Photoresist

A photoresist and photoinitiator technology, applied in the photoresist field, can solve the problems of low photoresist hardness and poor surface drying performance, and achieve the effects of high photosensitivity, high hardness and preventing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] An embodiment of the present invention provides a photoresist, which includes the following components by weight: 10-50 parts of alkali-soluble resin, 5-25 parts of photopolymerizable monomer, 0.5-8 parts of photoinitiator, 20 -80 parts of solvent, 0.1-5 parts of pigment, the alkali-soluble resin is made of at least one of ethylenically unsaturated monomers and propylene-based unsaturated monomers, (meth)acrylic acid monomers, and maleic anhydride monomers The copolymerization reaction is obtained, and the glass transition temperature of the alkali-soluble resin is greater than or equal to 120°C.

[0038] The embodiment of the present invention provides a kind of photoresist, by 10-50 parts (hereinafter referred to as parts by weight) alkali-soluble resin whose glass transition temperature is greater than or equal to 120°C, 5-25 parts of photopolymerizable monomer, 0.5-8 The synergistic effect of the photoinitiator, 20-80 parts of solvent and 0.1-5 parts of pigment can ...

Embodiment 2

[0040] An embodiment of the present invention provides a photoresist, which includes the following components by weight: 10-50 parts of alkali-soluble resin, 5-25 parts of photopolymerizable monomer, 0.5-8 parts of photoinitiator, 20 - 80 parts of solvent, 0.1-5 parts of pigment, the glass transition temperature of the alkali-soluble resin is greater than or equal to 120 ° C, the alkali-soluble resin is composed of at least one of ethylenically unsaturated monomers and propylene-based unsaturated monomers and (Meth) acrylic acid monomer and maleic anhydride monomer are obtained through copolymerization reaction.

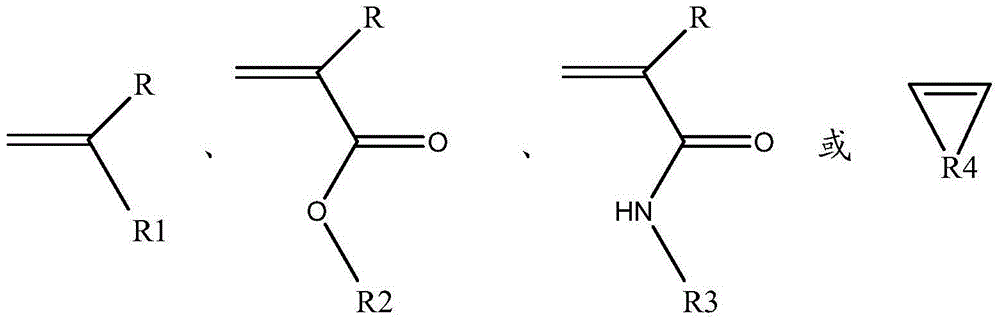

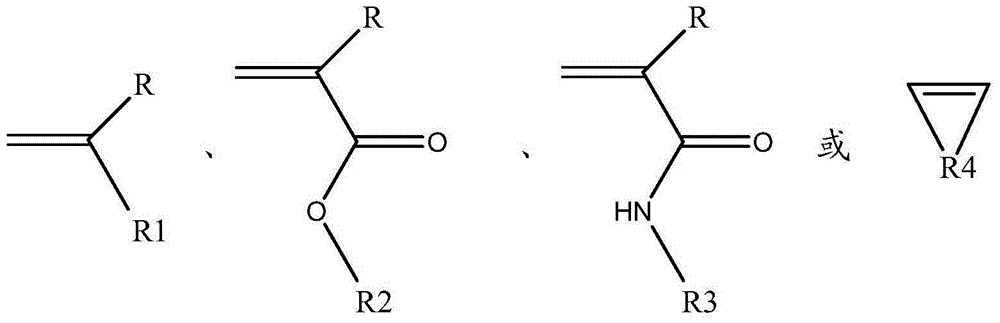

[0041] Wherein, the ethylene-based unsaturated monomer and propylene-based unsaturated monomer all have the following structural units:

[0042]

[0043] R is hydrogen or methyl;

[0044] R1 is phenyl, hydroxyphenyl, methylphenyl, ethylphenyl, naphthyl or nitrile;

[0045] Both R2 and R3 are alkyl groups with 1-8 carbon atoms, hydroxyalkyl groups with 1-8 carbon...

Embodiment 3

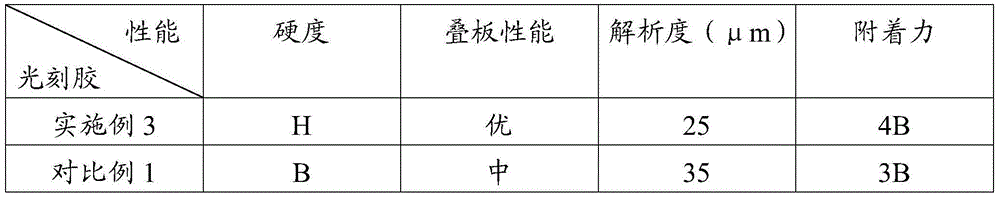

[0065] The embodiment of the present invention provides a photoresist, which includes the following components by weight: 25 parts of alkali-soluble resin, 12 parts of photopolymerizable monomer, 5 parts of photoinitiator, 54.5 parts of solvent, 0.5 part of pigment , and 3 parts of stabilizer.

[0066] Among them, the alkali-soluble resin is composed of 20% by weight of methacrylic acid, 60% of maleic anhydride and 20% of styrene, and the glass transition temperature of the alkali-soluble resin is 137 ° C, and the weight average molecular weight is 74200 (Mw), the molecular weight distribution index is 2.27, and the acid value is 135mgKOH / g.

[0067] The photopolymerizable monomer is composed of 7 parts by weight of trimethylolpropane triacrylate, 2 parts of dipentaerythritol hexaacrylate, and 3 parts of 1,6-butanediol diacrylate; the photoinitiator consists of 3 parts by weight of 2-methyl-1-(4-methylthiophenyl)-2-morpholine-1-propanone, 1 part of 2-isopropylthioxanthone, 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com