Degumming adsorbent for hotpot beef tallow and application of degumming adsorbent

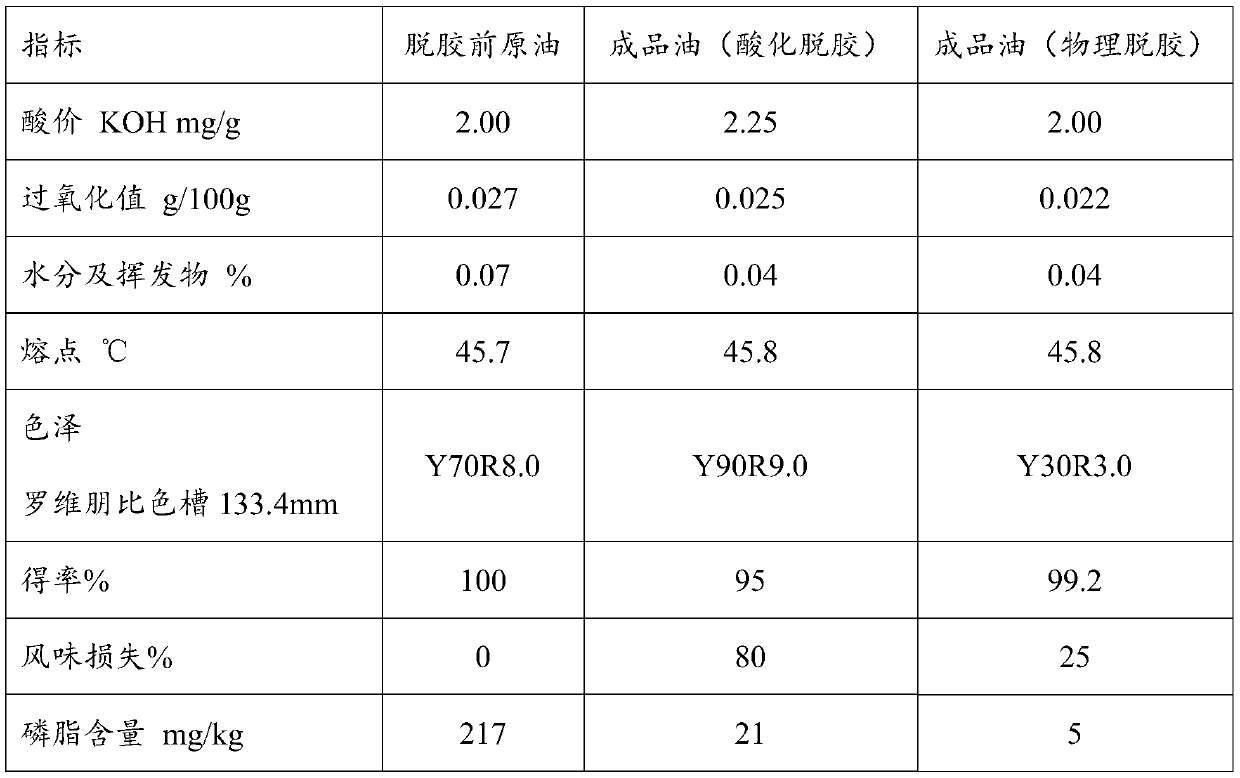

An adsorbent and degumming technology, applied in other chemical processes, oil/fat refining, fat production, etc., can solve the problems of large loss of butter flavor, low yield of refined oil, difficulty in colloid removal, etc., and achieves remarkable degumming effect. High porosity, the effect of maintaining the original flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

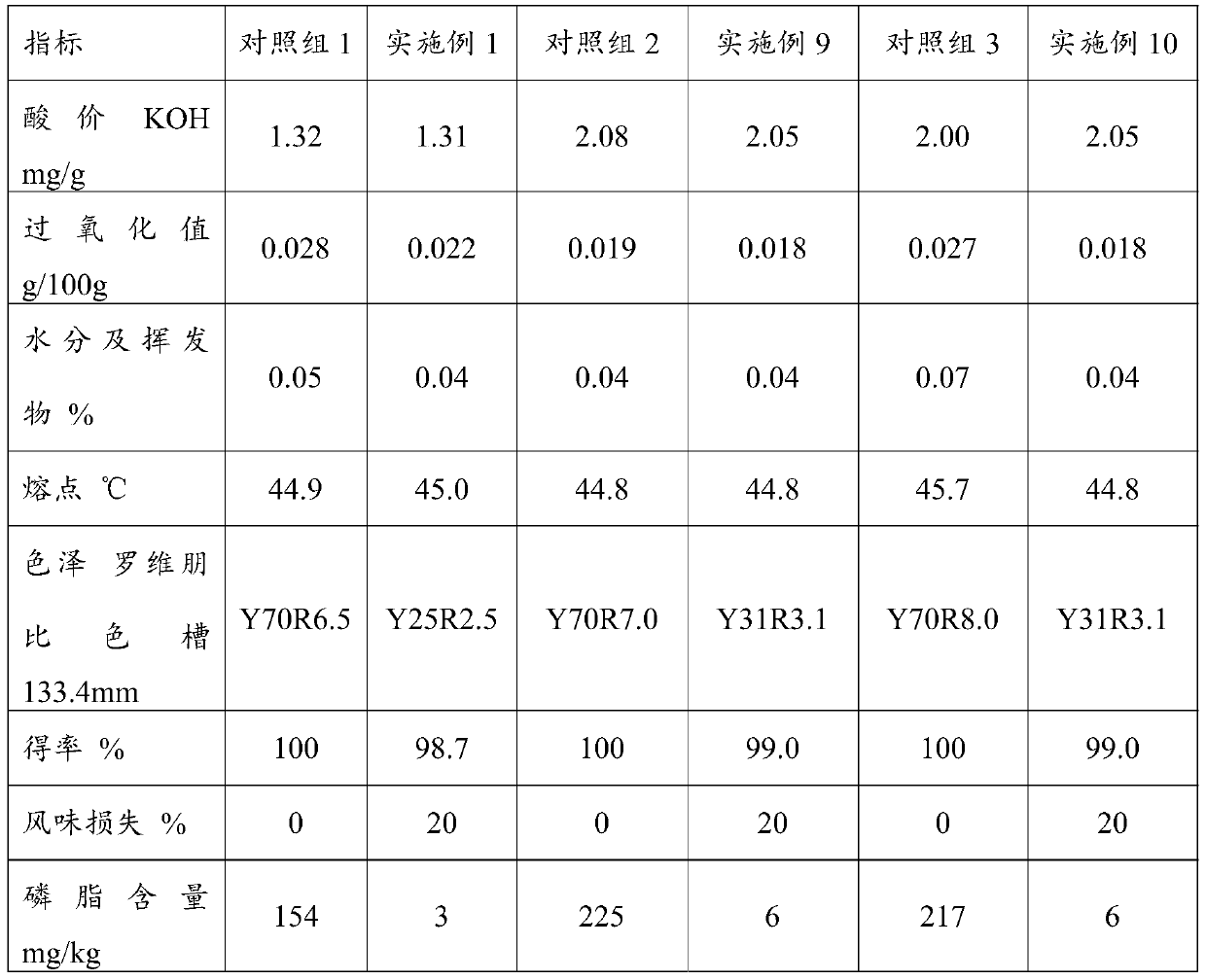

Embodiment 1

[0028] A degumming adsorbent for hot pot butter, the degumming adsorbent includes silicon dioxide, perlite and diatomite, wherein the degumming adsorbent accounts for 1.2% of the total weight of tallow, and silicon dioxide accounts for 0.7% of the total weight of tallow %, perlite accounts for 0.3% of the total weight of tallow, and diatomite accounts for 0.2% of the total weight of tallow. Perlite and diatomite are filter aids in this embodiment.

Embodiment 2

[0030] A degumming adsorbent for hot pot butter, the degumming adsorbent includes silicon dioxide, perlite and diatomite, wherein the degumming adsorbent accounts for 1.3% of the total weight of tallow, and silicon dioxide accounts for 1% of the total weight of tallow %, perlite accounts for 0.1% of the total weight of butter, and diatomite accounts for 0.2% of the total weight of butter. In this example, perlite and diatomaceous earth are filter aids.

Embodiment 3

[0032] A degumming adsorbent for hot pot butter, the degumming adsorbent includes silicon dioxide, perlite and diatomaceous earth, wherein the degumming adsorbent accounts for 3% of the total weight of tallow, and silicon dioxide accounts for 0.3% of the total weight of tallow %, perlite accounts for 1% of the total weight of butter, and diatomaceous earth accounts for 1.7% of the total weight of butter. In this example, perlite and diatomaceous earth are filter aids.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com