Method for washing pure cotton cone yarn dyed with light-medium-color active macromolecular dye

A reactive dye, post-washing technology, applied in dyeing, textile and papermaking, etc., can solve the problems of high water consumption, energy and time, complicated washing process, etc., to save time, reduce consumption, and shorten the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

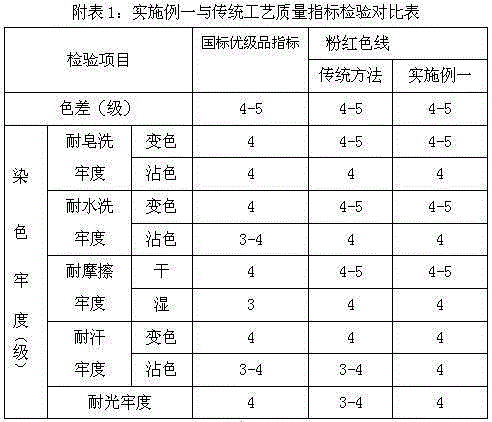

Examples

Embodiment 1

[0032] (1) Put the pure cotton thread of GJ7.3*2KB package in the cheese dyeing vat, cover it and tighten the dyeing vat, and use the conventional one-step pretreatment process of boiling and bleaching to pre-treat the pure cotton cheese yarn and use medium-temperature reactive dyes Carry out dyeing (3BSN red 1.2%owf), during the dyeing process, add sodium bicarbonate and add desalting agent DYE1.0g / L at the same time, after the dyeing is finished, drain the residual liquid; then fill it with soft water, and wash it with running water for 5 minutes Drain the residual liquid;

[0033] (2) Fill the dyeing vat with soft water, add engineering soaping enzyme 5NPF1.0g / L, heat up to 60°C for 10 minutes and then discharge the sewage;

[0034] (3) Continue to add tap water to the dyeing vat, add organic acid ACR1.0g / L, neutralize and wash with water at 50°C for 10 minutes, and then drain;

[0035] (4) Inject soft water into the dyeing vat, add organic acid ACR0.5g / L and color-fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com