Covalent organic framework and composite material, preparation method and application thereof

A technology of covalent organic framework and composite materials, which is applied in the field of preparation of covalent organic framework and its composite materials, can solve the problems of high energy consumption, high cost, low hydrogen isotope efficiency, etc., and achieve large comparison area and small pore size , Enhance the effect of dynamic sieving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation method of the covalent organic framework composite material containing the repeating unit shown in formula II of the present invention, the steps are as follows:

[0055] Step 1, under the protection of an inert atmosphere, the Pd(OAC) 2 Soluble in CH 2 Cl 2 In, a clear and transparent reddish-brown solution was obtained;

[0056] Step 2. Under the protection of an inert atmosphere, the covalent organic framework of formula I is placed in CH 2 Cl 2 disperse evenly, and under stirring, dropwise add the clear and transparent reddish-brown solution obtained in Step 1. After the dropwise addition is completed, stir at room temperature for more than 12h, preferably 12-24h, filter under reduced pressure, CH 2 Cl 2 Washing, washing with acetone, and drying in vacuum to obtain a covalent organic framework composite;

[0057] Take Pd(OAC) in step 1 2 For 360mg, the CH in step 1 2 Cl 2 is 50mL, the covalent organic framework in step 2 is 250mg, and the CH...

Embodiment 1

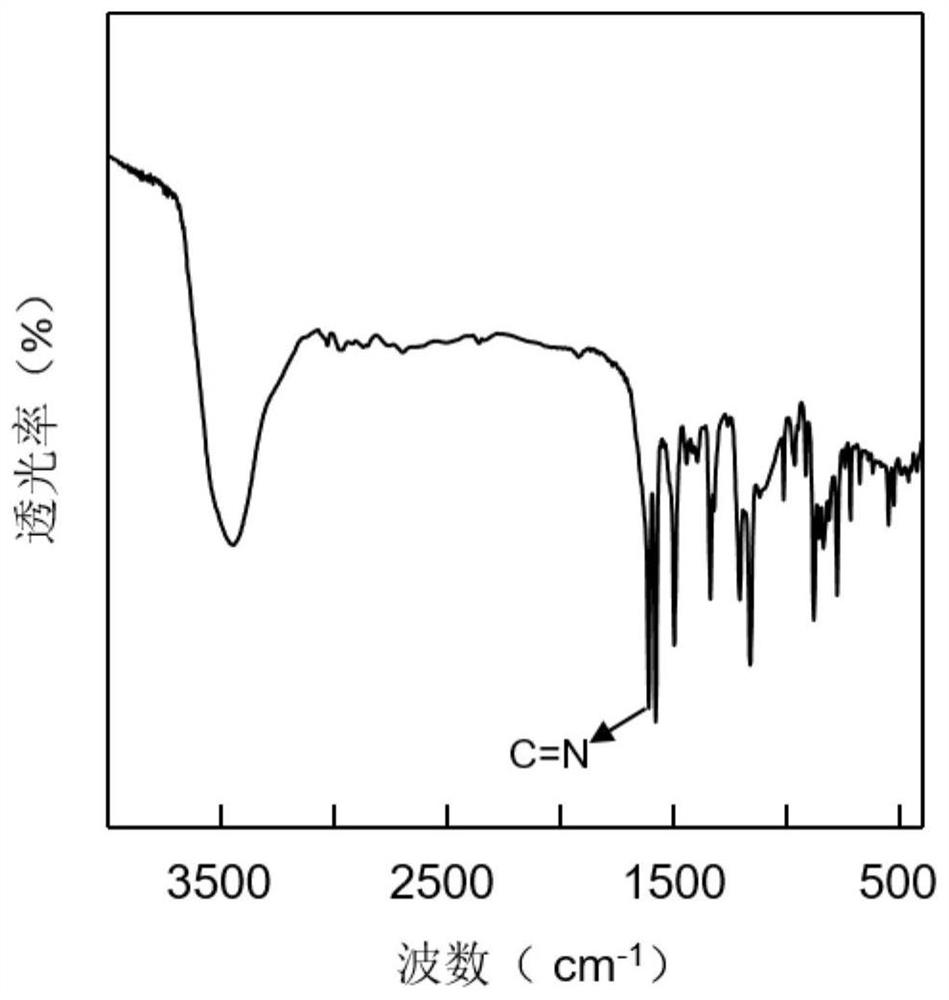

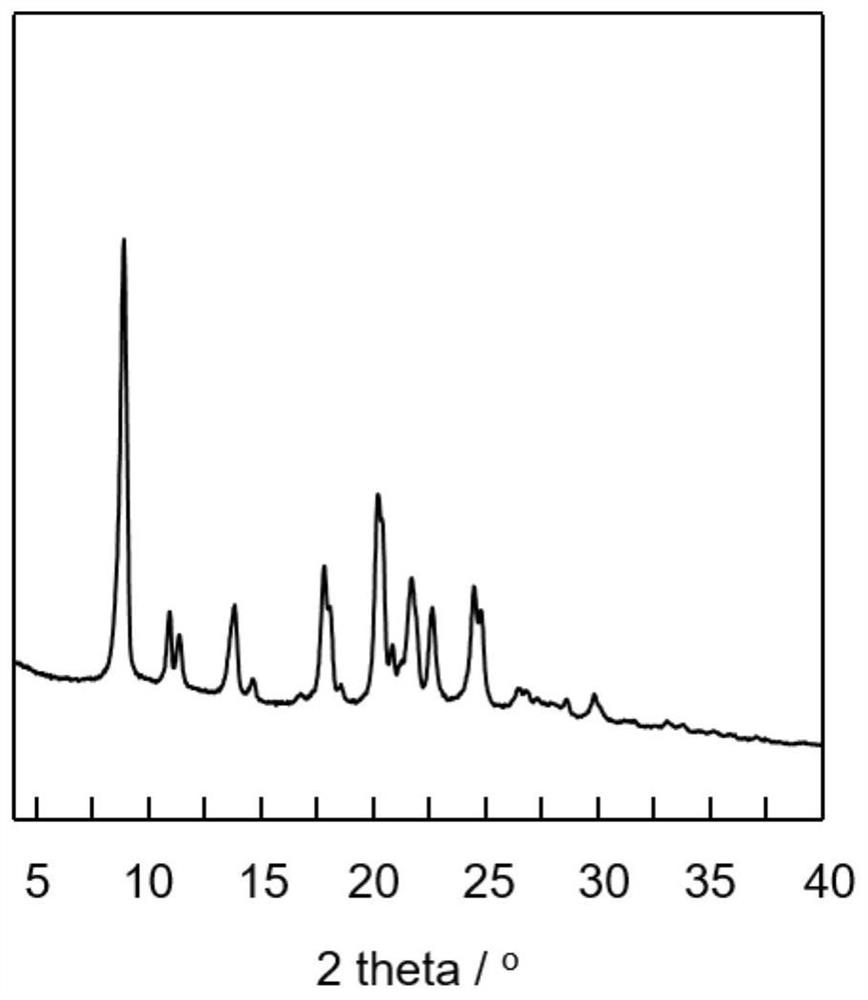

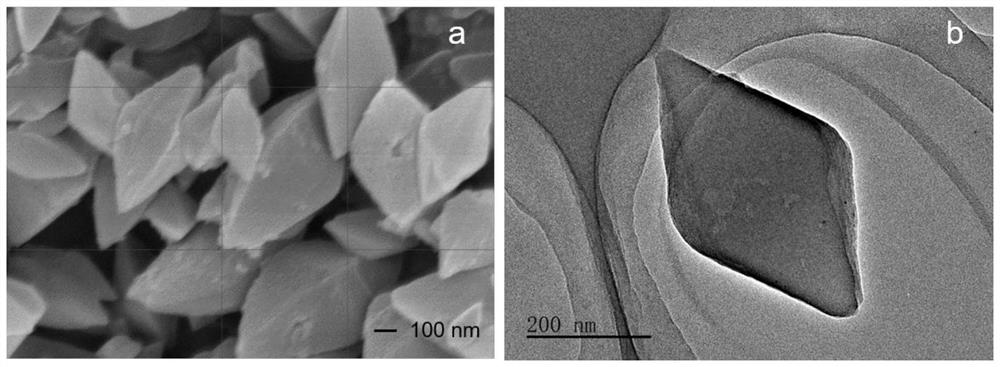

[0070] Accurately weigh tetraaminotetraphenylmethane (66.9mg, 0.176mmol) and 2,5-dihydroxyterephthalaldehyde (58.5mg, 0.352mmol) successively on a balance in a 100mL two-necked round-bottomed flask, every 15min Evacuation and replacement of the gas with argon was repeated three times. Add 8 mL of freshly steamed anhydrous and oxygen-free tetrahydrofuran to it with a long needle, sonicate for 5 minutes, and mix well. Then, under stirring, 1.6 mL of 3 mol / L glacial acetic acid aqueous solution was added at a rate of 1-2 drops per second, protected by argon, and refluxed in an oil bath at 70°C for 72 hours. After the reaction, cool to room temperature. Then use PVDF as the filter membrane to filter under reduced pressure with a membrane filter, and wash the product with 20 mL of freshly distilled anhydrous tetrahydrofuran, repeating three times. Finally, the obtained product was soaked in 20 mL of anhydrous tetrahydrofuran overnight, and filtered again under reduced pressure to...

Embodiment 2

[0078] Accurately weigh 360 mg of Pd(OAC) in the glove box 2 In a 250mL single-necked round bottom flask, add 50mL of freshly distilled anhydrous and oxygen-free CH 2 Cl 2 , sonicate to dissolve completely, and obtain a clear and transparent reddish-brown solution, which is set aside. Weigh 250 mg of the COF-301 powder prepared in Example 1 into a 250 mL two-necked round-bottomed flask, perform vacuum treatment and argon gas replacement every 15 minutes, and repeat the operation three times. Subsequently, 50 mL of freshly distilled anhydrous and oxygen-free CH 2 Cl 2 , protected by argon, stirred at room temperature for 1 h, so that the COF-301 powder was fully dispersed in CH 2 Cl 2 , to obtain COF-301 dispersion. Under stirring, drop the prepared clear and transparent red-brown solution into the above-mentioned COF-301 dispersion at a rate of 1-2 drops per second, and finally stir at room temperature for 24 hours. After the reaction, the solution was filtered under re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Hole size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com