Cantilever type purification plate adhesive spray system

A purification plate and cantilever type technology, applied in the direction of injection devices, etc., can solve the problems that cannot meet the production efficiency and quality requirements, and achieve the effect of meeting the requirements of efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

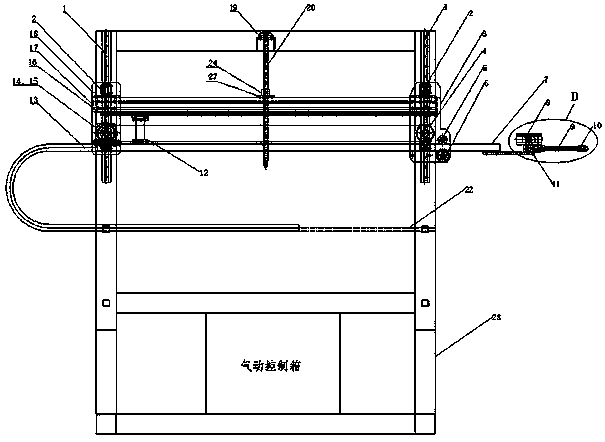

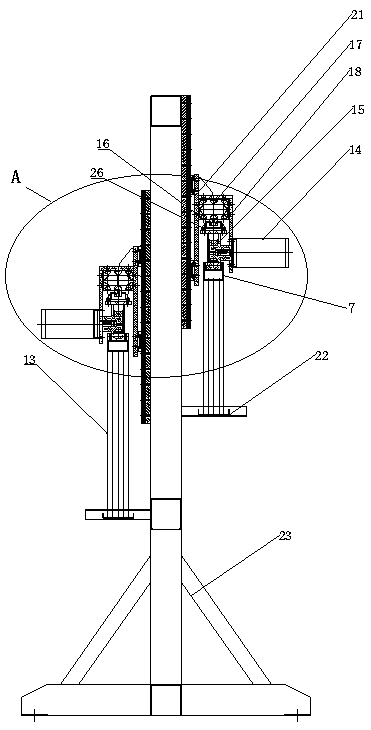

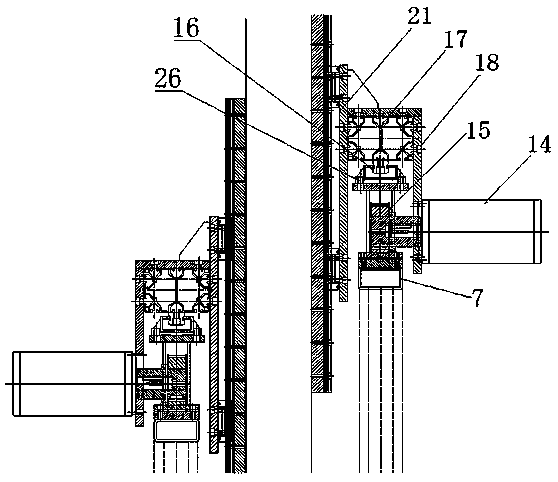

[0025] as attached Figure 1-4 As shown in , this embodiment includes a frame 23, two sets of glue spraying modules that are arranged on the left and right sides of the frame to spray glue to the panel of the purification plate and the core plate respectively, and drive the glue spraying module in the front-back direction and the up-down direction. Two sets of transmission modules that move on.

[0026] Wherein, the above-mentioned transmission module includes a linear guide rail I1 installed vertically on the front and rear sides of the frame 23, and a linear guide rail slider I2 that can slide up and down is connected to the linear guide rail I1. The iron plate I21 is fixed on the linear guide slider I2 of the linear guide rail, and the iron plate III3 is fixed on the linear guide slider I2 on the front side (driven side), and the aluminum profile 17 is fixed between the iron plate I21 and the iron plate III3. The bottom of the profile 17 is fixed with a linear guide rail I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com