Solid welding wire

A solid-core welding wire, welding wire technology, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of reduced spatter generation, insufficient C content, unstable droplet, etc. The effect of reducing the amount of occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

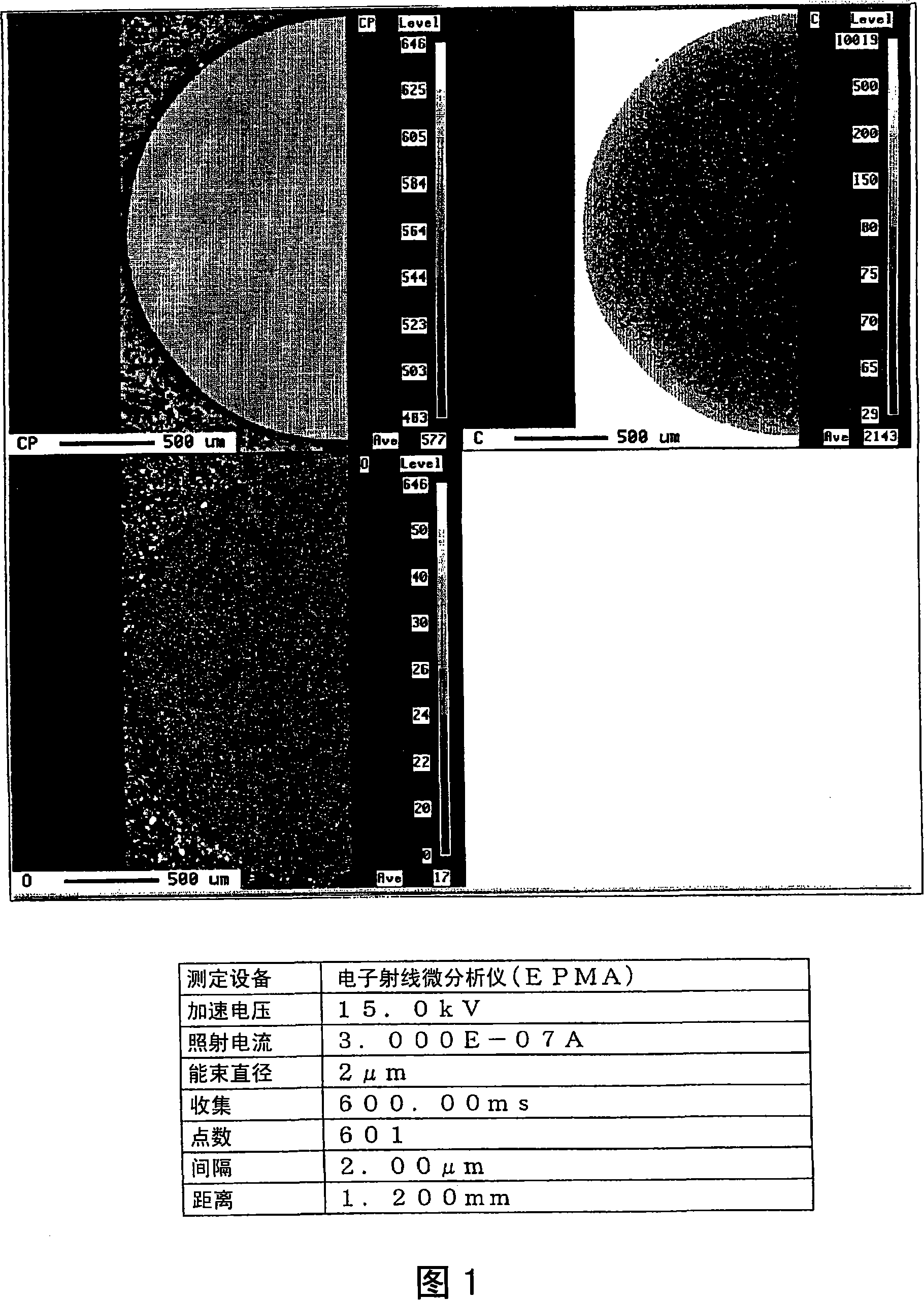

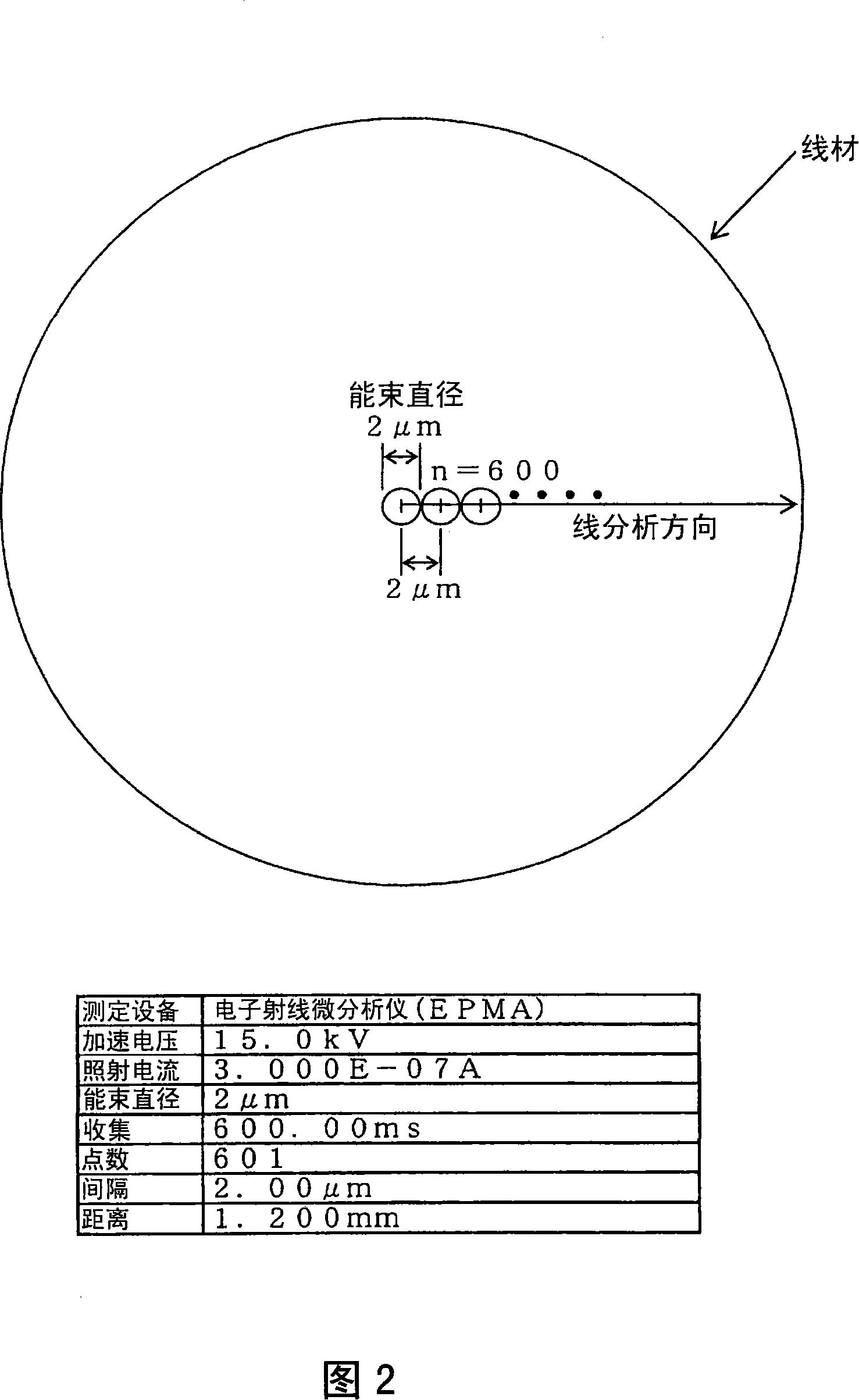

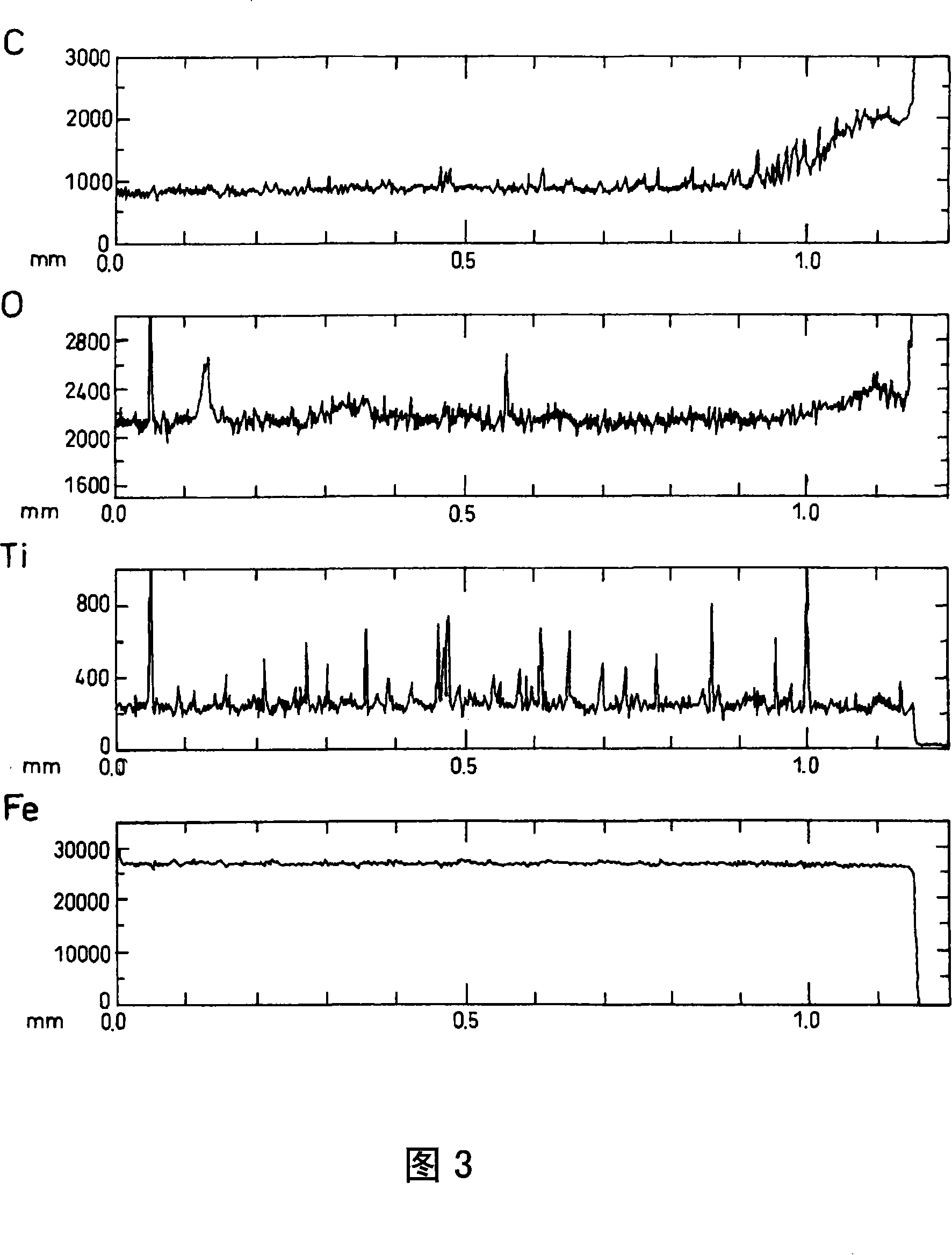

[0017] Hereinafter, embodiments of the present invention will be specifically described. The solid welding wire of the present invention is formed by making the atmosphere in the furnace in which the wire rod after the intermediate drawing is arranged to be 1 Torr or less, raising the temperature in the furnace, directly adding carburizing gas into the furnace, and then performing carburizing and quenching treatment. , for final drawing of the wire. Regarding the temperature and time for carburizing the wire rod, it has been found through various experiments that in consideration of the surface concentration of C accompanying this carburizing and quenching treatment and the subsequent wire drawing, at a temperature in the range of 650 to 900°C, 10 seconds to 10 minutes is appropriate. Fig. 1 is a composition image of a cross-section (cross-section) perpendicular to the longitudinal direction of the wire rod observed by an electron beam microanalyzer (EPMA) in a wire rod subje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com