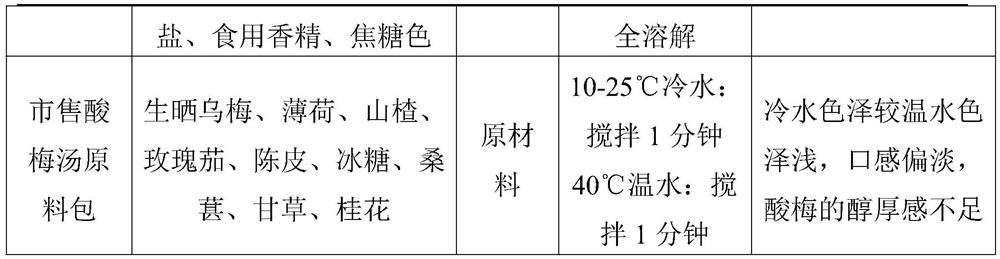

Instant plum syrup freeze-dried powder and preparation method thereof

PendingCN114568614AAvoid lostHigh active ingredientClimate change adaptationNatural extract food ingredientsBiotechnologySucrose

The invention relates to instant plum syrup freeze-dried powder and a preparation method thereof, and the instant plum syrup freeze-dried powder comprises the following raw material components: dark plum, hawthorn, dried orange peel, roselle, liquorice, kudzuvine root, lophatherum gracile, sweet-scented osmanthus honey, lemon slices, erythritol and sucralose. The plum syrup freeze-dried powder is the first type of plum syrup freeze-dried powder on the market, the plum syrup freeze-dried powder is prepared from the smoked plum, hawthorn and the like as raw materials without addition of additives such as essence and pigment by adopting extraction, cooling, filtration and freeze-drying processes, so that the loss of various nutritional ingredients and functional active ingredients in the processing process is avoided to the greatest extent; and the product can be drunk after being brewed with cold water, has strong stability within the shelf life, and is convenient to eat.

Owner:浙江顶亨生物科技有限公司

Method for preparing edible fresh-keeping film coating liquid for breakfast eggs

InactiveCN111053106AClean body and mindPrevent spoilageEggs preservation by coatingFood ingredientsBiotechnologyMenthol

The invention relates to a preparation method of an edible fresh-keeping coating liquid for breakfast eggs, and belongs to the field of food fresh-keeping technologies. Gelatin and chitosan are use aswall materials, and peppermint essential oil is microencapsulated to prepare the edible fresh-keeping film coating liquid for breakfast eggs. The microencapsulation technology is a technology of coating a solid, a liquid or a gas with a film-forming material to form tiny particles and releasing the tiny particles under certain conditions. The microencapsulation can prevent the volatilization of peppermint essential oil during storage, reduce the influence of environment during the preservation period of breakfast eggs, reduce the interaction between active components in peppermint essential oil and reduce oxidation reaction; the stability of peppermint essential oil can be effectively improved and the peppermint essential oil is free from the influence of the environment; and by embeddingthe peppermint essential oil, the volatilization of menthol in the peppermint essential oil can be effectively prevented, the flavor loss can be reduced, and the preservation time of breakfast eggs can be prolonged.

Owner:房正

Method for making dried edible mushroom

InactiveCN101433281BLimit or avoid the use ofMaintain colorFood preparationAdditive ingredientEdible mushroom

The invention discloses a method for producing preserved edible fungi. The method comprises the following steps: weighing edible fungi, white granulated sugar, malt syrup, honey, citric acid, common salt and sodium benzoate according to weight ratio; shaping bodies of the selected mushrooms; removing the impurities on the bodies of the mushrooms; subjecting the bodies of the mushrooms to color retention and blanching with a diluted citric acid solution; subjecting the bodies of the mushrooms to vacuum sugar infiltration and soaking the bodies of the mushrooms with sugar; getting out the bodies of the mushrooms, draining away water and drying the bodies of the mushrooms; and packing the bodies of the mushrooms with bags. The bodies of the mushrooms allow for quick sugar infiltration without being boiled during vacuum sugar infiltration treatment, have less nutrient and scent loss and uniform sugar infiltration, and can limit or avoid using sulfur dioxide, well protect organization and color and luster of products and shorten period of a production process.

Owner:高景海

Instant tea powder and processing method thereof

ActiveCN101385492BLess Flavor LossReduce subsequent enrichment linksTea extractionHigh concentrationFlavor

The invention provides a processing method of instant tea powder, which comprises the following steps: an extracted medium is mixed with tea leaves and at least one grade countercurrent leaching technology is adopted to obtain the first tea juice; the extracted first tea juice is filtered to obtain the second tea juice; a proper amount of auxiliary materials are added in the second tea juice to obtain the third tea juice; the third tea juice is pasteurized to obtain the fourth tea juice; and the fourth tea juice is then dehydrated and dried under the pressure condition to finally obtain fine and even instant powder. The extraction working procedures of the invention adopts multi-grade countercurrent leaching technologies, thereby being capable of obtaining the extraction solution with high concentration, reducing the subsequent concentration links, saving the energy consumption and reducing the loss of tea flavor; the addition of the auxiliary materials can play an embedding role, therefore, the loss of the tea flavor and the flavor matter contents in the spraying process can be reduced, the better tea flavor and the mellow mouthfeel can be brought after the instant tea powder is mixed with powdered milk and simultaneously the liquidity of the instant powder can be improved; and the granularity of the instant powder can be controlled better by the steps of spraying and drying.

Owner:婺源县聚芳永茶业有限公司

Method for concentrating pineapple stuffing

The invention discloses a method for concentrating pineapple stuffing. A conventional method for concentrating pineapple stuffing easily degrades the quality of the pineapple stuffing. Due to adoption of a method which comprises steps of pretreatment, squeezing, primary concentration and secondary concentration, and with the combination of vacuum concentration and normal-temperature concentration, the completeness of pineapple grains in the pineapple stuffing is maintained, the original flavor and the nutrition of pineapples are maintained to the maximum extent, and the phenomenon that the color of a product is darkened because of the Maillard reaction is avoided. The concentration time of a normal-temperature concentration procedure of the method is shortened by about one half when being compared with that of an ordinary process, so that the flavor loss and the nutrition loss of the pineapple stuffing are reduced, the original flavor, nutrition and color of pineapples are effectively maintained, and the product quality is further improved.

Owner:合浦果香园食品有限公司

Zanthoxylum bungeanum Baijiu and preparation method thereof

PendingCN114574312ALess Flavor LossImprove product stabilityAlcoholic beverage preparationAgainst vector-borne diseasesBiotechnologyZanthoxylum bungeanum

The invention belongs to the technical field of Baijiu preparation, and discloses pepper Baijiu and a preparation method thereof. The Chinese prickly ash flavor substance is derived from Chinese prickly ash volatile oil and Chinese prickly ash oleoresin, the Chinese prickly ash volatile oil is fully stirred and dissolved in base liquor, then the Chinese prickly ash oleoresin is mixed in the base liquor, and the Chinese prickly ash flavor mixed liquor is obtained after ultrasonic treatment. And mixing the treated staged Chinese prickly ash flavor mixed solution with the plant-derived flavor composition, and performing ultrasonic treatment to prepare the Chinese prickly ash white spirit. The Chinese prickly ash volatile oil and the Chinese prickly ash oleoresin are distributed and dissolved in a low-speed stirring and ultrasonic treatment mode, the Chinese prickly ash volatile oil in the base liquor can be fully and uniformly mixed in a system in a low-speed stirring mode, and meanwhile flavor loss is reduced. The Chinese prickly ash numb-taste substance can be fully dissolved in the white spirit, the layering or turbid phenomenon cannot be generated, and precipitates or floccules cannot be generated in the storage and transportation processes of the white spirit.

Owner:凉山州椒小郎生物科技开发有限责任公司

A kind of lemon rose compound solid drink

ActiveCN107495055BHigh flavor acceptanceCombination of good colorNatural extract food ingredientsFood ingredient functionsBiotechnologyFood colouring

Owner:拓丰粉体技术(昆山)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com