Kelp gourmet powder and preparation method thereof

A technology of kelp and monosodium glutamate, which is applied in the field of seasoning processing, can solve the problems of a large amount of residue, complex process, and long enzymatic hydrolysis time, and achieve the effects of reducing residue generation, simple process steps, and reducing flavor loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

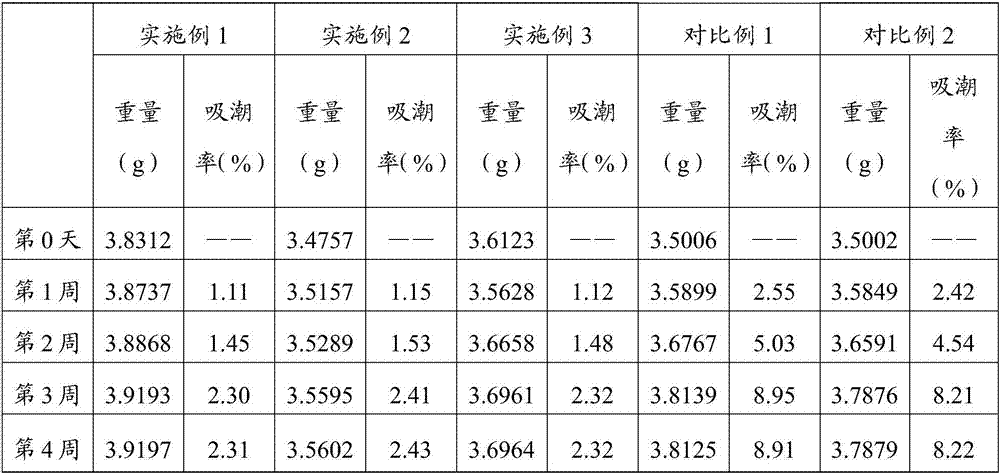

Examples

preparation example Construction

[0015] The invention provides a kind of preparation method of kelp monosodium glutamate, comprising the following steps:

[0016] Step 1: drying and pulverizing the washed kelp, passing through a 200-300 mesh sieve to obtain kelp powder;

[0017] Step 2: mix edible salt, spices, freshness enhancer, pregelatinized starch and the kelp powder of step 1, granulate and dry to obtain kelp monosodium glutamate granules;

[0018] Step 3: The moisture-proof coating material is prepared into a coating solution with a solid content of 3-10 wt%, and the coating solution is sprayed onto the kelp monosodium glutamate particles in step 2, and then dried to obtain a finished product of kelp monosodium glutamate.

[0019] The working principle of the present invention is: during the coating process, when the kelp monosodium glutamate granules rotate in the coating equipment, the coating liquid is sprayed out with fine droplets at the same time, reaching the surface of the kelp monosodium gluta...

Embodiment 1

[0035] A preparation method of kelp monosodium glutamate, comprising the following steps:

[0036] Step 1: remove moth-eaten kelp and rotten kelp, then wash the kelp, then freeze-dry the washed kelp until the water content is lower than 5wt%, then cut it into blocks and put it in a grinder for crushing, and then pass 200 mesh sieves to obtain kelp powder;

[0037] Step 2: Take by weighing 100g edible salt, 10g spices, 80g amino acid liquid (the mass concentration of ornithine in the amino acid liquid is 10%, the mass concentration of glutamic acid is 40%, and the mass concentration of aspartic acid is 20%) 100g of pregelatinized starch and 500g of kelp powder from step 1 are placed in a blender and fully stirred and mixed, then granulated in a granulator, and baked at 70°C for 1 hour to obtain kelp monosodium glutamate granules;

[0038] Step 3: Take hydroxypropyl cellulose to prepare a coating solution with a solid content of 3wt%, place the kelp monosodium glutamate particl...

Embodiment 2

[0041] A preparation method of kelp monosodium glutamate, comprising the following steps:

[0042] Step 1: remove moth-eaten kelp and rotten kelp, then wash the kelp, then freeze-dry the washed kelp until the water content is lower than 5wt%, then cut it into blocks and put it in a grinder for crushing, and then pass 300 mesh sieves to obtain kelp powder;

[0043] Step 2: Take by weighing 200g edible salt, 20g spices, 100g amino acid solution (the mass concentration of ornithine in the amino acid solution is 10%, the mass concentration of glutamic acid is 40%, and the mass concentration of aspartic acid is 20%) 150g of pregelatinized starch and 600g of kelp powder in step 1 were placed in a blender and fully stirred and mixed, then granulated in a granulator, and baked at 80°C for 0.5h to obtain kelp monosodium glutamate granules;

[0044]Step 3: Take hydroxypropyl methylcellulose and prepare a coating solution with a solid content of 10wt%, place the kelp monosodium glutamat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com