Preparation method of super-hydrophilic polyvinylidene fluoride/polydopamine composite films

A polyvinylidene fluoride, composite film technology, applied in spinning solution preparation, filament/thread forming, non-woven fabric and other directions, can solve the problems of short service life, membrane fouling membrane flux, poor wettability, etc. Achieving good oil-water separation effect and adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

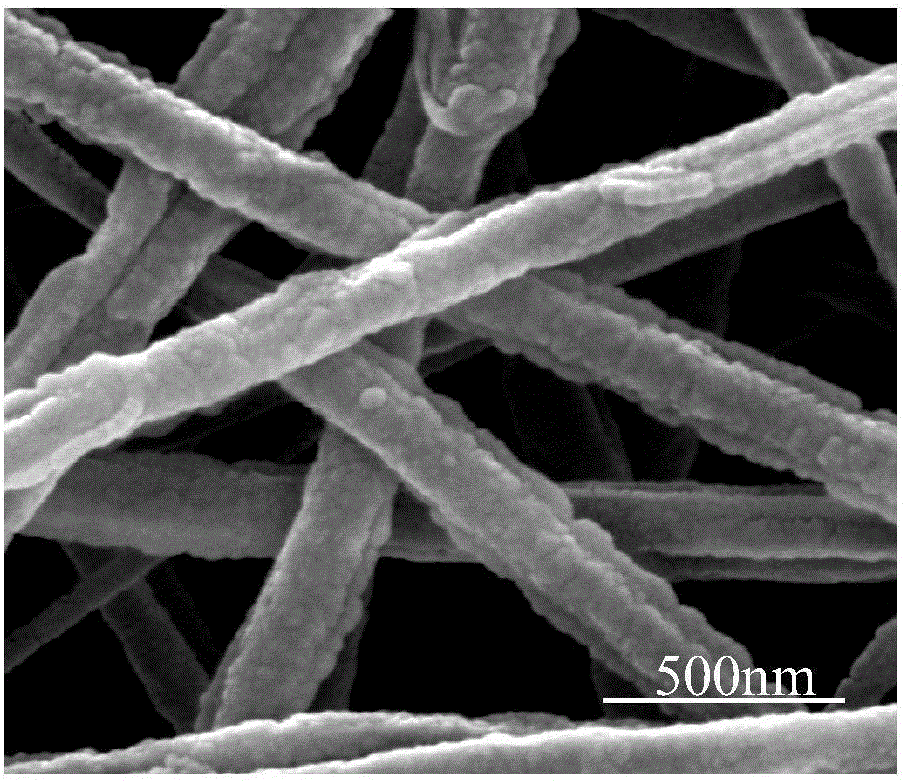

Image

Examples

Embodiment 1

[0021] A kind of preparation method of superhydrophilic polyvinylidene fluoride / polydopamine composite film, its step is:

[0022] A. Preparation of polyvinylidene fluoride / dopamine solution:

[0023] Dimethylacetamide and acetone are prepared into a mixed solvent at a volume ratio of 1:1, then polyvinylidene fluoride is added to the mixed solvent, and the temperature is raised to 45°C under stirring conditions, and the stirring is continued for 5 hours to obtain polyvinylidene fluoride The dimethylacetamide-acetone solution of vinylidene fluoride, the mass percent of polyvinylidene fluoride in the solution is 20%; Then add dopamine monomer in the dimethylacetamide-acetone solution of aforementioned polyvinylidene fluoride, Stir continuously for 1.5h, and then perform ultrasonic treatment for 1h, and the ultrasonic treatment intensity is 5×10 4 W / m 3 . The mass ratio of polyvinylidene fluoride to dopamine monomer is 100:50;

[0024] B. Preparation of polyvinylidene fluorid...

Embodiment 2

[0030] A. Preparation of polyvinylidene fluoride / dopamine solution:

[0031] Dimethylacetamide and acetone are prepared into a mixed solvent at a volume ratio of 1:1, then polyvinylidene fluoride is added to the mixed solvent, and the temperature is raised to 40°C while stirring, and the stirring is continued for 4 hours to obtain polyvinylidene fluoride The dimethylacetamide-acetone solution of vinylidene fluoride, the mass percent of polyvinylidene fluoride in the solution is 18%; Then add dopamine monomer in the dimethylacetamide-acetone solution of aforementioned polyvinylidene fluoride, Stir continuously for 1h, and then perform ultrasonic treatment for 0.5h, and the intensity of ultrasonic treatment is 2.5×10 4 W / m 3 . The mass ratio of polyvinylidene fluoride to dopamine monomer is 100:20;

[0032] B. Preparation of polyvinylidene fluoride / polydopamine composite film:

[0033] The polyvinylidene fluoride / dopamine solution was electrospun, the spinning speed was 0.01...

Embodiment 3

[0036] A. Preparation of polyvinylidene fluoride / dopamine solution:

[0037] Dimethylacetamide and acetone are prepared into a mixed solvent at a volume ratio of 1:1, then polyvinylidene fluoride is added to the mixed solvent, and the temperature is raised to 50°C under stirring conditions, and the stirring is continued for 6 hours to obtain polyvinylidene fluoride The dimethylacetamide-acetone solution of vinylidene fluoride, the mass percent of polyvinylidene fluoride in the solution is 25%; Then add dopamine monomer in the dimethylacetamide-acetone solution of aforementioned polyvinylidene fluoride, Stir continuously for 2 hours, and then perform ultrasonic treatment for 1 hour, and the intensity of ultrasonic treatment is 5×10 4 W / m 3 . The mass ratio of polyvinylidene fluoride to dopamine monomer is 100:80;

[0038] B. Preparation of polyvinylidene fluoride / polydopamine composite film:

[0039]The polyvinylidene fluoride / dopamine solution was electrospun, the spinning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com