Drying oven for manufacturing solar backboard film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

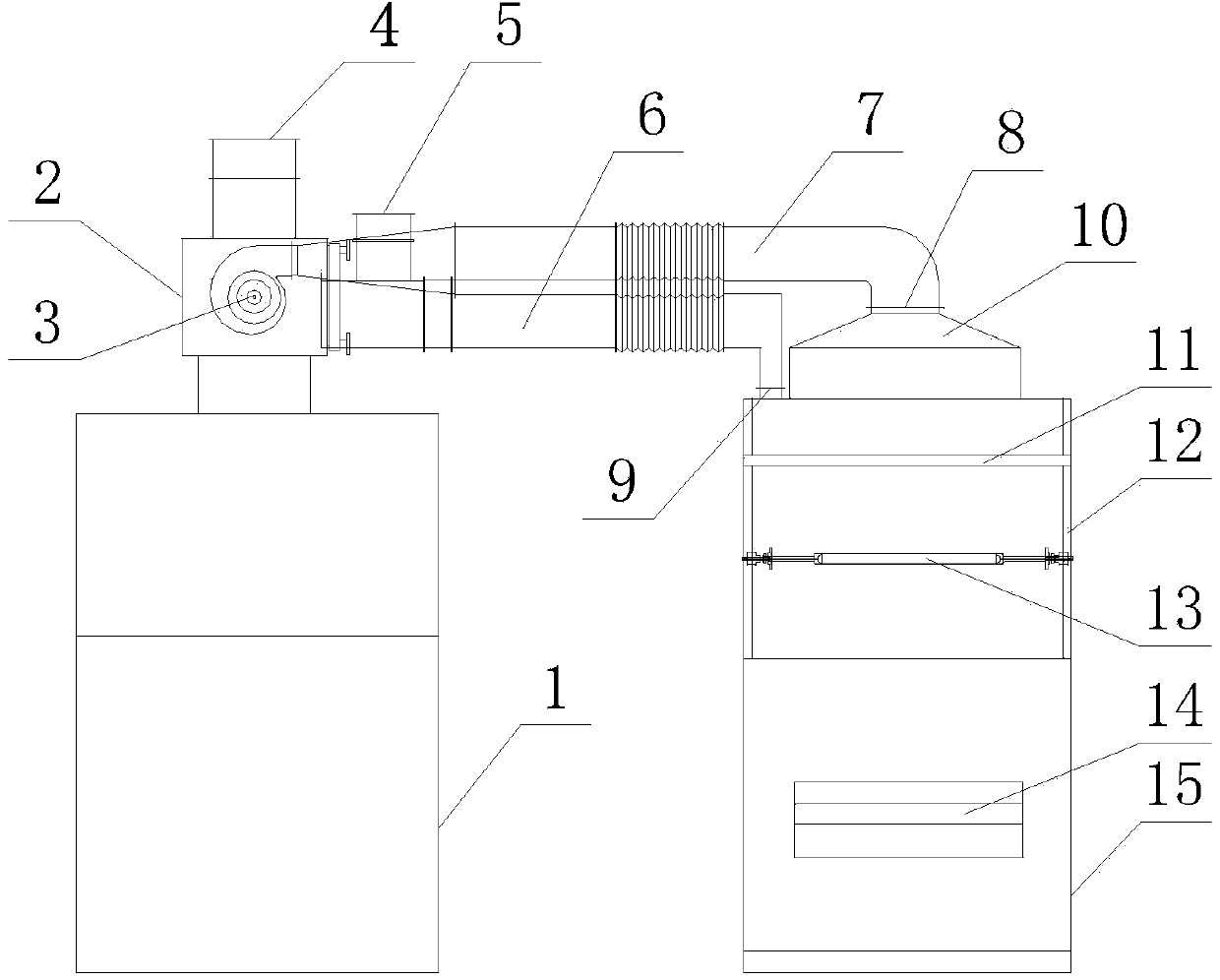

[0014] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0015] like figure 1 The shown oven for solar backplane film production has a base 1 and a main box 15, a blower box 2 is installed on the surface of the base 1, a blower 3 is built in the blower box 2, and a cold air inlet 4 is provided on the blower box 2; the main box 15 has a built-in There is a main machine 14, an oven 12 is arranged above the main box 15, a heating tube 11 and a backplane film material reel 13 are built in the oven 12, and the heating tube 11 is placed above the backplane film material reel 13; , the hood 10 is provided with an air inlet 8, and the top of the oven 12 is provided with an air outlet 9 near the hood 10; a cold air pipe 7 is connected between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com