Method for improving flavor substances of dried fruit and vegetable products through combination of nanometer embedding and integrated freeze-drying

A technology for flavor substances and dried fruits and vegetables, which is applied in the field of improving the flavor of dried fruits and vegetables, nano-embedding combined with integrated freeze-drying to improve the flavor substances of dried fruits and vegetables, and can solve the problem of affecting the comprehensive quality of freeze-dried fruit and vegetable products and reducing the flavor of freeze-dried fruits and vegetables. problem, achieve the effect of solving flavor loss, reducing energy consumption and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

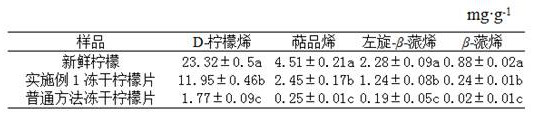

Embodiment 1

[0020] The present embodiment improves the flavor of freeze-dried fruits and vegetables by the following methods:

[0021] A method for improving flavor substances of lemon slice dry products by combining integrated freeze-drying with nano-embedding, comprising the following steps:

[0022] The first step is to screen raw materials and select fresh lemons without mechanical damage and mildew as raw materials;

[0023] The second step, cleaning and cutting, cleaning the lemon, cutting the lemon into lemon discs with a thickness of 5mm;

[0024] The third step is vacuum freeze-drying. Turn on the refrigeration device in the freeze dryer, freeze the lemon slices at -40°C for 4 hours, turn on the vacuum pump in the freeze dryer, evacuate until the pressure reaches below 30Pa, and turn on the freeze dryer. Heating device, vacuum freeze-drying for 10 hours, complete the sublimation drying, and obtain the semi-finished product of freeze-dried lemon slices with a porous network struc...

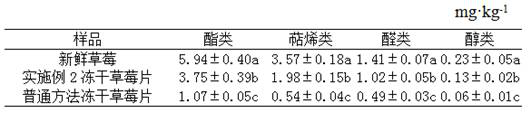

Embodiment 2

[0031] The present embodiment improves the flavor of freeze-dried fruits and vegetables by the following methods:

[0032] A method for improving the flavor of dried strawberry products through nano-embedding combined with integrated freeze-drying, comprising the following steps:

[0033] The first step is to screen raw materials and select fresh strawberries without mechanical damage and mildew as raw materials;

[0034] The second step, cleaning and cutting, cleaning the strawberries, cutting the strawberries into strawberry slices with a thickness of 5mm;

[0035] The third step is vacuum freeze-drying. Turn on the refrigeration device in the freeze-dryer, freeze the strawberry slices at -40°C for 4 hours, turn on the vacuum pump of the freeze-dryer, and vacuum the freeze-drying chamber until the pressure reaches below 30Pa, then start the freeze-drying process. Machine heating device, vacuum freeze-drying for 8 hours, complete sublimation drying, and obtain freeze-dried s...

Embodiment 3

[0044] The present embodiment improves the flavor of freeze-dried fruits and vegetables by the following methods:

[0045] A method for improving flavor substances of dried garlic products through nano-embedding and integrated freeze-drying, comprising the following steps:

[0046] The first step is to screen raw materials and choose fresh garlic without mechanical damage and mildew as raw materials;

[0047] The second step, cleaning and cutting, cleaning the garlic, peeling the garlic and cutting it into garlic slices with a thickness of 5 mm;

[0048] The third step, blanching and finishing, blanching the sliced garlic slices in hot water at 90°C for 1 minute, cooling in cold water and draining;

[0049] The fourth step is vacuum freeze-drying. Turn on the refrigeration device in the freeze-drying machine, freeze the garlic slices at -40°C for 4 hours, turn on the vacuum pump of the freeze-drying machine, and vacuum the freeze-drying chamber until the pressure reaches be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com