Solid capacitor carbon foil nano conductive carbon paste and preparation method thereof

A nano-conducting, solid-state capacitor technology, used in cable/conductor manufacturing, capacitors, electrolytic capacitors, etc., can solve the problems of limited acid resistance and oxidation resistance, rough adhesion of interface bonding, and easy occurrence of microscopic cracks, so as to avoid agglomeration. , The effect of reducing particle spacing and preventing oxidation or corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

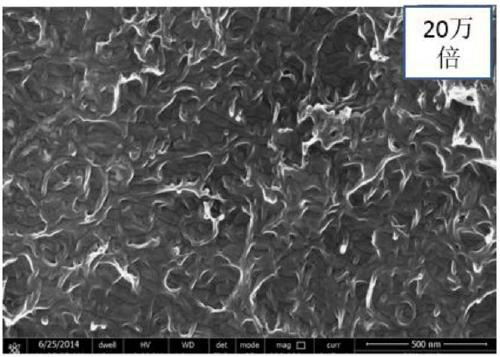

Image

Examples

Embodiment 1

[0020] A preparation method of solid capacitor carbon foil nano conductive carbon paste, wherein the preparation method is as follows:

[0021] (1) Soak carbon nanotubes in a mixture of concentrated nitric acid and concentrated sulfuric acid for 1.5 hours, wash with deionized water until neutral, dry to obtain acidified carbon nanotubes, and then mix with carbon nanotubes at a mass ratio of 2:1 Uniform, get nano conductive carbon fiber system;

[0022] (2) Take diethylene glycol butyl ether, polyoxyethylene alkylphenyl ether, methyl benzyl alcohol, N,N-dimethylacetamide and terpineol in a mass ratio of 3:1:3:2:1 , sequentially added to the stirring tank, at a stirring speed of 88r / min and a temperature of 42°C, stirring and mixing for 30 minutes to obtain a polymer solvent;

[0023] (3) Add binder accounting for half of the total binder volume into the polymer solvent, stir and mix for 0.6h at a stirring speed of 53r / min, then add the nano-conductive carbon fiber system, the ...

Embodiment 2

[0027] A preparation method of solid capacitor carbon foil nano conductive carbon paste, wherein the preparation method is as follows:

[0028] (1) Take carbon nanotubes and place them in a mixture of concentrated nitric acid and concentrated sulfuric acid for acidification for 1 hour, wash with deionized water until neutral, dry to obtain acidified carbon nanotubes, and then mix them with carbon nanotubes at a mass ratio of 2:1. , to obtain nano-conductive carbon fiber system;

[0029] (2) Take diethylene glycol butyl ether, N,N-dimethylacetamide and terpineol in a mass ratio of 3:2:1, and add them to the stirring tank in turn. When the stirring speed is 100r / min, the temperature At 44°C, stir and mix for 30 minutes to obtain a polymer solvent;

[0030] (3) Add binder accounting for half of the total binder volume into the polymer solvent, stir and mix for 0.9h at a stirring speed of 52r / min, then add the nano-conductive carbon fiber system, the mass of the nano-conductive c...

Embodiment 3

[0034] A preparation method of solid capacitor carbon foil nano conductive carbon paste, wherein the preparation method is as follows:

[0035] (1) Take carbon nanotubes and place them in a mixture of concentrated nitric acid and concentrated sulfuric acid for acidification for 2 hours, wash with deionized water until neutral, dry to obtain acidified carbon nanotubes, and then mix them with carbon nanotubes at a mass ratio of 2:1. , to obtain nano-conductive carbon fiber system;

[0036] (2) Take polyoxyethylene alkylphenyl ether, methyl benzyl alcohol, and N,N-dimethylacetamide in a mass ratio of 1:3:2 and add them to the stirring tank in sequence. Stir and mix for 30 minutes at 41°C to obtain a polymer solvent;

[0037] (3) Add binder accounting for half of the total binder volume in the polymer solvent, stir and mix for 0.8h at a stirring speed of 57r / min, then add the nano-conductive carbon fiber system, the mass of the nano-conductive carbon fiber system and the polymer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com