Interface pretreatment liquid for silicon-oxygen pre-lithiation negative electrode as well as preparation method and application of interface pretreatment liquid

A pretreatment liquid and pretreatment technology, applied in the direction of battery electrodes, electrochemical generators, final product manufacturing, etc., can solve the limitations of not being able to improve the SEI stability of the pre-lithiated negative electrode, the first charge and discharge efficiency and cycle life , limit large-scale application and other issues, achieve the effect of improving the first charge and discharge efficiency and long-term cycle performance, inhibiting the growth of lithium dendrites and side reactions, and good electrochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention also provides a method for preparing the interface pretreatment liquid for the silicon-oxygen pre-lithiation negative electrode as described above, comprising the following steps:

[0054] In an inert gas atmosphere, control the water content < 1ppm, and the oxygen content < 1ppm, and mix the solute and the solvent.

[0055] The inert gas described in the present invention comprises helium (He), neon (Ne), argon (Ar), krypton (Kr), xenon (Xe) and radioactive radon (Rn), at normal temperature and pressure, they are all Colorless and odorless monatomic gas, it is difficult to carry out chemical reactions.

[0056] The present invention also provides an interface pretreatment method for a silicon-oxygen pre-lithiated negative electrode, comprising the following steps:

[0057] Soak the pre-lithiated pole piece in the interface pretreatment solution for silicon-oxygen pre-lithiated negative electrode as described in any of the above embodiments.

[0...

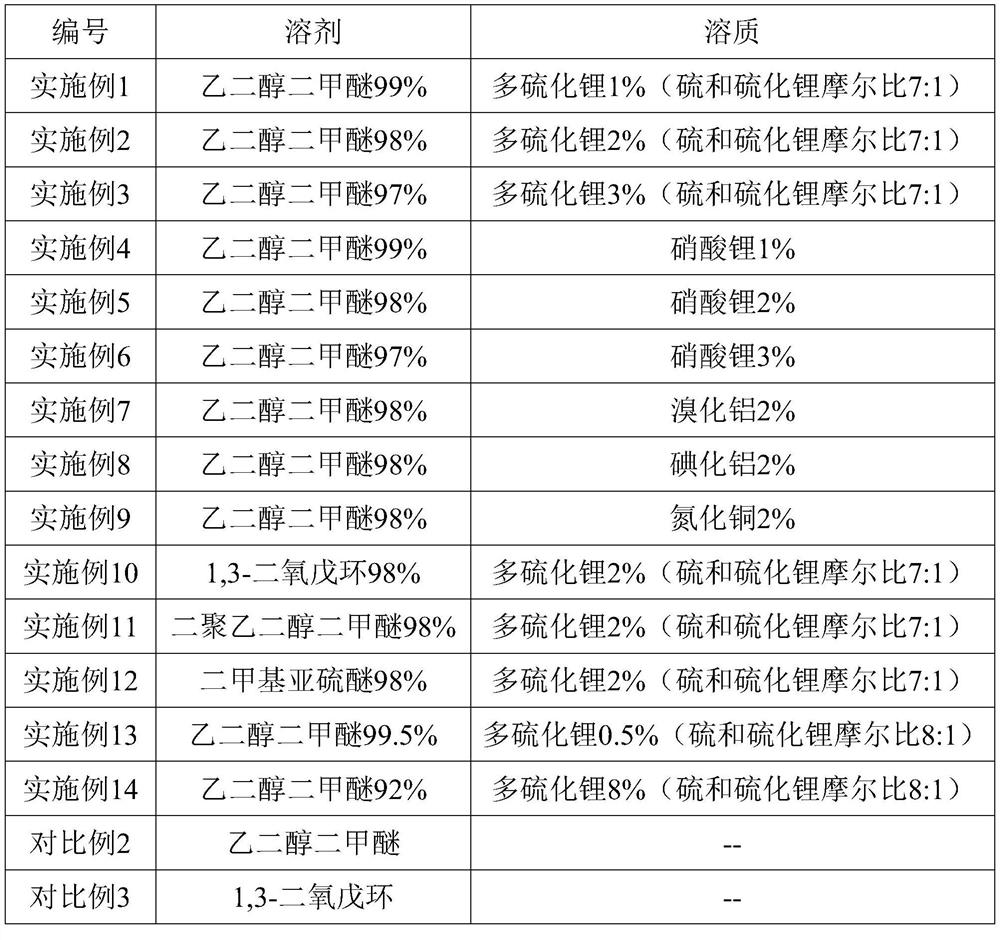

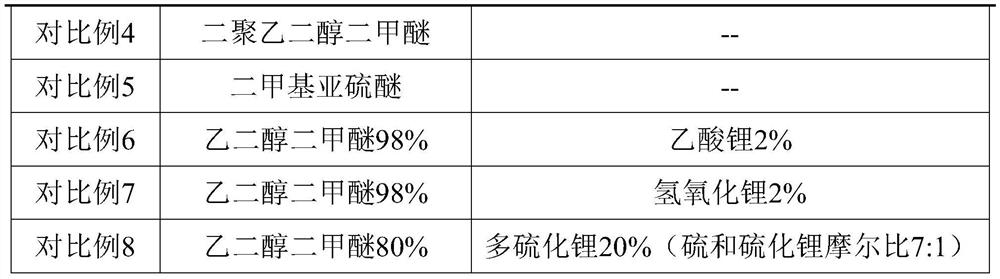

Embodiment 1

[0072] This embodiment provides an interface pretreatment solution for silicon-oxygen pre-lithiation negative electrode, its preparation method and application.

[0073] (1) In terms of mass percentage, the composition of the interface pretreatment liquid for the silicon-oxygen pre-lithiation negative electrode in this embodiment is:

[0074] Lithium polysulfide 1% and ethylene glycol dimethyl ether 99%; lithium polysulfide is prepared from sulfur and lithium sulfide in a molar ratio of 7:1.

[0075] (2) The preparation method of the interface pretreatment liquid for silicon oxygen prelithiation negative electrode in this embodiment is:

[0076] In an argon atmosphere glove box with a water content of <1ppm and an oxygen content of <1ppm, add ethylene glycol dimethyl ether into an aluminum-plastic bottle, and then add sulfur and lithium sulfide to the aluminum at a molar ratio of 7:1. In a plastic bottle, stir for 1 hour until the sulfur and lithium sulfide are completely dis...

Embodiment 2

[0091] This embodiment provides an interface pretreatment solution for silicon-oxygen pre-lithiation negative electrode, its preparation method and application.

[0092] (1) In terms of mass percentage, the composition of the interface pretreatment liquid for the silicon-oxygen pre-lithiation negative electrode in this embodiment is:

[0093] Lithium polysulfide 2% and ethylene glycol dimethyl ether 98%; lithium polysulfide is prepared from sulfur and lithium sulfide in a molar ratio of 7:1.

[0094] (2) The preparation method of the interface pretreatment liquid for silicon oxygen prelithiation negative electrode in this embodiment is:

[0095] In an argon atmosphere glove box with a water content of <1ppm and an oxygen content of <1ppm, add ethylene glycol dimethyl ether into an aluminum-plastic bottle, and then add sulfur and lithium sulfide to the aluminum at a molar ratio of 7:1. In a plastic bottle, stir for 1 hour until the sulfur and lithium sulfide are completely dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com