Non-slurry self-sizing method for cellulosic fiber containing yarns

A cellulose fiber and self-sizing technology, which is applied in fiber treatment, plant fiber, textiles and papermaking, etc., can solve the problems of destroying the respiration of aquatic organisms, strong moisture absorption and re-adhesiveness, and poor biodegradability, achieving low cost and promoting The effect of transformation and cheap price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

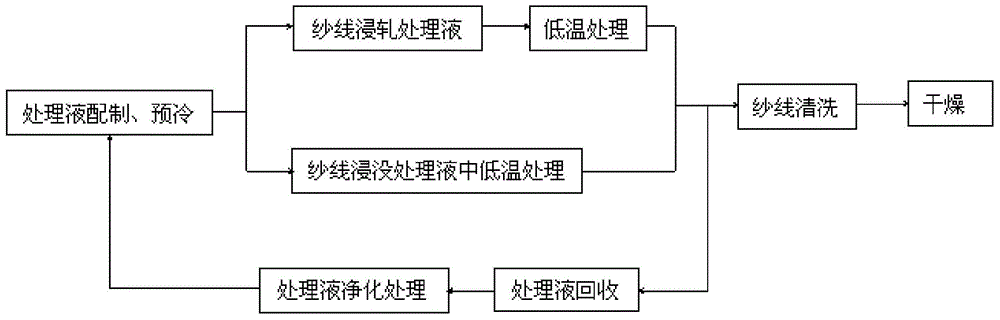

Method used

Image

Examples

Embodiment 1

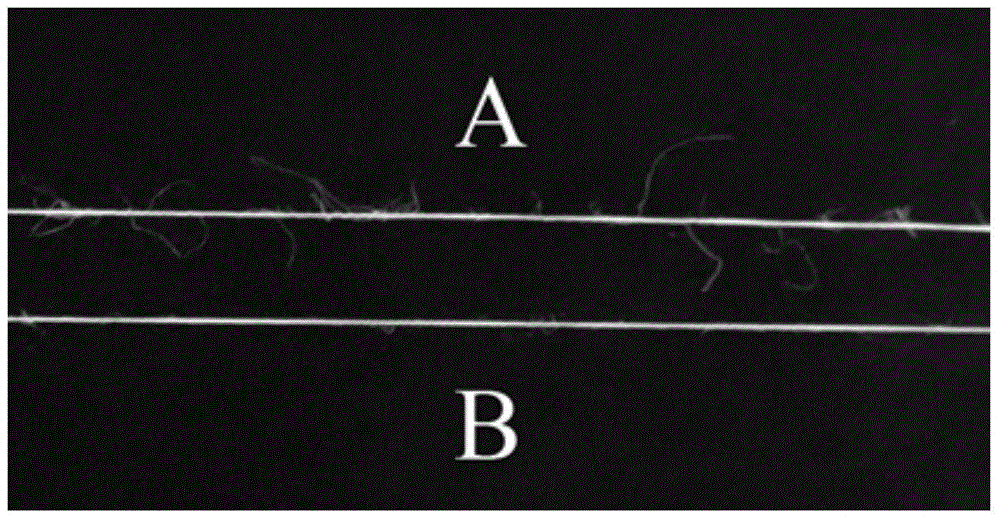

[0026] A treatment solution with a mass ratio of sodium hydroxide / urea / water of 7% / 12% / 81% was prepared, the cotton yarn was immersed in -15°C and frozen for 30s, washed with water, and dried to obtain a self-sizing yarn.

Embodiment 2

[0028] Prepare a treatment solution with a mass ratio of sodium hydroxide / thiourea / water of 7% / 12% / 81%, impregnate a piece of cotton yarn with a low-temperature treatment solution at -15°C, and place it in a -15°C environment for 1 min. After washing and drying, self-sizing yarns are obtained.

Embodiment 3

[0030] Prepare a treatment solution with a mass ratio of potassium hydroxide / urea / water of 9% / 12% / 79%, immerse the cotton yarn in -15°C and freeze for 1 minute, repeat the treatment for 3 times, wash with water, and dry to obtain self-sizing yarn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com