Manufacturing metod and equipment of sheet laminated aluminium section bar

A technology for laminating sheets and profiles, applied in other manufacturing equipment/tools, lamination, lamination devices, etc., can solve problems such as hindering sheet lamination profile manufacturing, chip adhesion, substrate chip pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

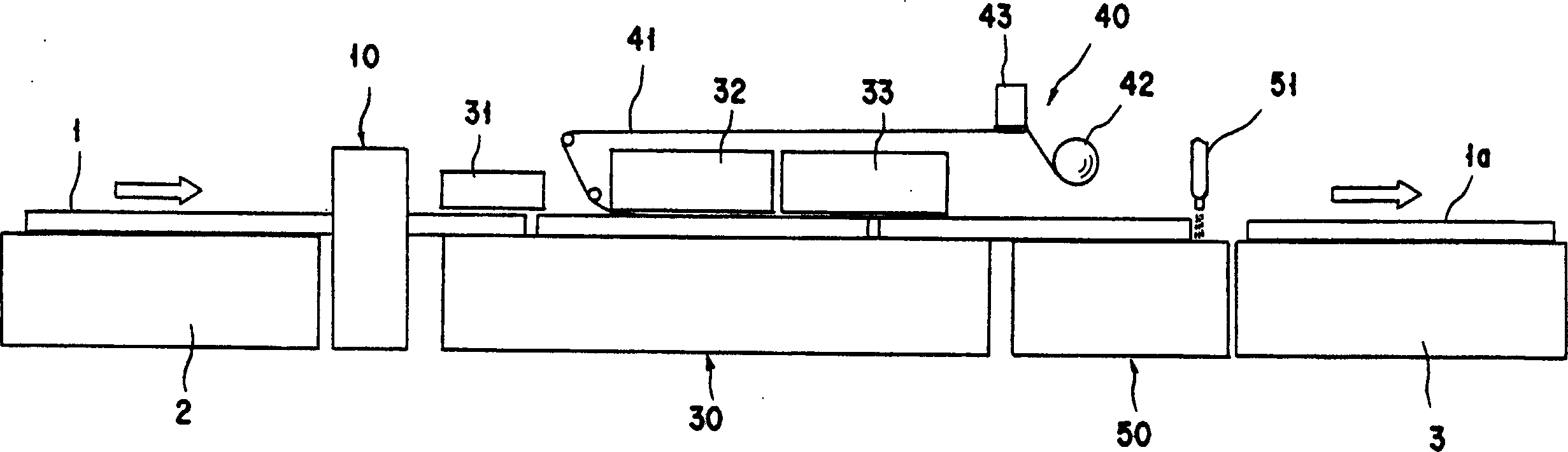

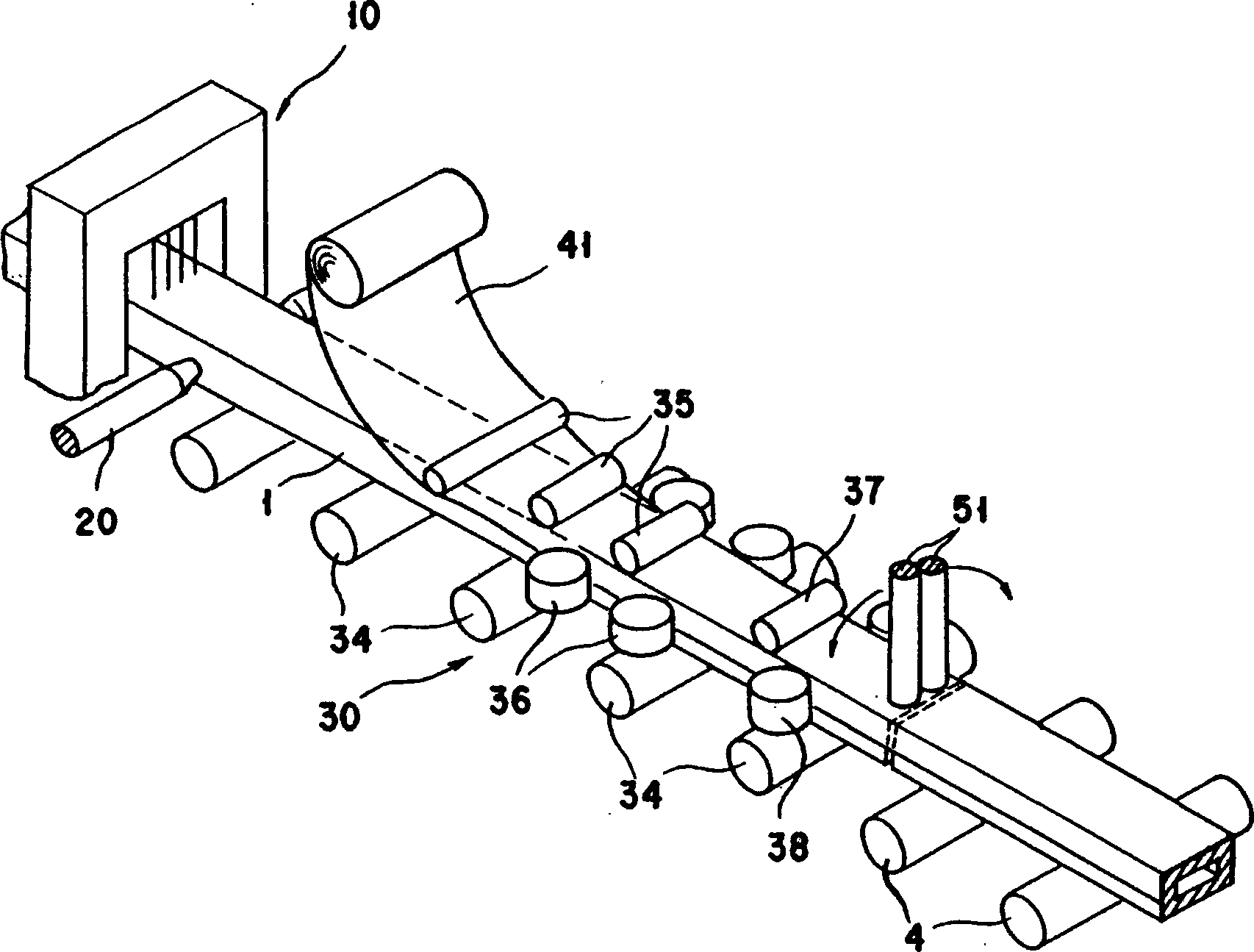

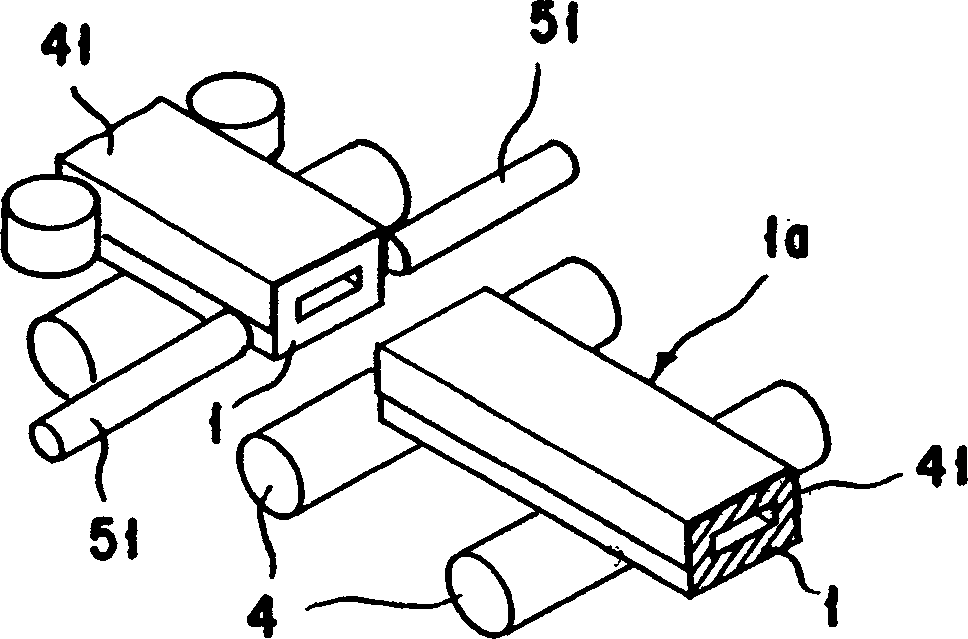

[0026] As mentioned above, according to the invention, the manufacture of sheet-laminated aluminum profiles is characterized by the steps of successively laminating sheets on a plurality of aluminum profiles, cutting the sheets at positions between the above-mentioned aluminum profiles by an electric discharge cutting process To form sheet laminated aluminum profiles.

[0027] In particular, the sheet is cut by thermal energy generated by an electrical discharge cutting process, rather than by a mechanical cutting device used in conventional methods. As a result, the following functions and effects are obtained:

[0028] (1) Only the sheet is cut without damaging the aluminum profile and the sheet laminated on its surface.

[0029] (2) Even if there is no gap between profiles, it is possible to cut only sheets.

[0030] (3) Since only the sheet is cut by thermal energy, there will be no chipping and no pollution to the product and the production line. Even when the sheets a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com