Acid pickling device for steel wire rope production technology

A production process and pickling equipment technology, applied in the field of pickling equipment for steel wire rope production process, can solve the problem of incapable of recycling pickling solution, and achieve the effect of preventing loss and avoiding influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

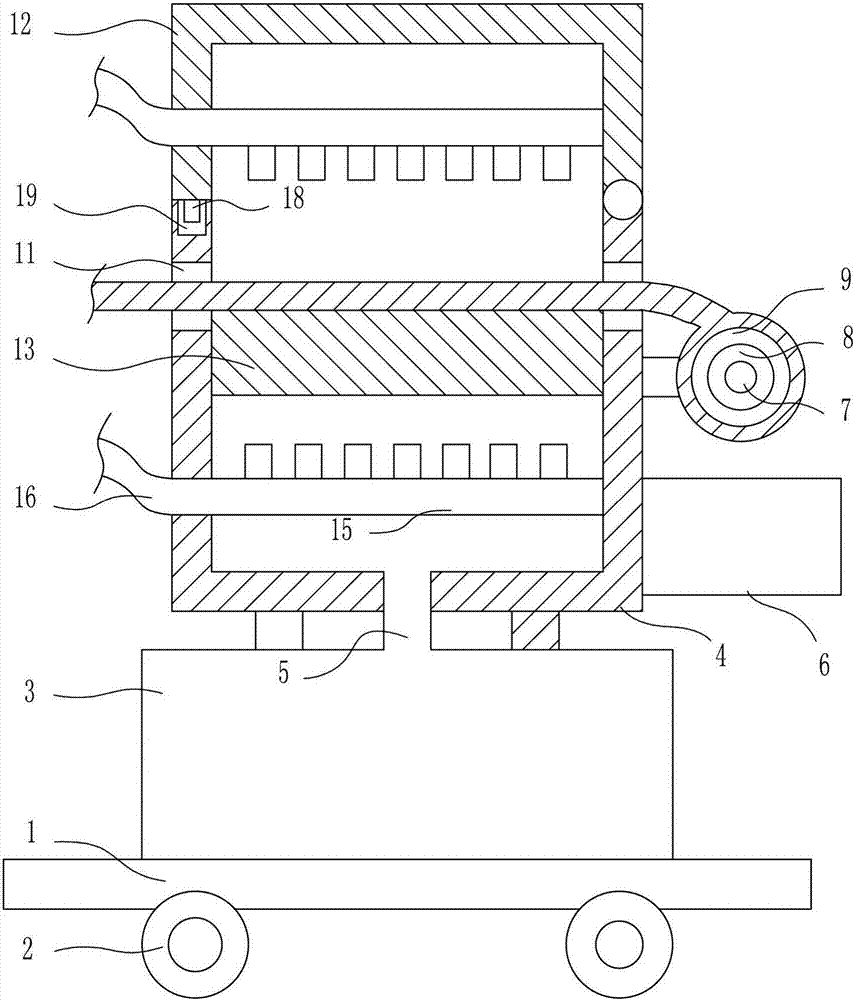

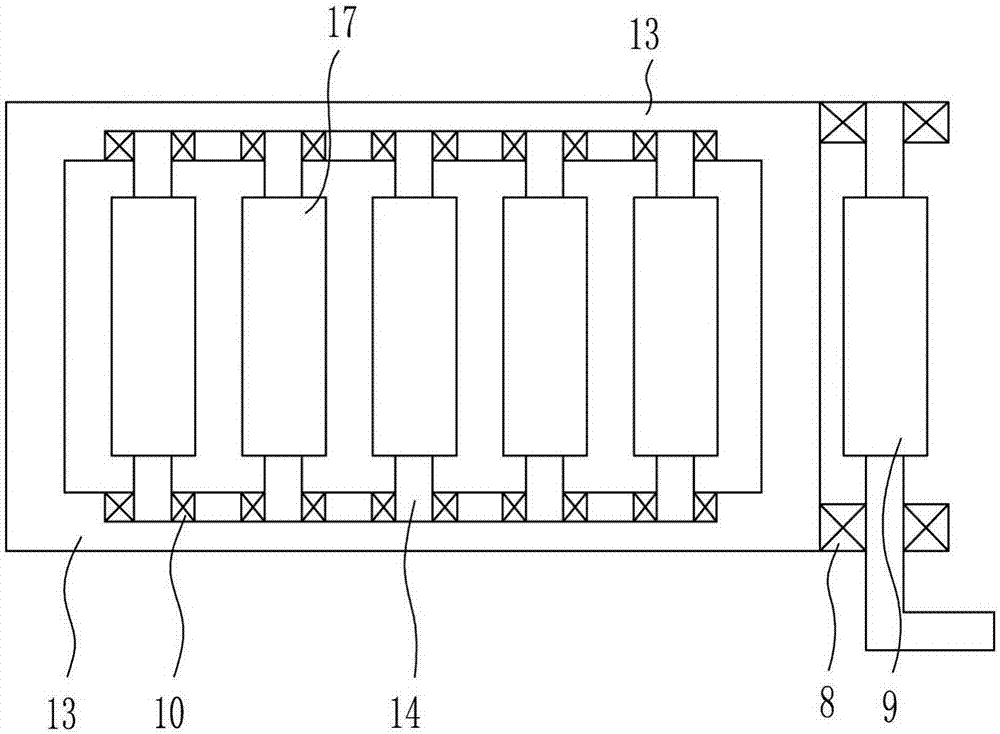

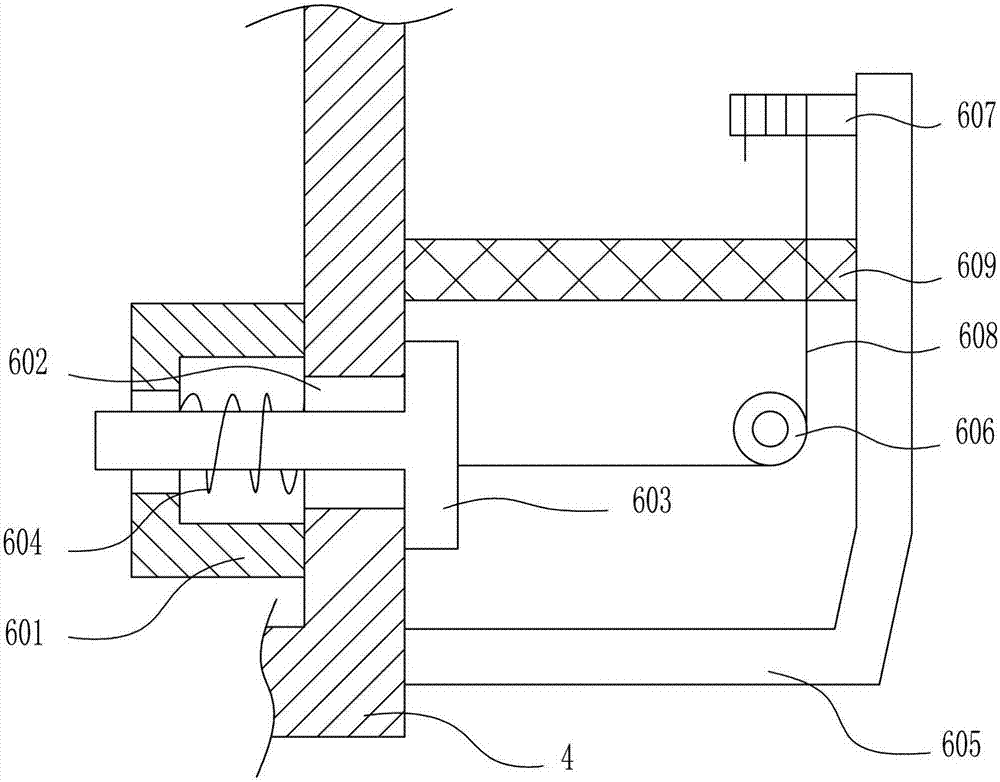

[0030] A kind of pickling equipment for steel wire rope production process, such as Figure 1-5As shown, it includes a bottom plate 1, a universal wheel 2, a purification mechanism 3, a first pickling tank 4, a liquid outlet pipe 5, a collection mechanism 6, a first rotating rod 7, a first bearing seat 8, a first drum 9, The second bearing seat 10, the second pickling box 12, the installation box 13, the second rotating rod 14, the spray pipe 15, the liquid inlet pipe 16, the second roller 17 and the block 18, the bottom of the bottom plate 1 is symmetrical on the front, back, left, and right sides The universal wheel 2 is connected in rotation, the top of the bottom plate 1 is connected with a purification mechanism 3, and the top of the purification mechanism 3 is connected with a first pickling tank 4, between the bottom middle of the first pickling tank 4 and the top middle of the purification mechanism 3 A liquid outlet pipe 5 is connected between them, a collection mecha...

Embodiment 2

[0032] A kind of pickling equipment for steel wire rope production process, such as Figure 1-5 As shown, it includes a bottom plate 1, a universal wheel 2, a purification mechanism 3, a first pickling tank 4, a liquid outlet pipe 5, a collection mechanism 6, a first rotating rod 7, a first bearing seat 8, a first drum 9, The second bearing seat 10, the second pickling box 12, the installation box 13, the second rotating rod 14, the spray pipe 15, the liquid inlet pipe 16, the second roller 17 and the block 18, the bottom of the bottom plate 1 is symmetrical on the front, back, left, and right sides The universal wheel 2 is connected in rotation, the top of the bottom plate 1 is connected with a purification mechanism 3, and the top of the purification mechanism 3 is connected with a first pickling tank 4, between the bottom middle of the first pickling tank 4 and the top middle of the purification mechanism 3 A liquid outlet pipe 5 is connected between them, a collection mech...

Embodiment 3

[0035] A kind of pickling equipment for steel wire rope production process, such as Figure 1-5 As shown, it includes a bottom plate 1, a universal wheel 2, a purification mechanism 3, a first pickling tank 4, a liquid outlet pipe 5, a collection mechanism 6, a first rotating rod 7, a first bearing seat 8, a first drum 9, The second bearing seat 10, the second pickling box 12, the installation box 13, the second rotating rod 14, the spray pipe 15, the liquid inlet pipe 16, the second roller 17 and the block 18, the bottom of the bottom plate 1 is symmetrical on the front, back, left, and right sides The universal wheel 2 is connected in rotation, the top of the bottom plate 1 is connected with a purification mechanism 3, and the top of the purification mechanism 3 is connected with a first pickling tank 4, between the bottom middle of the first pickling tank 4 and the top middle of the purification mechanism 3 A liquid outlet pipe 5 is connected between them, a collection mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com