Preparation method of phase-change material emulsion

A technology of phase change materials and emulsions, applied in heat exchange materials, chemical instruments and methods, sustainable manufacturing/processing, etc., can solve problems such as not fundamentally improving the stability of phase change material emulsion particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method of phase change material emulsion, comprising the following steps:

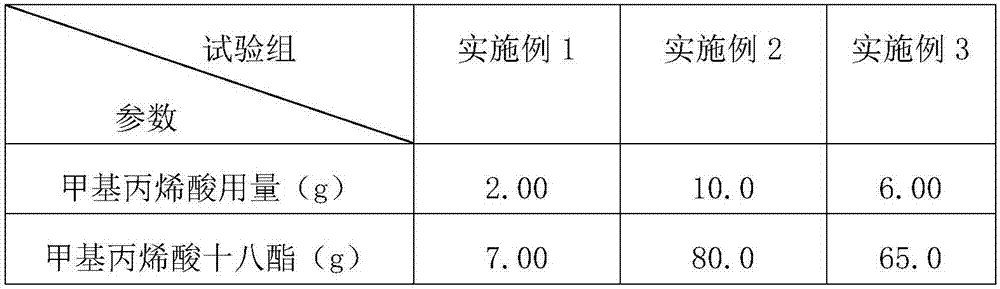

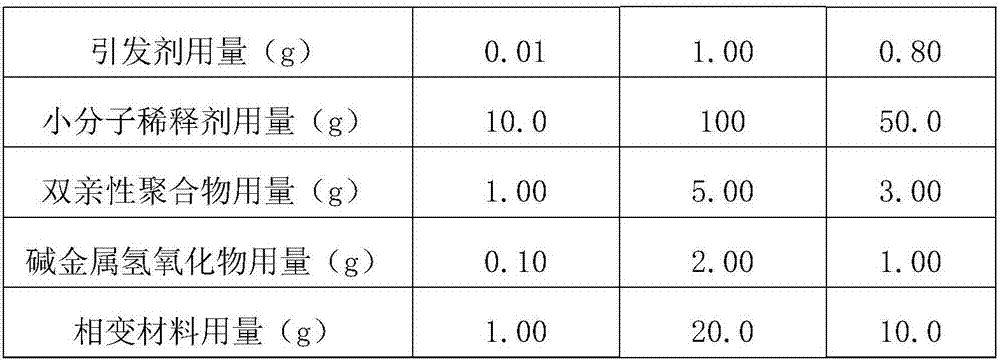

[0020] (1) Preparation of amphiphilic polymer: Weigh 2 g of methacrylic acid, dissolve 7 g of octadecyl methacrylate in benzophenone, add 0.01 g of sodium persulfate, and heat up to 60 ° C under stirring to initiate polymerization After reacting for 5 hours, add 10 g of methanol to terminate the reaction, filter, wash, and dry to obtain a white polymer;

[0021] (2) Preparation of Phase Change Material Emulsion: Dissolve 1g of the amphiphilic polymer prepared in step (1) and 0.1g of sodium hydroxide in pure water to form an aqueous phase. After dissolving 1g of polyethylene glycol in temperature, Add it into the water phase at an emulsification rate of 2000r / s, use a particle size detector to monitor the particle size of the emulsion in real time, stop emulsification when the particle size reaches 20nm-100μm, and obtain a phase change material emulsion.

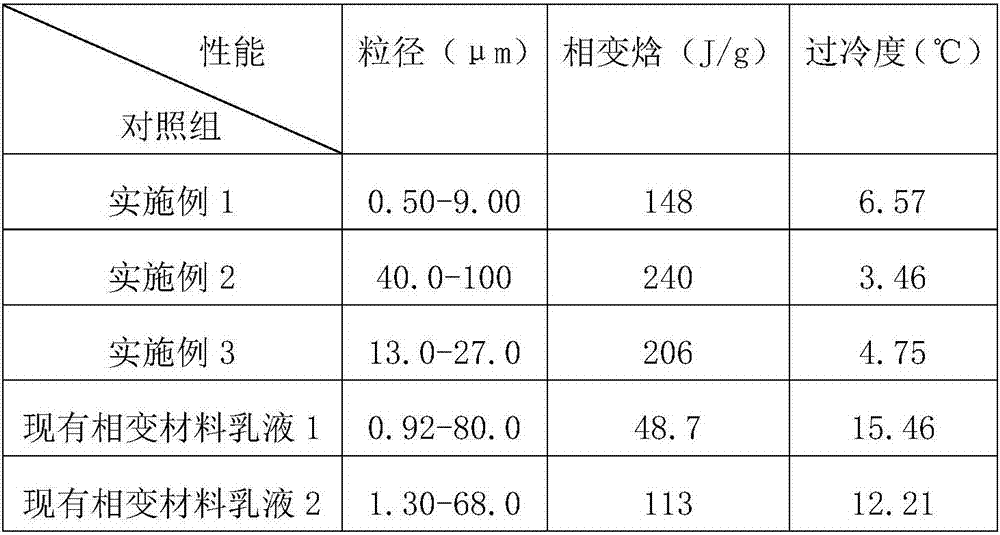

[0022] Table 1

[0023] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com