Plastics

A coating agent and coating technology, which is applied in the direction of photosensitive materials used in optomechanical equipment, etc., can solve the problems of lack of structure and design freedom, and no record of surface dryness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

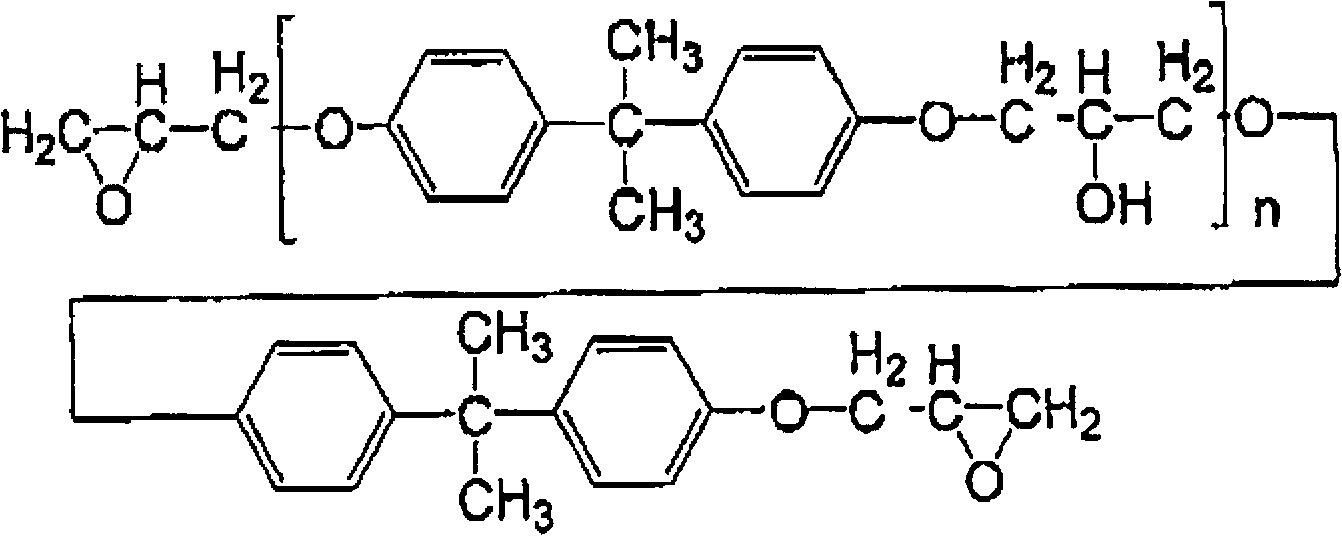

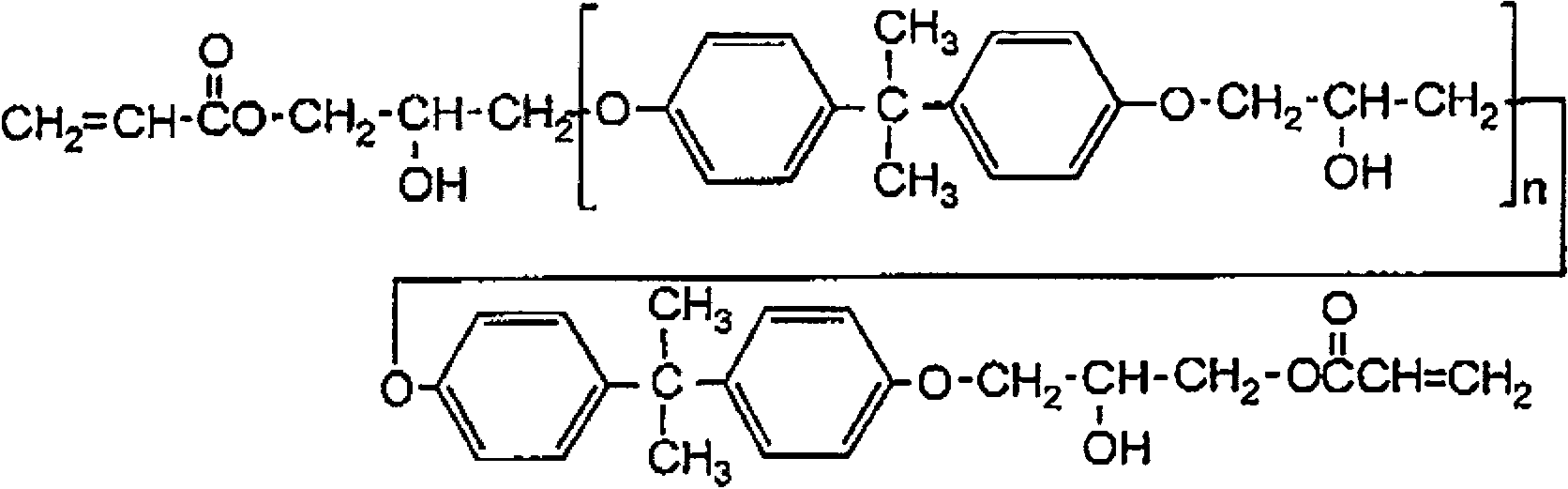

[0064] 1. Manufacture of coating agent [Manufacture example 1] (manufacture of urethane acrylate A)

[0065] Add 1048 g (2 moles) of acrylate of bisphenol A type epoxy resin (manufactured by Mitsubishi Chemical Co., Ltd., jER828, glycidyl ethers, epoxy equivalent = 190 g / eq), hydroquinone monomethyl ether 0.6 g and 188 g (1 mole) of xylylene diisocyanate (XDI), which is an organic polyisocyanate, were reacted at 70 to 80°C until the residual isocyanate concentration was 0.1% or less.

manufacture example 2~5

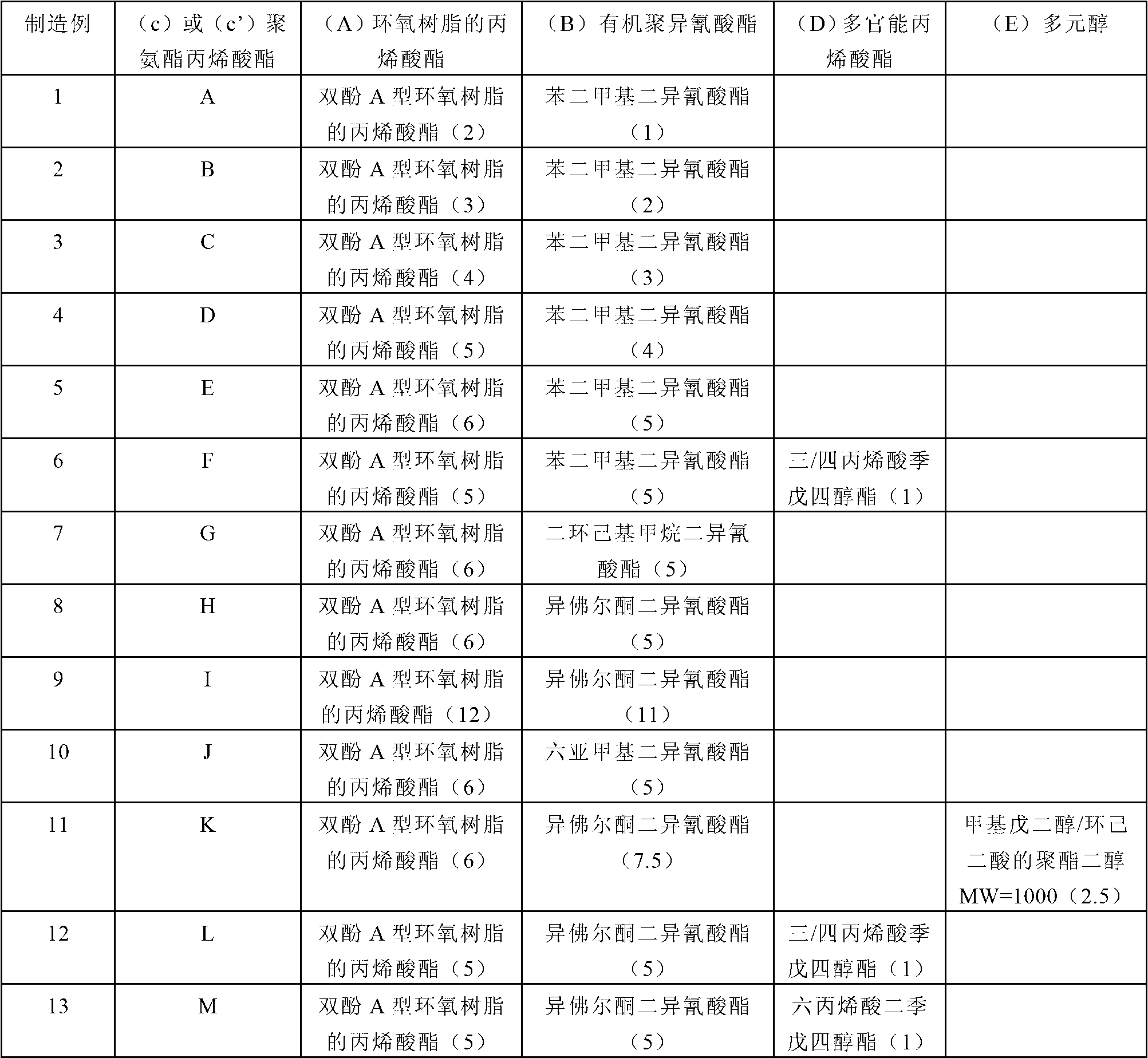

[0066] [Manufacture examples 2 to 5] (Manufacture of urethane acrylates B to E)

[0067] It produced similarly to urethane acrylate A except having changed the addition amount of the acrylate of epoxy resin (Mitsubishi Chemical Corporation make, jER828) and xylylene diisocyanate as shown in Table 1.

manufacture example 6

[0068] [Manufacture Example 6] (Manufacture of Urethane Acrylate F)

[0069] 2620 g (5 moles) of acrylate of epoxy resin (manufactured by Mitsubishi Chemical Co., Ltd., jER828), 450 g ( 1OH equivalent), 2.0g of hydroquinone monomethyl ether, 940g (5 moles) of xylylene diisocyanate (XDI) as an organic polyisocyanate, and react at 70-80°C until the concentration of residual isocyanate is Below 0.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com