Closed cooling tower and closed circulating water system

A closed cooling tower and internal circulation technology, which is applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve fouling, reduce heat exchange efficiency and cooling capacity, and reduce heat transfer area and other problems, to achieve the effect of improving heat transfer capacity, reducing scaling, and improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

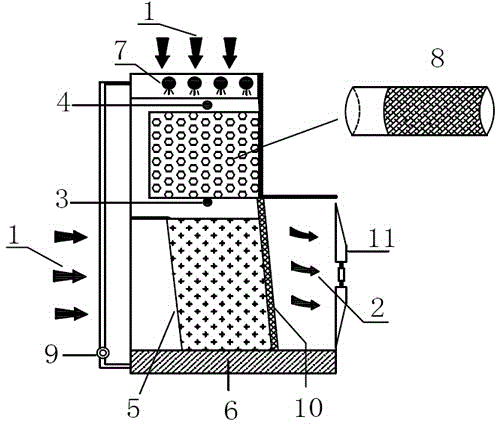

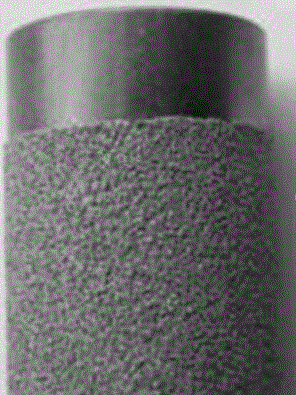

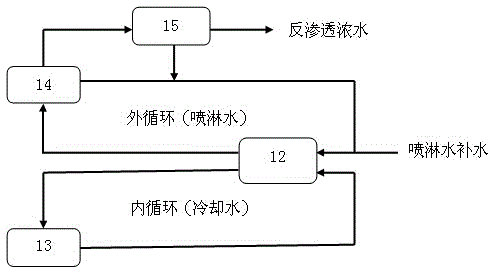

[0035] use image 3 The process flow shown and figure 1 The fluid cooling tower shown has a treatment scale of 600m 3 / h, in July to August in summer, the monthly average temperature is 26°C, the daytime wet bulb temperature is 26.3°C, and it will decrease at night, the inlet temperature of the cooling medium is 40°C, and the outlet temperature of the cooling medium to be treated is 30°C. Among them, the flow of spray water is opened to 300m 3 / h, tap water is used for spray water replenishment, and the conductivity is 265μs / cm. The treatment capacity of the reverse osmosis device in the side line of the circulating spray water is adjusted according to 3% of the actual spray water flow, that is, 9m 3 / h. The heat exchange coil adopts sintered high-flux tubes, and the cooling medium inlet of the coil is on the bottom, the cooling medium outlet is on the top, and the circulating cooling water and spray water adopt a countercurrent heat exchange method. By increasing the air...

Embodiment 2

[0037] use image 3 The process flow shown and figure 1 The closed cooling tower shown has a processing scale of 600m 3 / h, in October, the monthly average temperature is 13.7°C, the maximum wet bulb temperature is 15°C, the inlet temperature of the cooling medium is 40°C, and the outlet temperature of the cooling medium to be treated is 30°C. The flow rate of spray water is 50-200m 3 It can be adjusted within the range of / h, and tap water is used for spray water replenishment, and the conductivity is 247μs / cm. The heat exchange coil adopts sintered high-flux tubes, and the cooling medium inlet of the coil is on the bottom, the cooling medium outlet is on the top, and the circulating cooling water and spray water adopt a countercurrent heat exchange method. Considering the large temperature difference between day and night, the ambient temperature drops to 2-6°C at night, so the spray water flow can be adjusted to 50m during this time period. 3 About / h, using slow flow o...

Embodiment 3

[0039] use image 3 The process flow shown and figure 1 The closed cooling tower shown has a processing scale of 600m 3 / h, in December, the monthly average temperature is -10°C, and the water has already frozen. Regardless of the wet bulb temperature, the inlet temperature of the cooling medium is 40°C, and the outlet temperature of the cooling medium to be treated is 30°C. The heat exchange coil adopts sintered high-throughput tubes, and the inlet of the cooling medium of the coil is on the bottom, and the outlet of the cooling medium is on the top. Stop the external circulation loop, that is, stop the spray water, filter and reverse osmosis device, drain the water in the sump, and only adjust the air volume of the axial flow fan of the closed cooling tower to maintain the outlet of the cooling medium at about 30°C. After 30 days of stable operation, compared with the open circulating water system (traditional cooling water tower), it can save 98% of water and 20% of elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com