Scratching-resisting waterborne transfer coating

A transfer coating, water-based technology, applied in fireproof coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor compatibility, bluing, and decreased printing performance of transfer films, and achieve excellent compatibility and high durability. High temperature performance and high transparency of film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

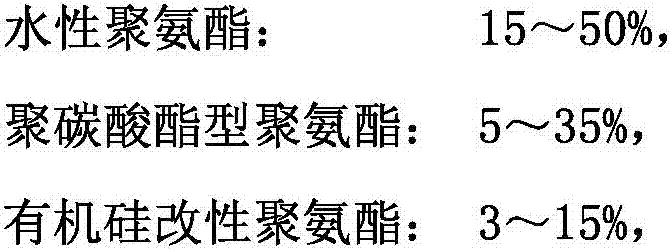

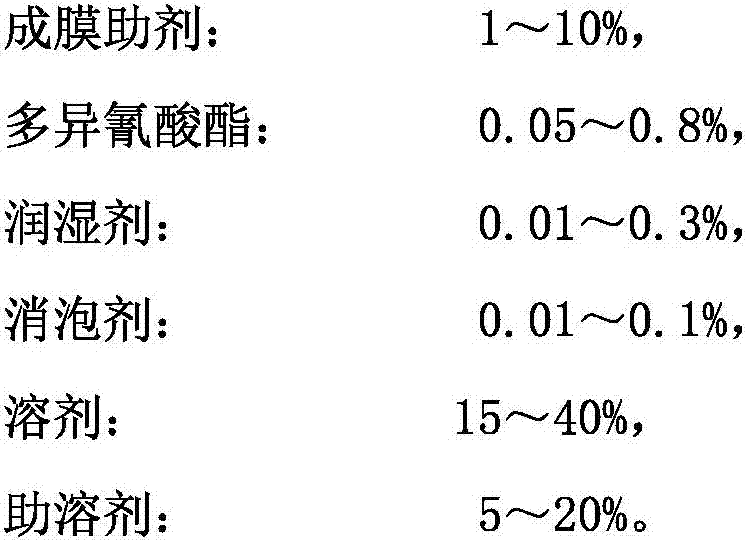

[0033] The present embodiment provides an anti-scratch water-based transfer coating, which is made of the following components and contents as raw materials:

[0034] Table 1

[0035] type

specific components

weight content

waterborne polyurethane

WPU-0105I

20%

WPU-1206B

20%

Silicone Modified Polyurethane

WPU-1205D

13%

Coalescent

Phosphate Triester

5%

polyisocyanate

TDI

0.40%

Dow Corning DC-51

0.05%

Germany BYK BYK-810

0.05%

solvent

water

32.00%

cosolvent

9.50%

[0036] Among them, WPU-0105I, WPU-1206B, WPU-1205D are all the raw materials of Chengying brand polyurethane produced by Shanghai Weikai Photoelectric New Materials Co., Ltd.

[0037] During preparation, S1. Mix the water-based polyurethane, the water-based polycarbonate-type polyurethane, and the organosilicon-modified...

Embodiment 2

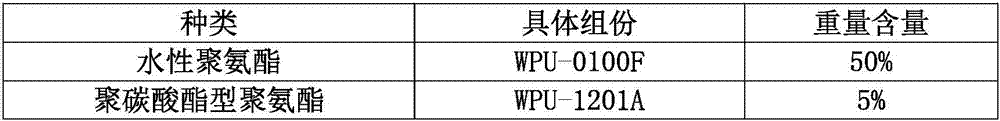

[0044] The present embodiment provides an anti-scratch water-based transfer coating, the preparation method is the same as that of embodiment 1, and the coating adopts the following components and contents as raw materials:

[0045] Table 2

[0046] type

Embodiment 3

[0048] The present embodiment provides an anti-scratch water-based transfer coating, the preparation method is the same as that of embodiment 1, and the coating adopts the following components and contents as raw materials:

[0049] table 3

[0050] type

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com