Production method and production line for obtaining Chinese fir essential oil at low energy and high yield

A high-yield, low-energy-consumption technology, used in essential oils/spices, fat production, etc., can solve the problems of unreasonable production lines and technological processes, unsatisfactory use effects, and unsatisfactory yields, and shorten the total distillation time. Use Ideal effect, reduced water consumption and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

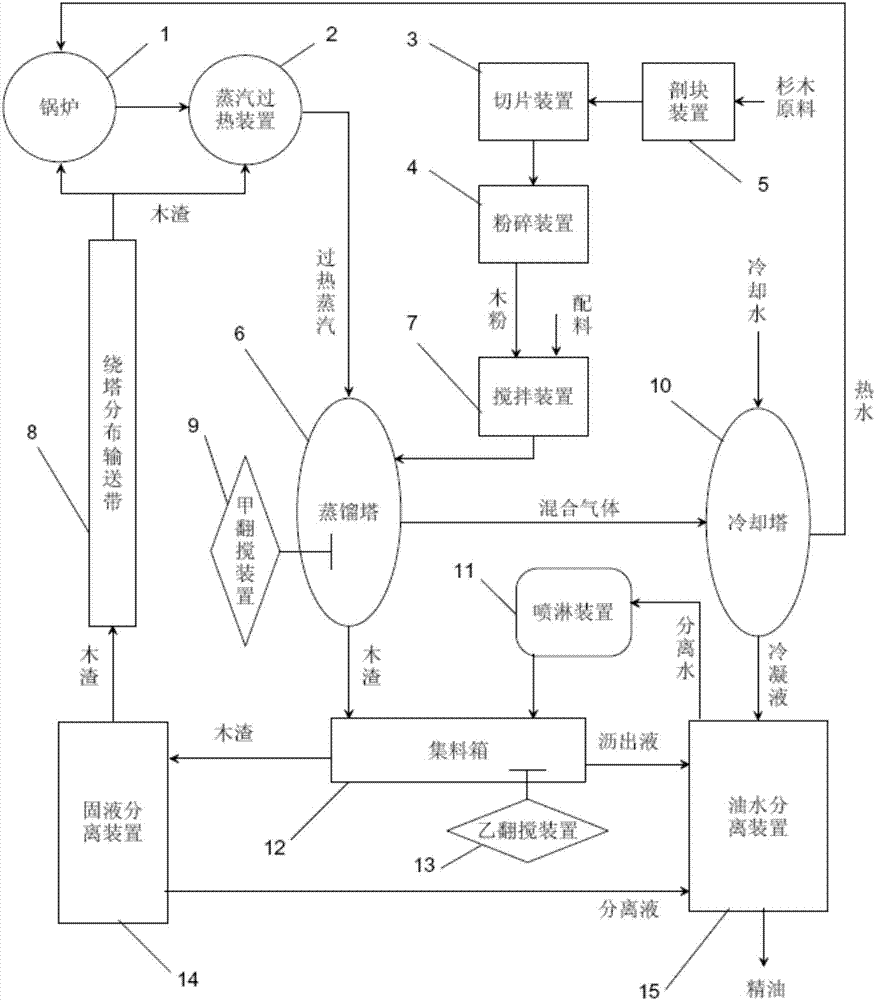

Image

Examples

Embodiment 2

[0039] Embodiment 2 of the present invention is a production line for obtaining Chinese fir essential oil with low energy consumption and high yield, and its structure is exactly the same as that of Embodiment 1.

[0040] A production method for obtaining fir essential oil with low energy consumption and high yield, adopting the production line for obtaining fir essential oil with low energy consumption and high yield, the specific steps are as follows:

[0041] A, milling, by splitting blocks, slicing, pulverizing, the Chinese fir raw material is pulverized into 120 order Chinese fir powder;

[0042] B, mix, add edible alkali and industrial salt in fir powder and stir and mix, the proportioning of three parts by weight is: 750 parts of Chinese fir powder, 3.5 parts of edible alkali, 2.2 parts of industrial salt;

[0043] C, a distillation, the Chinese fir powder that mixes is sent in the distillation tower, and in the distillation tower, pass into the superheated steam that t...

Embodiment 3

[0050] Embodiment 3 of the present invention is a production line for obtaining Chinese fir essential oil with low energy consumption and high yield, and its structure is exactly the same as that of Embodiment 1.

[0051] A production method for obtaining fir essential oil with low energy consumption and high yield, adopting the production line for obtaining fir essential oil with low energy consumption and high yield, the specific steps are as follows:

[0052] A, milling, by splitting blocks, slicing, pulverizing, Chinese fir raw material is pulverized into 100 order Chinese fir powder;

[0053] B, mix, add edible alkali and industrial salt in the Chinese fir powder and stir and mix, the proportioning of three parts by weight is: 750 parts of Chinese fir powder, 3 parts of edible alkali, 2 parts of industrial salt;

[0054] C, a distillation, the Chinese fir powder that mixes is sent in the distillation tower, and in the distillation tower, feed into the superheated steam th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com