A kind of preparation method of thermal sublimation ink based on disperse dye

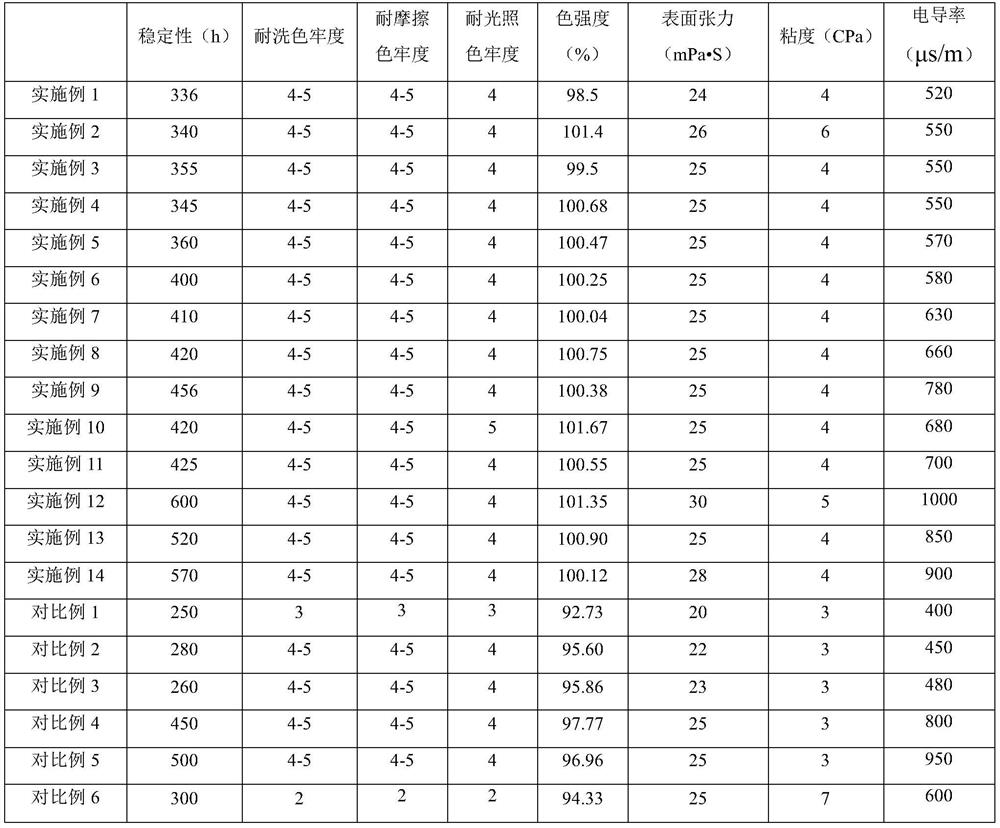

A disperse dye and dye sublimation technology, applied in ink, household utensils, applications, etc., can solve the problems of environmental protection, difficulty in meeting the requirements of coloring rate, coloring rate and color fastness, and high cost, and achieve good storage Stability, excellent color fastness, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

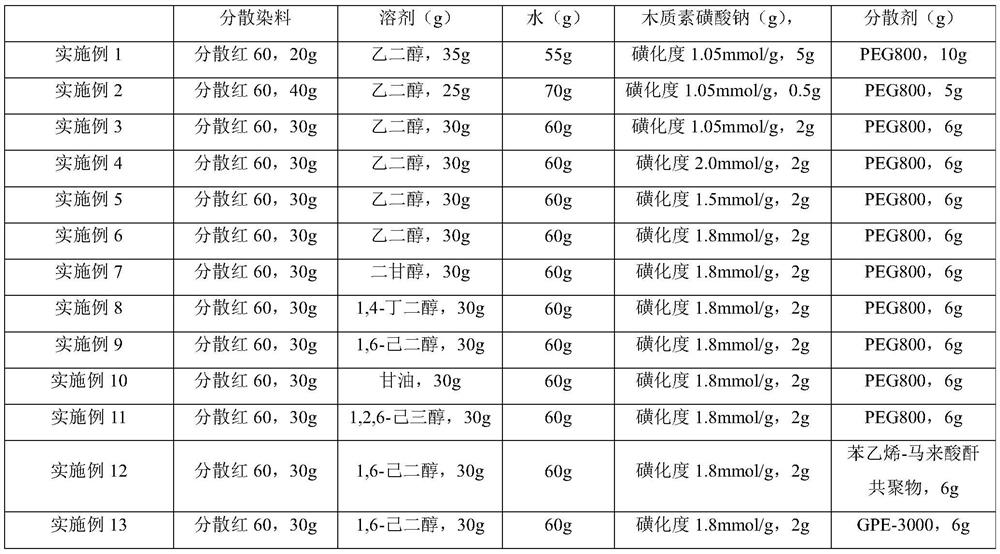

[0019] The preparation method of the thermal sublimation ink based on disperse dyes of the present invention comprises the following steps: (a) adding water, dispersant, solvent and surfactant to the container successively to carry out shear dispersion; Disperse dyes are stirred and dispersed to obtain a first mixture; the first mixture includes the following components in parts by weight: 15-25 parts of disperse dyes, 25-35 parts of solvents, 40-70 parts of water, and 0.5-5 parts of surfactants and 5-10 parts of dispersant; (b) using zirconia beads of different particle sizes to grind the first mixture, the particle size of the zirconia beads changing from large to small; (c) the step (b) The product is subjected to centrifugation, and the filtrate is obtained by filtration; water of the same quality as the obtained filtrate is added to the filtrate, and the large particle residue is removed to obtain a color paste; (d) the color paste is prepared with a wetting agent, a level...

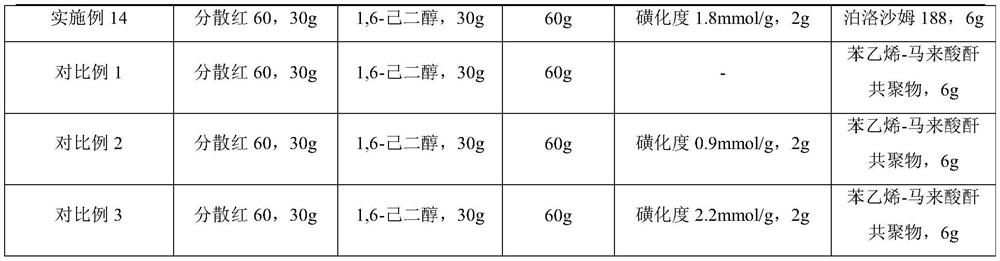

Embodiment 1-14、 comparative example 1-3

[0024] Embodiment 1-14, comparative example 1-3 provide a kind of preparation method of sublimation ink based on disperse dye respectively, it comprises the following steps:

[0025] (a) add water, dispersant, solvent and tensio-active agent successively in container, carry out shear dispersion; Continue to add disperse dye in described container again, carry out stirring and disperse to obtain the first mixture (each component of the first mixture content as shown in table 1);

[0026] (b) Use zirconia beads of 0.6-0.8mm, 0.4-0.6mm, 0.25-0.35mm and 0.1-0.2mm in sequence to grind the first mixture for 2 hours each, so that the particle diameter of the dye particles is D90≤200nm, D80≤ 150nm and D75≤100nm;

[0027] (c) in the product of step (b) (the dyestuff solid content of product is about 20%), add the water of its same quality, centrifuge then and remove large particle residue, use three grades of in-line filters to filter, filter to obtain color paste ( The solid content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degree of sulfonation | aaaaa | aaaaa |

| Degree of sulfonation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com