Low modulus silicone sealing gum and its manufacturing method

A silicone sealant, low modulus technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of inability to ensure long-term sealing of joints, unsatisfactory concrete adhesion, and large permanent deformation of the sealant. Achieve excellent displacement ability, excellent expansion and recovery ability, and the effect of small permanent deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: 200 parts by mass of a, ω-dihydroxy polydimethylsiloxane with a viscosity of 50 Pa·S at 25°C, and 180 parts by mass of nano-active light calcium carbonate, at a temperature of 120°C and a vacuum degree of 0.06 Dehydration and blending at ~0.095MPa for 60min, transferred into a high-speed dispersing mixer and cooled to room temperature to obtain a base material; at room temperature, 24 parts by mass of methyl vinyl bis (ε-caprolactamyl) silane, dimethyl bis (ethyl acetoacetate) 4 parts by mass of methyl) silane, 2 parts by mass of methyl tris (N-methylacetamido) silane, 5 parts by mass of fumed silica, 10 parts by mass of toluene diisocyanate, the viscosity at 25°C is 1 Pa· 40 parts by mass of polydimethylsiloxane of S was added into the high-speed disperser, stirred and mixed with the base material, and the chemical reaction was carried out for 80 minutes under the vacuum degree of 0.06-0.095MPa and the rotation speed of 350rpm to produce high elongation and l...

Embodiment 2

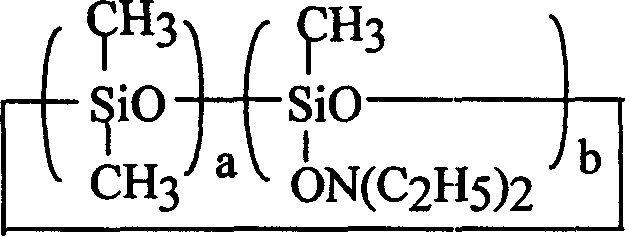

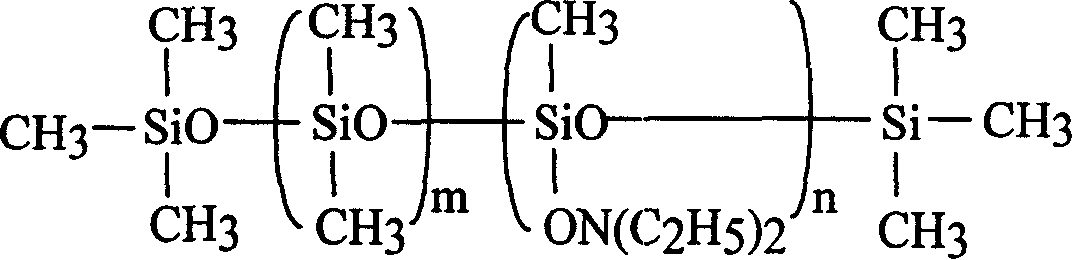

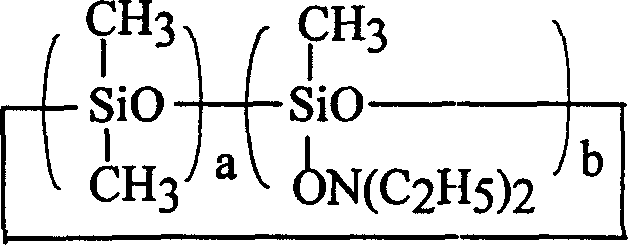

[0038] Example 2: 200 parts by mass of a, ω-dihydroxy polydimethylsiloxane with a viscosity of 30 Pa·S at 25° C., 100 parts by mass of nano-active light calcium carbonate, and 150 parts by mass of silicon micropowder were heated at a temperature of 120 ℃, the vacuum degree is 0.06~0.095MPa, dehydration and blending for 60min, transfer into a high-speed dispersing mixer and cool to room temperature to obtain the base material; at room temperature, 20 parts by mass of dimethylbis(ε-caprolactamyl)silane, methyl vinyl 18 parts by mass of bis(N-phenylacetamido)silane, aminooxysilane 2.5 parts by mass, 15 parts by mass of hydrogenated castor oil, 25 parts by mass of polydimethylsiloxane with a viscosity of 1 Pa·S at 25°C, and 6 parts by mass of toluene diisocyanate, which were added to a high-speed disperser and mixed with the base material. Stir and mix, carry out chemical reaction under vacuum degree of 0.06-0.095MPa and rotational speed of 350rpm for 80 minutes to manufacture hi...

Embodiment 3

[0039] Example 3: 200 parts by mass of a, ω-dihydroxy polydimethylsiloxane with a viscosity of 80 Pa·S at 25°C, 60 parts by mass of nano-active light calcium carbonate, 20 parts by mass of light calcium carbonate, 20 parts by mass of calcium carbonate are dehydrated and blended for 60 min at a high temperature of 120 ° C and a vacuum degree of 0.06 to 0.095 MPa, and then transferred into a high-speed dispersing mixer and cooled to room temperature to obtain the base material; 13 parts by mass of acetylacetamido)silane, 2 parts by mass of dimethylbis(N-methylacetamido)silane, and aminooxysilane 7.5 parts by mass, 20 parts by mass of fumed silica, 1.5 parts by mass of toluene diisocyanate, and 10 parts by mass of polydimethylsiloxane with a viscosity of 0.8 Pa·S at 25°C were added to the high-speed disperser, and mixed with the base material by stirring , under the vacuum degree of 0.06 ~ 0.095MPa, the chemical reaction was carried out at 350rpm for 90 minutes to manufacture hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com