Method for oil removal from wastewater in field of coal chemical industry

A technology for coal chemical industry and waste water, which is applied in separation methods, extraction water/sewage treatment, grease/oily substances/suspton removal devices, etc., which can solve the difficulty and cost of increasing management, affect waste water treatment, and it is difficult to remove dissolved oil, etc. problems, to achieve the effect of simplifying the wastewater treatment process and time, optimizing the extraction effect and recovery efficiency, and reducing the cost of sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

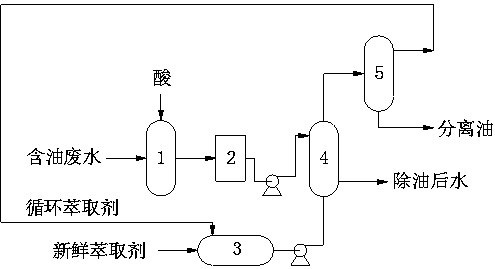

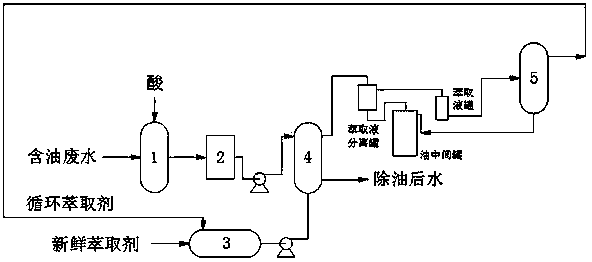

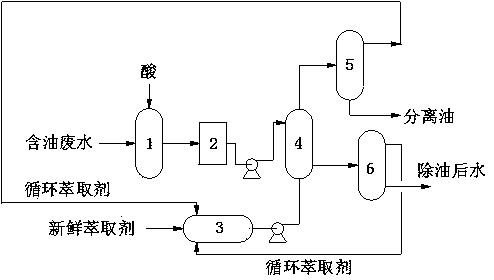

[0038] In a coal chemical plant, the coal chemical wastewater treatment capacity is 53 tons / hour, of which the oil content is 1257 mg / L, and the soluble oil content in the oil content is 420 mg / L. figure 1 The process equipment flow chart for wastewater degreasing, the steps are as follows:

[0039] a. Wastewater pretreatment: First, the wastewater enters the adjustment tank and adds acid to make the pH at 5.0, and then cools to 40℃ through a cooler;

[0040] b. Extraction and degreasing: the pretreated wastewater is pumped to the top of the extraction tower, and countercurrent extraction is performed with the n-hexane entering from the bottom. The volume ratio of the extractant to the wastewater is 1:20, the number of plates is 4, and the tower The top pressure is 0.1MPa, the temperature is 40°C, the bottom pressure is 0.3MPa, and the temperature is 45°C; the extraction phase is extracted from the top of the tower; the water phase after extraction and degreasing is extracted from t...

Embodiment 2

[0044] In a coal chemical plant, the coal chemical wastewater treatment capacity is 65 tons / hour, of which the oil content is 1322mg / L, and the soluble oil content in the oil content is 480mg / L. figure 1 The process equipment flow chart for wastewater degreasing, the steps are as follows:

[0045] a. Wastewater pretreatment: First, the wastewater enters the adjustment tank and adds acid to make the pH 4.0, and then cools to 35°C through a cooler;

[0046] b. Extraction and degreasing: The pretreated wastewater is pumped to the top of the extraction tower, and it is extracted countercurrently with the petroleum ether entering from the bottom. The volume ratio of extractant to wastewater is 1:12, the number of plates is 7, and the tower The top pressure is 0.2MPa, the temperature is 34°C, the bottom pressure is 0.8MPa, and the temperature is 35°C. The extraction phase is extracted from the top of the tower; the water phase after extraction and degreasing is extracted from the bottom o...

Embodiment 3

[0050] In a coal chemical plant, the coal chemical wastewater treatment capacity is 80 tons / hour, of which the oil content is 1530 mg / L, and the soluble oil content in the oil content is 570 mg / L. figure 1 The process equipment flow chart for wastewater degreasing, the steps are as follows:

[0051] a. Wastewater pretreatment: First, the wastewater enters the adjustment tank and adds acid to make the pH at 3.0, and then cools to 30°C through a cooler;

[0052] b. Extraction and degreasing: The pretreated wastewater is pumped to the top of the extraction tower, and the hexane and petroleum ether (3:1) entering from the bottom are subjected to countercurrent extraction. The volume ratio of extractant to wastewater is 1:7 , The number of trays is 10, the pressure at the top of the tower is 0.1MPa, the temperature is 60°C, the pressure at the bottom of the tower is 1.0MPa, and the temperature is 30°C. The extraction phase is extracted from the top of the tower; the water phase after ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oil removal rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com