Method for preparing LixFeyPzO4 from ferrophosphorous

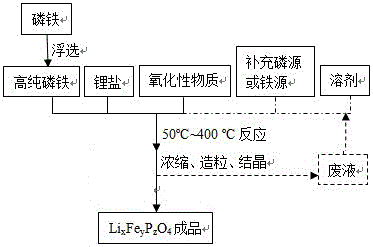

A technology of ferrophosphorus and phosphorus sources, applied in chemical instruments and methods, phosphorus compounds, nanotechnology for materials and surface science, etc. The content is uncertain and other problems, so as to overcome the difficulty of raw material ratio, eliminate the easy corrosion of equipment, and easy to control the appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

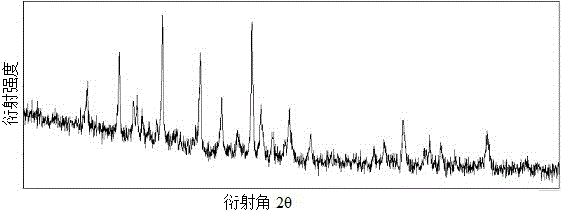

[0024] Using solid-liquid low-temperature reaction to produce iron and phosphorus Fe 1.5 Preparation of Lithium Iron Phosphate LiFePO by P 4 , the ferrophosphate slag Fe 1.5 P is crushed until the particle size is above 700 mesh. According to the magnetic difference between ferrophosphorus and impurities, the high-purity ferrophosphorus is transferred into a clean container by magnetic flotation to eliminate the influence of impurity elements in the raw material of ferrophosphorus on the product, and the high-purity ferrophosphorus Put it in a hydrothermal kettle lined with polytetrafluoroethylene, according to LiFePO 4 The molar ratio of total lithium, total iron and total phosphorus is 1.0:1.0:1.0. Phosphoric acid and lithium hydroxide are added, and hydrogen peroxide is added according to the composition of raw materials and products. The external magnetic field can be used to strengthen the reaction and transfer process, according to If necessary, water or ethanol solven...

Embodiment 2

[0028] Preparation of lithium ferrous phosphate LiFePO from ferrophosphorus FeP by solvothermal method 4 , the ferrophosphorus powder with a particle size greater than 1000 mesh is purified by density and magnetic difference flotation, and the high-purity ferrophosphorus FeP is transferred into a reactor lined with fluororubber, and then mixed with lithium phosphate Li 3 PO 4 , Phosphate H 3 PO 4 , Iron oxide Fe 2 o 3 by LiFePO 4 The molar ratio of the total lithium element, the total iron element and the total phosphorus element is 1.0:1.0:1.0 for batching, a certain amount of hydrogen peroxide is added according to the composition of raw materials and products, and a certain amount of ethanol can be added as a solvent. The total amount of reaction materials is not More than 2 / 3 of the volume of the reactor, heating with molten salt, reacting at 150°C-350°C for 20-40h, to obtain LiFePO 4 Precursor aqueous solution, through the process of concentration and granulation to...

Embodiment 3

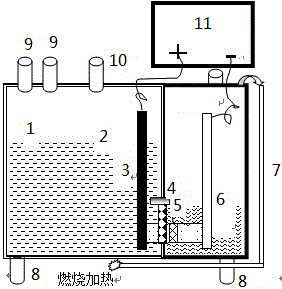

[0032] An electrolytic cell is added to the low-temperature reaction kettle, and the atomic oxygen generated in situ by the anode is used to directly oxidize the phosphorus element in the ferrophosphorus, and the pressure generated by the system is used to accelerate the reaction. Raw materials and process parameters to achieve LiFePO 4 The in-situ synthesis of the product, the specific operation process is as follows: the high-purity ferrophosphorus Fe obtained by flotation 1.5 P, lithium carbonate, phosphoric acid according to LiFePO 4 The molar ratio of the total lithium element, the total iron element and the total phosphorus element is 1.0:1.0:1.0 for batching, the total amount of reaction materials does not exceed 3 / 4 of the volume of the reactor, and the graphite anode of the electrolytic cell is put into the reaction In the kettle, the anode chamber and the cathode chamber are connected through a valve and a diaphragm-lined fluorine plastic 304 stainless steel tube. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com