Fast quenching amorphous alloy ribbon and preparation method thereof

A kind of amorphous alloy, thin strip technology, applied in the field of rapid quenching amorphous alloy thin strip and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

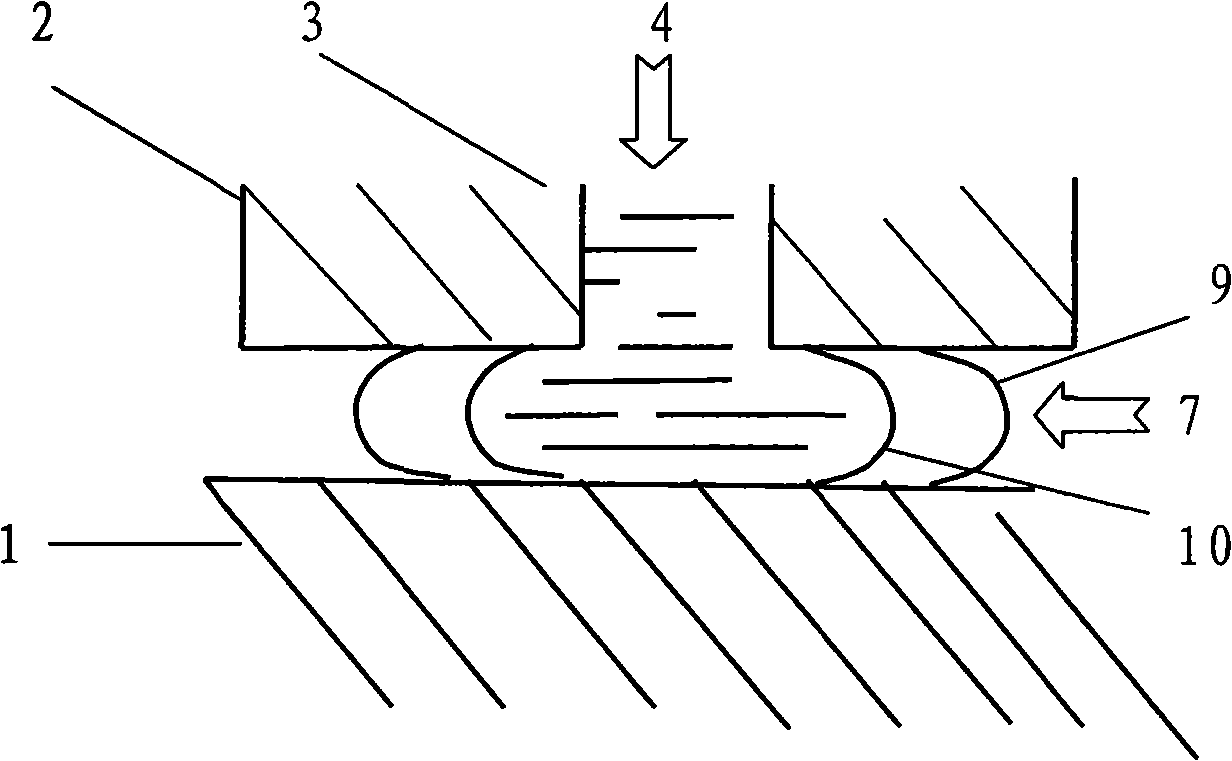

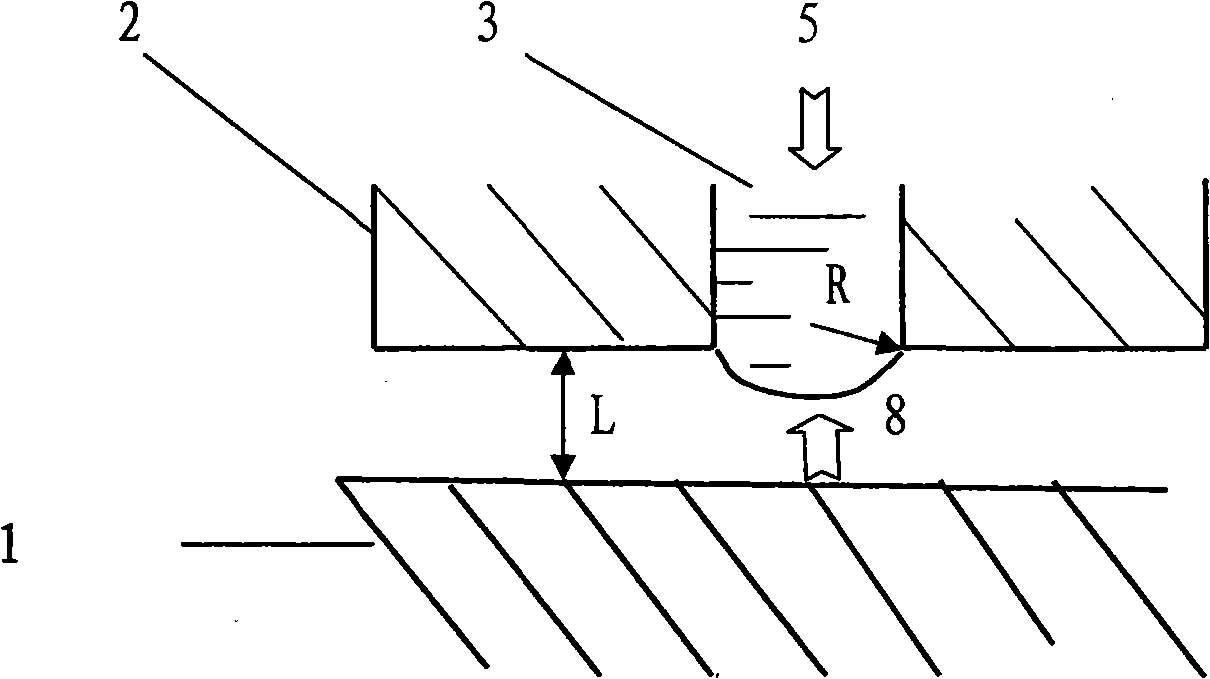

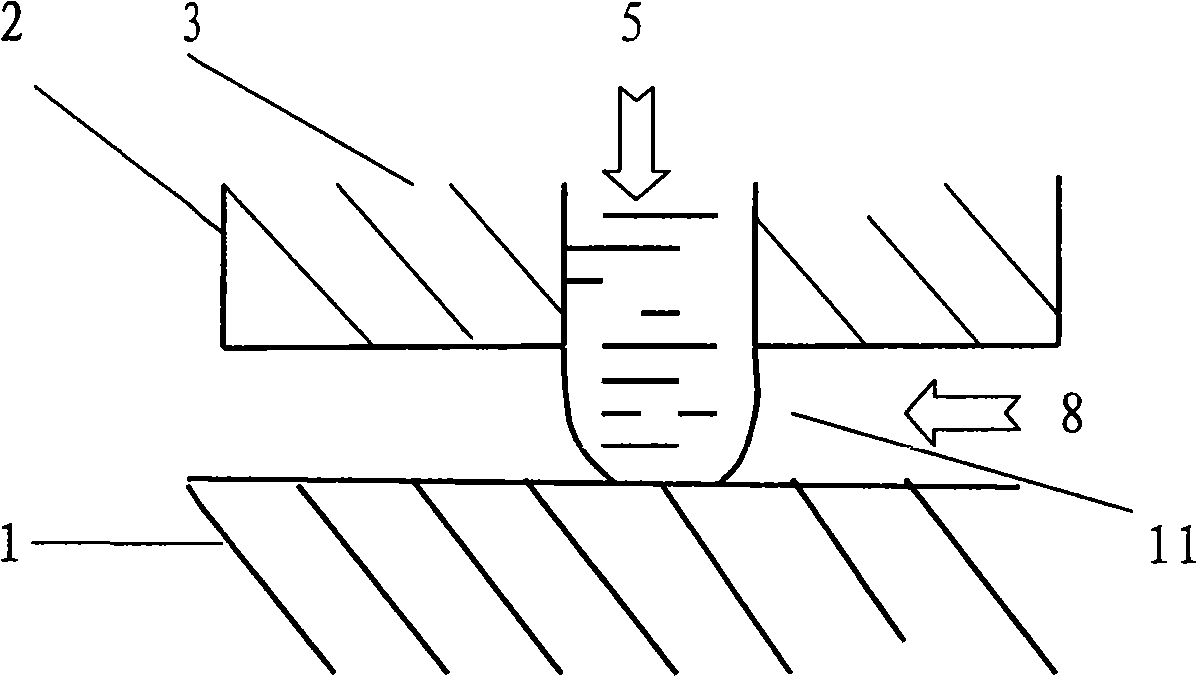

Method used

Image

Examples

Embodiment 1

[0092] Use industrial pure iron, niobium-iron alloy containing 60-68% niobium, industrial crystalline silicon and boron-iron alloy, and electrolytic copper as ingredients Fe73.5Cu1Nb3Si13.5B9 by atomic percentage, and melt it into a master alloy in a vacuum furnace. In the 2-pack method ( The induction ladle and nozzle bag) are melted twice, the tapping temperature is 1400°C, the liquid level of the nozzle bag is kept at 400 mm, and the nozzle slot width is 0.4 mm. Due to the increase of the liquid level, the pressure inside the molten pool is increased, forming a "convex" shaped molten pool, the surface finish of the strip is obviously improved, and the thickness of the strip can reach 24 microns. The composition and temperature of the comparative example are the same, while the comparative example adopts a low liquid level of 200mm, and a nozzle gap with a width of 0.7mm must be used, and a "convex" shaped molten pool cannot be formed, resulting in the thickness of the strip ...

Embodiment 2

[0096] Use industrial pure iron, ferroniobium alloy containing 60-68% niobium, industrial crystalline silicon and boron-iron alloy, and electrolytic copper as ingredients Fe73.5Cu1Nb3Si16.47B6Al0.02Ti0.01 in atomic percentage, and melt it into a master alloy in a vacuum furnace. In the bag method (induction ladle and nozzle bag) secondary melting, the tapping temperature is 1400°C, the nozzle bag is sealed, the liquid level is kept at 400mm, high-pressure gas is applied inside, the pressure is 0.02MPa, and the nozzle slit width is 0.3mm. Due to the further increase of the internal pressure of the molten pool and the reduction of the nozzle gap, the surface finish of the strip is significantly improved, and the thickness of the strip can be reduced to 22 microns. Due to the thinning of the strip, the high-frequency loss of the material is greatly reduced, and the composition of the comparative example is the same, but the content of Ti and Al is not controlled, the tapping tempe...

Embodiment 3

[0101] Industrial pure iron, industrial crystalline silicon and boron-iron alloy are used as ingredients according to the atomic percentage of Fe79Si9B11.96Al0.04, melted into a master alloy in a vacuum furnace, and secondary melted in the 2-pack method (induction ladle and nozzle package), and the tapping temperature 1400°C, keep the temperature of the molten pool at 1280°C, seal the nozzle bag, keep the liquid level at 200 mm, use a suction fan at the nozzle to create negative pressure, and the width of the nozzle slit is 0.3 mm, forming a "convex" shaped molten pool, and the thickness of the tape made is 22 microns. Depend on Image 6 Micrographs of the strip surface shown show less air bubbles and a high surface finish.

[0102] The conditions of the comparative example are consistent with the above, only the suction fan is closed, it is difficult to unpack the spray belt, no "convex" shaped molten pool is formed, and only a small amount of strip material is ejected to te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Remanence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com