Method for efficiently degumming hemp by means of peroxidating at low temperatures under low-emission conditions

A technology of hemp peroxide and degumming method is applied in the direction of producing bast fiber by chemical method, which can solve the problems of difficulty in promotion, difficult to master the production process, long time for microbial treatment, etc. dyeability and dyeability, the effect of shortening the degumming process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

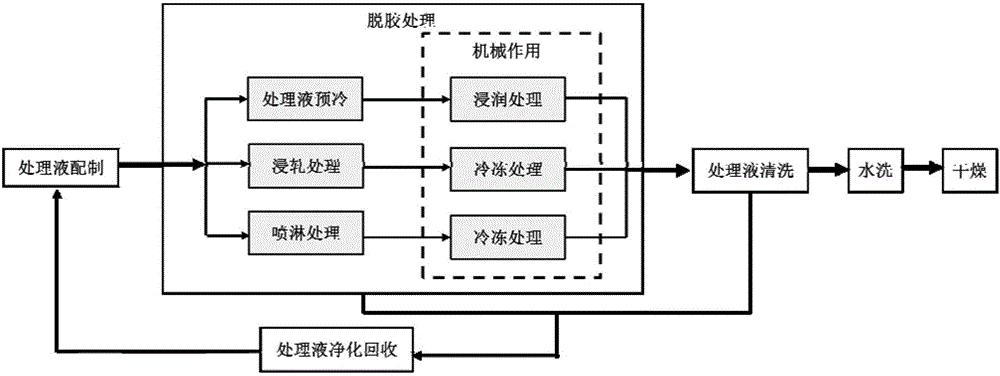

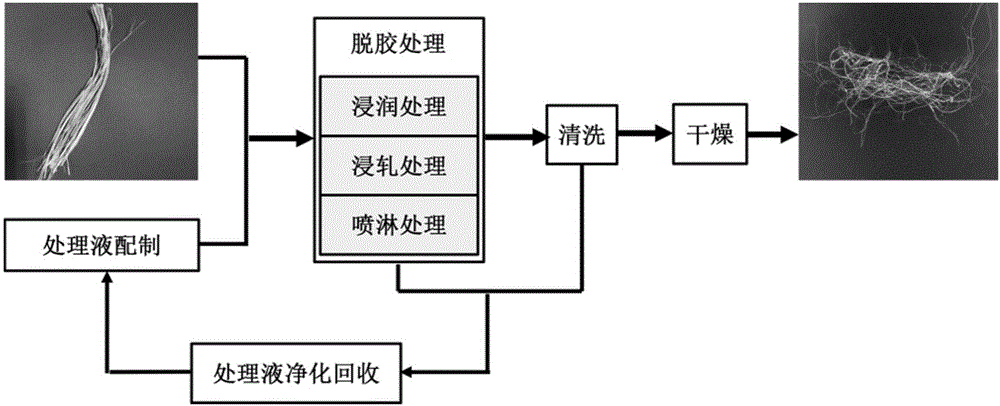

Method used

Image

Examples

Embodiment 1

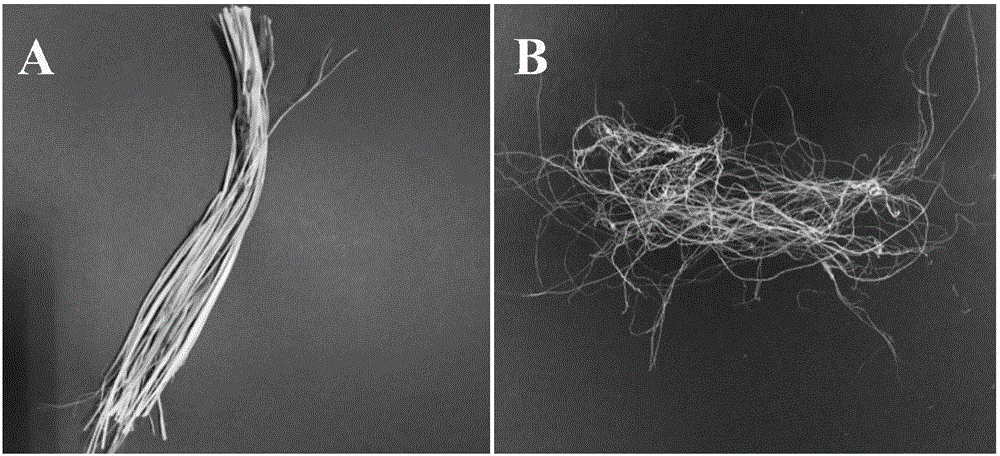

[0030] Sodium peroxide / urea / water is formulated into a treatment solution with a mass ratio of 10% / 9% / 81% and pre-cooled to -10°C. After the raw ramie is cleaned, it is spread on the treatment net and immersed in Pre-cool the treatment solution for 1 min while applying a slight mechanical tapping. After treatment, the fiber is washed with a -10°C treatment solution and the treatment solution is recovered. The fiber is washed with water at 25°C until it is neutral and then dried naturally at room temperature. Raw ramie before degumming treatment and ramie fiber after degumming treatment such as figure 2 Shown in A and 2B. The initial modulus of the degummed fiber is reduced to 8.1±3.2GP from 19.9±5.9GPa of the traditional process, the crystallinity is reduced from 81.78% of the fiber obtained by the traditional process to 50.02%, and the moisture regain is increased from 8.83% to 11.07%. The dyeing performance is significantly improved, and the K / S value of dyeing depth is inc...

Embodiment 2

[0032] The mass ratio of lithium peroxide / thiourea / water is 10% / 12% / 78% to prepare the degumming treatment solution. After the raw flax hemp is washed, it is laid on the treatment net, and the treatment solution is sprayed. The moistened raw hemp was frozen at -5°C for 5 minutes, and mechanically tapped. Then the fibers were washed with a -5°C treatment solution. After washing, the treatment solution was recovered. The fibers were washed with water at 20°C until they were neutral, and then at 50°C. Fast drying treatment. By comparing the dyeing performance of the fiber before and after the low temperature treatment, the dyeing depth K / S value of the flax fiber after the treatment is increased by 101.4%. The initial modulus of flax fiber after treatment decreased by 40.4%, indicating that low temperature treatment can improve the softness of flax fiber.

Embodiment 3

[0034] The mass ratio of potassium peroxide / urea / water is 9% / 12% / 79% to prepare the degumming treatment solution and put it into the padding tank, the hemp fiber bundle is applied with the treatment solution through the padding tank, and then the fiber bundle is placed Frozen treatment at -25°C for 30s, repeat the padding and freezing process for 2 times. After padding, with mechanical tapping, the fiber bundle is cleaned with -5°C treatment solution, the treatment solution is recovered, and then the fibers are washed to neutrality at 20°C. And dry naturally at room temperature. By comparing the dyeing performance of the fibers before and after the low temperature treatment, it is obtained that the dyeing depth K / S value of the hemp fiber after the treatment is increased by 66.1%, indicating that the dyeing performance of the hemp fiber is improved after the treatment. The initial modulus of hemp fiber after treatment decreased by 24.1%, indicating that low temperature treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com