Shunt valve component and dish-washing machine

A water diversion valve and dishwasher technology, applied in the field of cleaning utensils, can solve problems such as difficult to achieve layered washing and combined washing, unfavorable energy consumption and water consumption of dishwashers, and affecting the cleaning effect of dishwashers. The structure is simple, the effect of improving the cleaning rate and reducing the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

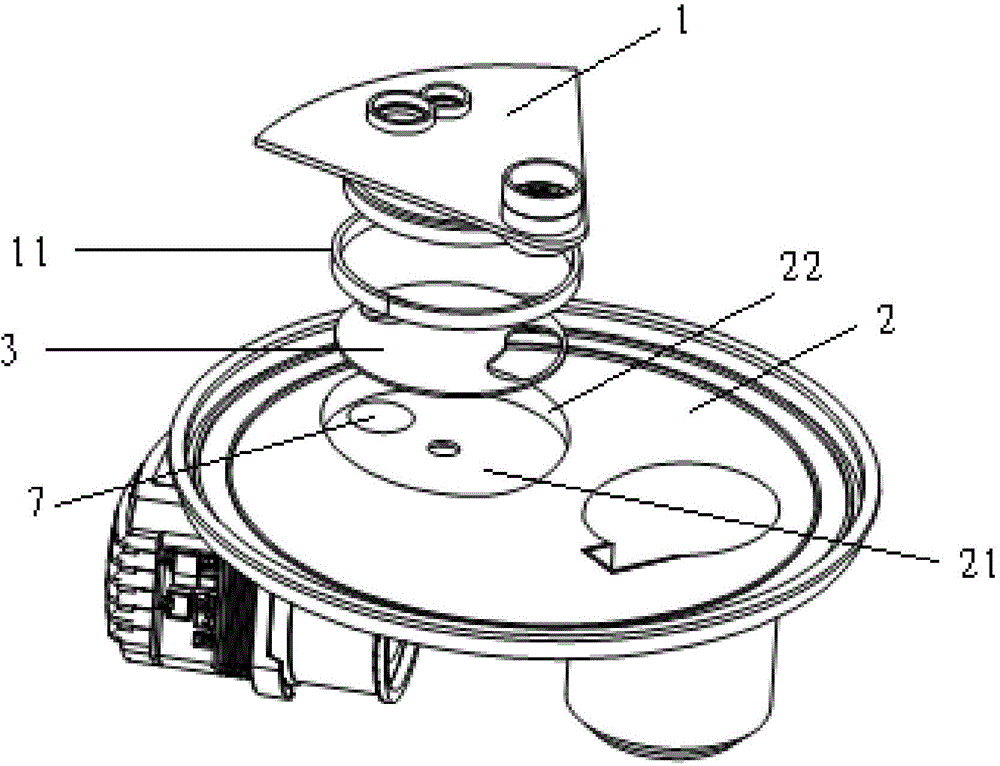

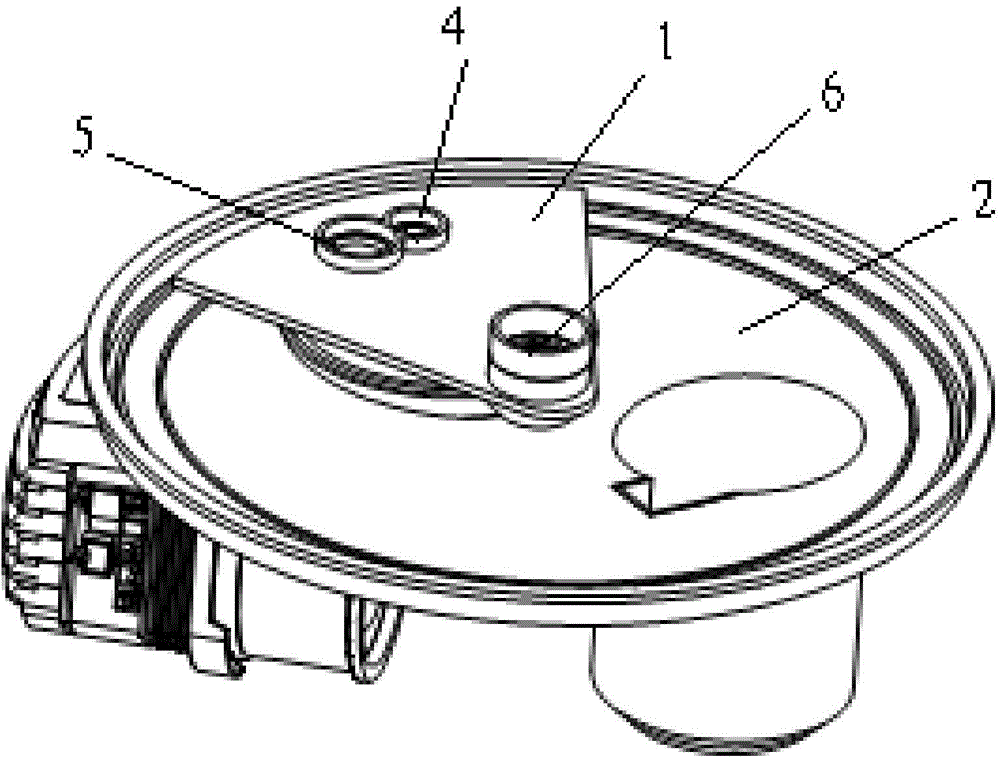

[0039] This embodiment provides a water diversion valve assembly, such as figure 1 and figure 2 As shown, the water diversion valve assembly includes a valve seat 1 and a valve cover 2 buckled on the valve seat 1, and a disc-shaped water diversion baffle 3 is arranged between the valve seat 1 and the valve cover 2, through which the water diversion baffle 3 Realize the diversion of the internal waterway of the water diversion valve.

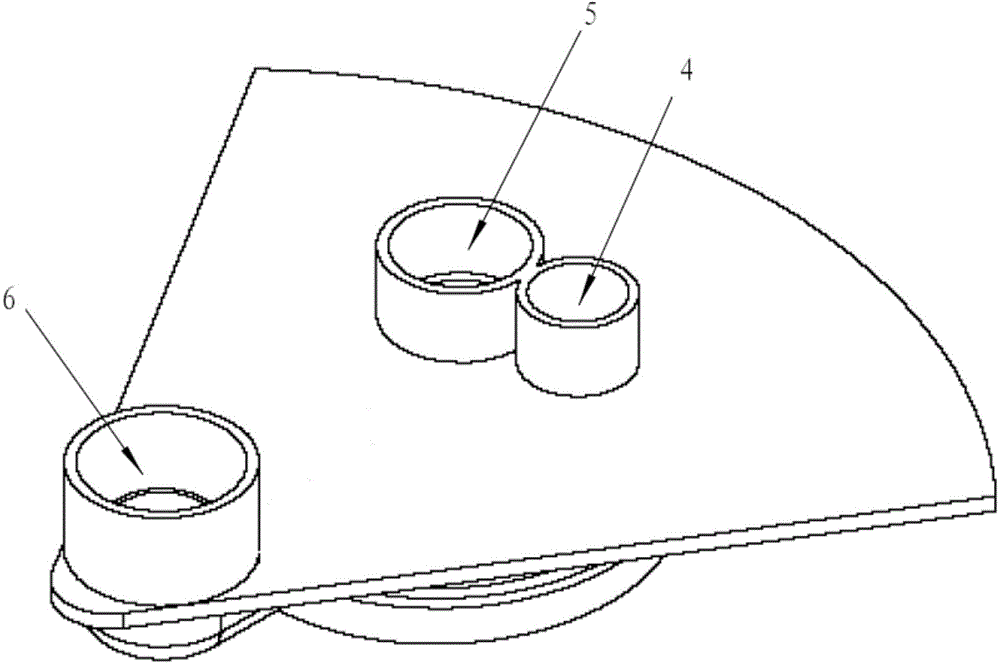

[0040] Among them, such as image 3 As shown, the valve seat 1 is a flat structure, and there are three water outlets running through the upper and lower surfaces, which are respectively the upper spray outlet 4, the middle spray outlet 5 and the lower spray outlet 6, and the three outlets The axes are all parallel to the axis of the valve seat 1. The upper spray water outlet 4 and the middle spray water outlet 5 are arranged adjacently, and the lower spray water outlet 6 is arranged on the opposite side of the upper spray water outlet 4 and ...

Embodiment 2

[0053] This embodiment provides a dishwasher, which adopts the water diversion valve assembly as described in Embodiment 1. The multiple showers of the dishwasher are respectively connected to the multiple water outlets of the water diversion valve assembly. Under the rotation of the water diversion block in the water valve assembly, various washing methods such as layered washing and combined washing are realized, with low energy consumption and high washing rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com