Vehicle washing machine

A car washing machine and car body technology, which is applied in the field of car washing machines, can solve the problems that cannot be completely dealt with, and it is difficult to exert the drying effect, and achieve the effect of improving the drying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

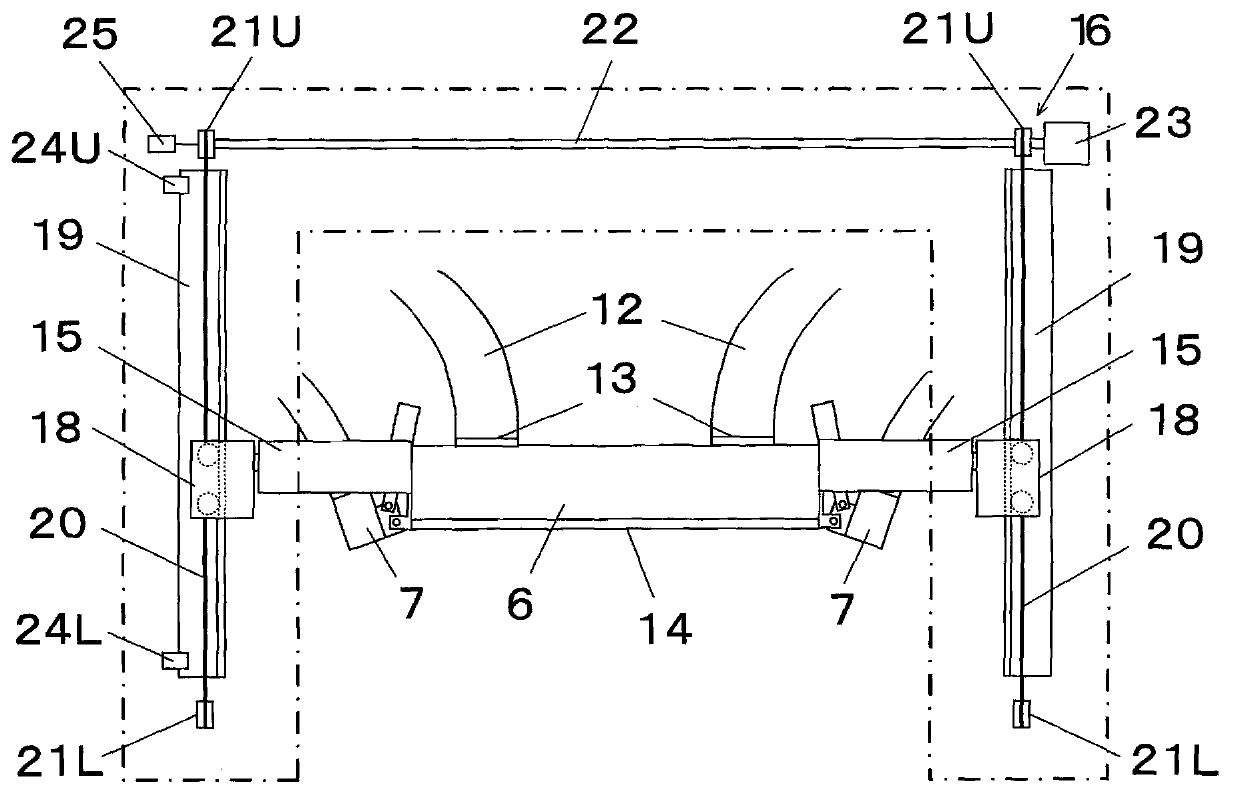

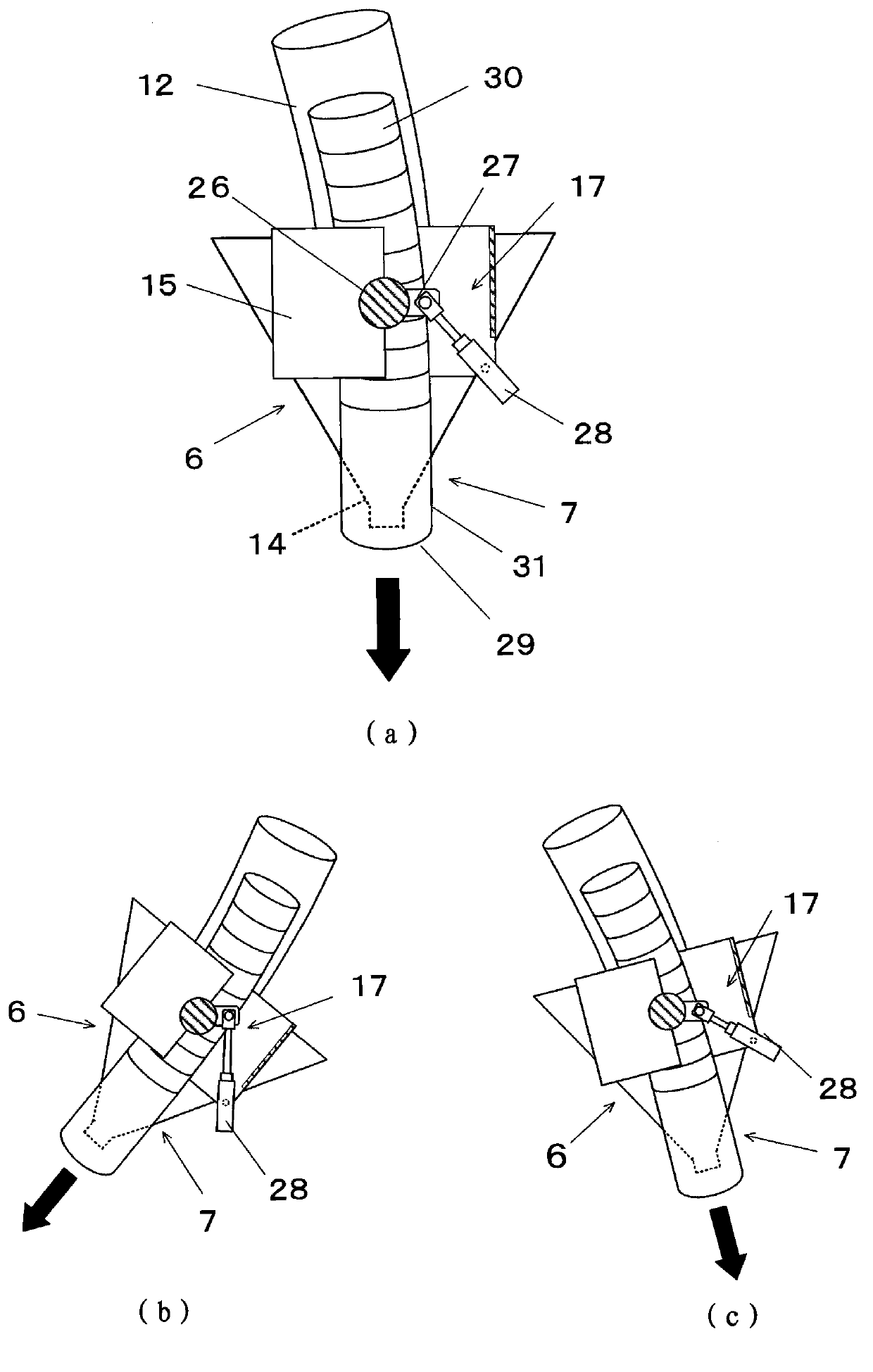

[0023] Embodiments of the present invention will be described below with reference to the drawings.

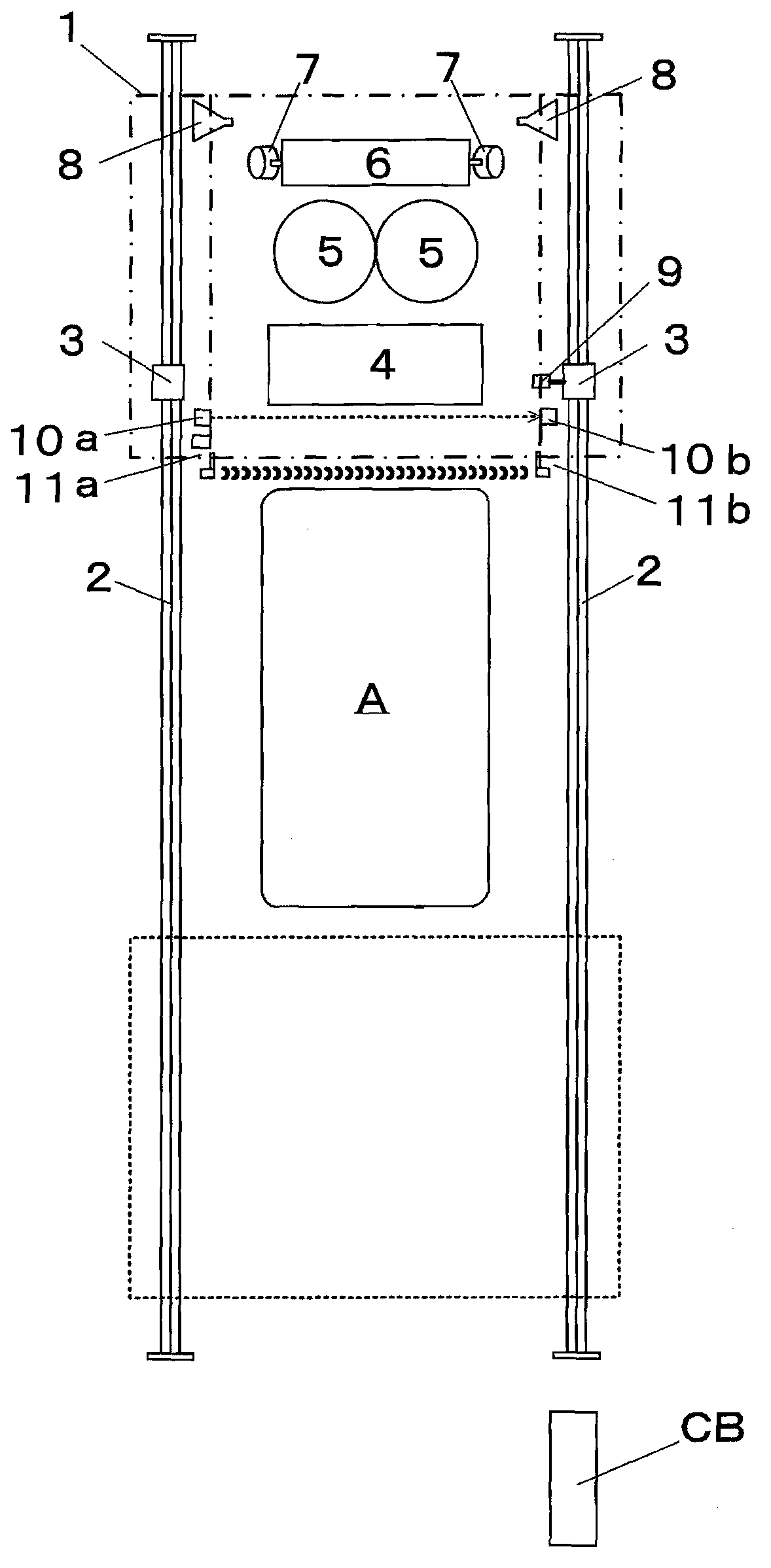

[0024] figure 1 It is a plan view which shows the car washing machine provided with this invention.

[0025] Reference numeral 1 denotes a main body frame formed in a door shape, and is driven by a travel motor 3 to reciprocate on rails 2 and 2 laid on the ground. Such as figure 1 As shown, the main body frame 1 is stopped at the rear end of the travel range given by the rails 2, 2, and the car wash is started from this position. On the main body frame 1, brush devices 4, 5, 5, blowing nozzles 6, 7, 7, 8, 8 and sprinkler nozzles (not shown) etc. are provided as various processing devices for washing the car. The traveling of the main body frame 1 by driving the traveling motor 3 performs a cleaning operation of spraying water, detergent, wax, etc., followed by blushing, and a drying operation of blowing air from an air blowing nozzle.

[0026] The brush device includes an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com