Acidic silicone sealant with good bonding performance on stainless steel, and preparation method thereof

A technology of stainless steel and acid silicon, applied in chemical instruments and methods, adhesives, other chemical processes, etc., can solve the problems of stainless steel not having bonding performance, glass falling off, poor bonding, etc., and achieve significant economic benefits and social benefits Benefits, fast curing speed, and no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

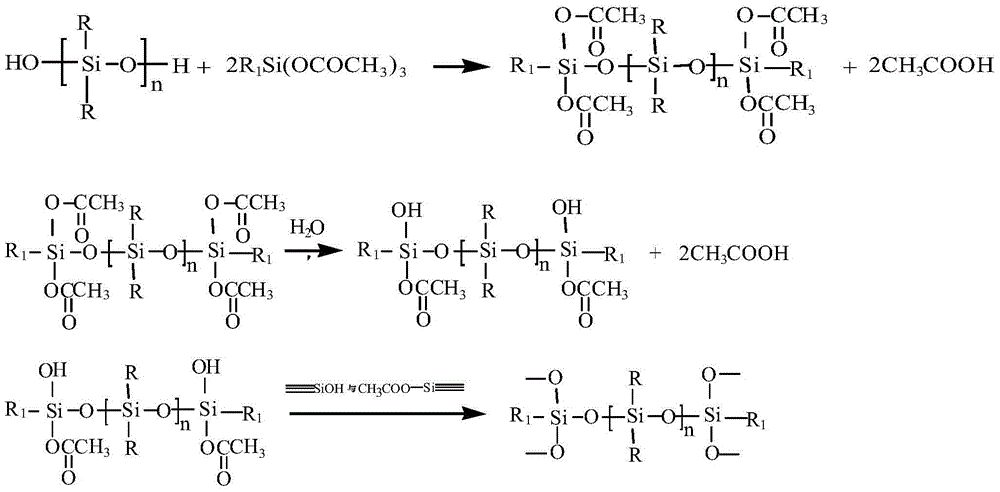

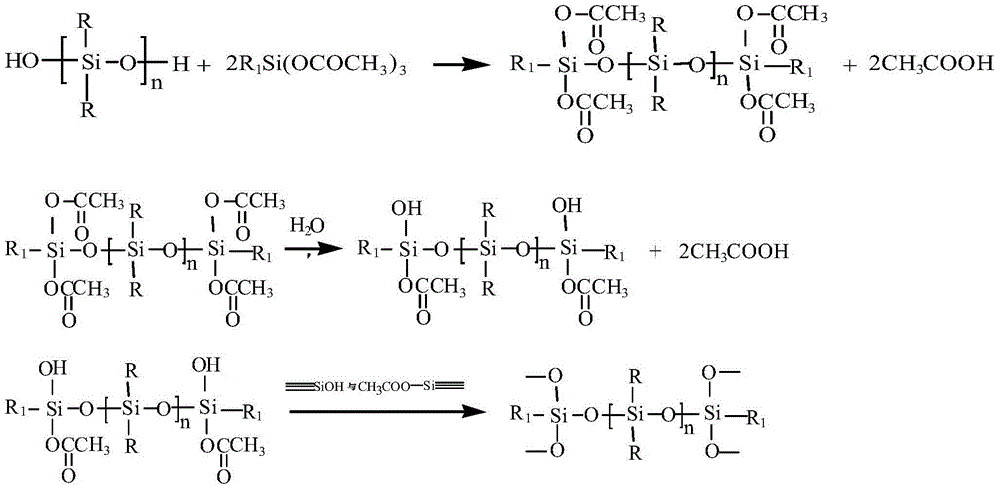

Method used

Image

Examples

Embodiment

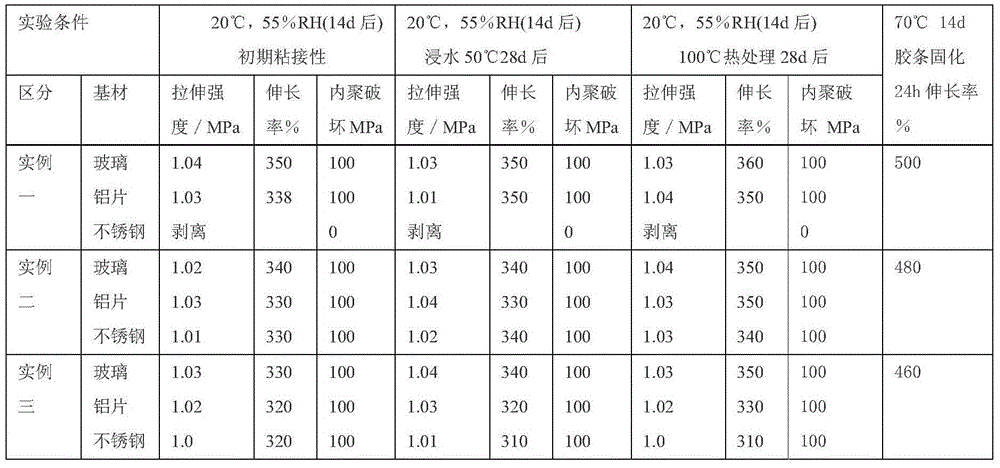

[0026] 1. Add a, w-dihydroxypolydimethylsiloxane 36KG and a, w-methylhydroxypolydimethylsiloxane 15KG white oil 15KG into the high-speed disperser, the vacuum degree is 0.09-0.095MPa, the speed 300rpm, mixing for 30 minutes. Add 4.2KG of methyltriacetoxysilane into the high-speed disperser, the vacuum degree is 0.09-0.095MPa, the speed is 300rpm, mix for 30 minutes, add 6KG of fumed white carbon black, and the speed is 800rpm for 45 minutes, and dibutyltin diacetate 0.04kg, the vacuum degree is 0.09-0.095MPa, the rotation speed is 400rpm, and the chemical reaction is carried out for 30 minutes. The ordinary acidic silicone sealant product was prepared, and the details of the performance test results of the product and the product in different states are shown in Table 1.

[0027] 2. Add a, w-dihydroxypolydimethylsiloxane 36KG and a, w-methylhydroxypolydimethylsiloxane 15KG white oil 15KG into the high-speed disperser, the vacuum degree is 0.09-0.095MPa, the speed 300rpm, mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com