Processing method for cold instant white tea powder

A processing method and technology of white tea powder, which is applied in the field of tea powder processing, can solve problems such as poor solubility, not fresh and full taste, loss, etc., and achieve the effects of improving quality, reducing flavor loss, and improving yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

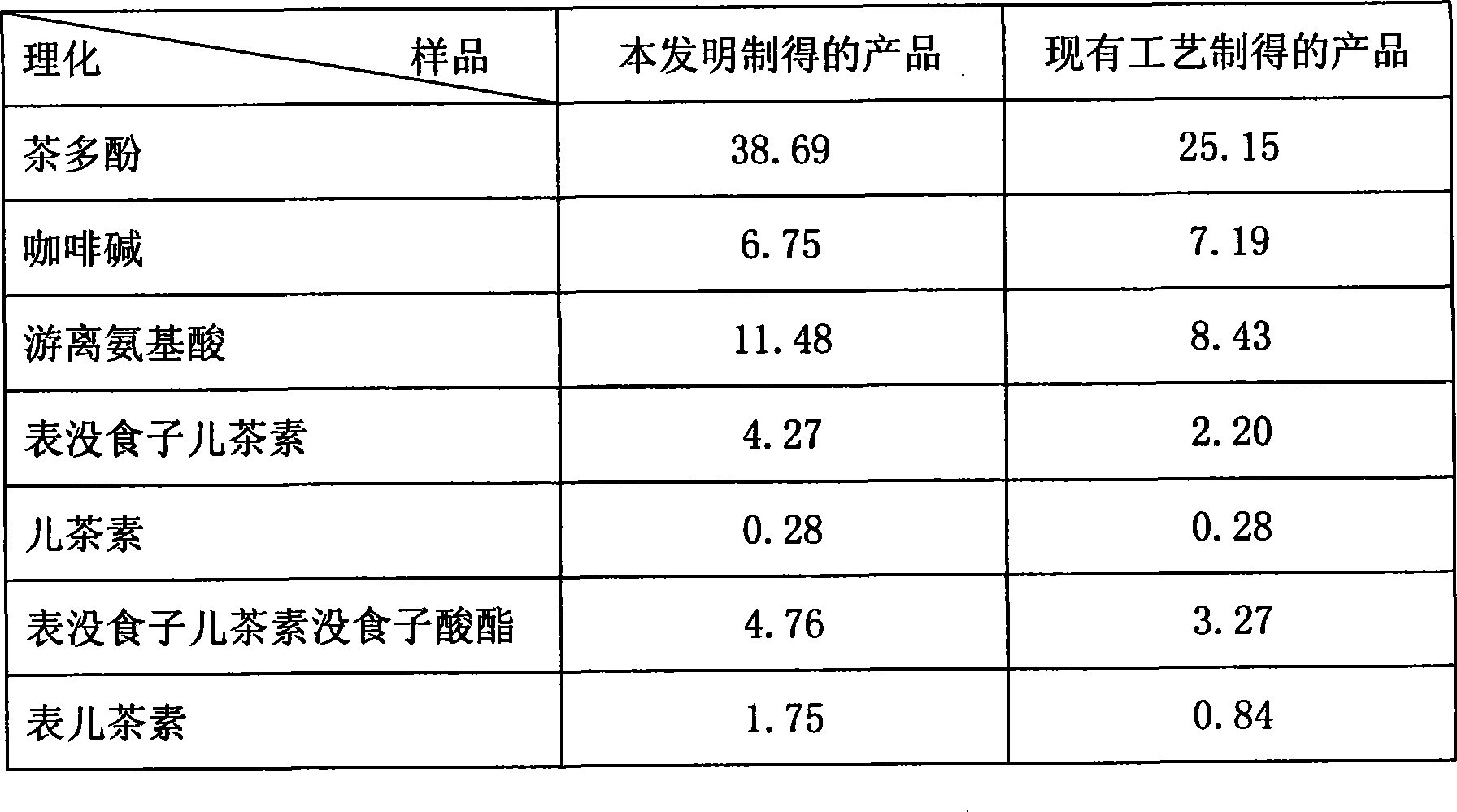

Embodiment 1

[0011] Take 1 kg of Fuding high-quality white tea raw material and add it to 20 kg of 80°C hot water, add 10 g of sodium isoVC according to 0.05% of the water volume, soak and extract for 40 minutes, and filter with a 160-mesh filter cloth to obtain the tea filtrate. After the tea filtrate was cooled to 45° C., 1.5 grams of tannase was added, stirred, and allowed to stand for 60 minutes for enzymolysis to obtain a tea enzymolysis solution. After cooling the tea enzymolysis solution to 15°C, it is separated by a disc separator, and then concentrated to 20 Brix by a reverse osmosis membrane. Finally, the concentrated tea extract is spray-dried, the air inlet temperature is 185-190° C., the air outlet temperature is 98-102° C., and the feed amount is set according to the liquid concentration to obtain 200 grams of instant tea powder. According to specific requirements, certain auxiliary materials can be added to prepare and packaged into finished products. The product prepared b...

Embodiment 2

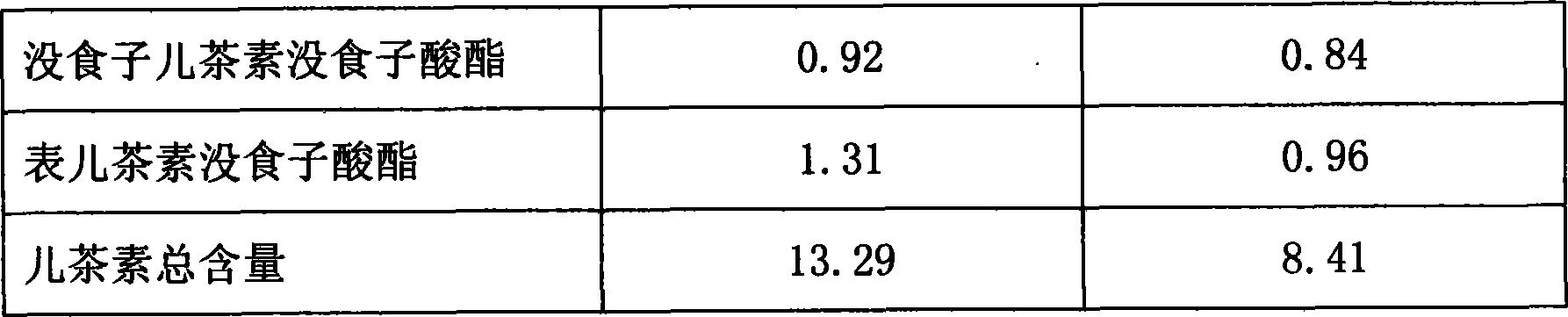

[0018] Add 1 kg of Zhenghe high-quality white tea raw material to 20 kg of hot water at 60°C, add 6 grams of sodium isoVC according to 0.03% of the water volume, soak and extract for 40 minutes, and filter with a 160-mesh filter cloth to obtain a tea filtrate. After the tea filtrate was cooled to 40° C., 1.5 grams of tannase was added, stirred, and allowed to stand for 60 minutes for enzymolysis to obtain a tea enzymolysis solution. After cooling the tea enzymatic solution to 15°C, it is separated by a disc separator, and then concentrated to 20-25 Brix through a reverse osmosis membrane. Finally, the concentrated tea extract is spray-dried, the air inlet temperature is 185-190° C., the air outlet temperature is 98-102° C., and the feed amount is set according to the liquid concentration to obtain 200 grams of instant tea powder. According to specific requirements, certain auxiliary materials can be added to prepare and packaged into finished products. The product prepared by...

Embodiment 3

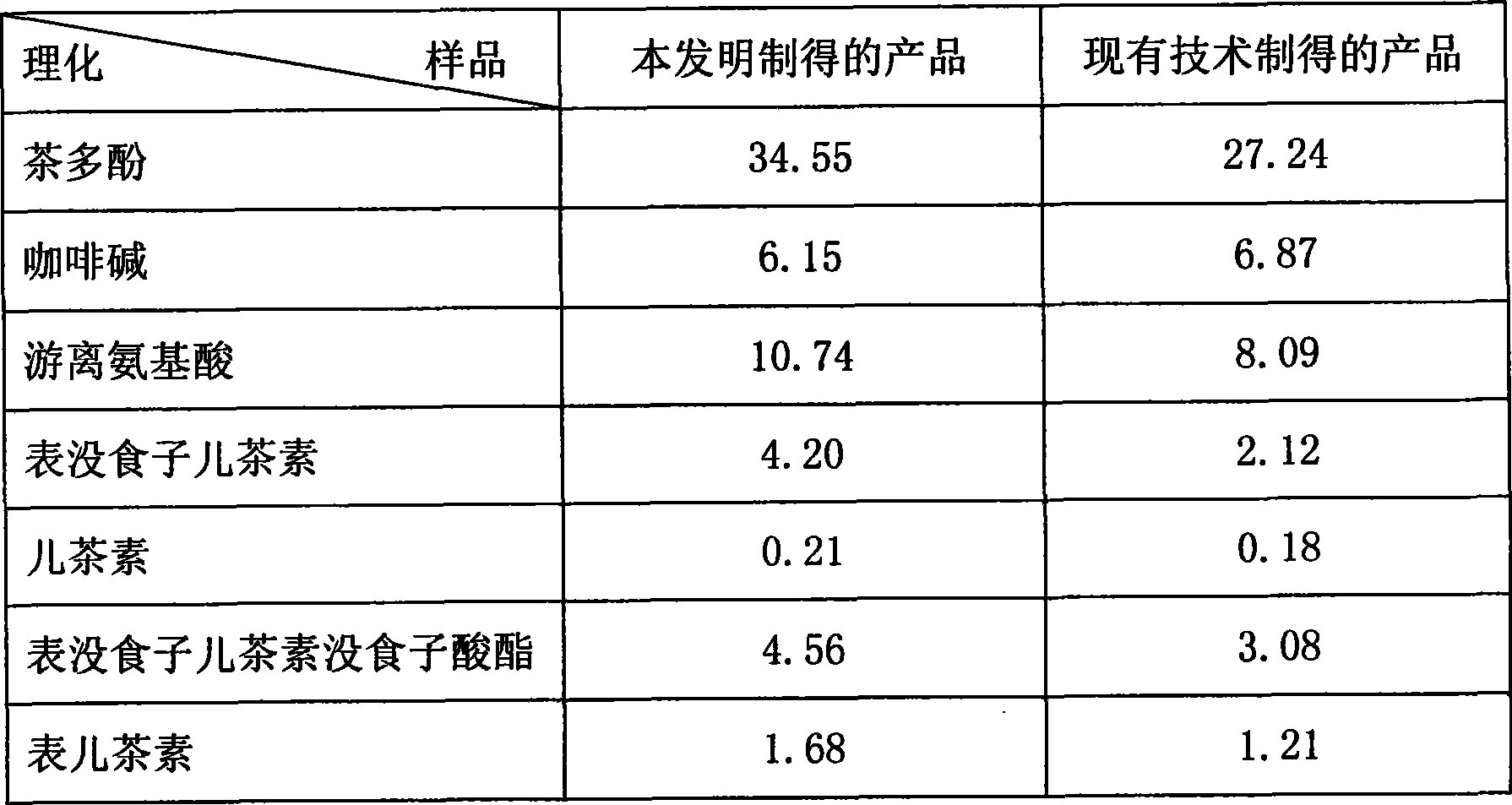

[0025] Take 1 kg of Jianyang high-quality white tea raw material and add it to 20 kg of 80°C hot water, add 10 g of sodium isoVC according to 0.05% of the water volume, soak and extract for 40 minutes, and filter with a 160-mesh filter cloth to obtain the tea filtrate. After the tea filtrate was cooled to 45°C, 3 grams of tannase was added, stirred, and allowed to stand for 60 minutes for enzymolysis to obtain a tea enzymolysis solution. After cooling the tea enzymatic solution to 15°C, it is separated by a disc separator, and then concentrated to 20-25 Brix through a reverse osmosis membrane. Finally, the concentrated tea extract is spray-dried, the air inlet temperature is 185-190° C., the air outlet temperature is 98-102° C., and the feed amount is set according to the liquid concentration to obtain 200 grams of instant tea powder. According to specific requirements, certain auxiliary materials can be added to prepare and packaged into finished products. The product prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com