Adhesive sheet, metal laminate sheet and printed wiring board

A technology of bonding board and bonding layer, applied in the direction of printed circuit, printed circuit, printed circuit manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0172] Next, the present invention will be explained in more detail by referring to the following Examples and Comparative Examples, which are not to be construed as limiting. Evaluation methods of properties in the following examples are shown below, in which the degree of curl after heat treatment at 300°C is based on the above-mentioned method.

[0173] 1. Thickness of polyimide film

[0174] A micrometer (Millitron (registered trademark) 1245D manufactured by FEINPRUF) was used for the measurement.

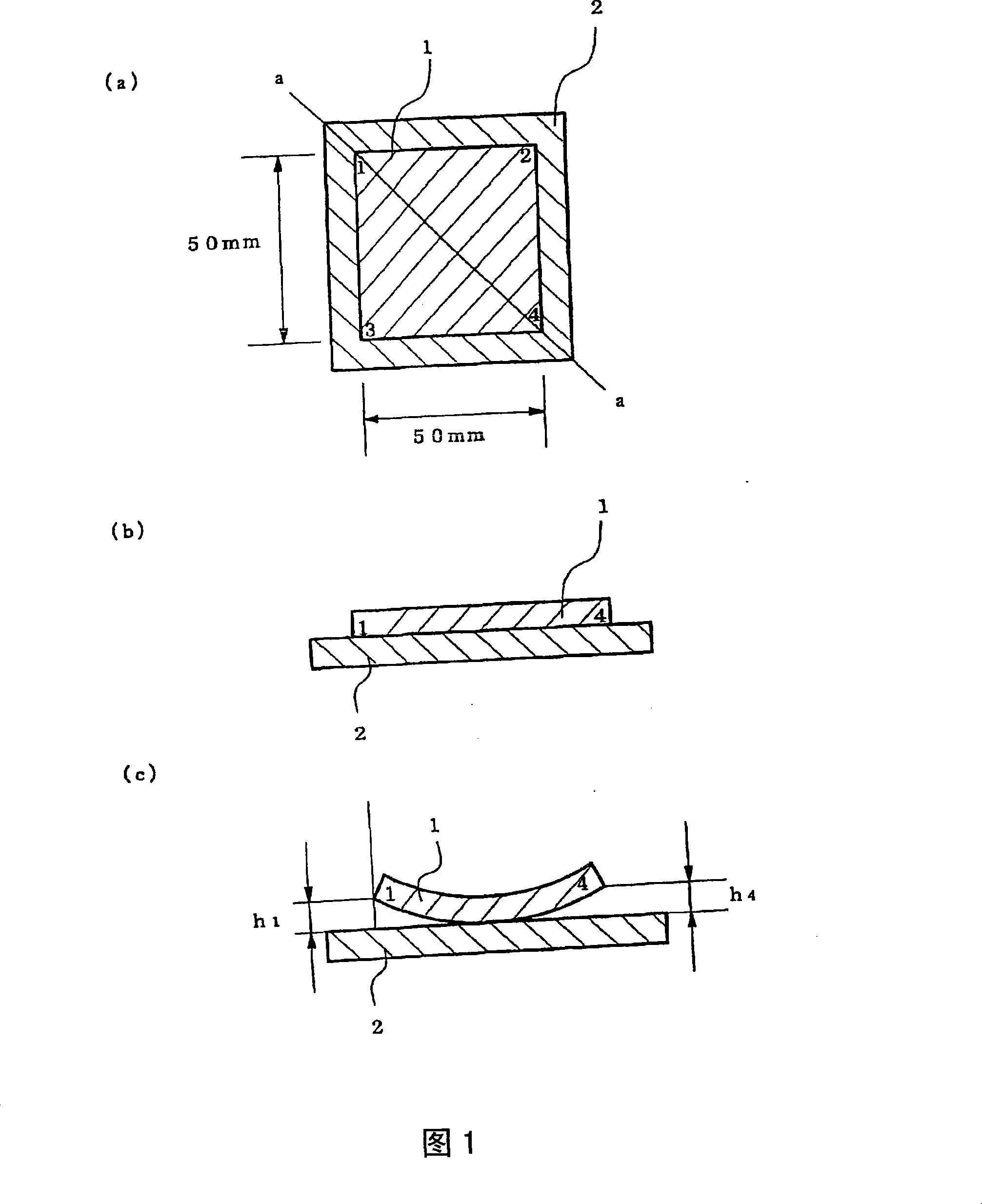

[0175] 2. Warpage of polyimide film and board (apparent warpage)

[0176] As shown in Figure 1 (C), the 50mm × 50mm film test piece is stood still on a flat plane to form a concave surface, and the average distance from each vertex on the test piece to the flat plane (h1, h2, h3, h4: unit mm) was taken as the amount of warpage (mm), and a value shown by the percentage (%) of the amount of warpage relative to the distance (35.36 mm) from each vertex on the test piece to the c...

preparation Embodiment 1-3

[0193] A vessel equipped with a nitrogen inlet tube, a thermometer, and a stirring bar was replaced with nitrogen, and ODA was placed therein. Then, add DMAC, after dissolving completes, add PMDA, be 1 / 1 ODA and PMDA at 25 ℃ by being stirred in DMAC by the molar ratio by monomer by 5 hours, regulate monomer addition concentration simultaneously to be 15 mass %, to polymerize the mixture. As a result, a brown viscous polyamic acid solution was obtained.

[0194] AA (15 parts by mass) and IQ (3 parts by mass) were added to the resulting polyamic acid solution (100 parts by mass), and the mixture was applied to a polyester film (COSMOSHINE (registered trademark) A4100, produced by Toyo Boseki Kabushiki Kaisha) on a non-lubricating surface, with a coating width of 740 mm (gap of squeegee / belt 430 μm). The film was dried during continuous passage through a continuous drying oven with 4 drying zones. In each zone, 3 rows of slit-shaped air outlets are respectively set above and b...

preparation Embodiment 4-6

[0215] Using PMDA and BPDA as the aromatic tetracarboxylic dianhydride component and ODA and P-PDA as the diamine component, the four monomers were mixed with PMDA / BPDA / ODA at a molar ratio of 1 / 0.5 / 1 / 0.5 / P-PDA was polymerized in DMF while adjusting the monomer addition concentration to 16% by mass to produce a solution of polyamic acid in DMF. The resulting polyamic acid solution was coated on a stainless steel belt (the gap between the squeegee / belt was 400 μm), and dried in the same manner as in Preparation Examples 1-3. Green films having various thicknesses of 49.5 μm were obtained by peeling the polyamic acid film which became self-supporting after drying from the stainless steel belt, ie, Preparation Examples 4-6. |IM of each GF A -IM B | values are 1.4, 4.2 and 4.8.

[0216] By passing the film through a nitrogen-substituted continuous heat treatment furnace, the obtained GF was heated in 2-steps under the following conditions to carry out imidization reaction: 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com