Preparation method of wear-resistant, heat-insulation and corrosion-resistant powder coating

A powder coating and composite ultrasonic technology, applied in powder coatings, anti-corrosion coatings, fire-retardant coatings, etc., can solve problems such as limiting the scope of application, and achieve the effect of expanding the scope of application, maintaining color and gloss, and meeting the needs of efficient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

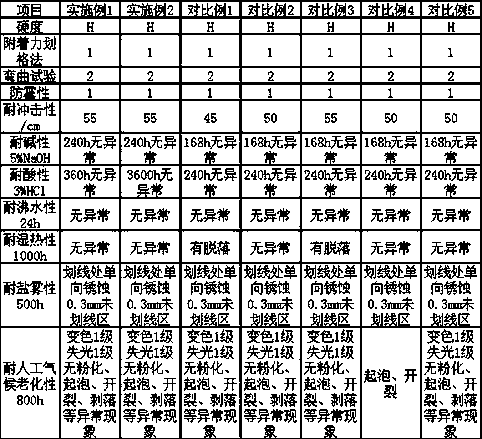

Examples

Embodiment 1

[0021] A kind of its preparation method of wear-resisting, heat-insulating and anti-corrosion powder coating, concrete steps are as follows: 1, put mercaptan and epoxy resin in the reaction still that has condensing tube, heat, then add acid catalyst to carry out ring-opening reaction, reaction temperature The temperature is 40°C, and the open-loop reaction time is 2.5h. The entire reaction process is carried out in a multi-frequency composite ultrasonic auxiliary device, wherein the multi-frequency composite ultrasonic auxiliary is a triple-frequency composite ultrasonic auxiliary. The triple-frequency composite ultrasonic auxiliary is specifically: The axial ultrasonic frequency is 28kHz, 48kHz; the radial ultrasonic frequency is 35kHz; during the reaction process, samples are taken regularly to measure the epoxy value. When the epoxy value no longer decreases, stop the reaction, cool the above reaction system to room temperature, and filter and recover Solid catalyst, place ...

Embodiment 2

[0029] A preparation method of wear-resistant, heat-insulating and anti-corrosion powder coating, the specific steps are as follows: 1. Put mercaptan and epoxy resin in a reaction kettle with a condenser tube, heat, then add an acid catalyst to carry out ring-opening reaction, and the reaction temperature is 30~40°C, the open-loop reaction time is 1h, and the entire reaction process is carried out in a multi-frequency composite ultrasonic auxiliary device, wherein the multi-frequency composite ultrasonic assistance is a triple-frequency composite ultrasonic assistance, and the triple-frequency composite ultrasonic assistance is specifically, The axial ultrasonic frequency is 28kHz, 48kHz; the radial ultrasonic frequency is 35kHz; during the reaction process, samples are taken regularly to measure the epoxy value. When the epoxy value no longer decreases, stop the reaction, cool the above reaction system to room temperature, and filter and recover Solid catalyst, place the remai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com