A method to facilitate disassembly and assembly of molds in the production of concrete prefabricated parts

A technology for concrete prefabricated parts and easy disassembly and assembly. It is applied in the direction of molds and mold auxiliary parts. It can solve the problems of repeated reproduction, damage to hole shape, and inability to realize large-scale production. It achieves easy mold manufacturing and convenient disassembly. , The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

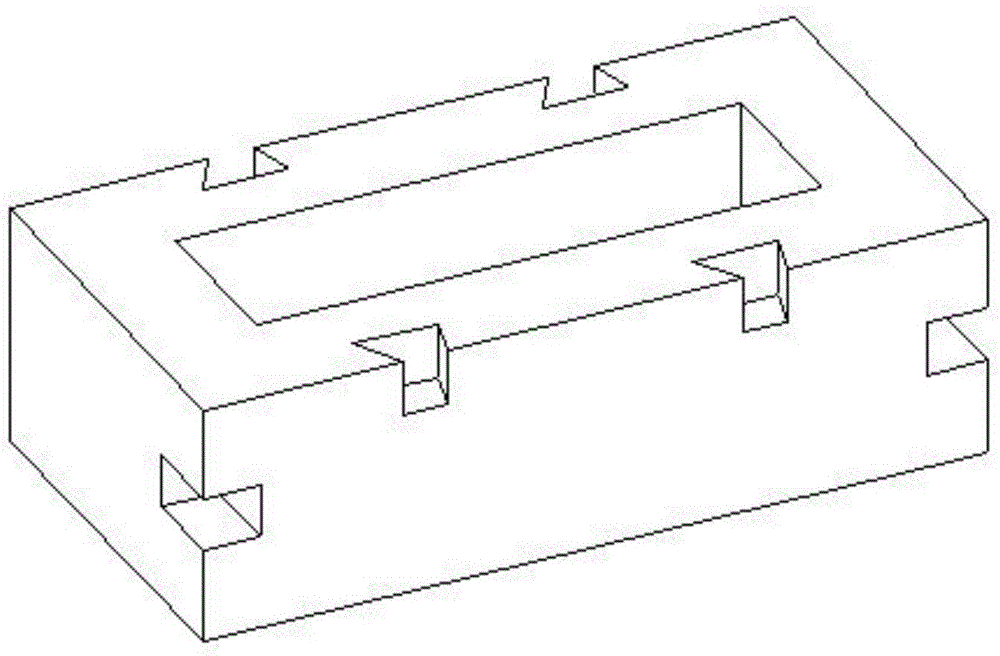

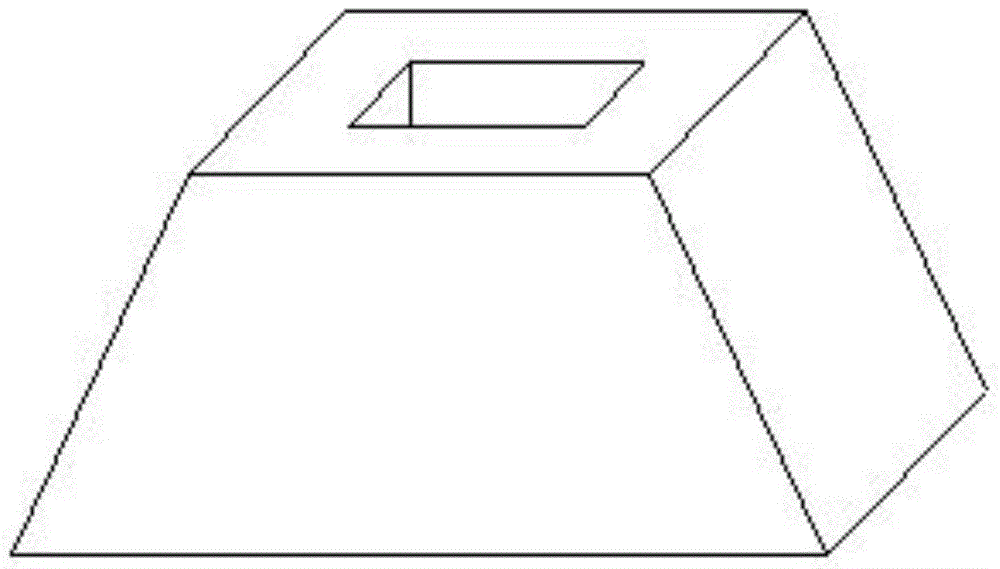

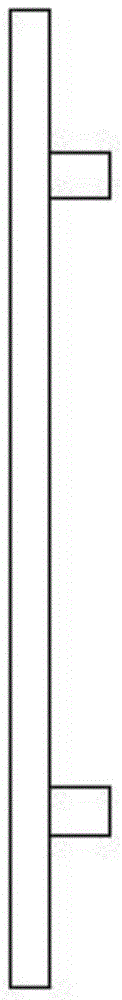

[0018] Such as figure 1 , figure 2 , image 3 As shown, a method for convenient disassembly and assembly of molds during the production of concrete prefabricated parts described in this embodiment, the steps are as follows:

[0019] The first step is to make a pair of molds with metal materials. The mold is composed of a bottom plate, four side plates and a top plate. The four side plates are flexibly connected to the bottom plate, and there are two adjacent side plates. Connected by a detachable buckle;

[0020] In the second step, the two ends of the two sides in the length direction of the side plate are provided with the clamping positions of the silicone parts, and the two sides of the length direction of the top plate are respectively provided with two clamping positions of the silicone parts. There is a protruding block on the top; the silicone part is set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com