Steel structure non-contact actual measurement method and system based on three-dimensional scanning technology

A non-contact, three-dimensional scanning technology, used in measuring devices, measuring instruments, surveying and navigation, etc., can solve the problem that the control of component errors is difficult to refine, consumes a lot of labor, affects secondary structures, installation engineering steel structures, and curtain wall structures. and decoration projects, to achieve the effect of simplifying the time required, reducing the use of manpower, and improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. Note that the aspects described below in conjunction with the drawings and specific embodiments are only exemplary, and should not be construed as limiting the protection scope of the present invention.

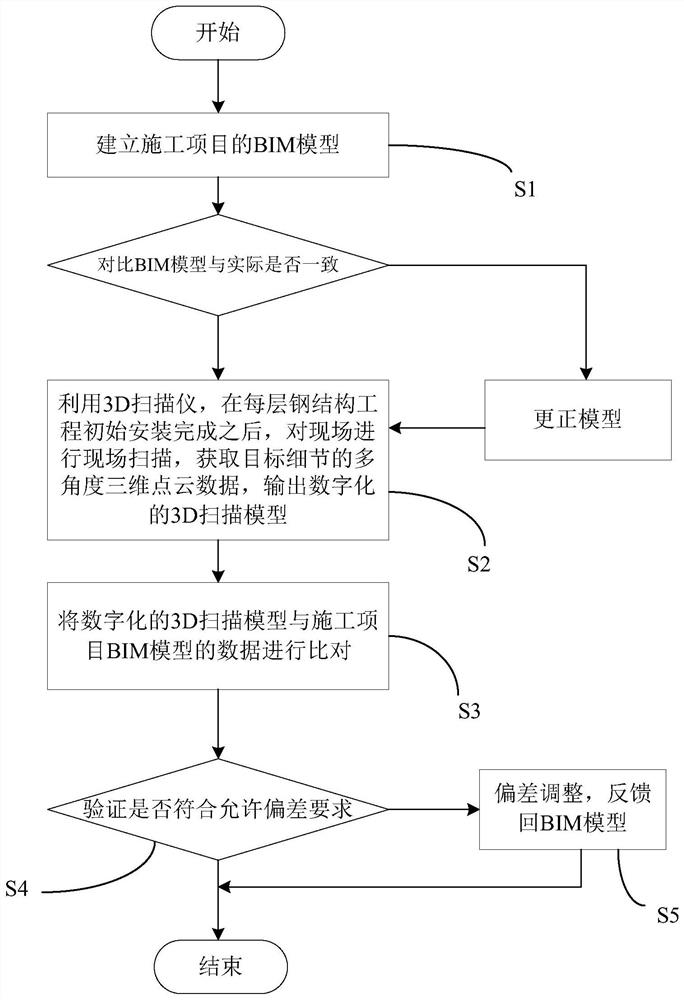

[0047] figure 1 The flow chart of an embodiment of the non-contact actual measurement method for steel structures based on the three-dimensional scanning technology of the present invention is shown. See figure 1 , the following is a detailed description of the implementation steps of the method of this embodiment.

[0048] Step S1: Establish the BIM model of the construction project, and verify the consistency between the BIM model and the actual building.

[0049] For the BIM model of a construction project, it generally includes the size and elevation information of its basic components. At the same time, the pipelines, steel bars, and max...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com