Nozzle heating type drying equipment

A drying equipment and heating technology, applied in printing, lamination auxiliary operations, printing machines, etc., can solve the problems of complex and large equipment and limit the scope of application, so as to ensure the drying speed, improve the drying performance, prevent Surface dry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0050] The drying equipment described in this embodiment is suitable for a coating machine.

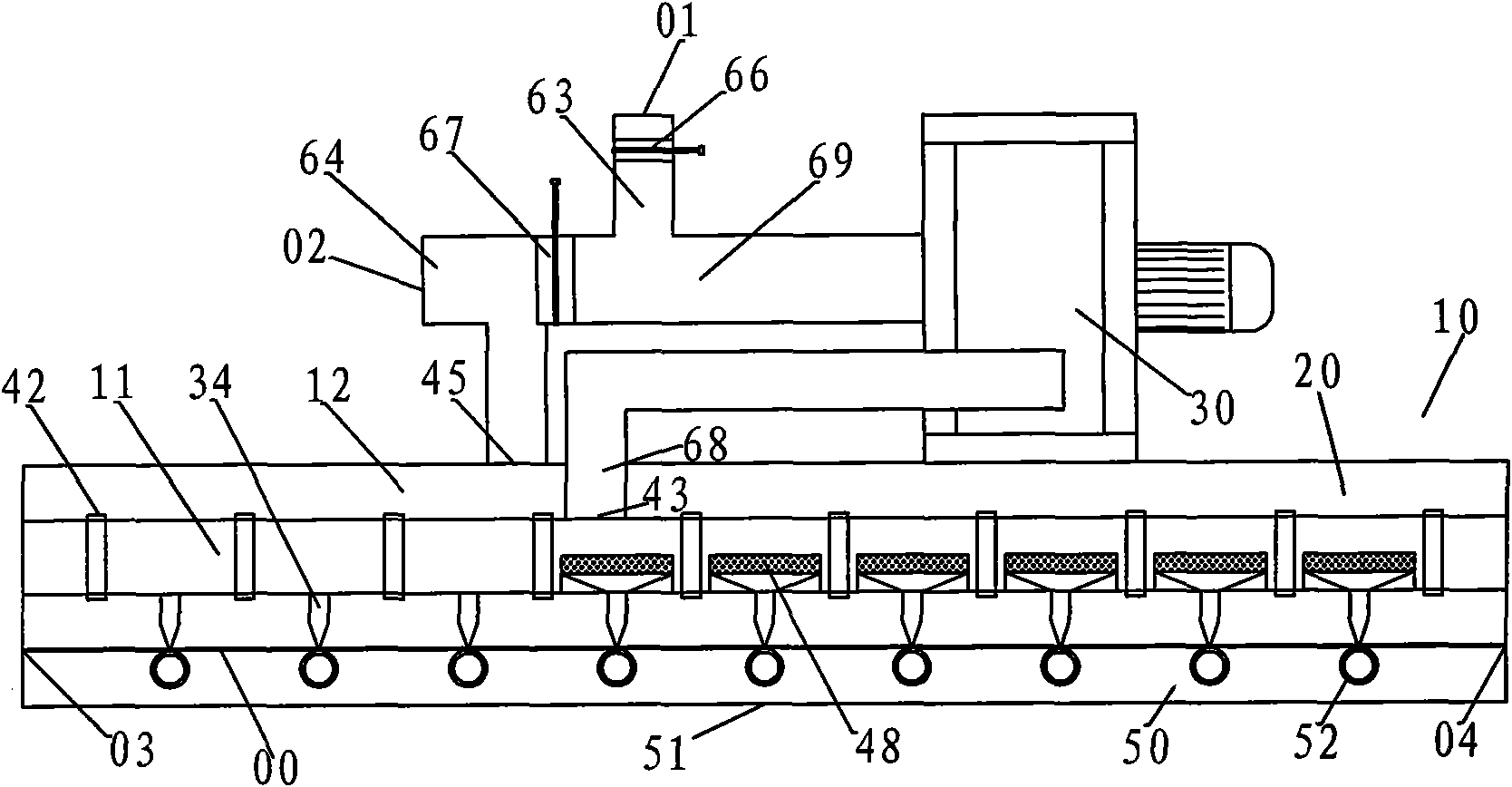

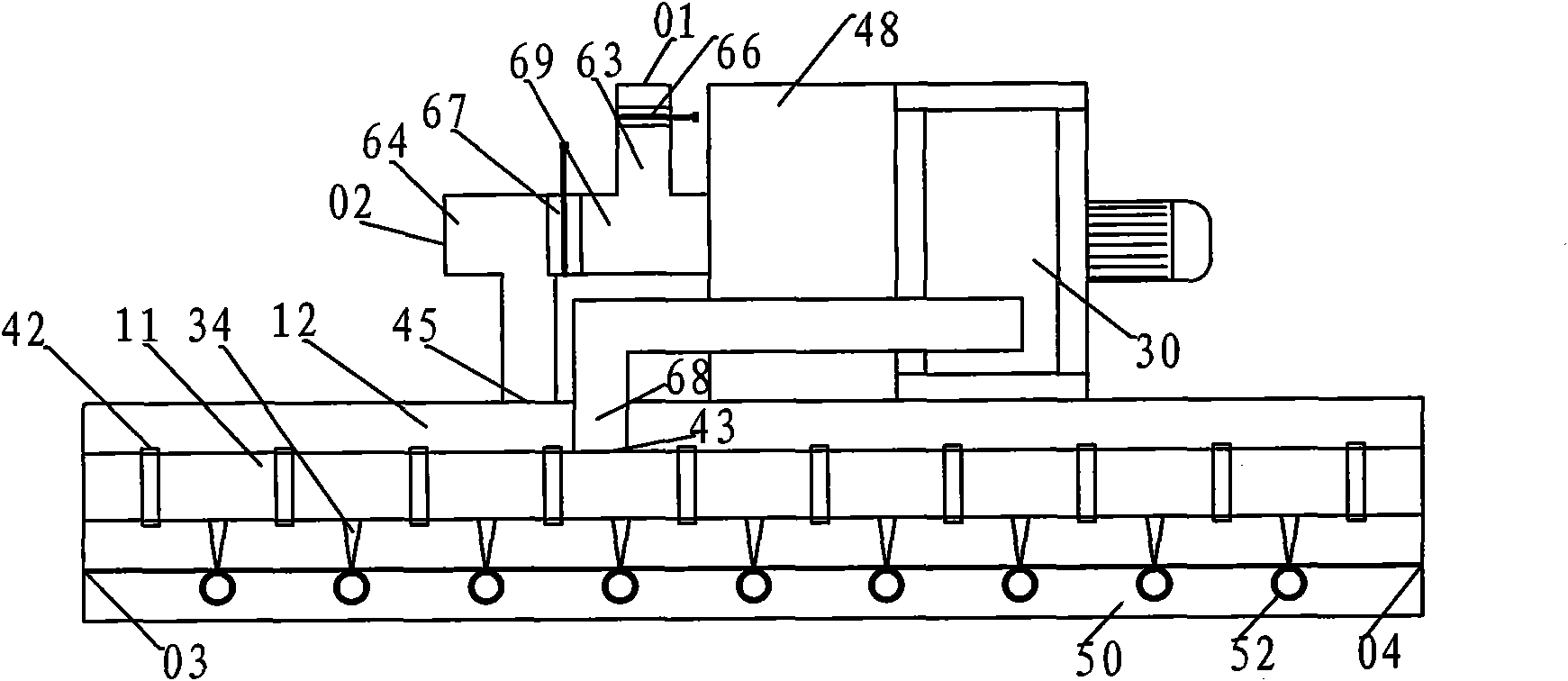

[0051] refer to figure 1 , the present embodiment includes an oven 10, a fan 30 and a heater 48, and the air outlet of the fan communicates with the inner cavity of the oven; the oven 10 includes an oven cover 20 and a base 50, between which there is a The transmission channel of the product; the air inlet cavity 11 is arranged in the oven cover, and several nozzles 34 are arranged above the transmission channel in the oven cover 20; the nozzles 34 communicate with the air intake cavity 11 or are arranged in the air intake cavity 11; The heater 48 is installed in the nozzle (34); the air outlet of the fan 30 communicates with the air inlet 43 of the air inlet cavity 11 through the air inlet passage 68.

[0052] Wherein: the blower fan 30 is installed on the oven 10, and the air outlet of the blower fan communicates with the oven inner cavity, or the blower fan 30 is installed beside...

specific Embodiment 2

[0064] The drying equipment described in this embodiment is suitable for a coating machine. It aims at improving the shortcoming of specific embodiment 1 that the energy-saving effect is not significant.

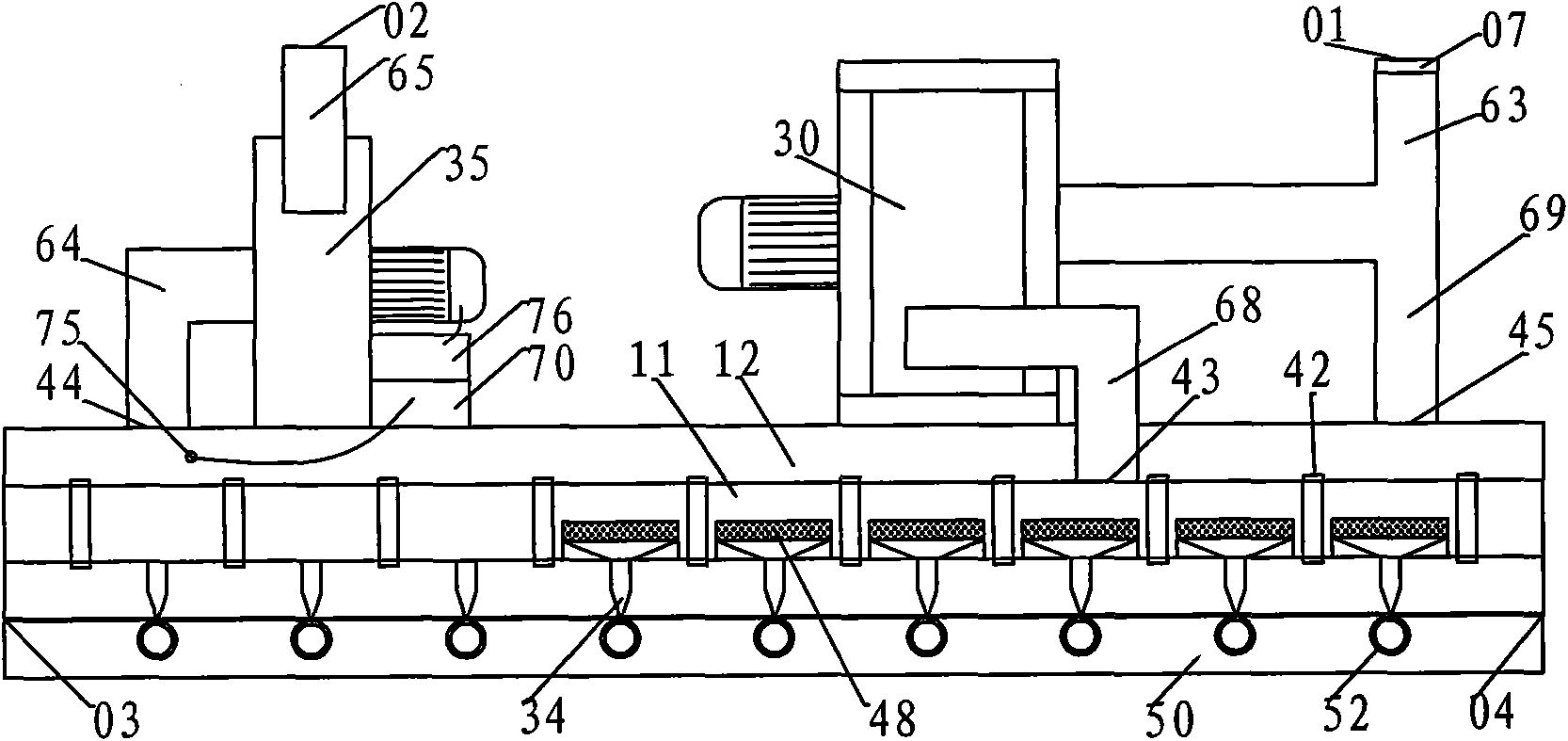

[0065] refer to figure 2 , The drying equipment described in this embodiment is composed of an oven 10, a fan 30, an exhaust fan 35, a control drive device 70, a connecting air duct, and an exhaust system.

[0066] The oven 10 includes an oven cover 20, a base 50, and is provided with a printed product inlet 03 and a printed product outlet 04;

[0067] The oven cover 20 includes an air inlet chamber 11 , an air exhaust chamber 12 , ten nozzles 34 , and ten heaters 48 .

[0068] The air inlet cavity 11 is provided with an air inlet 43 , which communicates with the air outlet of the fan 30 through the air inlet channel 68 .

[0069] The heater 48 is installed in the nozzle 34 , and the nozzle 34 is installed in the air inlet cavity 11 .

[0070] The air exhaust cavity 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com